Compressible U-shaped steel bracket

A type of steel and U-shaped technology, applied in the field of U-shaped steel brackets that can be pressed, can solve problems such as reduced service life, deformation, and unstable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

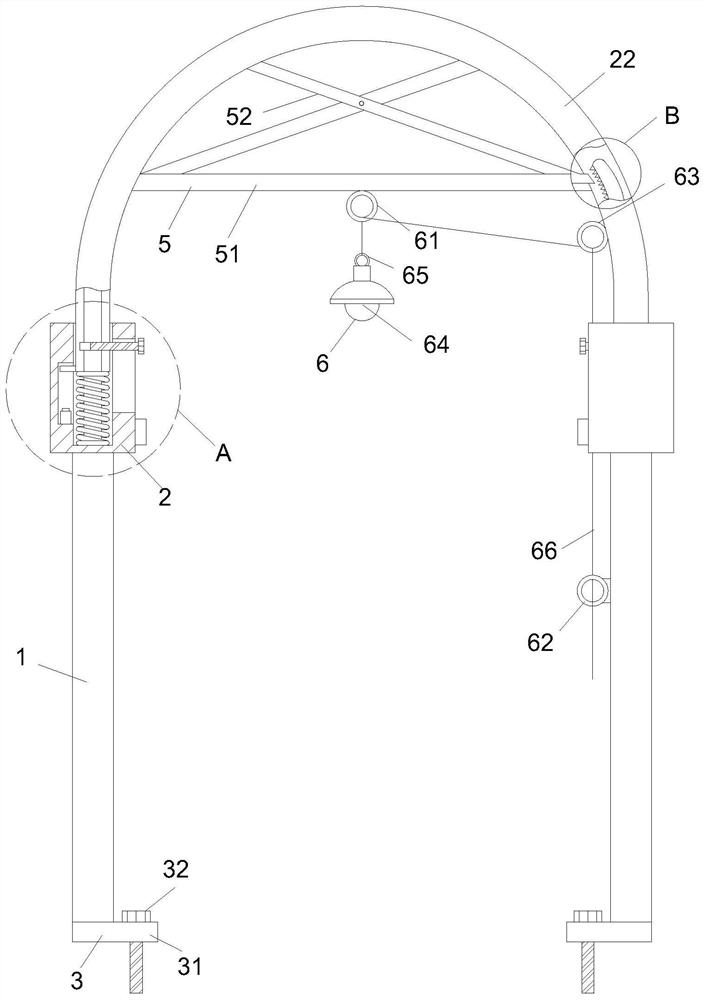

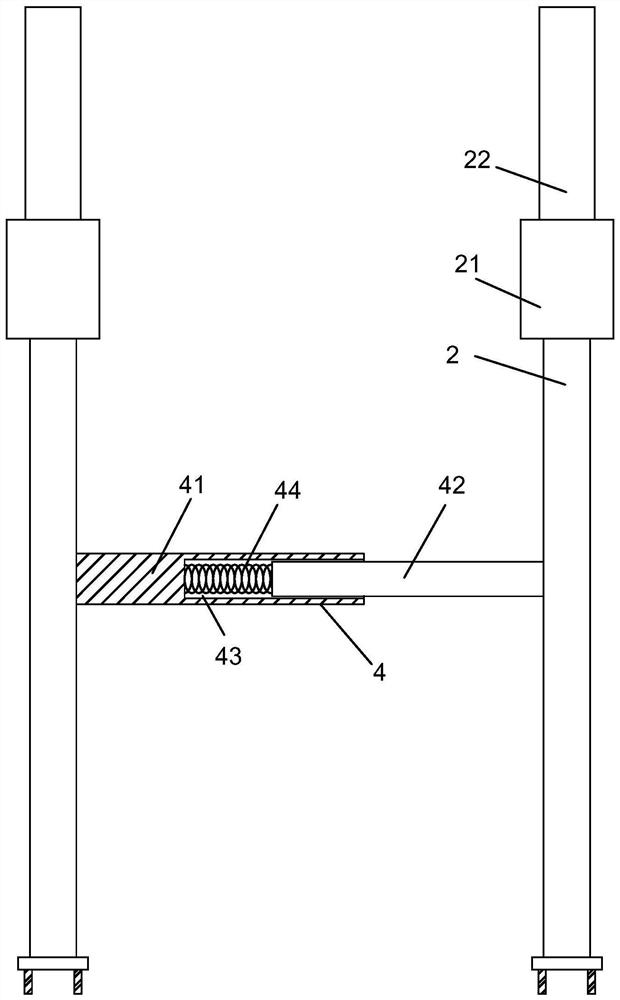

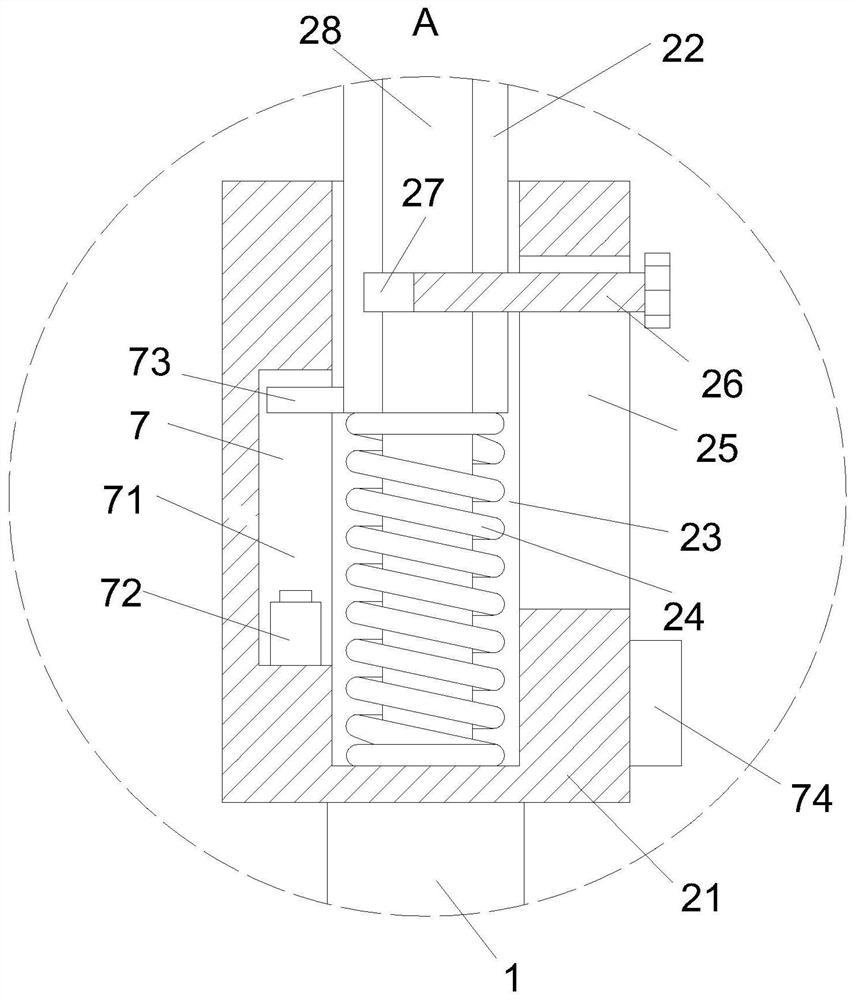

[0020] Please refer to figure 1 , figure 2 , image 3 with Figure 4 , a U-shaped steel bracket that can be pressed, including a support rod 1, a support mechanism 2, a fixing mechanism 3, a connecting mechanism 4, a reinforcement mechanism 5, a lighting mechanism 6, and an alarm mechanism 7, and the support mechanism 2 is fixedly connected to the upper end of the support rod 1 , the support mechanism 2 includes a mounting block 21, a U-shaped frame 22, a slot 23, a compression spring 24, a strip opening 25, a limit screw 26 and a threaded groove 27, the mounting block 21 is fixedly connected to the upper end of the support rod 1, and inserted Groove 23 is opened on the upper side wall of mounting block 21, and two U-shaped frames 22 are inserted in two groups of slots 23 upside down, then allow compression spring 24 to be connected on the lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com