Template component construction monitoring method based on pulse laser ranging device

A pulsed laser ranging and template technology, which is used in measurement devices, re-radiation of electromagnetic waves, radio wave measurement systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

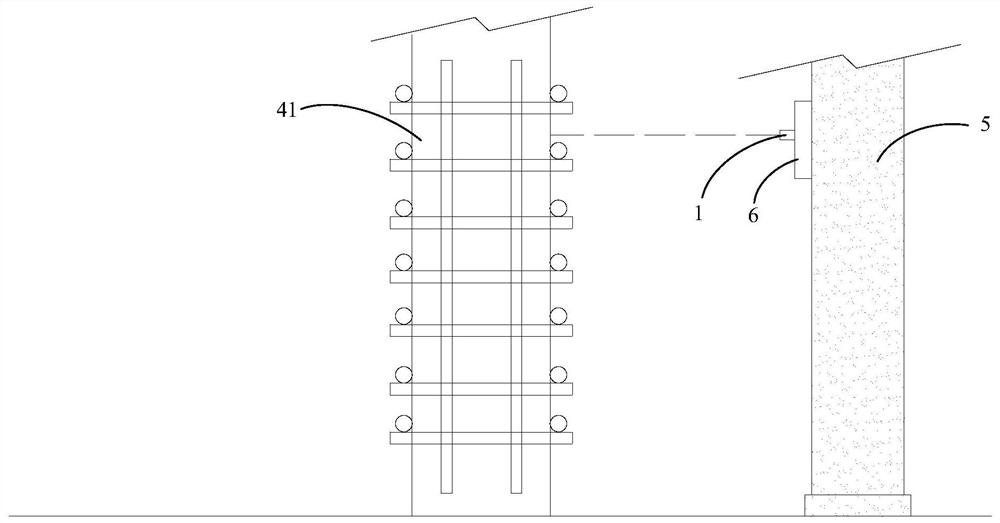

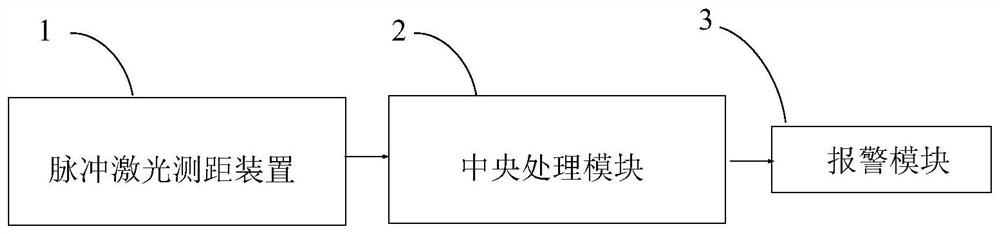

[0035] see figure 1 and image 3 , the present embodiment 1 proposes a formwork member construction monitoring method based on a pulsed laser distance measuring device, which is characterized in that it includes the following steps:

[0036] Fixedly install several pulse laser distance measuring devices 1 on the reference object, and make the pulse laser distance measuring devices 1 be at the side of the template member to be measured;

[0037] Use the pulsed laser distance measuring device 1 to measure the horizontal distance between it and the template component to be tested in real time, and transmit the measured horizontal distance to the central processing module 2 to monitor the relative distance between the template component to be measured and the reference object in real time. The horizontal displacement situation;

[0038] When the horizontal distance measured by the pulsed laser distance measuring device 1 exceeds the preset threshold in the central processing mod...

Embodiment 2

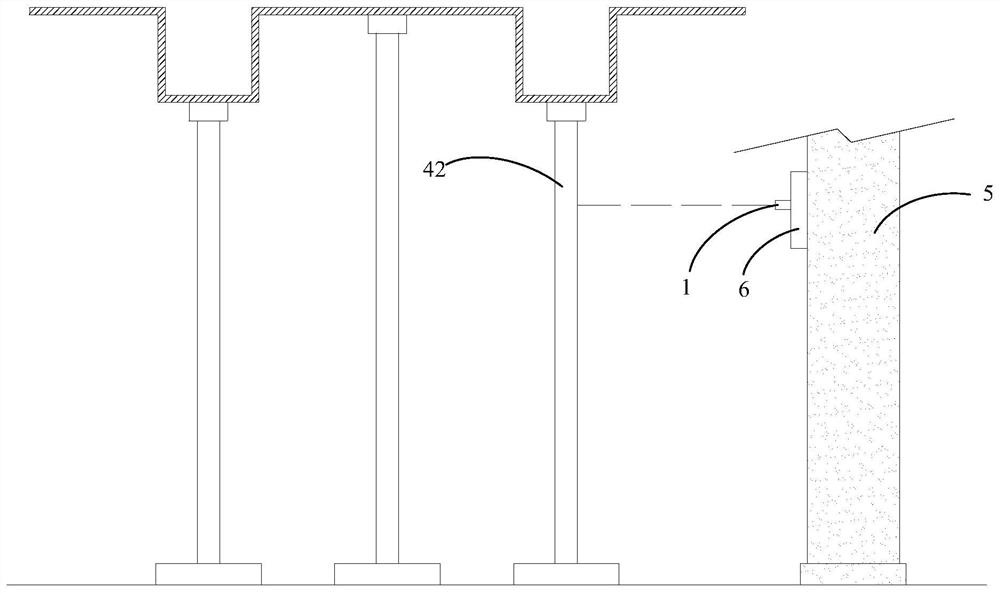

[0053] see figure 2 , Embodiment 2 is substantially the same as Embodiment 1, and the main difference between the two is that the specific template components to be tested are different. In Embodiment 2, the template components to be tested are formwork support poles 42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com