Efficient filter element for air filter

An air filter and filter element technology, which is applied in the field of air purification, can solve the problems of unfavorable filter element service life, failure to pass multiple filters, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

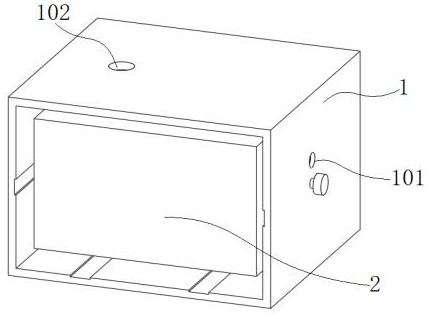

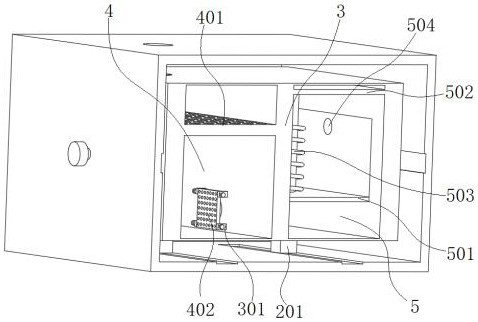

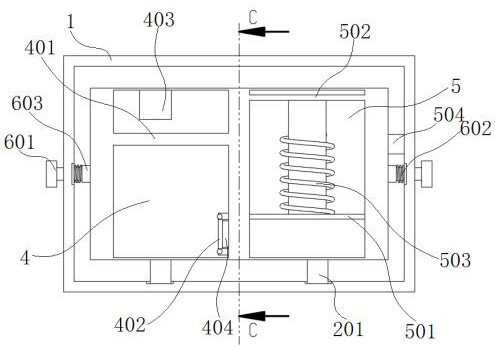

[0028] Please refer to figure 1 7, the present invention is a high-efficiency filter element for an air filter, comprising a protective casing 1, a filter element 2, a vertical plate 3, a first chamber 4, a second chamber 5, a disassembly and assembly device 6, and a return spring 7. The casing 1 includes a protective casing body, a first connection hole 101 and a second connection hole 102. The protective casing 1 and the filter element 2 are connected by a disassembly and assembly device 6, and the vertical plate 3 is welded with the inner two surfaces of the filter element 2. The vertical plate 3 connects the inside of the filter element 2. The part is the first chamber 4 and the second chamber 5, one end of several return springs 7 is connected to one surface of the protective casing 1, the other surface of the return spring 7 is connected to one surface of the filter element 2, and the filter element 2 is divided into the first part by the vertical plate 3. A chamber 4 an...

Embodiment 2

[0037] Please refer to figure 1 As shown in 7, the present invention is a high-efficiency filter element for an air filter. In the present invention, the disassembly and assembly device 6 includes a pull rod 601, a second buffer spring 602 and an elastic pin 603. The disassembly and assembly device 6 is linked with the return spring 7 to realize the filter element 2. The working principle of the quick disassembly and assembly of the protective casing 1 is as follows: when the disassembly is required, the pull rod 601 is pulled, and the pull rod 601 exerts a force on the second buffer spring 602, and the elastic pin 603 will pop out of the filter element 2 slot under the reaction force. Then apply resistance to the filter element 2. Since the return spring 7 is always in a compressed state in the installed state, when the elastic pin 603 no longer exerts resistance to the filter element 2, the return spring 7 will exert a reaction force on the filter element 2, so that the The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com