A robot for working at heights

A high-altitude operation and robot technology, which is applied in overhead installation, cable installation, overhead line/cable equipment, etc., can solve the problems of wire surface freezing, high-altitude wire maintenance robot movement stop, slipping, etc., and achieve the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

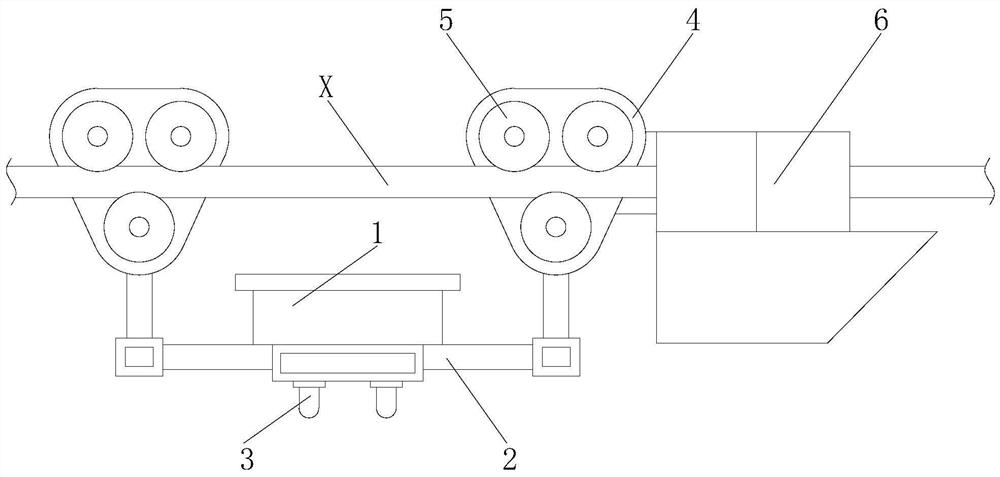

[0022] as attached figure 1 to attach Figure 5 Shown:

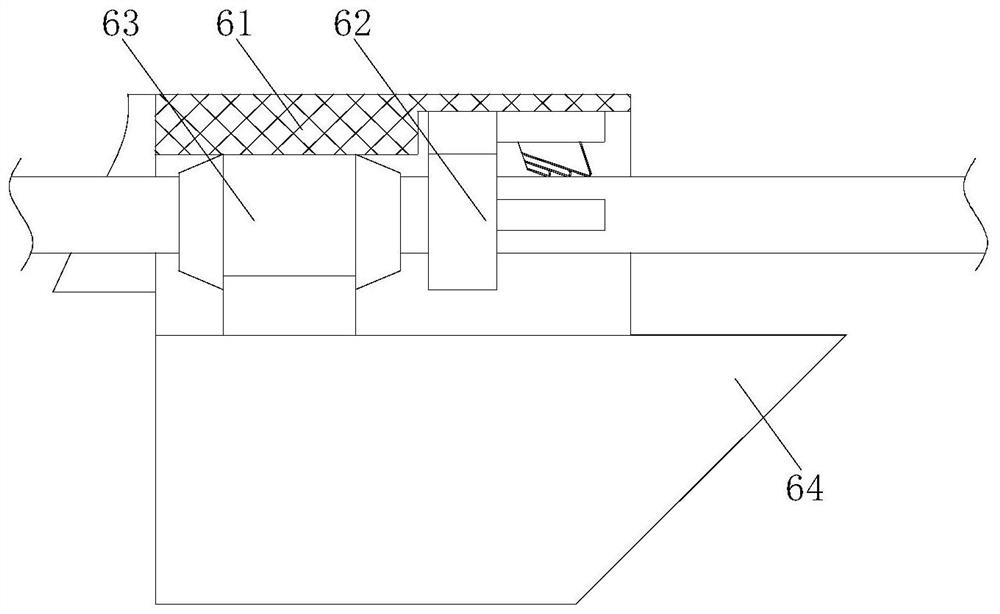

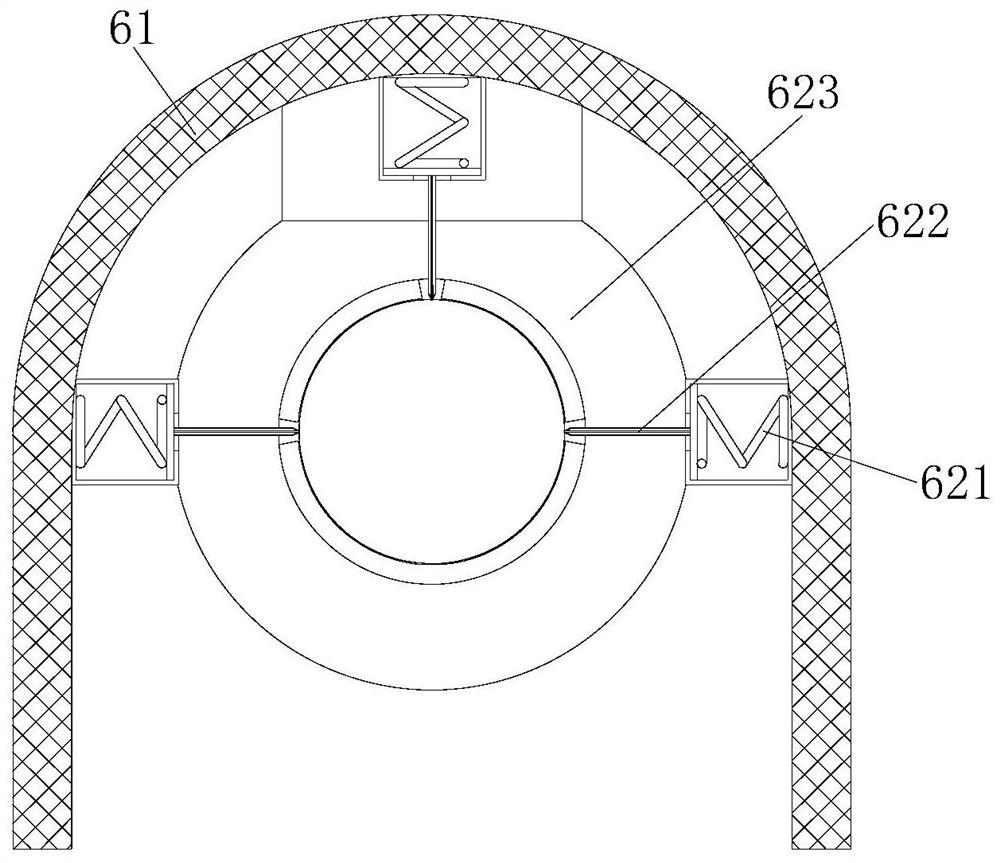

[0023] The invention is a robot for high-altitude operations, the structure of which includes a detection box 1, a connection seat 2, an indicator light 3, a driver 4, a moving wheel 5, and a deicing mechanism 6, and the middle end of the detection box 1 is fixedly installed on the connection seat 2, the bottom of the detection box 1 is provided with an indicator light 3 and is electrically connected, the front surface of the driver 4 is fixedly mounted with a moving wheel 5, the lower end of the driver 4 is fixed to the upper end of the connecting seat 2, and the right end of the driver 4 is connected to the upper end of the connecting seat 2. The left end of the deicing mechanism 6 is fixed. The deicing mechanism 6 includes a connecting sleeve 61, a rejecting mechanism 62, a wiping mechanism 63, and an ice slag collecting frame 64. The left end of the connecting sleeve 61 is fixedly installed on the right side of the ...

Embodiment 2

[0030] as attached Image 6 to attach Figure 7 Shown:

[0031] Wherein, the wiping mechanism 63 includes a fixed tube 631, an extruding mechanism 632, a sponge pad 633, and a water outlet 634. The fixed tube 631 is fixedly installed on the left end of the connecting sleeve 61. Mechanism 632, the inner wall of the extrusion mechanism 632 is closely attached to the sponge pad 633, the lower end of the fixed pipe 631 is provided with a drain port 634, and the lower end of the drain port 634 is connected with the ice slag collection frame 64, and the sponge pad 633 It has a ring-shaped structure, and the diameter of the sponge pad 633 is slightly larger than that of the high-altitude wire X, which is beneficial to absorb the residual moisture on the surface of the high-altitude wire X. The drain port 634 has a narrow structure with a wide upper end and a lower end, which is beneficial for water removal. Drain to prevent backflow of moisture.

[0032] Wherein, the extruding mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com