A Safety Assessment Method for Metallurgical Cranes Based on Mean Square Error Method and Entropy Weight Method

A mean square error method and safety assessment technology, which is applied in the field of metallurgical crane safety assessment based on the mean square error method and entropy weight method, can solve problems such as strong subjectivity, low accuracy, and failure to meet the requirements of the evaluation system, so as to avoid subjective Factors, to avoid the effect of low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

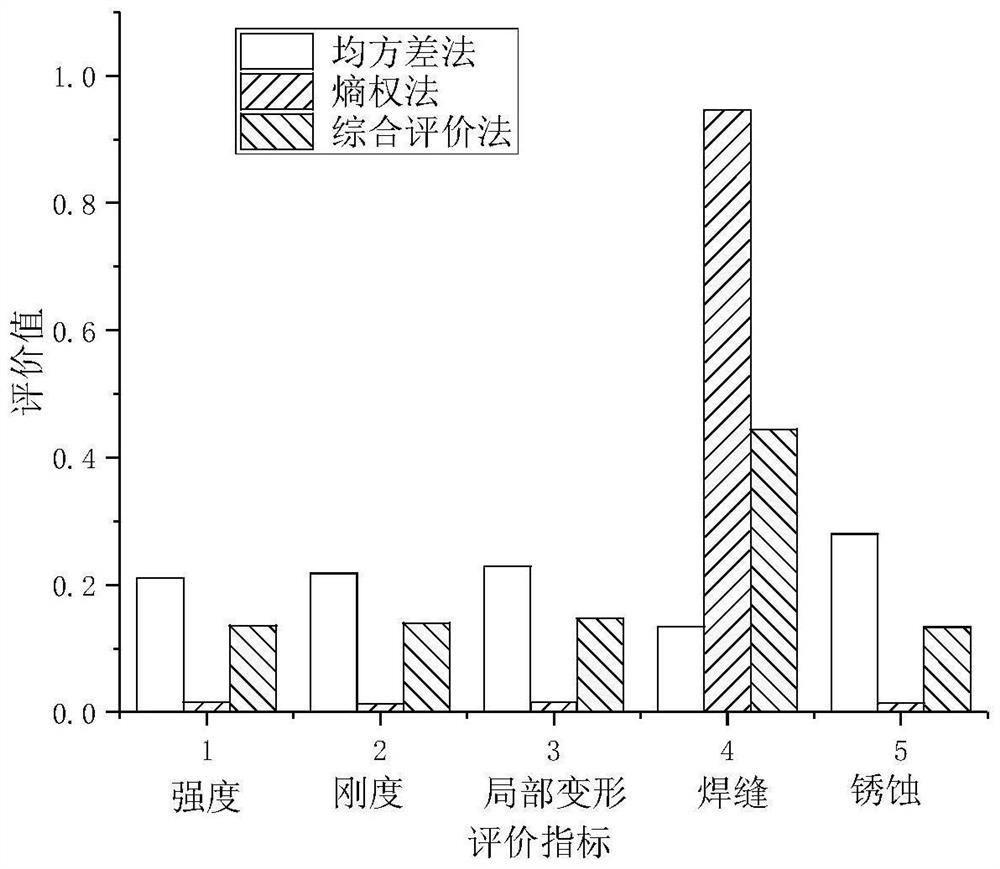

[0082] Taking a single girder as an example to evaluate its safety. Safety indicators include strength, stiffness, local deformation, cracks, welds, and corrosion.

[0083] The state value of the single factor index layer is obtained by consulting the historical detection records of the main beam of a metallurgical crane, among which detection 4 is the latest detection result, as shown in Table 1.

[0084] Table 1 The state value of the main girder index of a metallurgical crane

[0085]

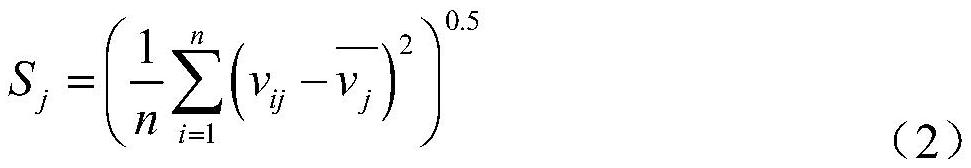

[0086] 1) Mean square error method:

[0087] According to the attributes and status values of each indicator, the original data is dimensionless:

[0088]

[0089] The degree of variation of each indicator:

[0090] S=[0.4064 0.4213 0.4423 0.2592 0.4017]

[0091] The weight of each indicator calculated based on the mean square error method:

[0092] W 1 =(0.2104,0.2182,0.2291,0.1342,0.2081)

[0093] 2) Entropy weight method:

[0094] According to the attributes and status val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com