Metal plate processing clamping device for constructional engineering

A technology of metal plates and construction engineering, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve problems such as troubles and increase equipment use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

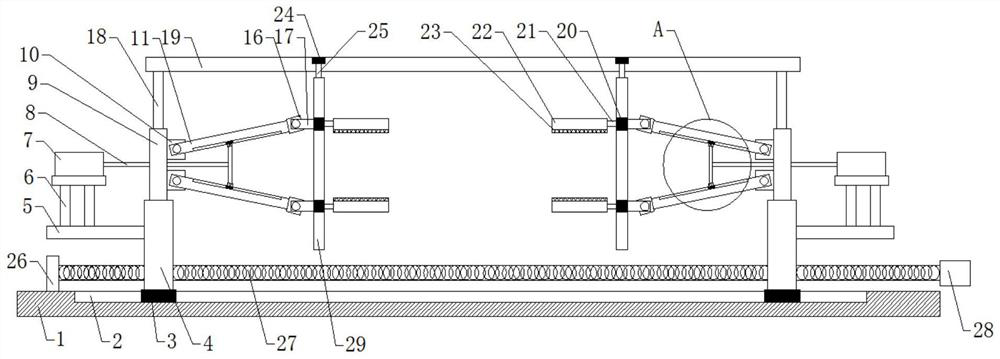

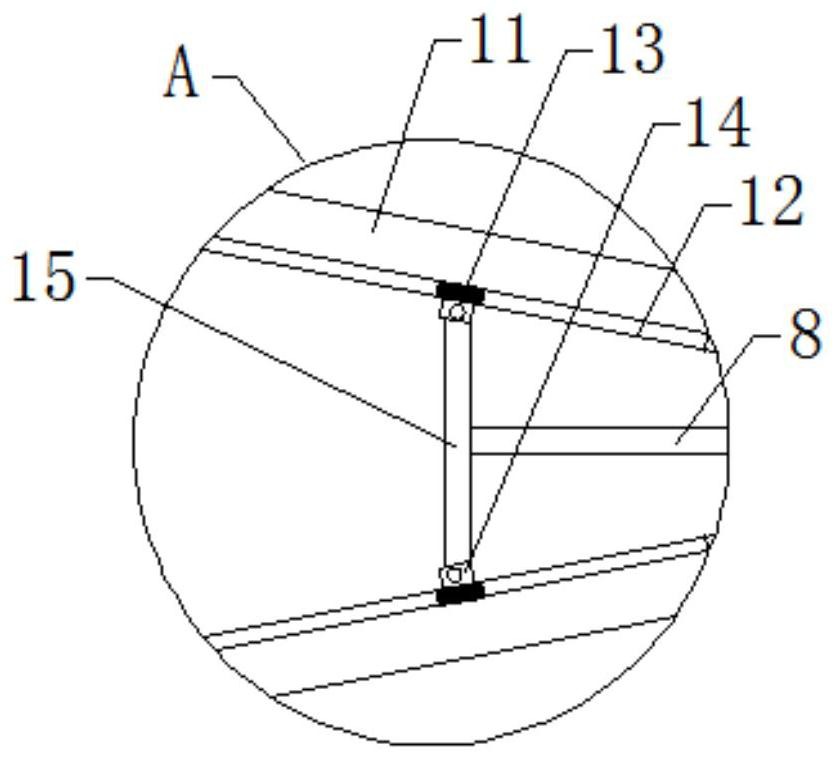

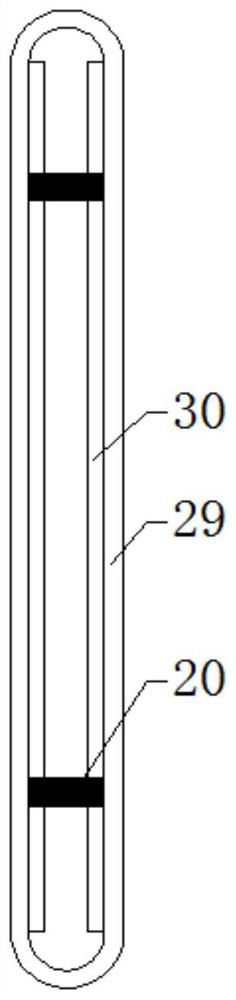

[0021] see Figure 1~4 , in an embodiment of the present invention, a metal plate processing and clamping device for construction engineering includes a workbench 1, a first chute 2 is opened on the upper surface of the workbench 1, and two a first slider 3, the upper sides of the two first sliders 3 are respectively fixedly equipped with a moving plate 4, the upper side of the moving plate 4 is fixedly installed with a fixed plate 9, and the two fixed plates 9 are close to each other Two fixed blocks 10 are respectively fixedly installed on one side, and a transmission rod 11 is connected with rotation on the fixed block 10, and an installation block 16 is fixedly connected with the end of the transmission rod 11 away from the fixed block 10, and the installation block 16 is rotated A connecting rod 17 is connected, and the end of the connecting rod 17 away from the mounting block 16 is fixedly connected with a third slider 20, and the third slider 20 is slidably arranged in ...

Embodiment 2

[0028] see figure 1 , in order to facilitate the adjustment of the distance between the two moving plates 4 in the clamping device for processing metal plates for construction engineering of the present invention, this embodiment has been further improved on the basis of Embodiment 1, and the improvements are: the two described Threaded holes are provided on the moving plate 4 respectively, and the same screw rod 27 matched with the two threaded holes is pierced in the two threaded holes; Bearing seat 26 is arranged, and described screw mandrel 27 left ends are rotatably installed in bearing seat 26, and described screw mandrel 27 right-hand ends are fixedly installed with the handle 28 that screw mandrel 27 is rotated.

[0029] The working principle of the present invention is:

[0030] When using the metal plate processing clamping device for construction engineering of the present invention, first adjust the distance between the two moving plates 4 according to the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com