A biogas tank automatic exhaust device

An automatic exhaust and biogas digester technology, applied in the field of biogas digesters, can solve the problems of a single exhaust hole structure in the biogas digester and the inability to automatically adjust the switch state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

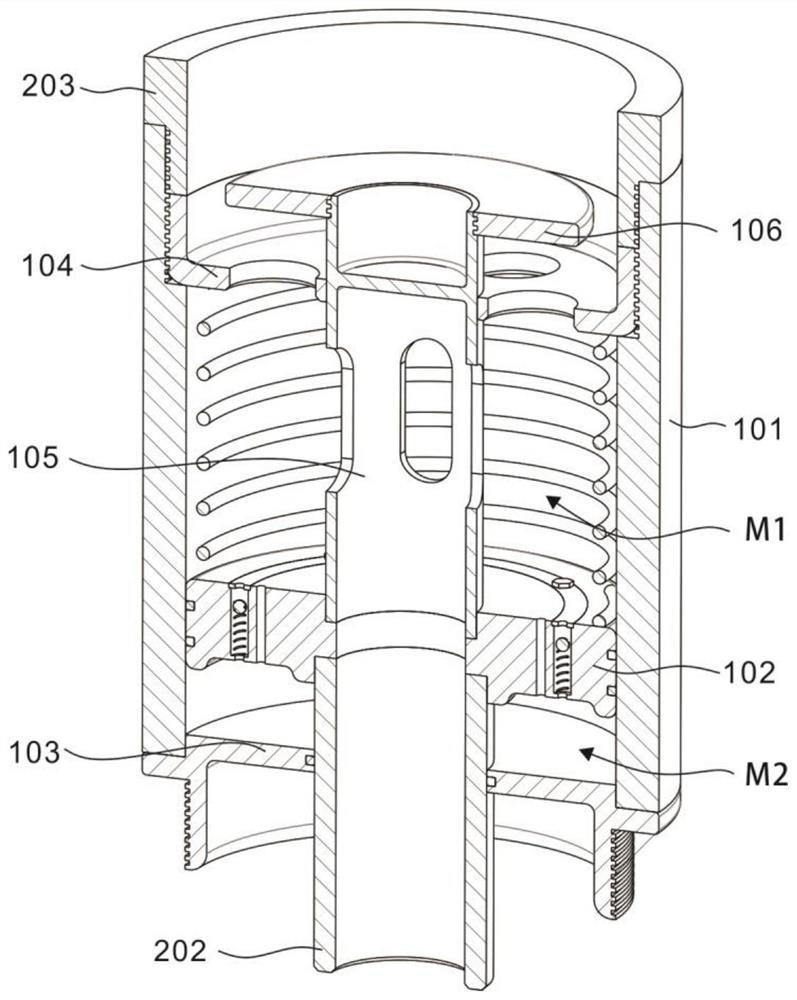

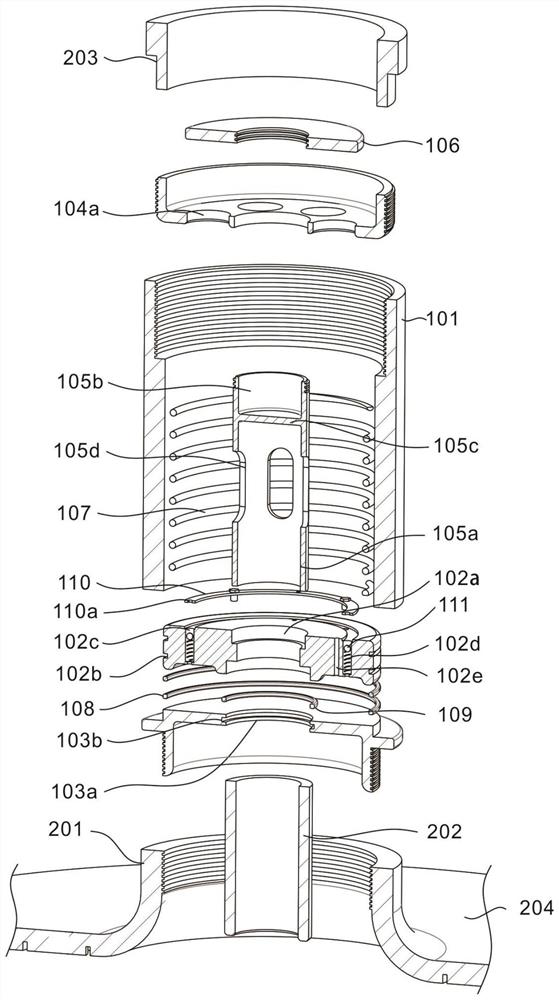

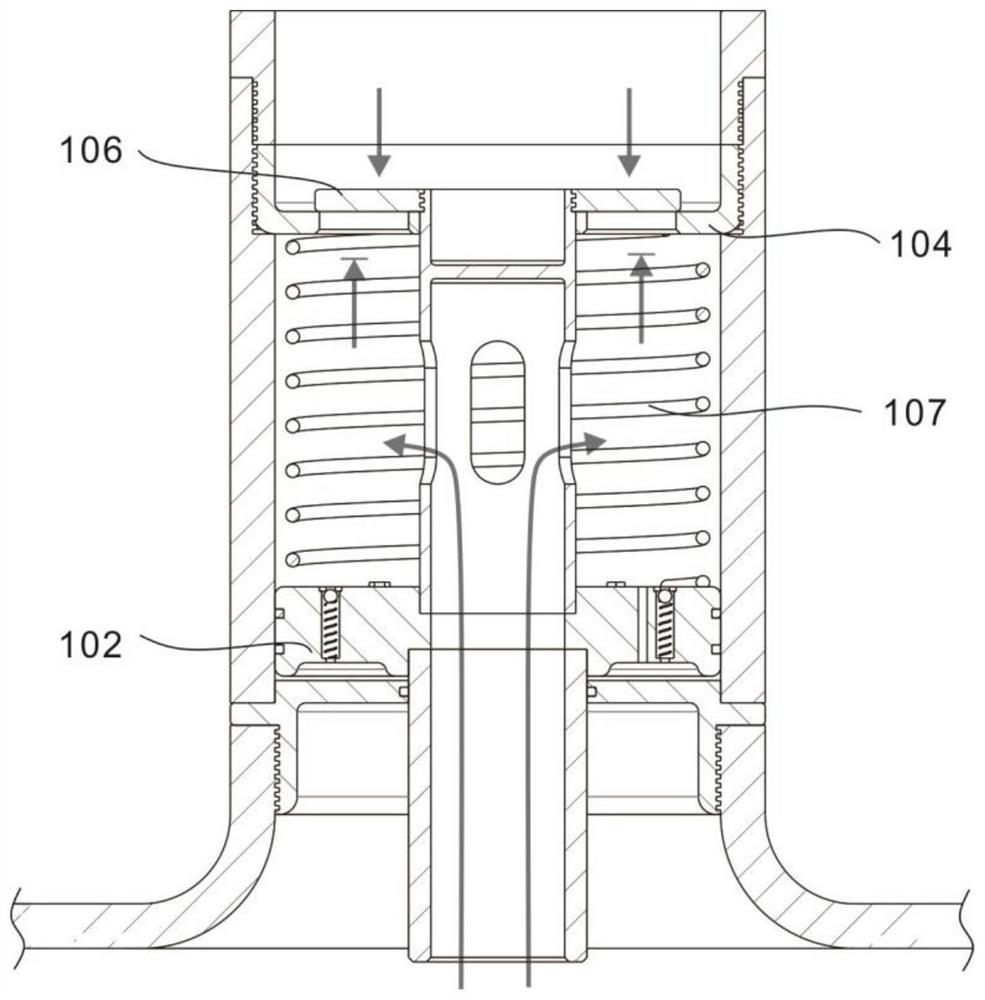

[0032] refer to Figure 1~5 , This embodiment provides an automatic exhaust device for a biogas pit, which can automatically discharge biogas when there is too much biogas generated in the biogas pit, and automatically shut down when the amount of biogas is too small. It includes an exhaust unit 100 and a connection unit 200; the specific exhaust unit 100 includes a valve body 101, a piston 102 located in the valve body 101, a sealing seat 103 connected to one end of the valve body 101, and a row connected to the other end of the valve body 101. The gas plate 104, the first air guide pipe 105 connected with the piston 102, and the cover plate 106 connected with the first air guide pipe 105; the valve body 101 is in the shape of a cylinder, which can connect the original exhaust port of the biogas digester and the external biogas pipeline, the piston 102 can slide on the valve body 101 along the axial direction of the valve body 101, the sealing seat 103 and the exhaust plate 1...

Embodiment 2

[0039] refer to Figure 1-9 , is the second embodiment of the present invention, this embodiment is based on the previous embodiment, and the difference from the previous embodiment is: when the raw materials in the biogas digester react fully, more biogas is generated, and stable discharge is required, Then the present invention also includes the following devices; specifically, including a lifting member 205 located inside the biogas tank, the lifting member 205 is divided into a lifting plate 205a and a lifting protrusion 205b located at the center of the lifting plate 205a, and a sliding rod 206 is connected to the outside of the lifting plate 205a , the sliding rod 206 passes through the top plate 204 of the biogas tank, and the function of the lifting member 205 is to apply a thrust to the part of the second air guide pipe 202 located in the biogas tank, so that the piston 102 and the cover plate 106 are far away from the exhaust hole 104a to discharge biogas, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com