Integrated prefabricated pump station

A pumping station and casing technology, applied in the field of integrated prefabricated pumping stations, can solve problems such as unsafety, hidden dangers, etc., and achieve the effect of reducing safety hazards and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is attached Figure 1-8 The application is described in further detail.

[0033] The embodiment of the present application discloses an integrated prefabricated pumping station.

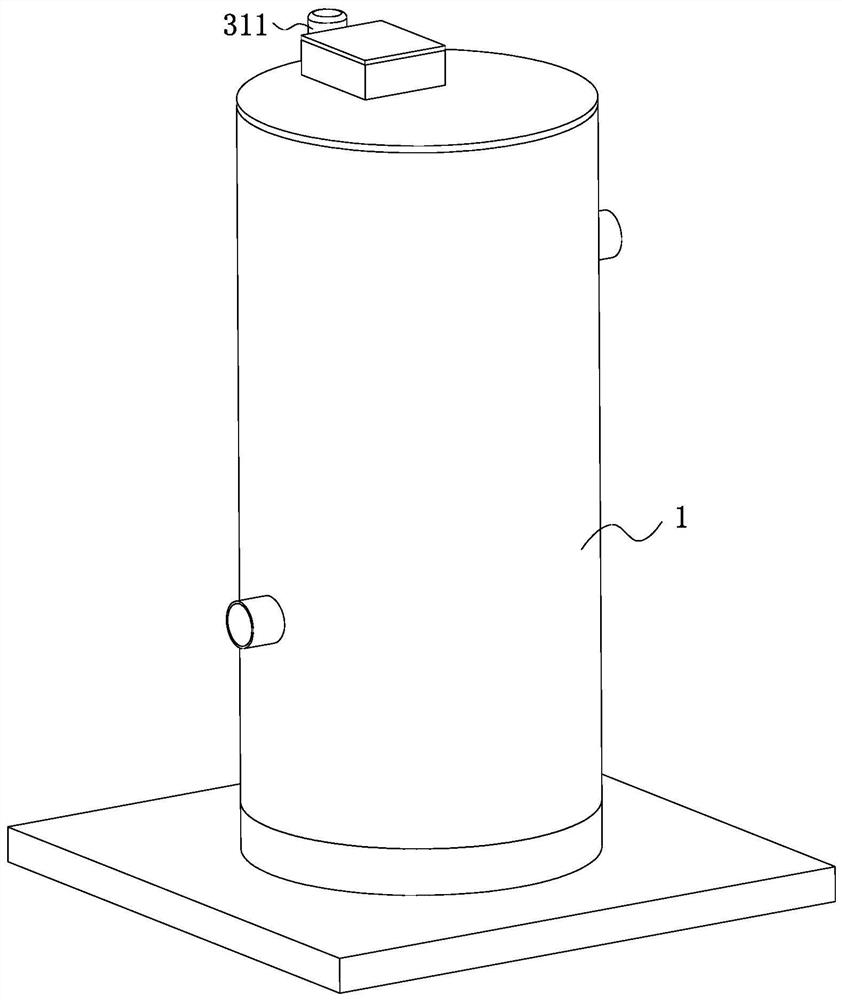

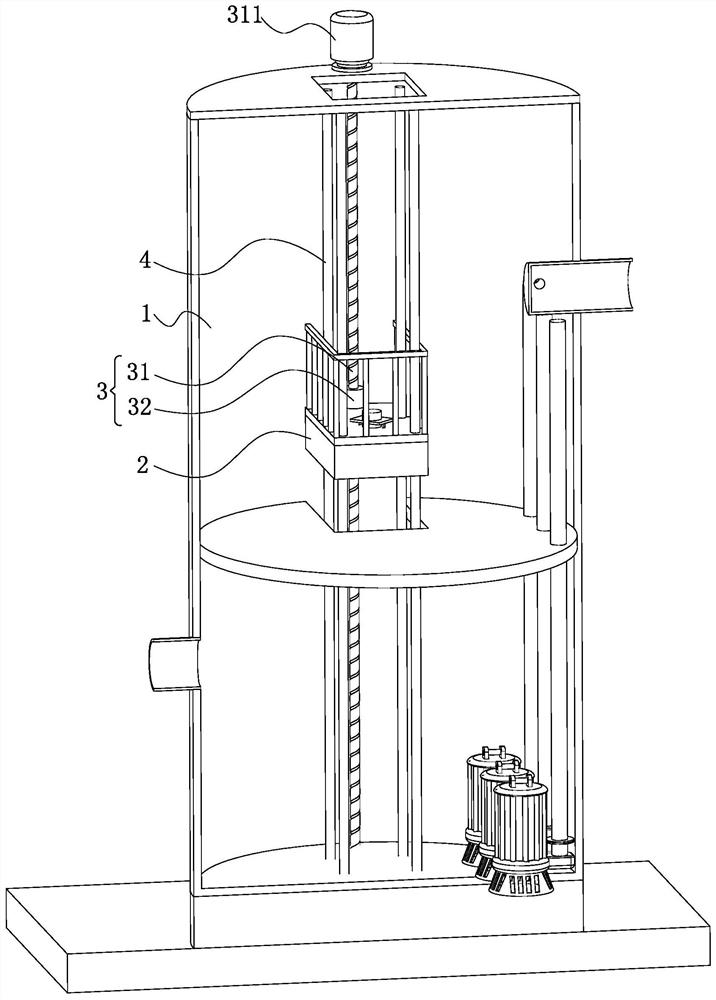

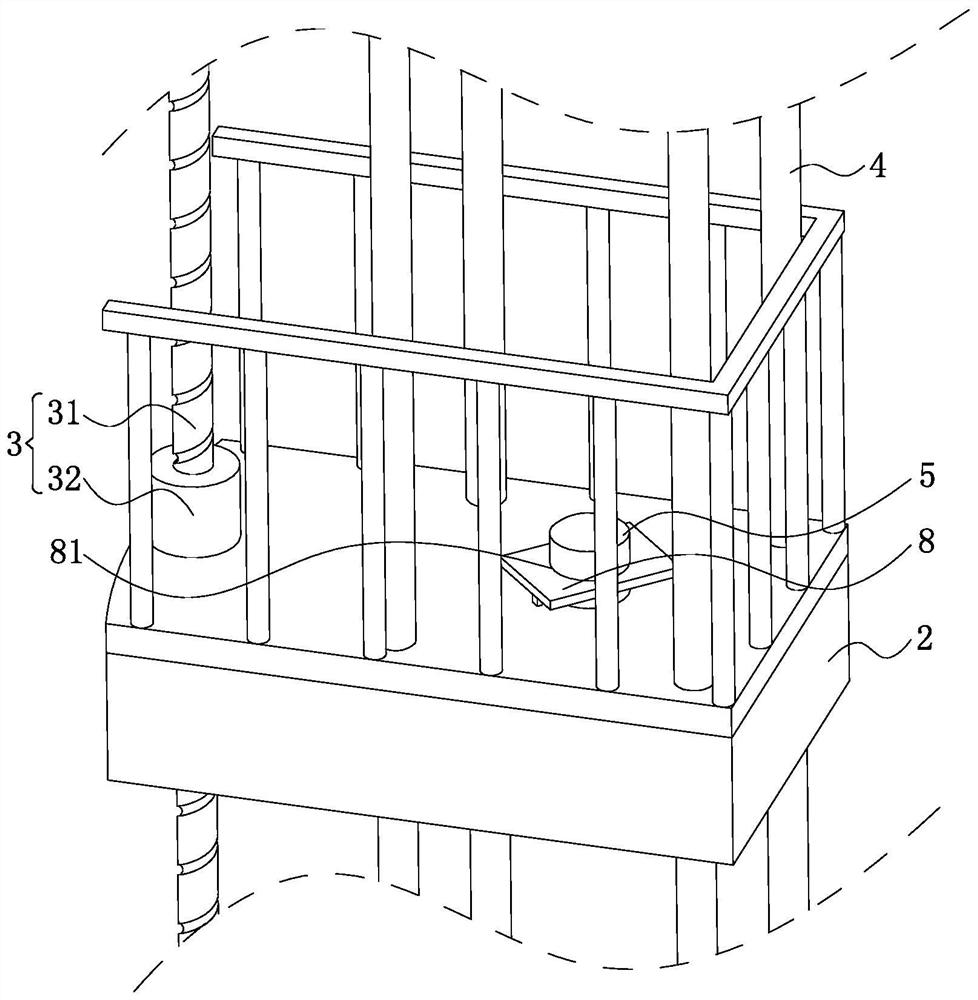

[0034] refer to figure 1 with figure 2 , the integrated prefabricated pumping station includes a casing 1, a horizontal workbench 2 is arranged in the casing 1, a lifting device 3 for lifting the workbench 2 is arranged in the casing 1, and a lifting device 3 for the workbench is arranged in the casing 1 2-position fixed locking mechanism. When the staff needs to overhaul the interior of the pump station, they can carry relevant tools and stand on the workbench 2, and move the workbench 2 to a suitable position through the lifting device 3, and then fix the position of the workbench 2 through the locking mechanism. To improve the stability of workbench 2. To sum up, the pumping station provides convenience for the staff to enter the casing 1 for inspection and maintenance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com