Pavement simulation detector

A road surface simulation and testing machine technology, applied in measurement devices, vehicle testing, automobile tire testing, etc., can solve problems such as inability to simulate real road conditions and research difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

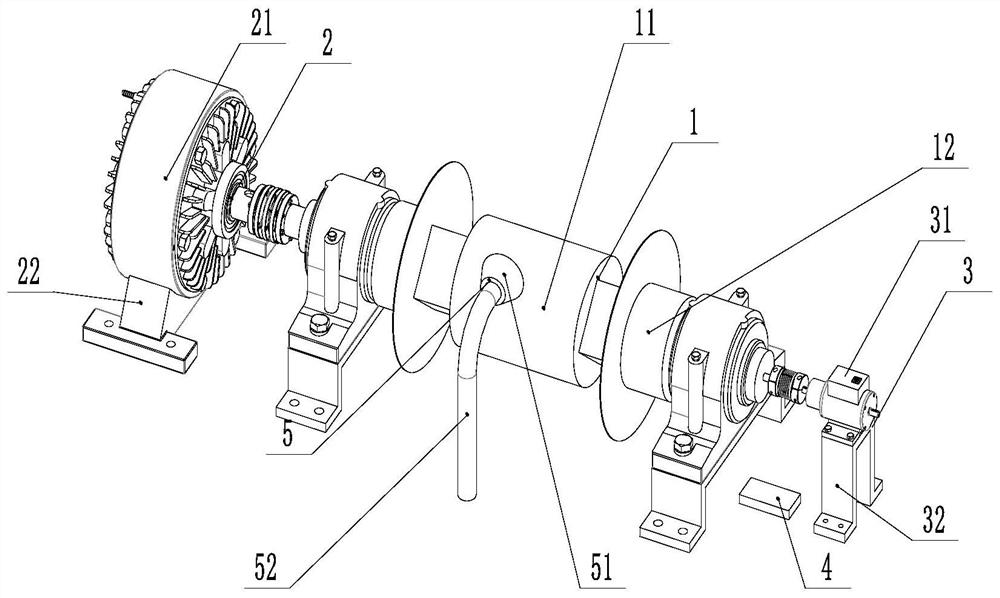

[0041] Embodiment 1 A kind of road surface simulation detection machine described in the present invention includes a road surface simulator 1 for simulating the running state of the wheels of a warehouse logistics vehicle, an auxiliary torque drive device 2 for delivering torque to the road surface simulator, and a road surface simulator for measuring the road surface The speed measuring device 3 of the simulator speed and the controller 4 used to control the operation of the whole test device, wherein the road simulator 1, the auxiliary torque drive device 2 and the speed measuring device 3 are all installed on the installation surface or lifting equipment at the same level The torque input end and the torque output end of the road simulator 1 are respectively connected with the auxiliary torque driving device and the speed measuring device; the signal connection ports of the road simulator, the auxiliary torque driving device and the speed measuring device are respectively co...

Embodiment 2

[0047] Embodiment 2 A kind of road simulation detection machine of the present invention comprises a road simulator 1, an auxiliary torque driving device 2, a speed measuring device 3, a spray device 5 and a controller 4, wherein the road simulator 1, the auxiliary torque The driving device 2 and the speed measuring device 3 are all installed on the installation surface or lifting equipment at the same level; the torque input end and the torque output end of the road simulator 1 are respectively connected with the auxiliary torque driving device and the speed measuring device; the road simulator, The signal connection ports of the auxiliary torque drive device and the speed measuring device are respectively electrically connected with the corresponding signal connection ports of the controller;

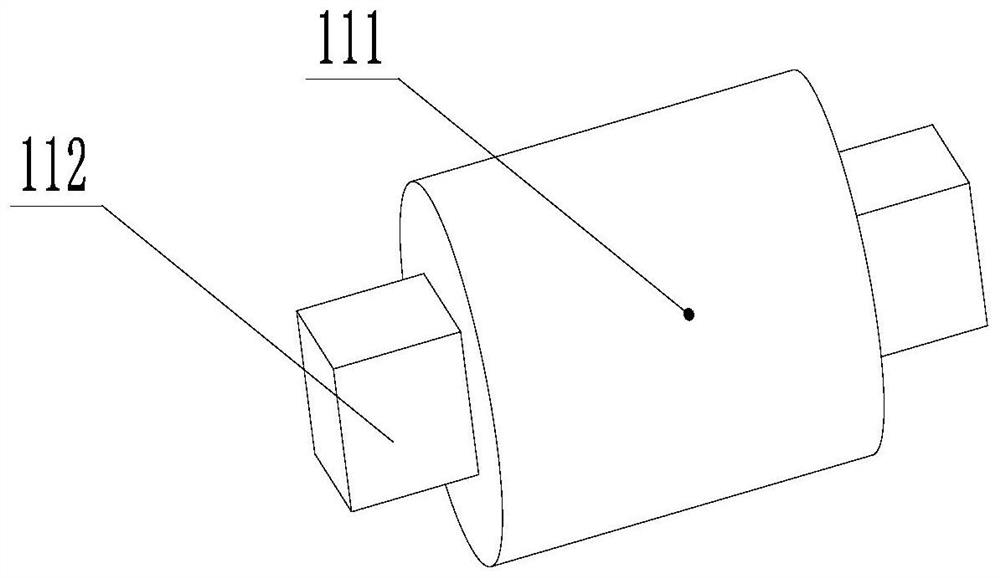

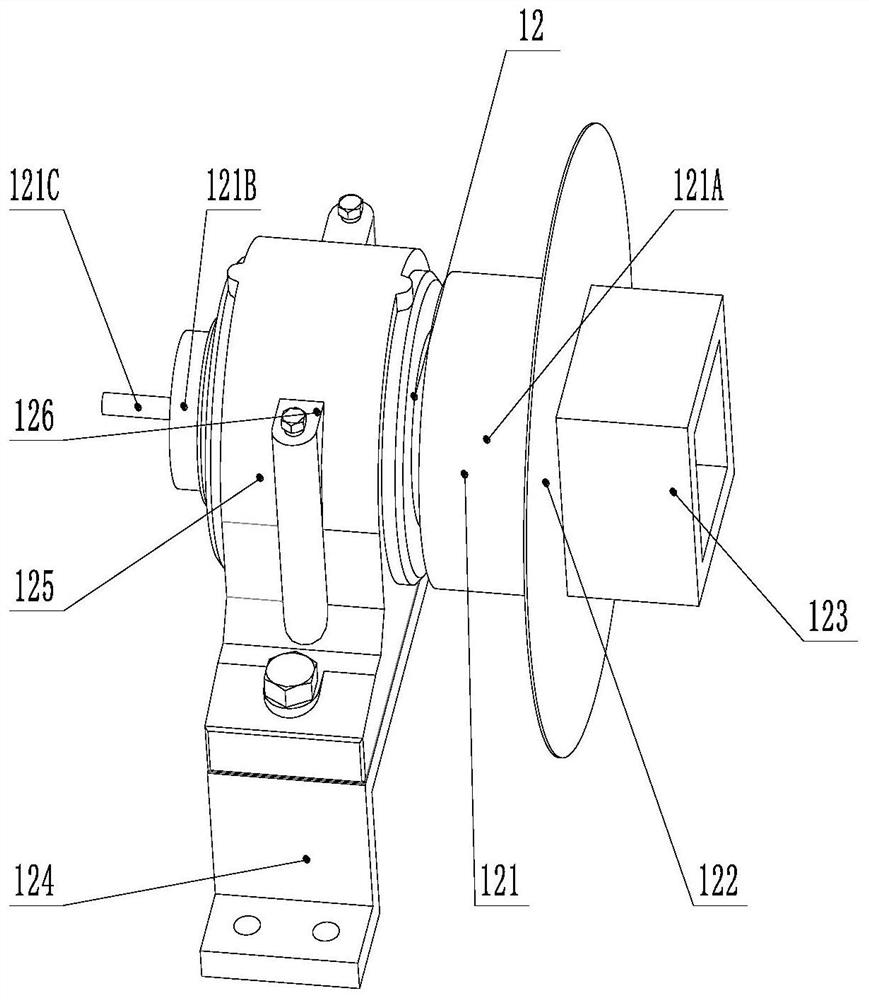

[0048] The road simulator 1 includes a runner assembly 11 for simulating the road surface and two sets of transmission shaft assemblies 12 for transmitting torque. Simulate the drivin...

Embodiment 3

[0058] Embodiment 3 The difference between this embodiment and Embodiment 1 is that the torque output device is a servo motor, and the two stepped shafts are respectively connected with the servo motor and the speed sensor through a coupling, and their high coaxiality is guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com