Rebar loading and unloading device

A technology of loading and unloading devices and steel bars, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., which can solve the problems of single work object and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

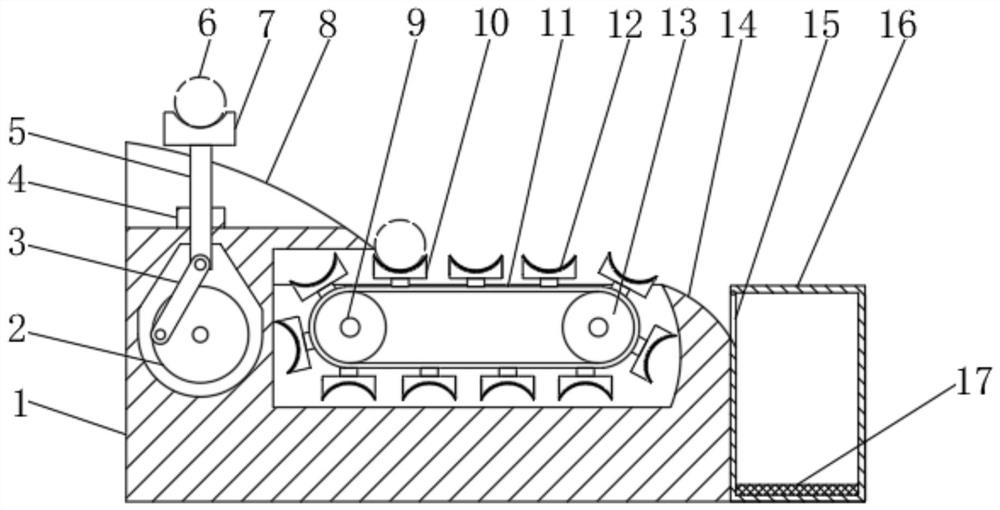

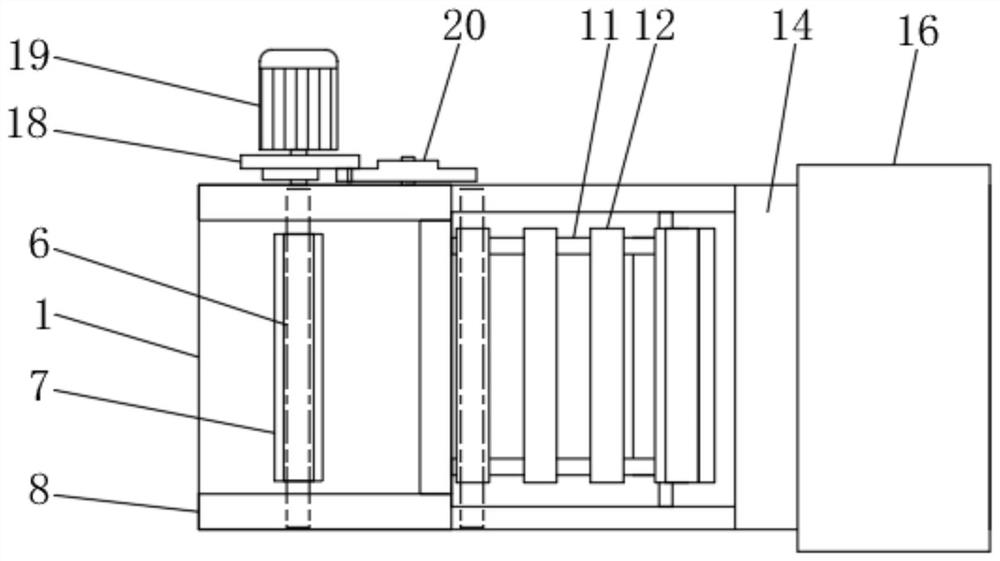

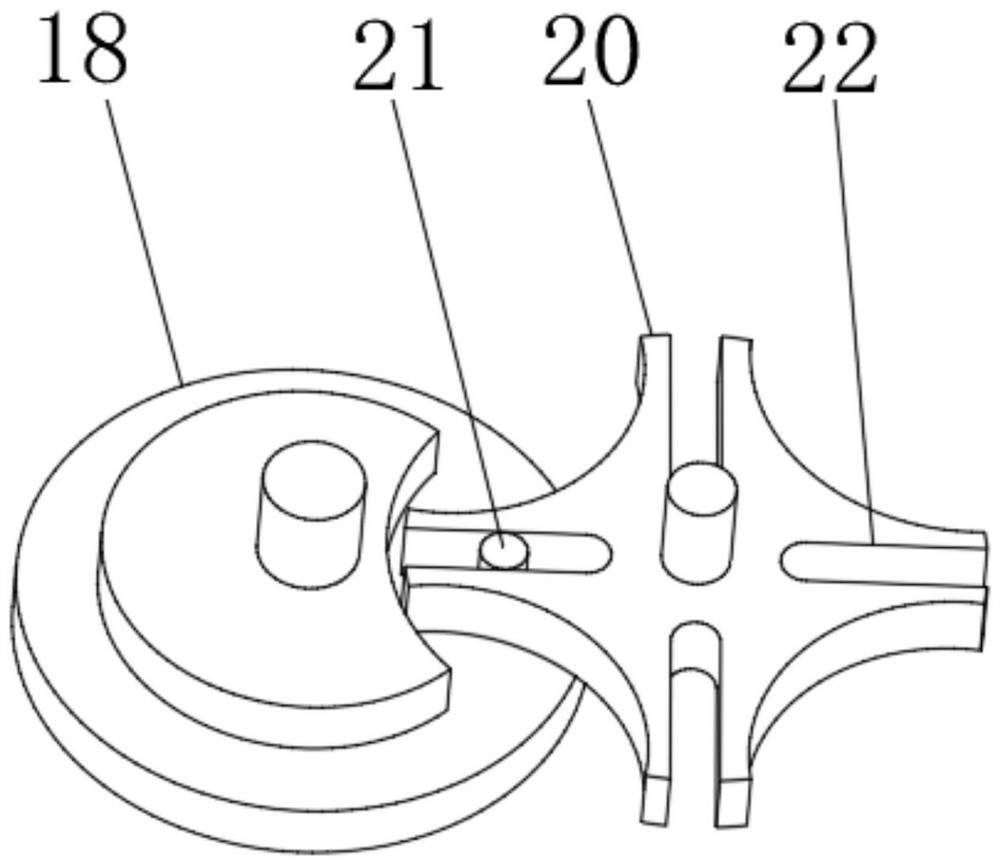

[0026] Embodiment one: refer to Figure 1~4 , in an embodiment of the present invention, a steel bar loading and unloading device includes a base 1, a motor 19 is arranged at the rear end of the base 1 to provide a power source, the output shaft end of the motor 19 is connected to a turntable 2, and the turntable 2 is arranged inside the base 1 In operation, the front end of the turntable 2 is rotatably connected to the connecting rod 3, and the connecting rod 3 is rotatably connected to the support column 5, and the outer end of the support column 5 passing through the base 1 is fixedly connected to the tray 7, and the steel bar body 6 is placed on the tray 7. When the tray 7 reciprocates up and down, the continuous loading and unloading of the steel bar body 6 is realized. The front and rear positions of the upper end of the base 1 are provided with a first slope belt 8, and the slope of the first slope belt 8 is gentle, so as to avoid the steel bar body 6 from rolling down. ...

Embodiment 2

[0035]Embodiment 2: This invention also provides another embodiment, which is improved on the basis of the above embodiment. The right end of the base 1 is provided with a second slope belt 14, so as to realize the adjustment of the steel bar body 6 Another buffer, the lower end of the second slope belt 14 is facing the entrance 15, and the whole device realizes that the delivery of the steel bar body 6 is stable.

[0036] In summary, when the invention works, the motor 19 is turned on, the same motor 19 provides power, and the turntable 2 is used to drive the connecting rod 3 to rotate. Drive the tray 7 to reciprocate up and down. When moving down, the tray 7 moves into the gap between the first slope belts 8, and the steel bar body 6 is supported by the first slope belt 8 and leaves the tray 7 and slides down along the first slope belt 8. Into the conveying tray 10, with the help of the cushion 12 to reduce the impact force, at the same time, the motor 19 drives the runner 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com