Horizontal linear vibration motor

A vibration motor, horizontal linear technology, applied in vibration suppression adjustment, TV, electromechanical devices, etc., can solve the problems of high vibration difficulty and difficult to ensure life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

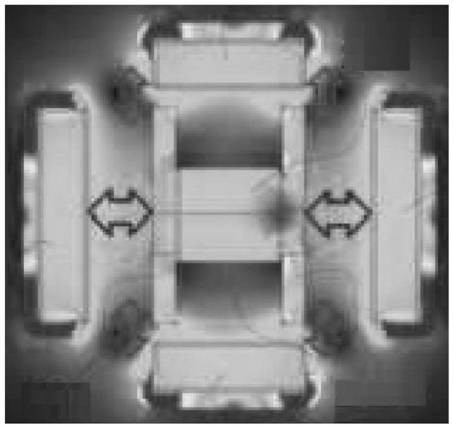

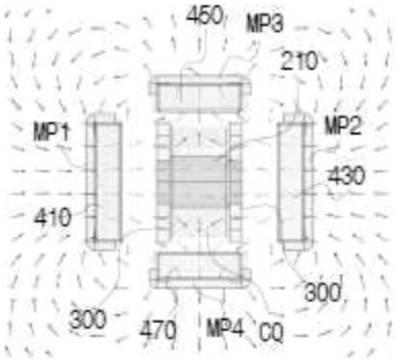

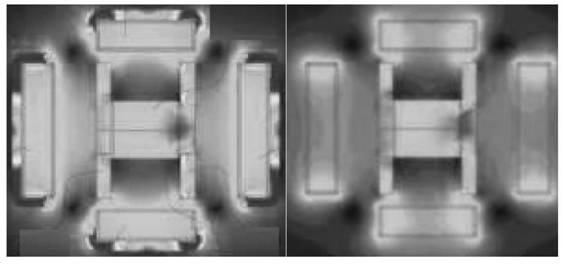

Image

Examples

Embodiment Construction

[0035] In the following, the present invention can be transformed in many ways, and can have various embodiments, and the specific embodiments will be described in detail through the drawings. However, the present invention is not limited to these specific embodiments, and it should be understood that the present invention includes all transformations, equivalents and even replacements within the spirit and technical scope of the present invention.

[0036] In order to enable those skilled in the art to understand the present invention in more detail, the embodiments of the present invention are provided. Therefore, the form of each element shown in the drawings may be exaggerated in order to explain these forms more clearly. When describing the present invention, when it is considered that the specific description of related known technologies will obscure the gist of the present invention, it will be A detailed description thereof is omitted.

[0037] Terms such as first an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com