Current collector for trolley conductor, construction hoist and power supply system

A technology for construction elevators and power supply systems, applied to collectors, non-rotating collectors, circuits, etc., can solve problems such as different running trajectories, increased project cost, and inability to exchange relative positional relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

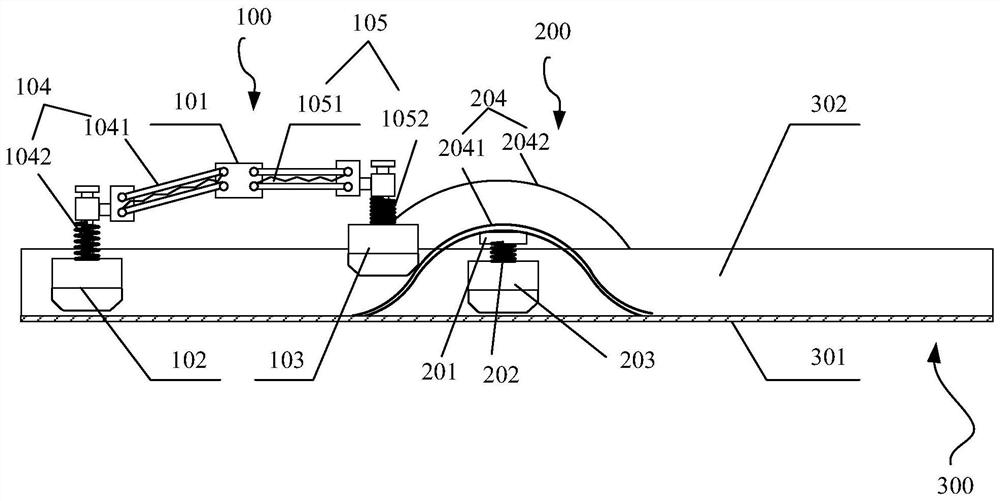

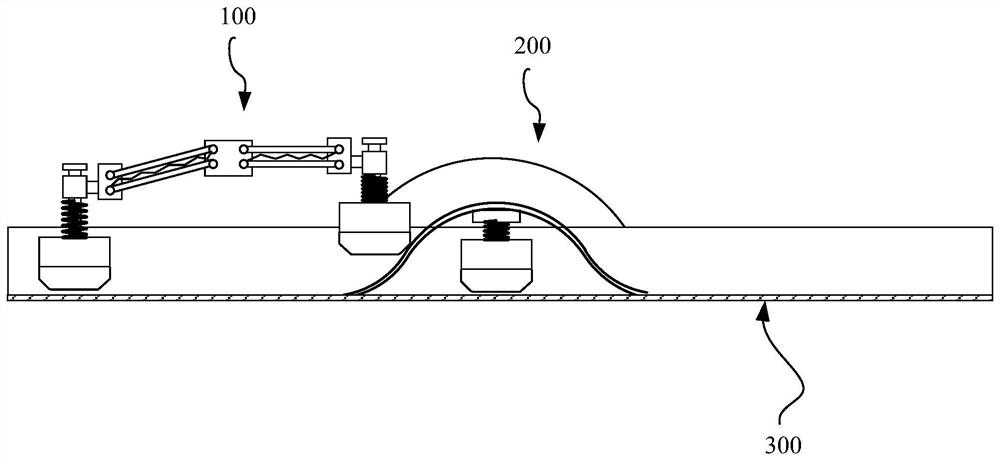

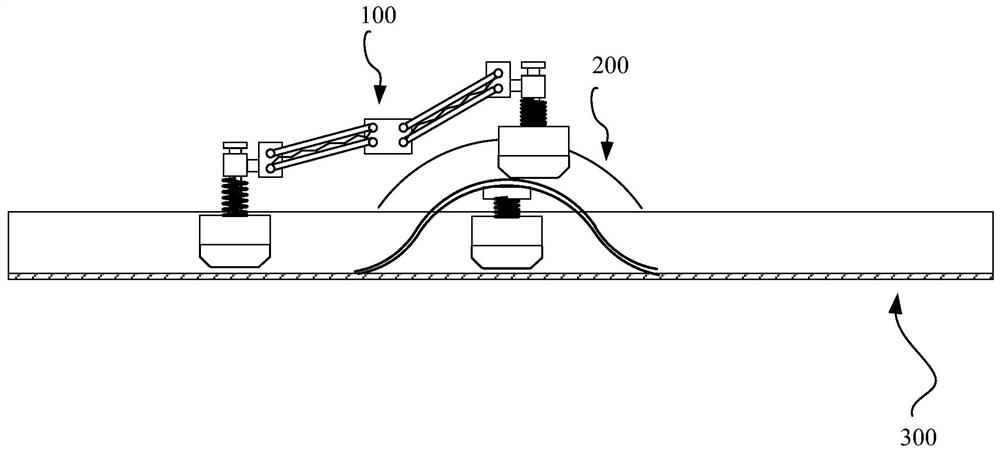

[0050] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings. The described embodiments should not be regarded as limiting the present invention. Those of ordinary skill in the art have not made All other embodiments obtained under the premise of creative work belong to the protection scope of the present invention.

[0051] In the description of the present invention, “some embodiments” are involved, which describe a subset of all possible embodiments, but it is understood that “some embodiments” may be the same subset or different subsets of all possible embodiments, And can be combined with each other without conflict.

[0052] In the description of the present invention, the terms "first, second", etc. involved are only to distinguish similar objects, and do not represent a specific order for the objects. Understandably, "f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com