Patents

Literature

50results about How to "Move normally" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

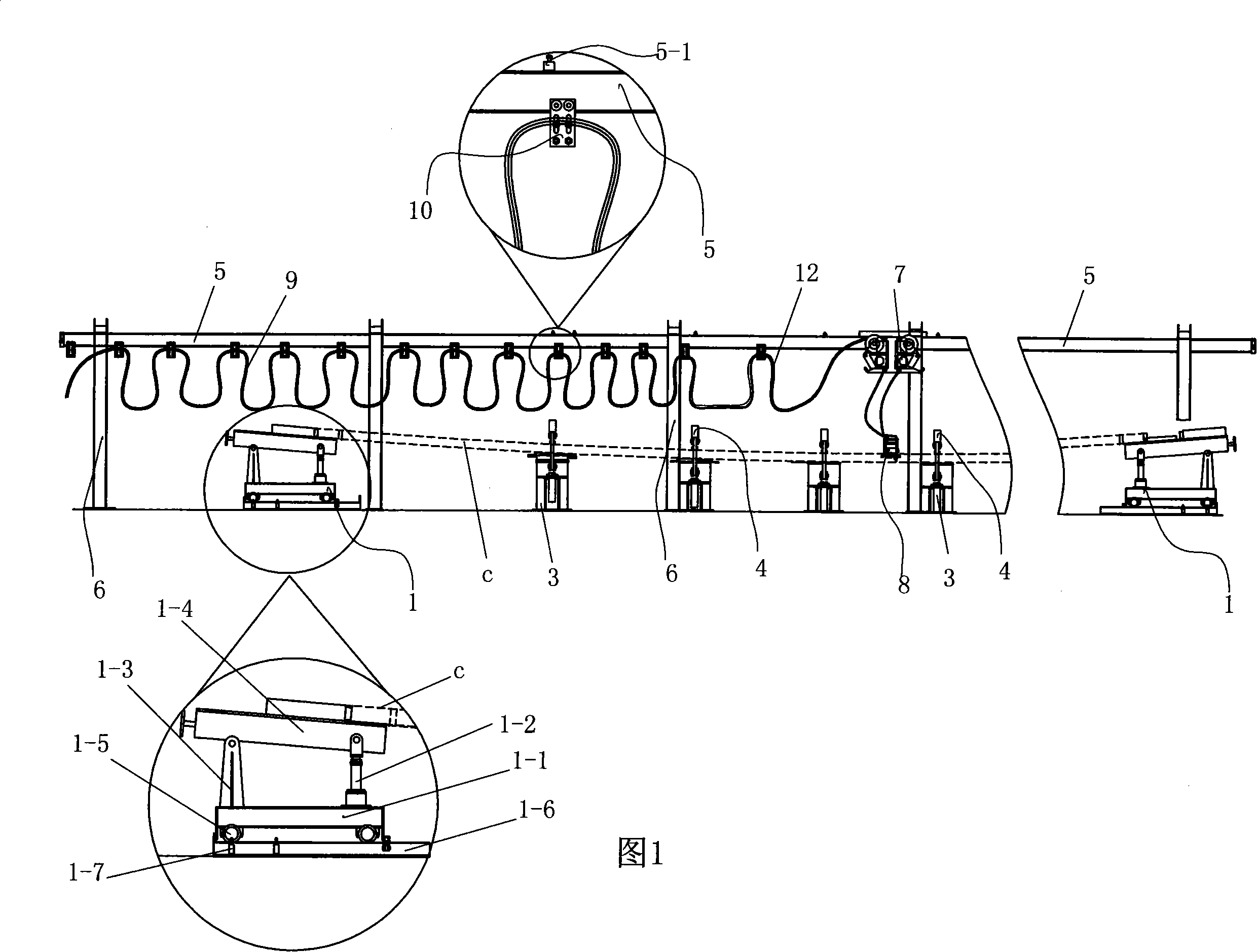

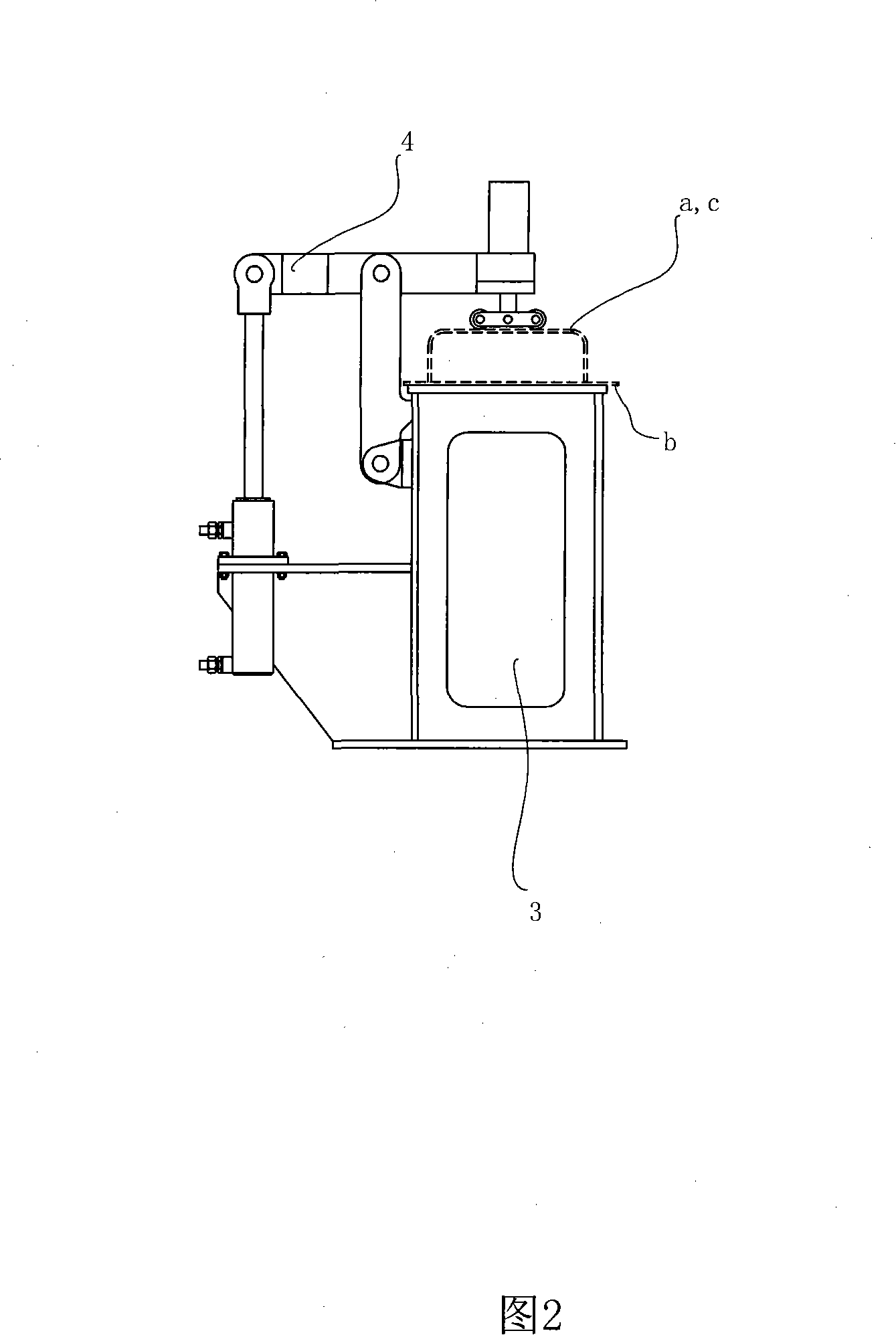

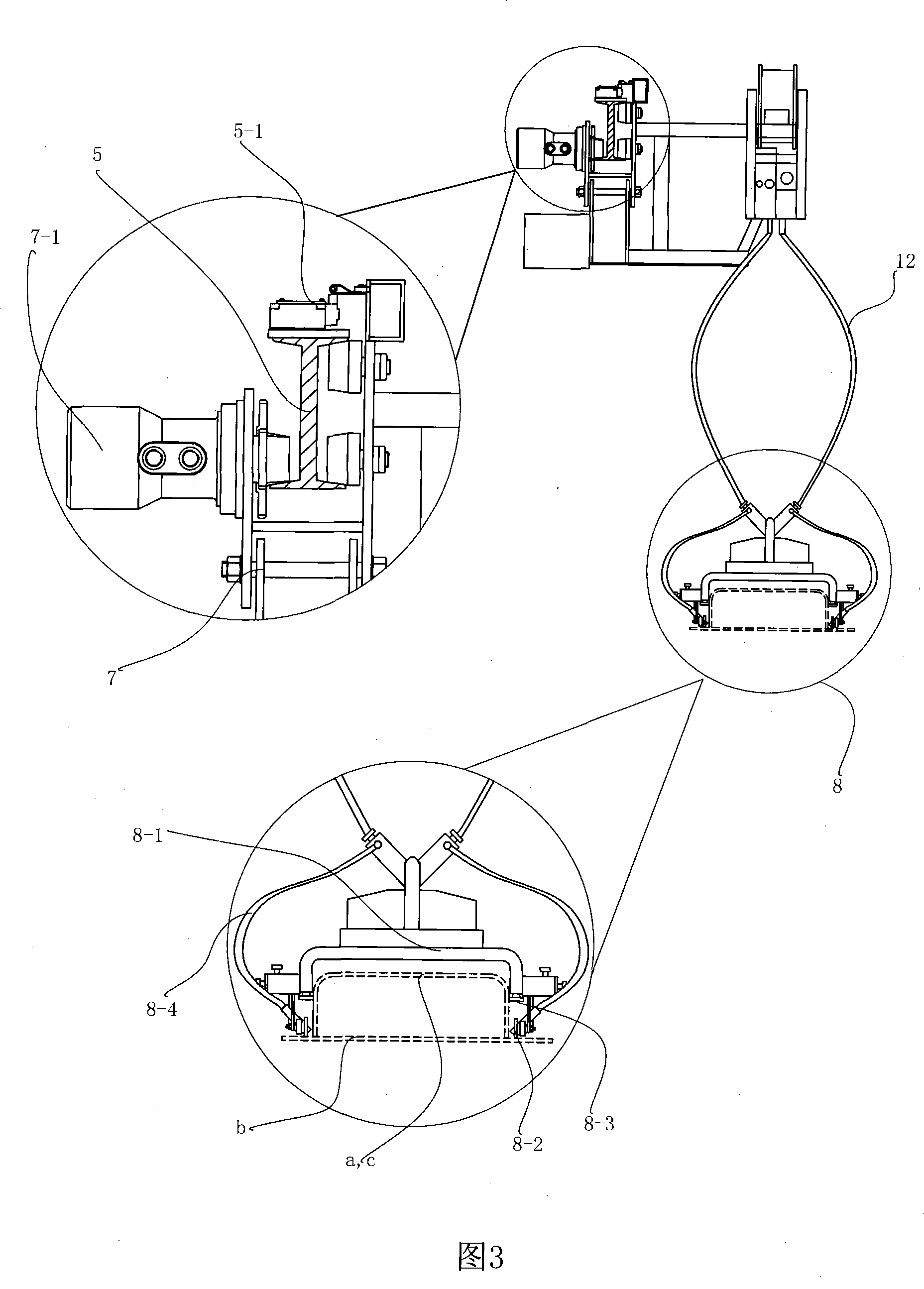

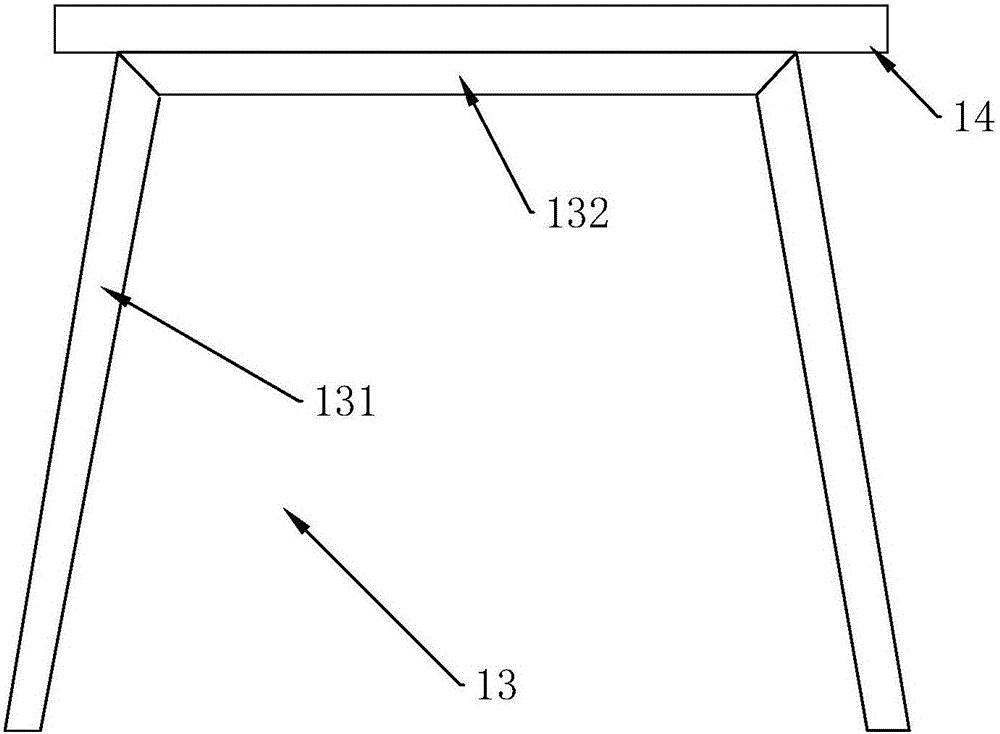

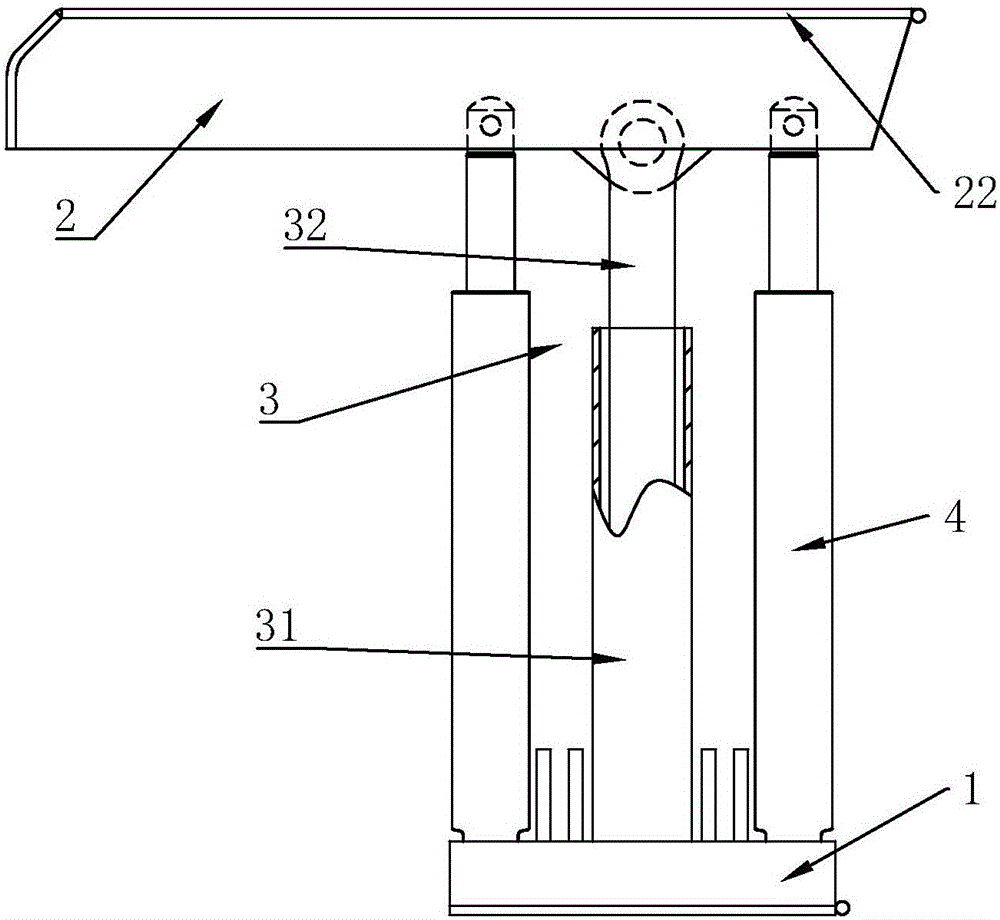

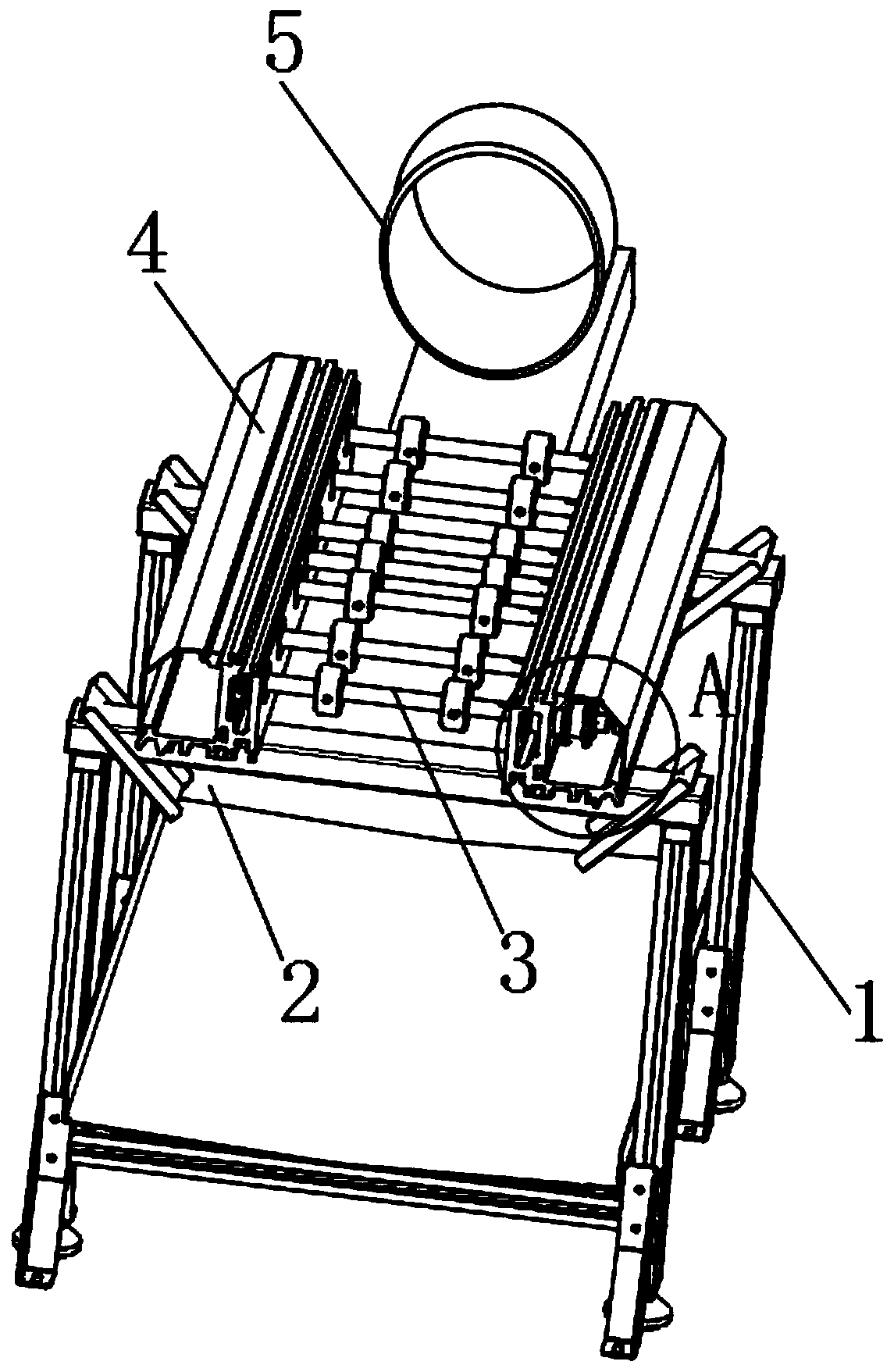

Automatic assembly welding device for car frame side beam

ActiveCN101121224ANormal supplySecurity supplyWelding/cutting auxillary devicesArc welding apparatusVehicle frameEngineering

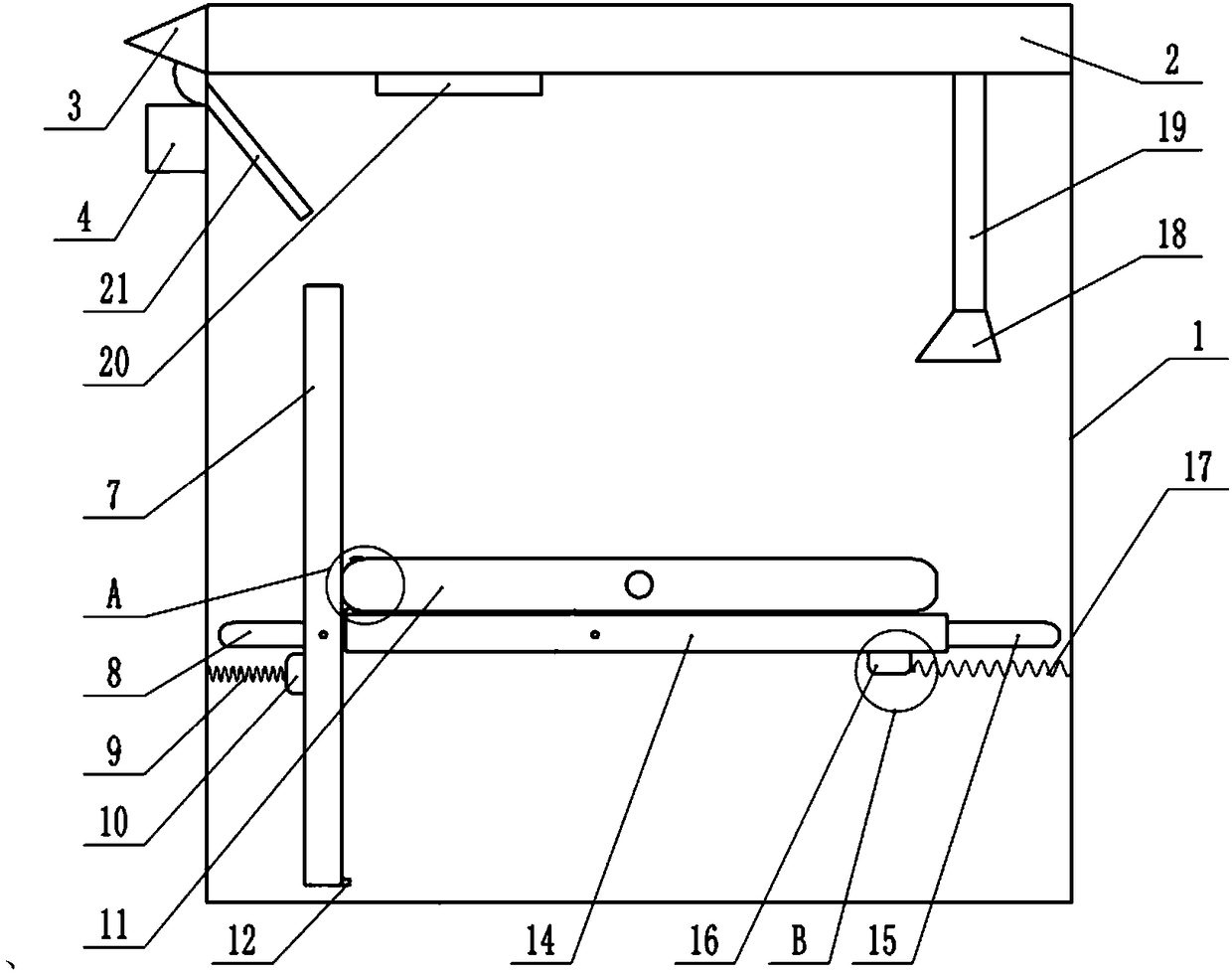

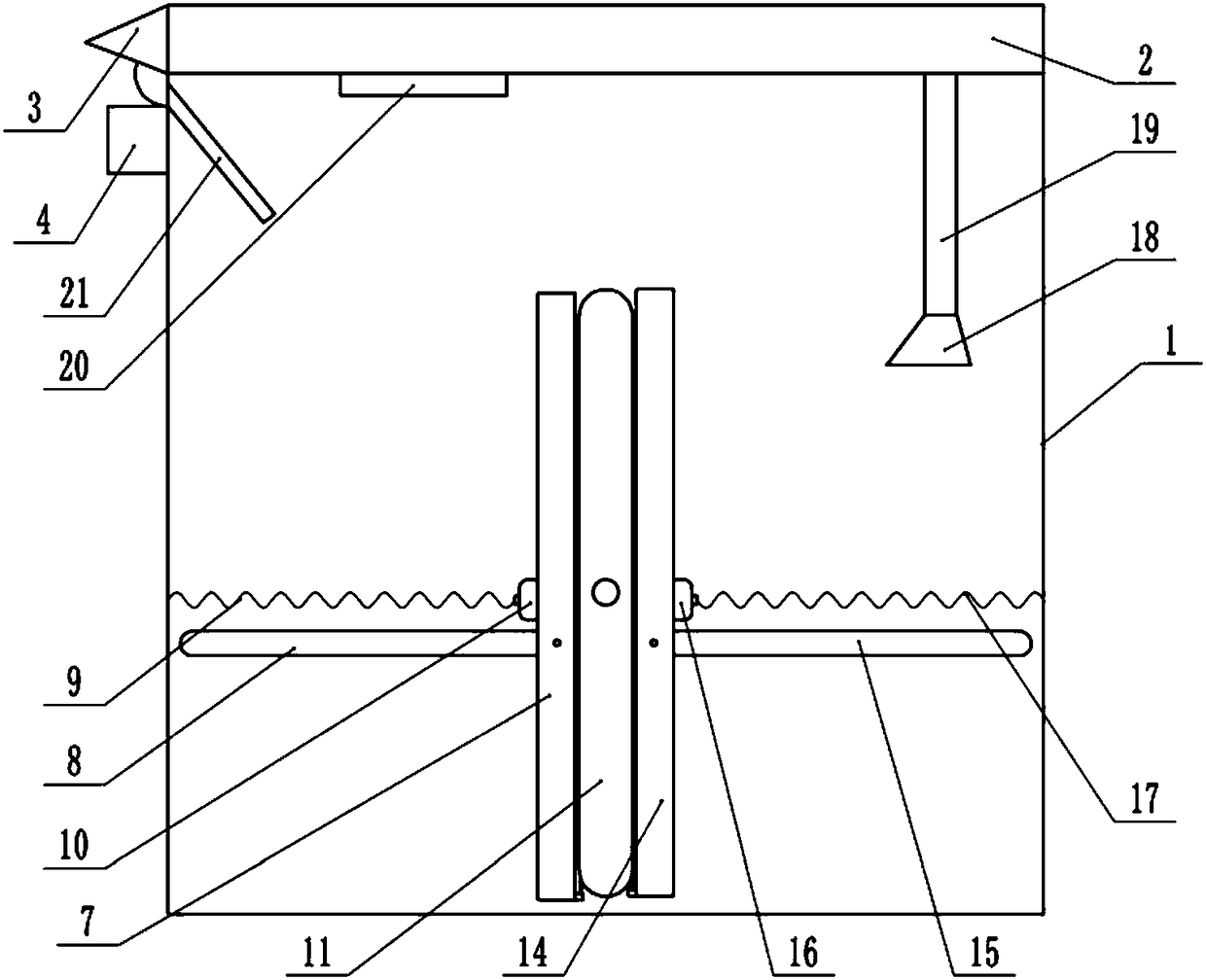

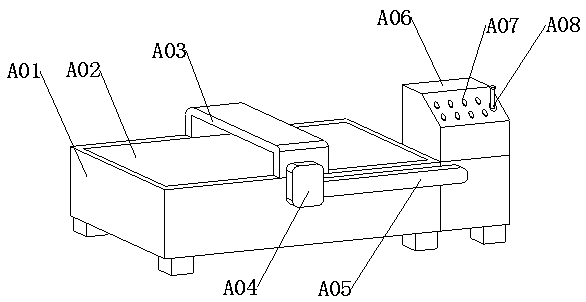

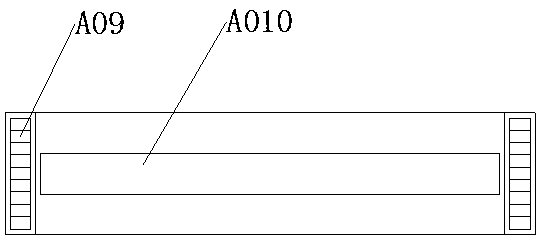

The present invention relates to an automatic welding device for vehicle frame side beam comprising two adjusting bases equipped face to face for placing frame side beam, at least two support saddles equipped between the two adjusting bases, a hydraulic clamp equipped on the support saddle and a welding car supported by two sides of the frame side beam; the upper ends faces of the two adjusting bases are relatively tilted; the upper end faces of the support saddles are lower than the lowest point of the upper end face of the adjusting base. The upper ends faces of the two adjusting bases are relatively tilted and the upper end faces of the support saddles are lower than the lowest point of the upper end face of the adjusting base, i.e. the two adjusting bases and every support saddle form a curved surface; welding is implemented on the curved surface, i.e. a camber is preset before welding; when the frame side beam is taken down after welding, the frame side beam begins to deflect and deform inversely, i.e. the preset camber is balanced out by the deflection and deformation to control the frame side beam camber in the permitted range which ensures the production quality; in addition, the welding car is adopted for the implementation of the automatic welding; in this way, the welding labor intensity is small.

Owner:CRRC QISHUYAN CO LTD

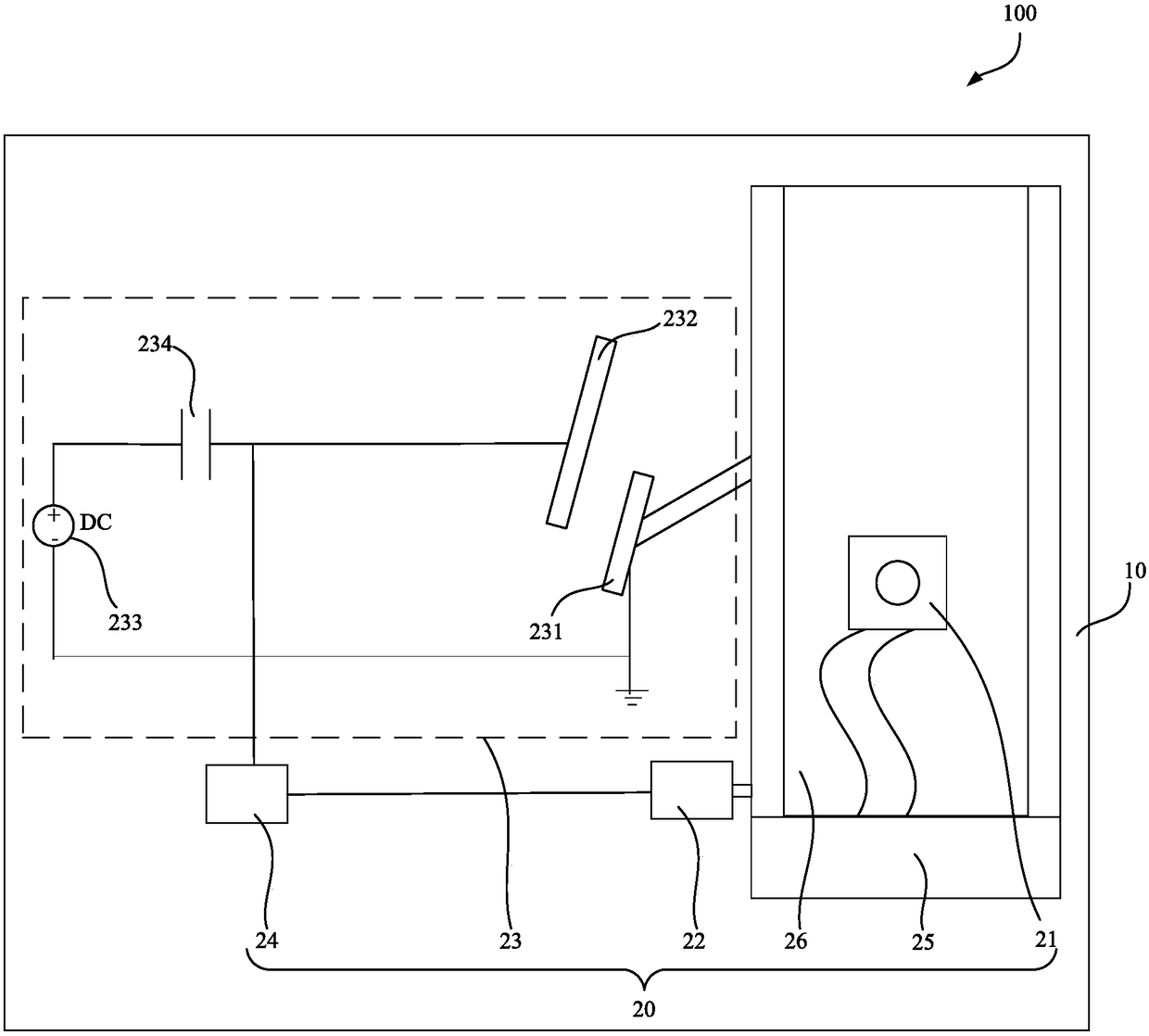

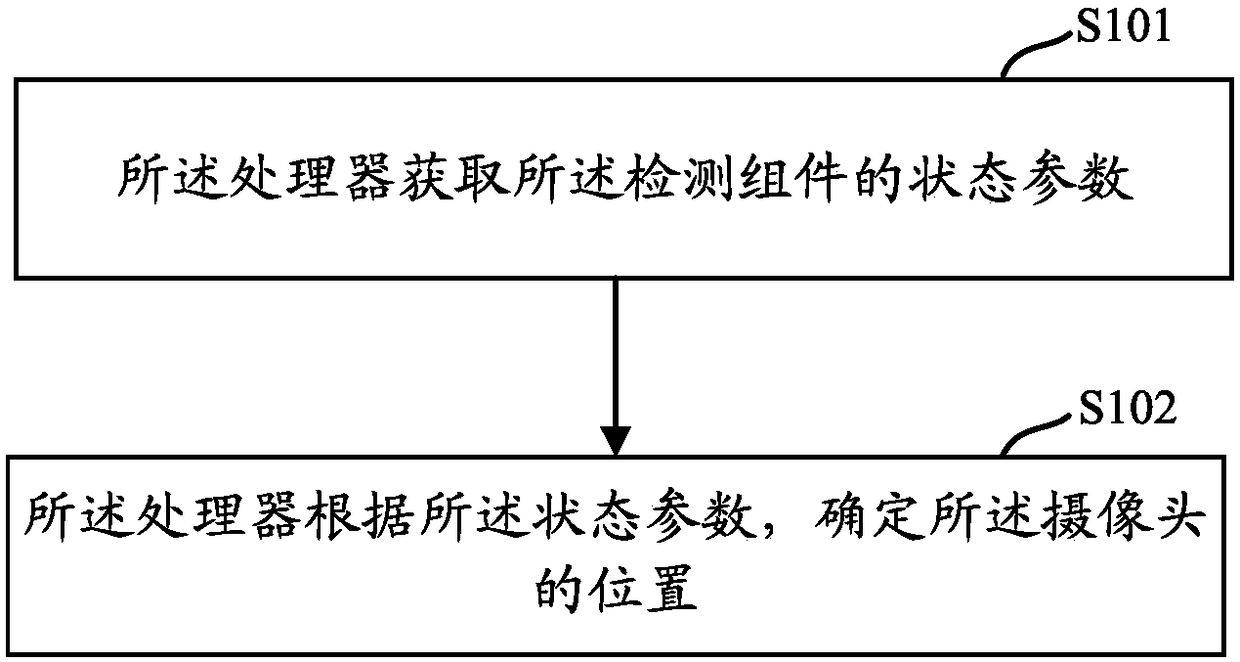

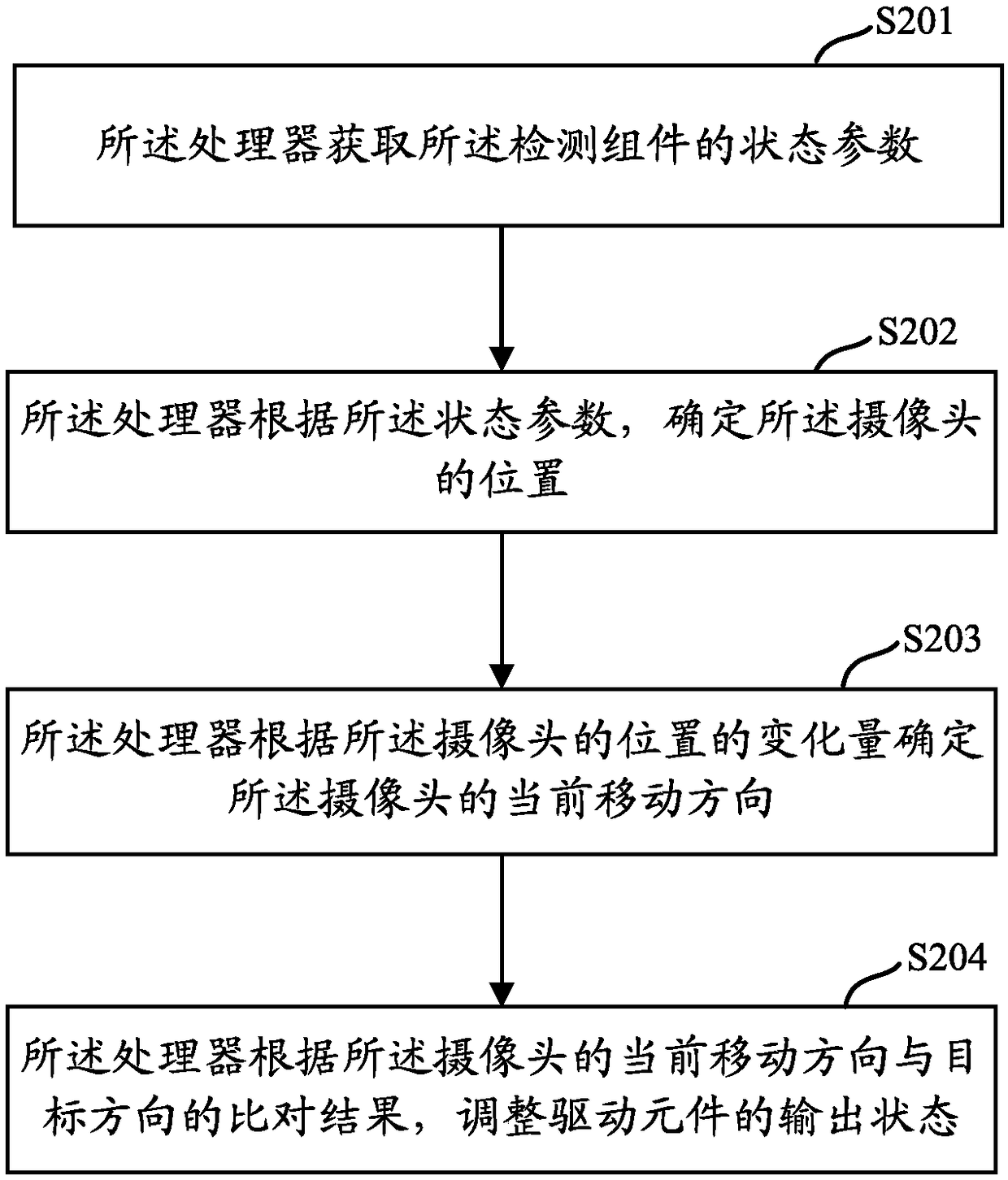

Camera module, control method and mobile terminal

ActiveCN108173993AMove normallyTelevision system detailsColor television detailsState parameterCamera module

The invention discloses a camera module, a control method and a mobile terminal, and the camera module comprises a camera, a driving element, a detection component and a processor, wherein the drivingelement is connected with the camera and used for driving the camera to move; the detection component comprises a first element and a second element arranged oppositely, the first element is connected with the camera and moves along with the camera relative to the second element, the detection component has state parameters, and the state parameters are used for representing relative distance ofthe first element and the second element; and the processor is electrically connected with the detection component and used for acquiring the state parameters of the detection component and determining a position of the camera according to the state parameters. The camera is connected with the first element in the detection component, thus, the first element can move along with the camera; subsequently, the moving first element can change the state parameters of the detection component. So, the position of the first element can be determined according to the state parameters, then the positionof the camera can be determined, and whether the camera moves normally can be confirmed in combination with the positions of the camera at different moments.

Owner:VIVO MOBILE COMM CO LTD

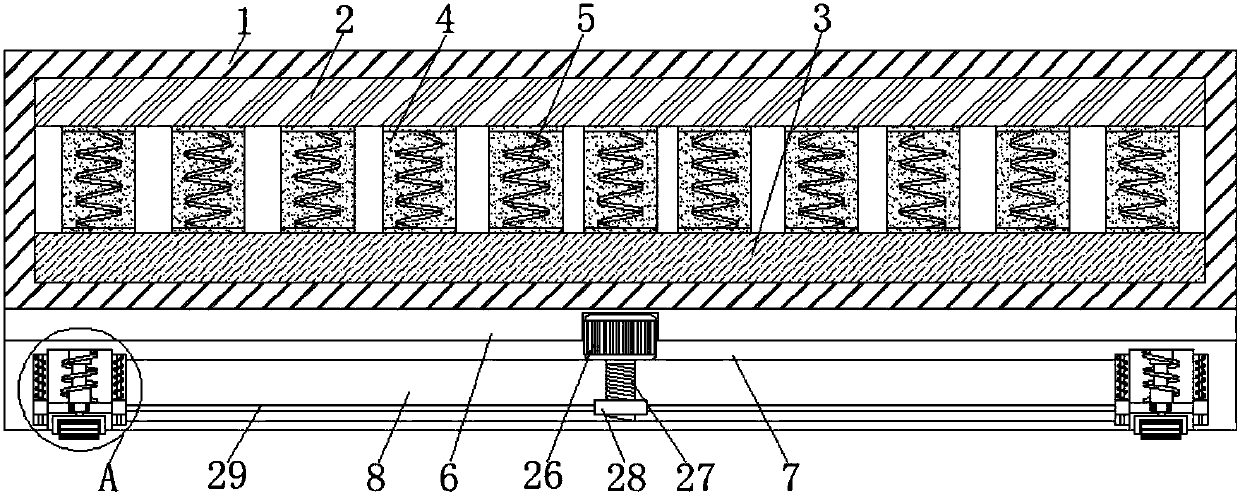

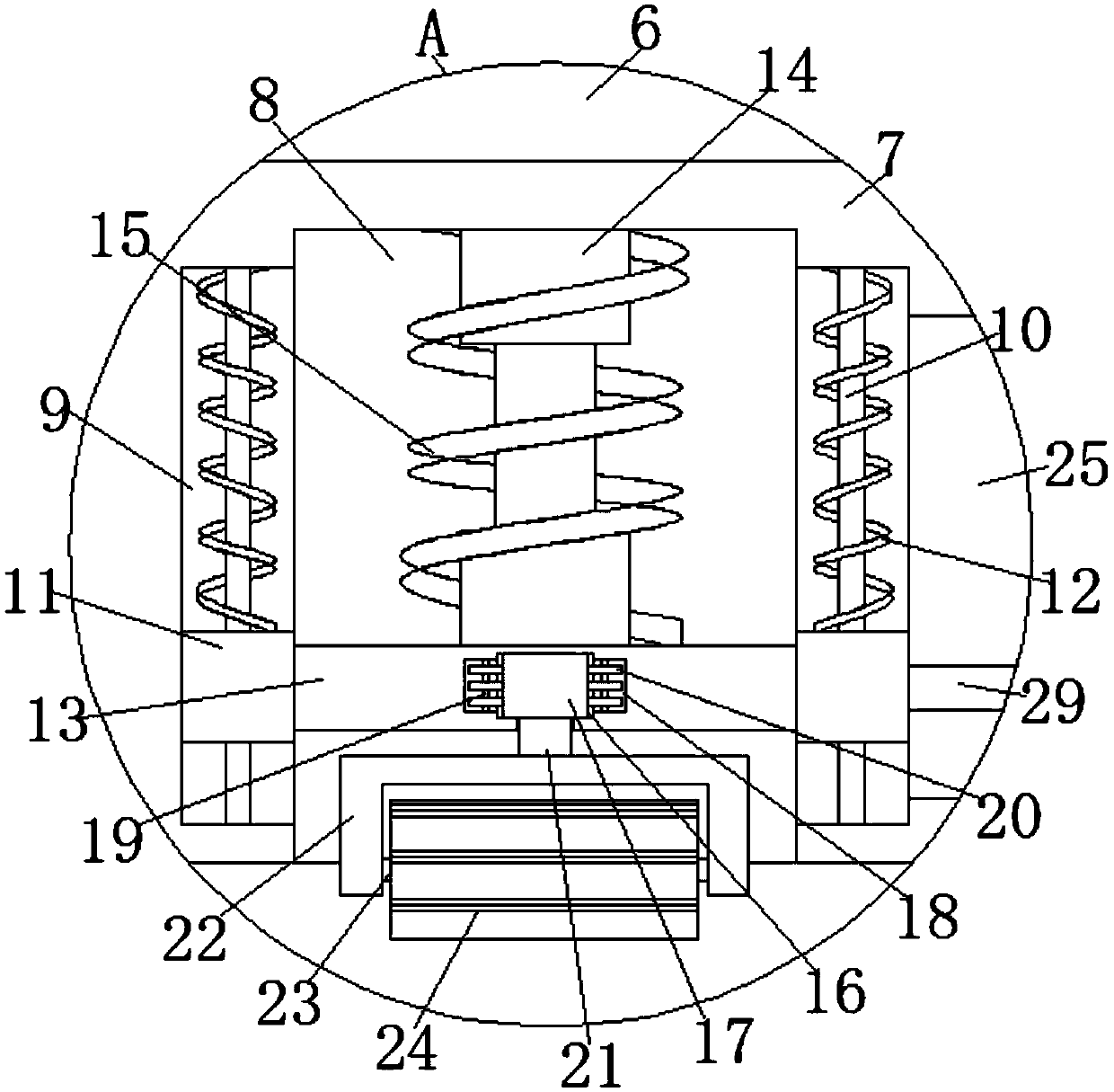

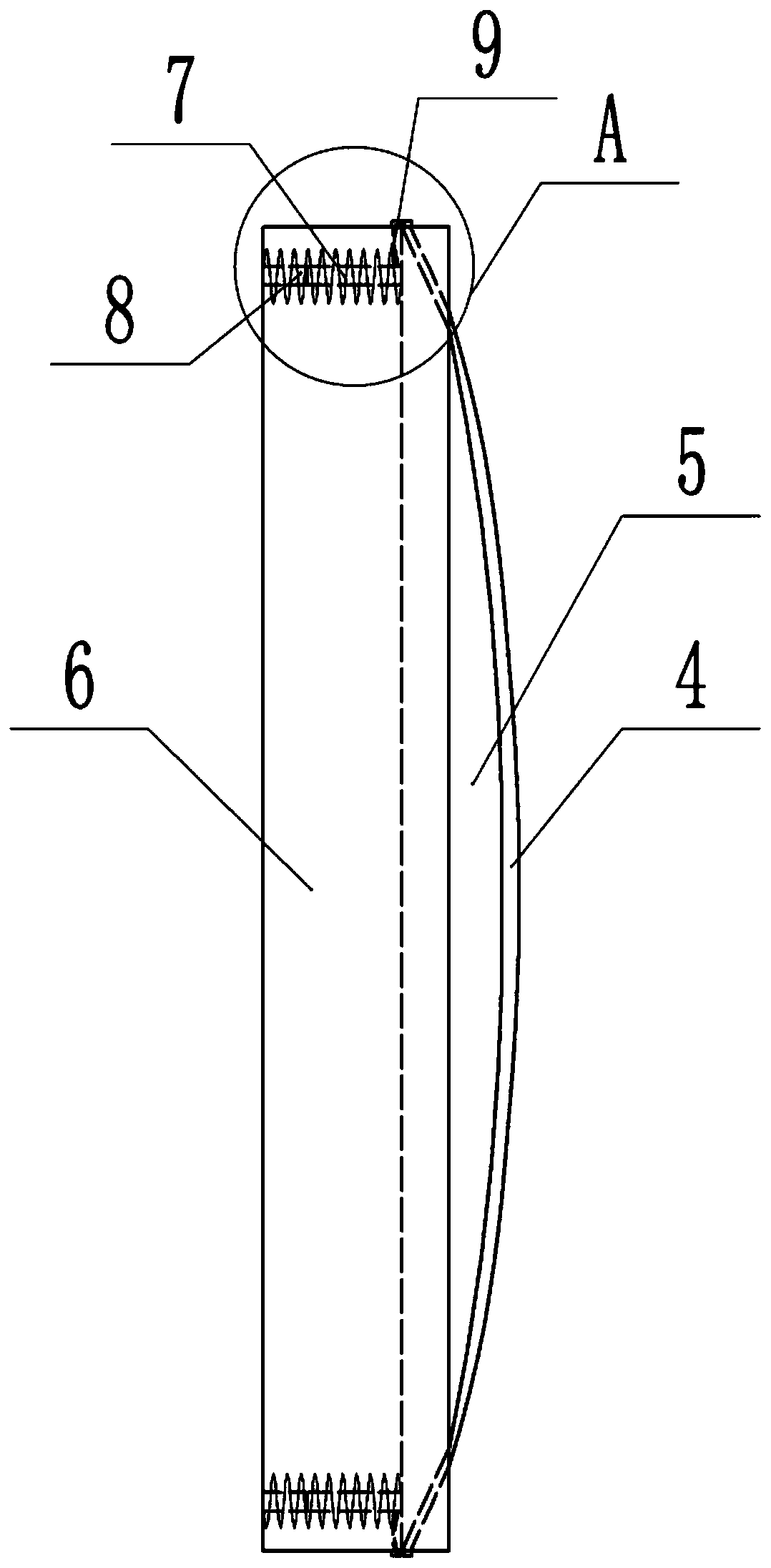

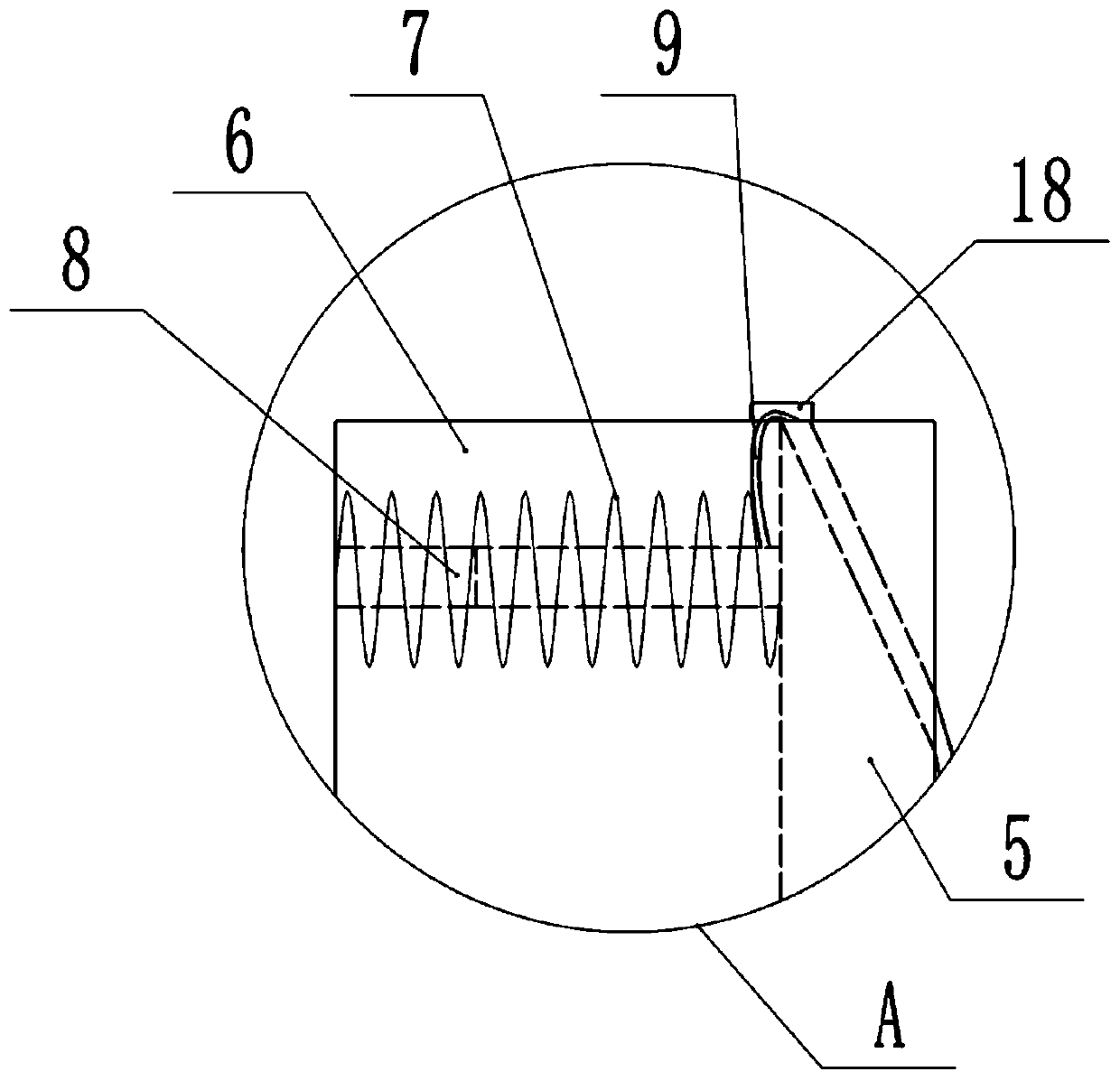

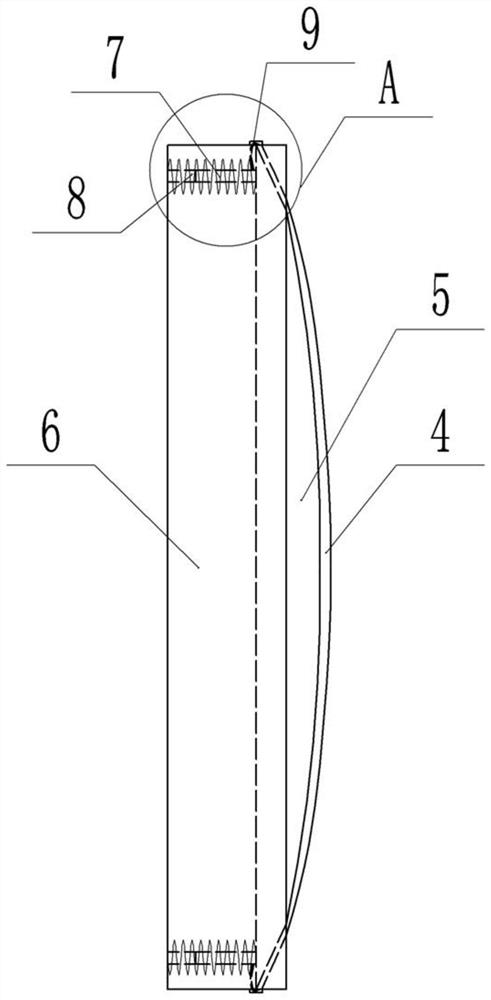

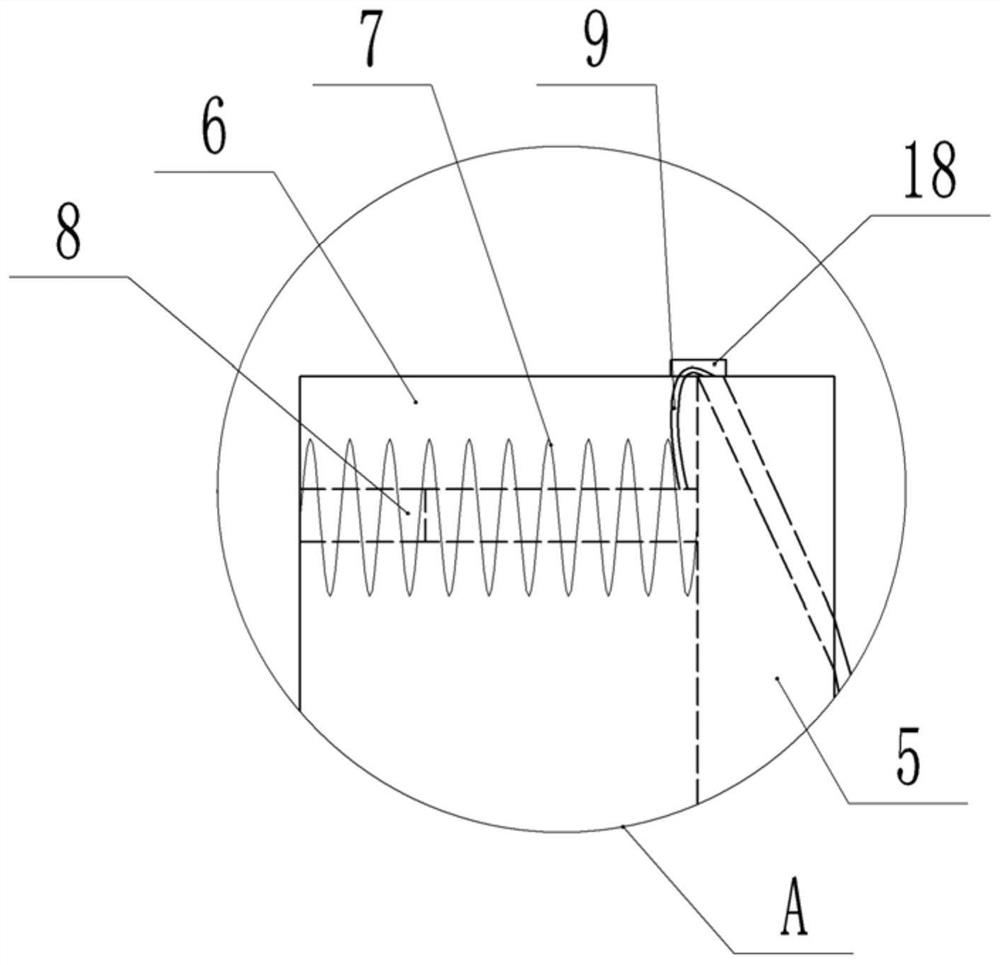

Conveniently used shock-absorbing pad for uneven-bars training

InactiveCN107694010AImprove shock absorptionHigh hardnessParallel barsShock absorber matsEngineeringMechanical engineering

The invention discloses a shock-absorbing cushion for uneven bars training which is convenient to use, which comprises a cloth cover, the top and bottom of the inner wall of the cloth cover are respectively fixedly connected with a rubber pad and a leather pad, and the opposite side of the rubber pad and the leather pad Connected by a rubber block, the rubber block is sleeved with a shock-absorbing spring, the bottom of the cloth cover is fixedly connected with a shock-absorbing plate, the bottom of the shock-absorbing plate is fixedly connected with a bottom plate, and the four right angles at the bottom of the bottom plate There are through grooves at all places, and slide grooves are arranged on both sides of the inner wall of the through grooves. Through the improvement of the pull plate, when the servo motor starts, the screw can be rotated, so that the ball nut can slide on the screw, and when the ball nut slides down on the screw, the two pull plates can drive the two The two slide blocks move downwards simultaneously. At this time, the carrier plate can drive the rollers arranged in the U-shaped plate to move downwards, so that the rollers can be exposed outside the bottom plate, and the whole shock pad can be moved normally.

Owner:赵顺豪

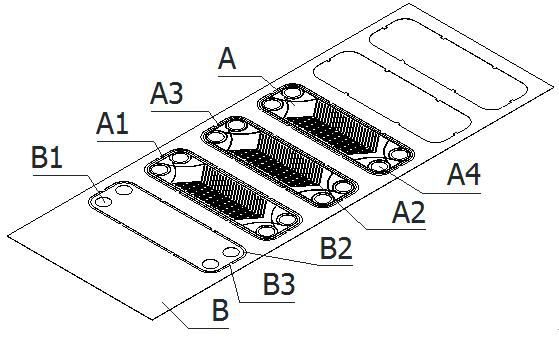

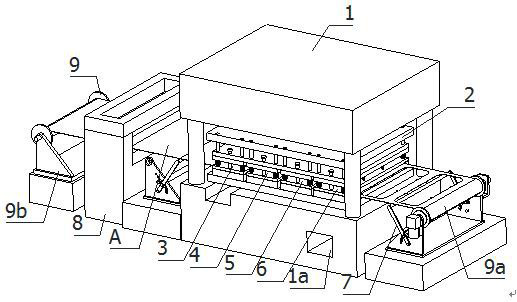

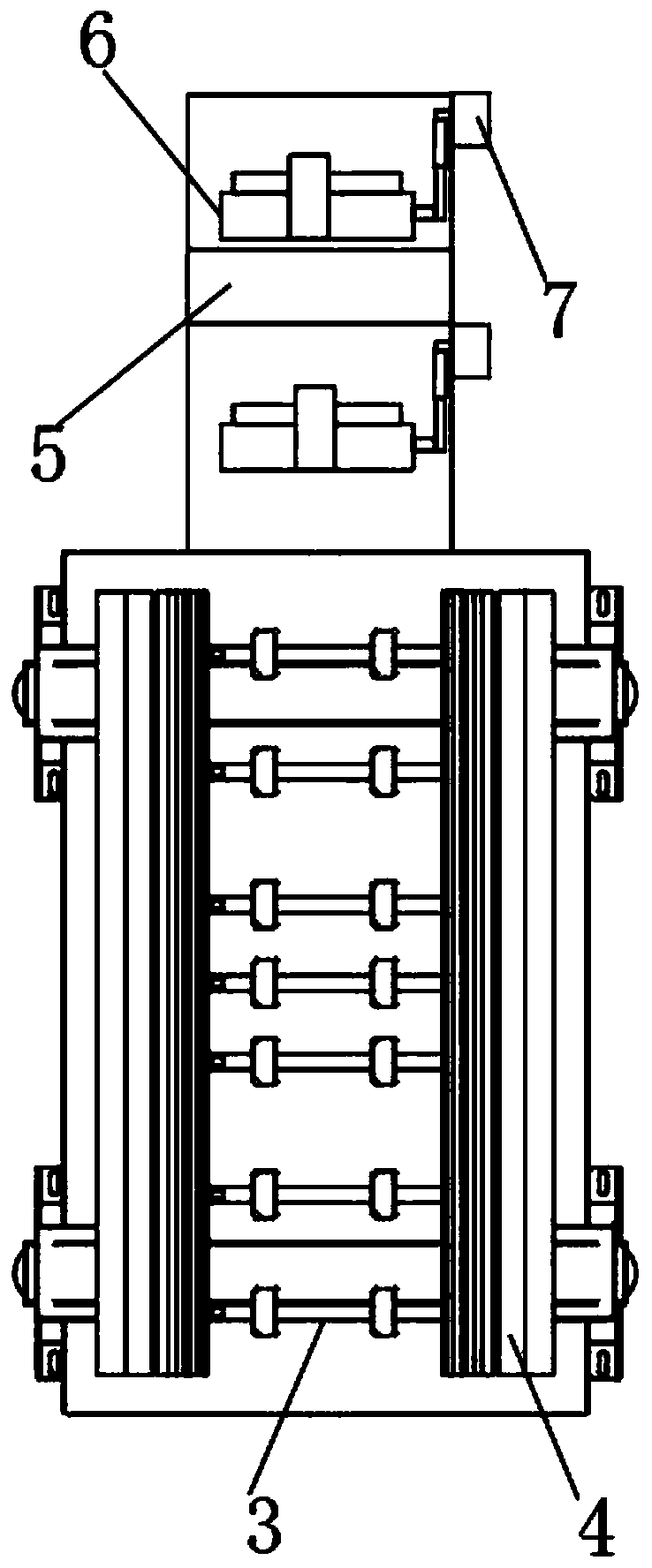

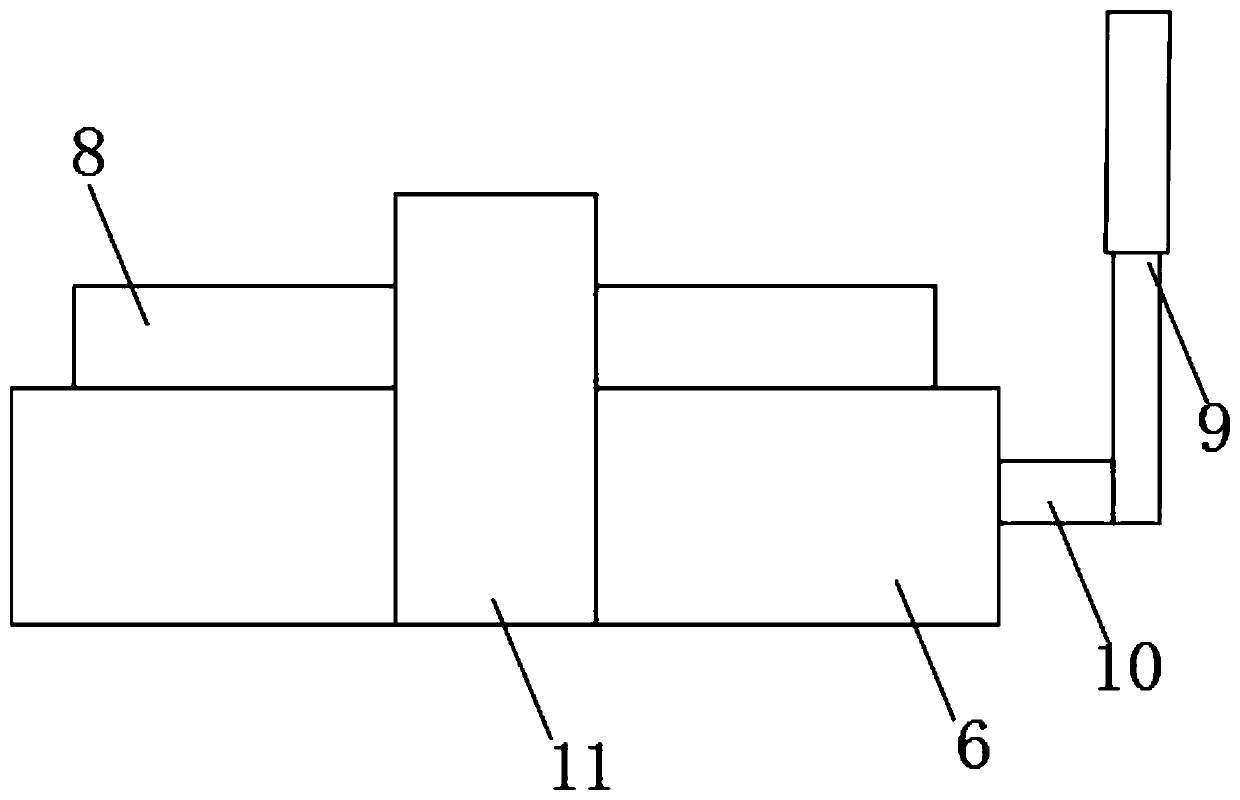

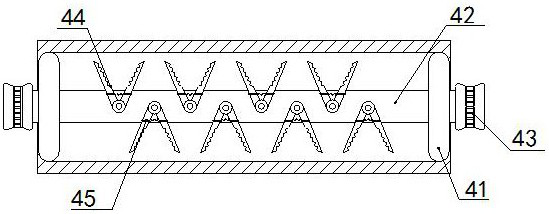

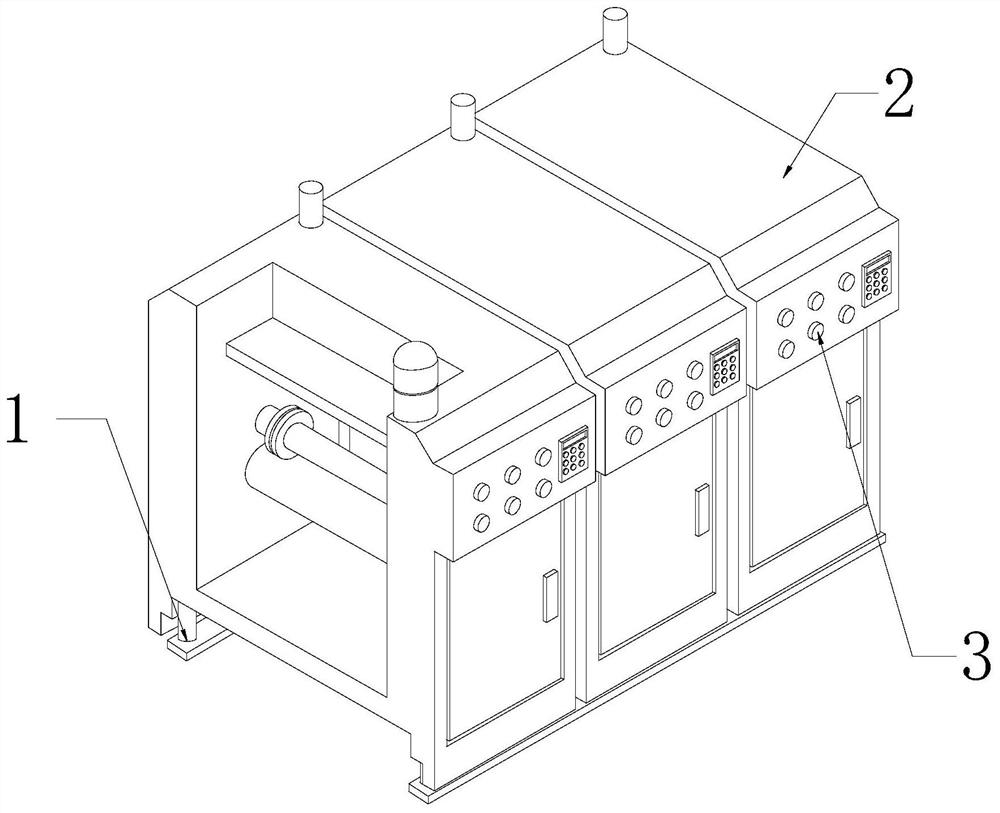

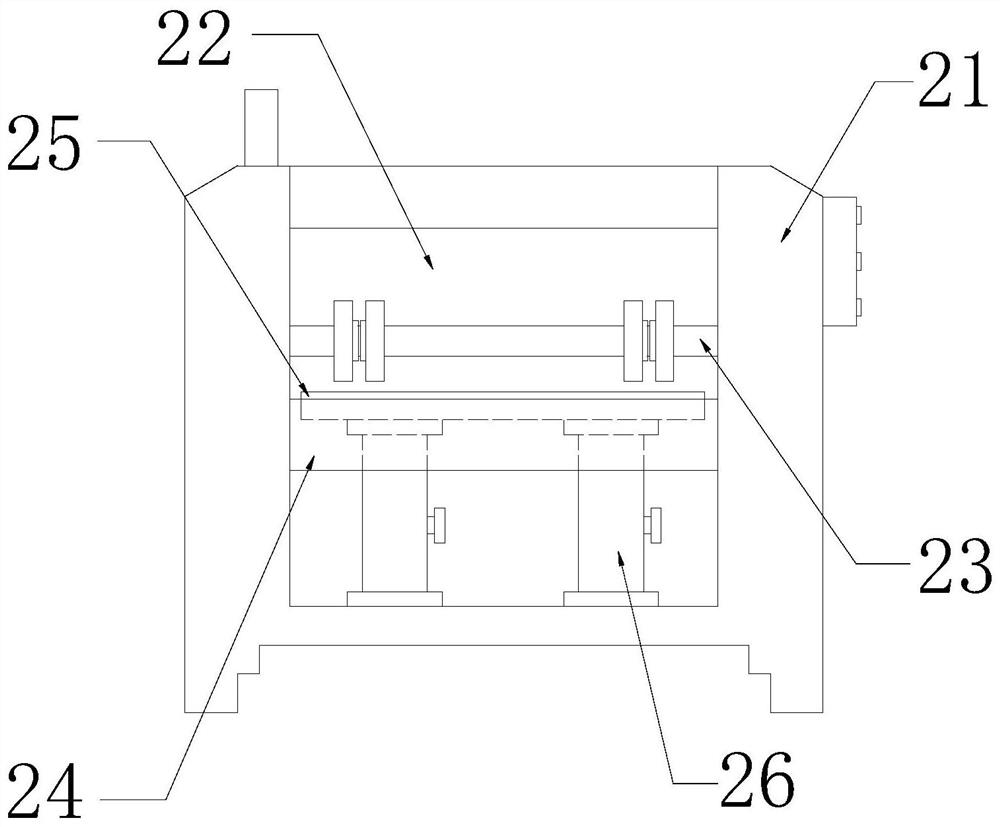

Sheet forming equipment for brazed plate heat exchanger

InactiveCN112091112AImprove yieldImprove securityShaping toolsPerforating toolsPlate heat exchangerEngineering

The invention relates to the technical field of plate heat exchanger machining, in particular to sheet forming equipment for a brazed plate heat exchanger. The forming equipment is used for blanking astrip into a sheet and comprises a stamping machine, a continuous stamping die, elastic supporting frames, a metal flatting machine and a rolling-up piece, wherein a fetching port communicating withthe outer side is formed in the bottom end of one side of a working face; the continuous stamping die comprises a die frame which is arranged on the working face of the stamping machine, and a punching die, a first stamping die, a second stamping die and a stamping cut-off die are sequentially arranged in the die frame in the material feeding direction; the elastic supporting frames are arranged at the feeding end and the discharging end of the continuous stamping die; the metal flatting machine is arranged at the outer side of the elastic material supporting frame located at the feeding end of the continuous stamping die; and the rolling-up piece comprises an automatic collecting assembly and an unwinding assembly, the automatic collecting assembly is arranged on the elastic supporting frame located at the discharging end of the continuous stamping die, and the unwinding assembly is arranged at the outer side of the corresponding elastic supporting frame. The device is high in safetyand working efficiency.

Owner:王大成

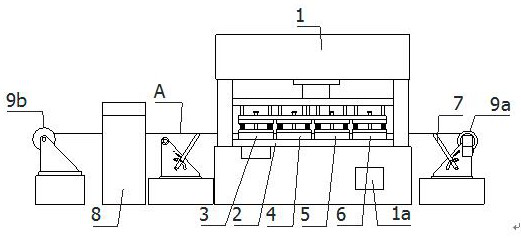

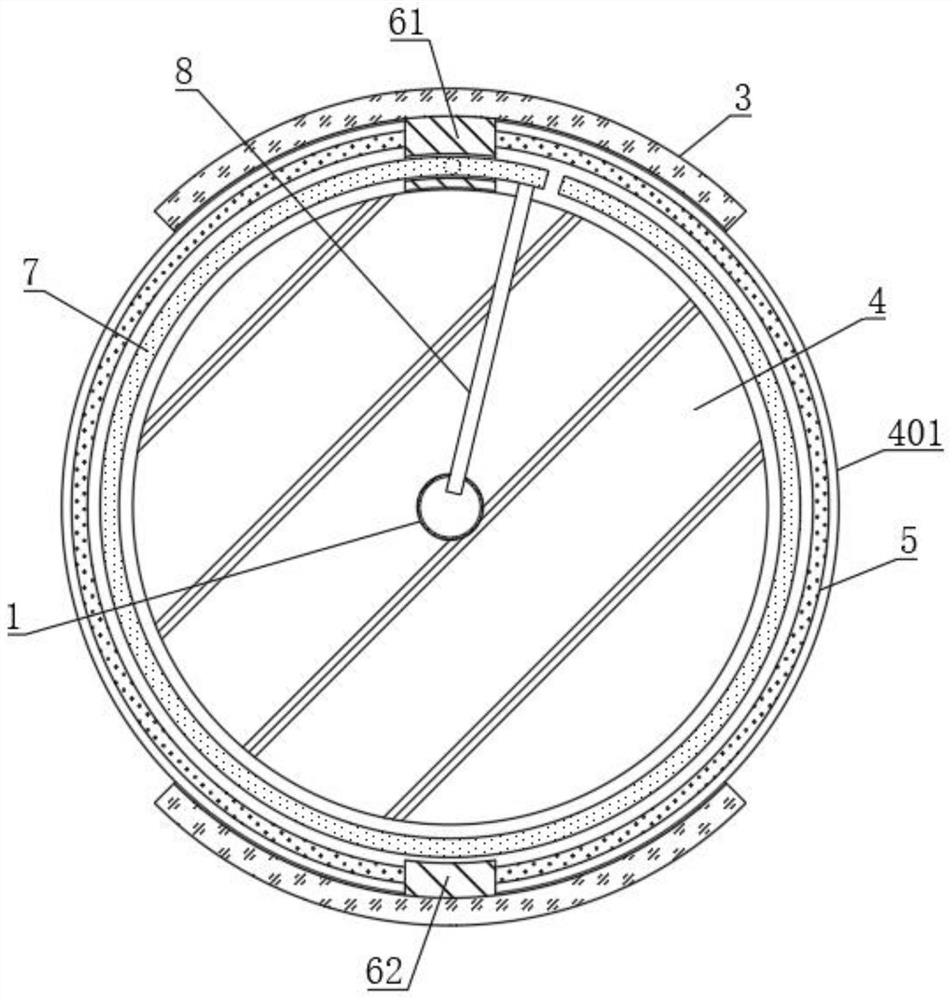

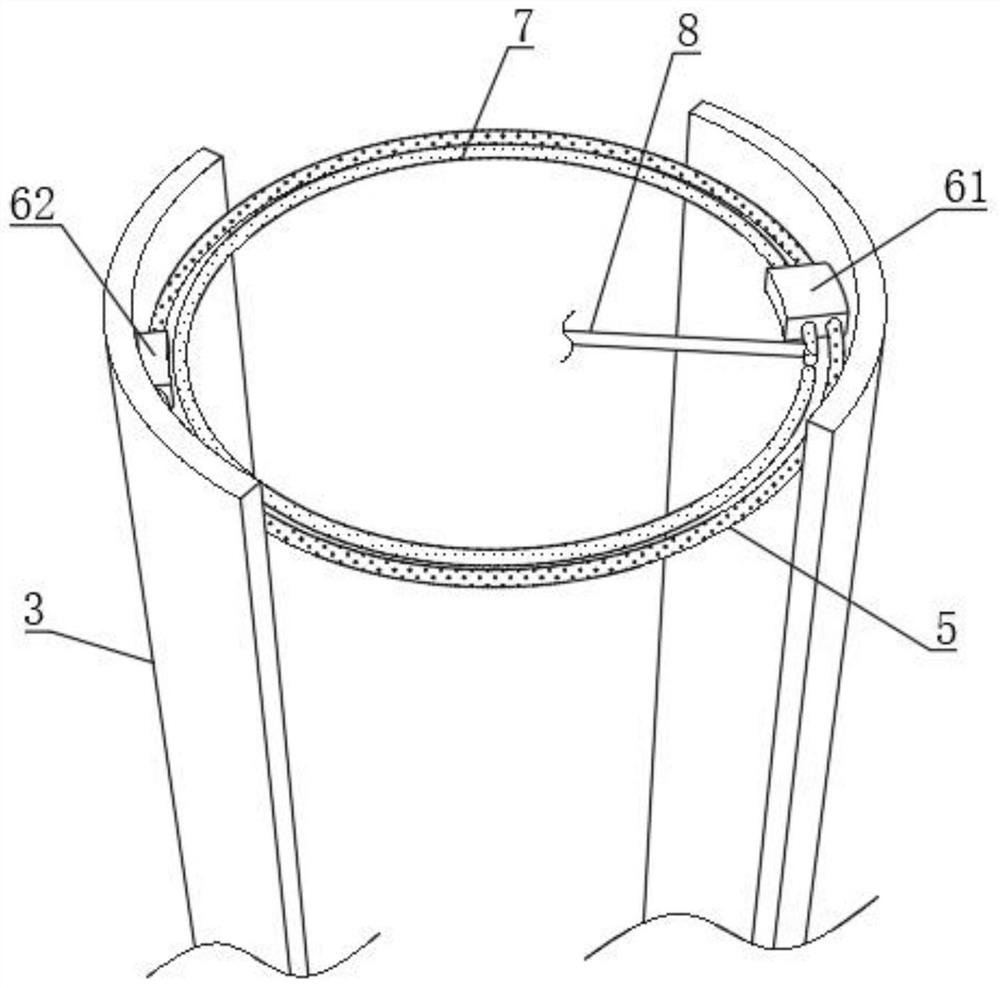

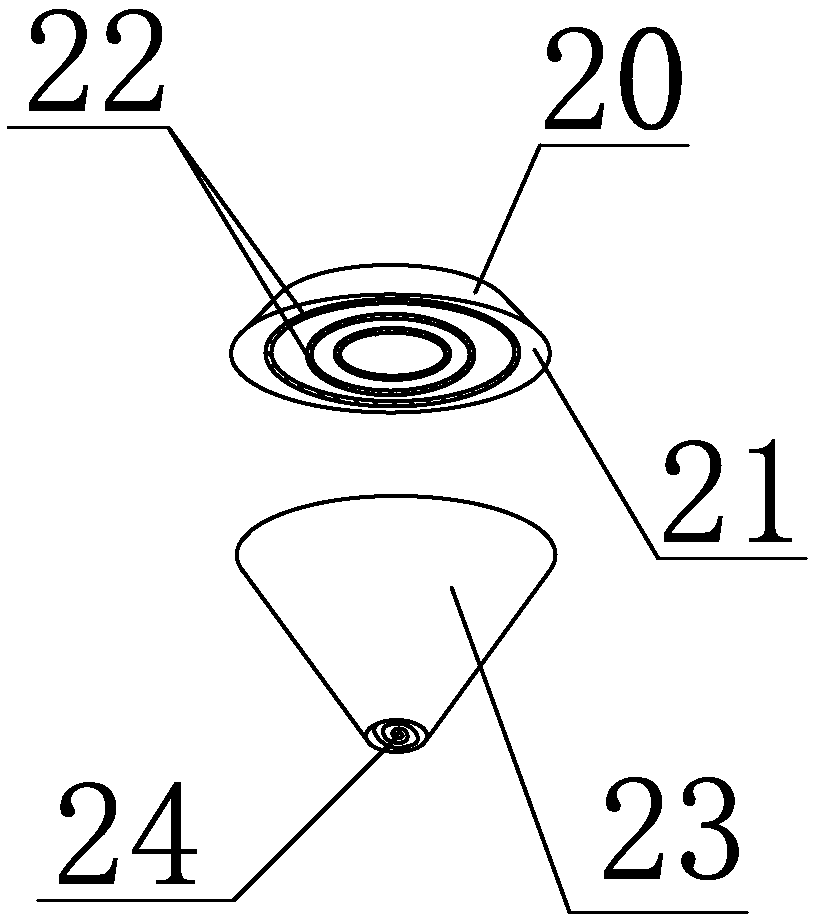

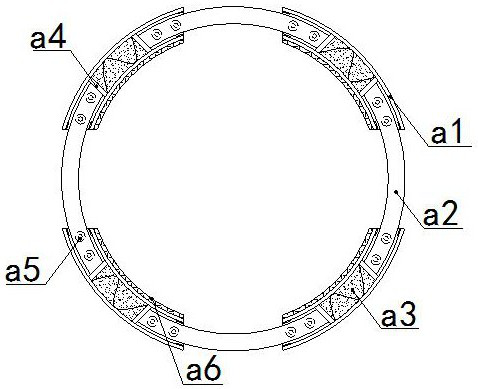

Redirection drainage type sewage treatment combined filler

InactiveCN112591879AChange internal clearancePromote sheddingSpecific water treatment objectivesSustainable biological treatmentBiofilmWater flow

The invention discloses a redirection drainage type sewage treatment combined filler, which belongs to the field of combined fillers, and is characterized in that an air inflation and suction processis circularly carried out in a hollow soft sleeve, and a pair of arc plates is attracted by a magnetic ball to rotate clockwise and anticlockwise, so that the orientation of a water flow channel formed by the pair of arc plates is continuously changed; therefore, the flow direction of water flowing through a biofilm culturing disc is changed, water flow impact in all directions is caused to the biofilm, falling of the aged biofilm is promoted, meanwhile, the falling aged biofilm can flow out of the biofilm culturing disc rapidly, blockage is not prone to being formed in the biofilm culturing disc, and in combination with the driving effect of the arc plate on the rotating rope, a hydroformylation vinylon filament bundle is stirred by a rotating rope, an internal gap of the hydroformylationvinylon filament bundle is changed, the flow of sewage in the hydroformylation vinylon filament bundle is promoted, the aged biological membrane is further enabled to quickly flow out from the insideof the biofilm culturing disc, and a combined filler which is not easy to block and can be continuously and efficiently degraded is provided for sewage treatment.

Owner:徐州达娇物资贸易有限公司

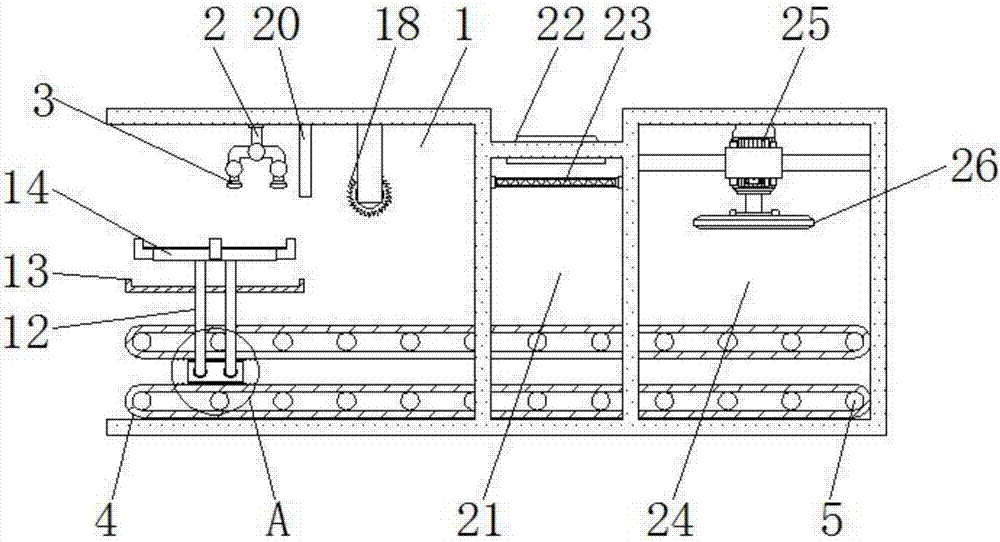

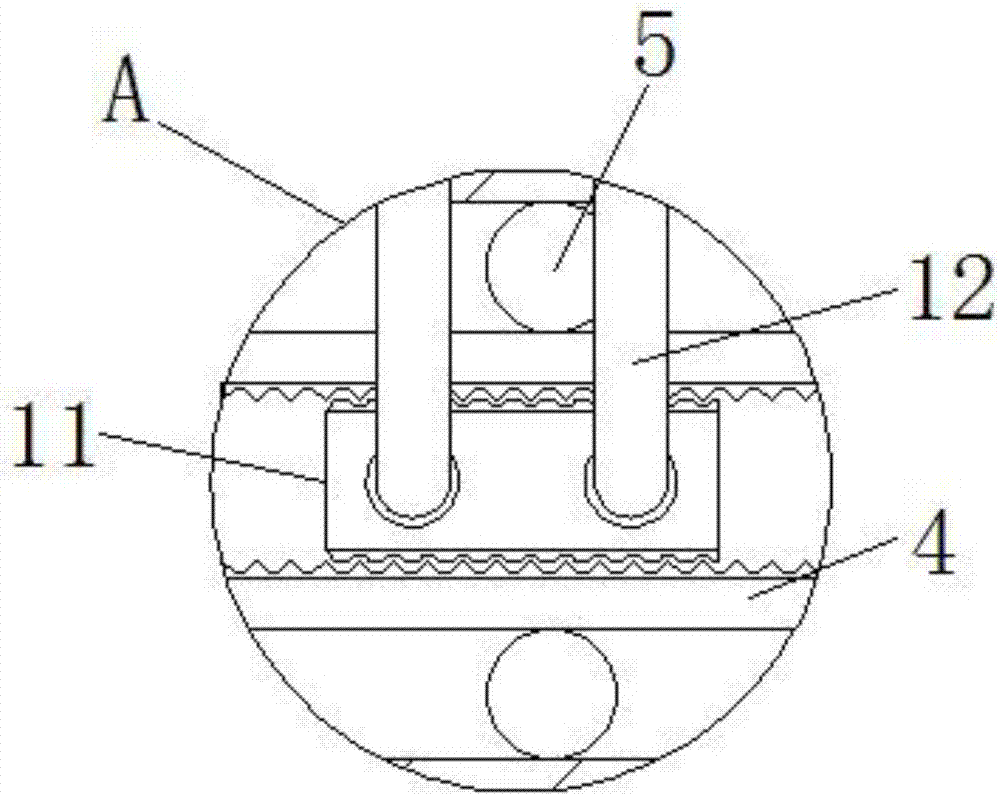

Wood polishing device for building construction and capable of achieving pre-grinding

InactiveCN107414646AAvoid offsetConvenient polishing operationGrinding carriagesPolishing machinesArchitectural engineeringWater spray

Owner:ANHUI JINAIER ELECTRICAL APPLIANCE TECH

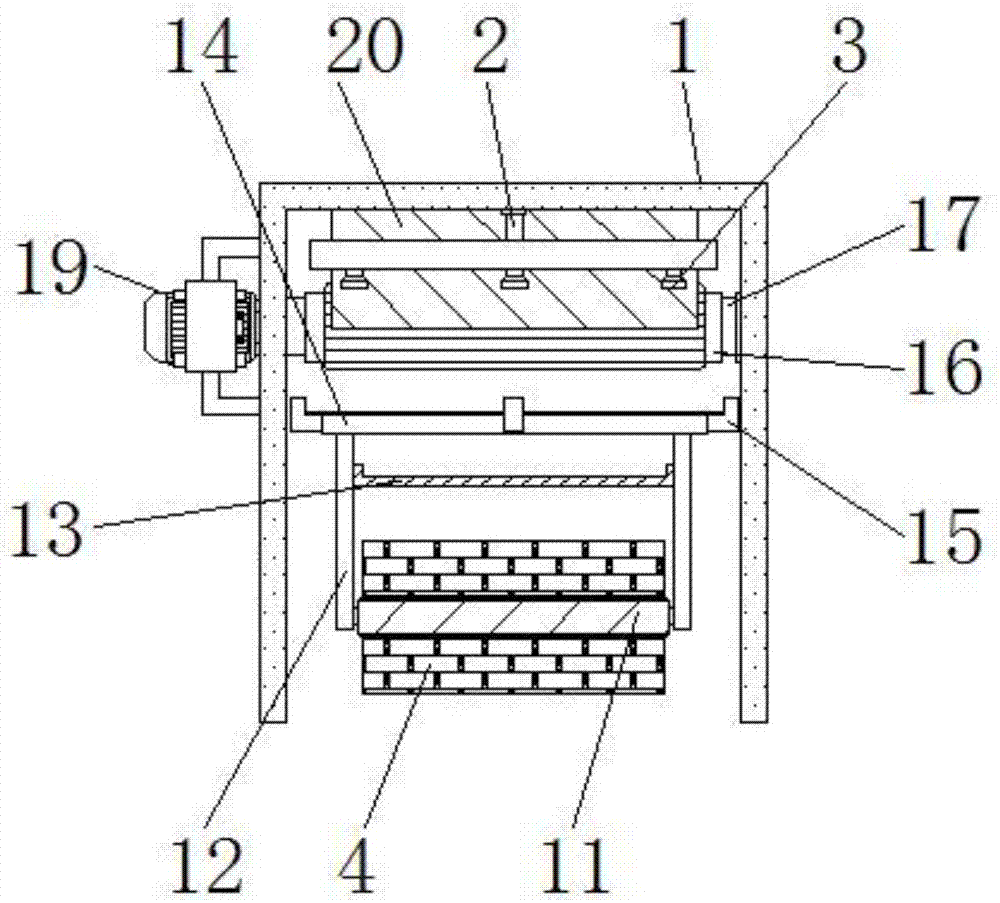

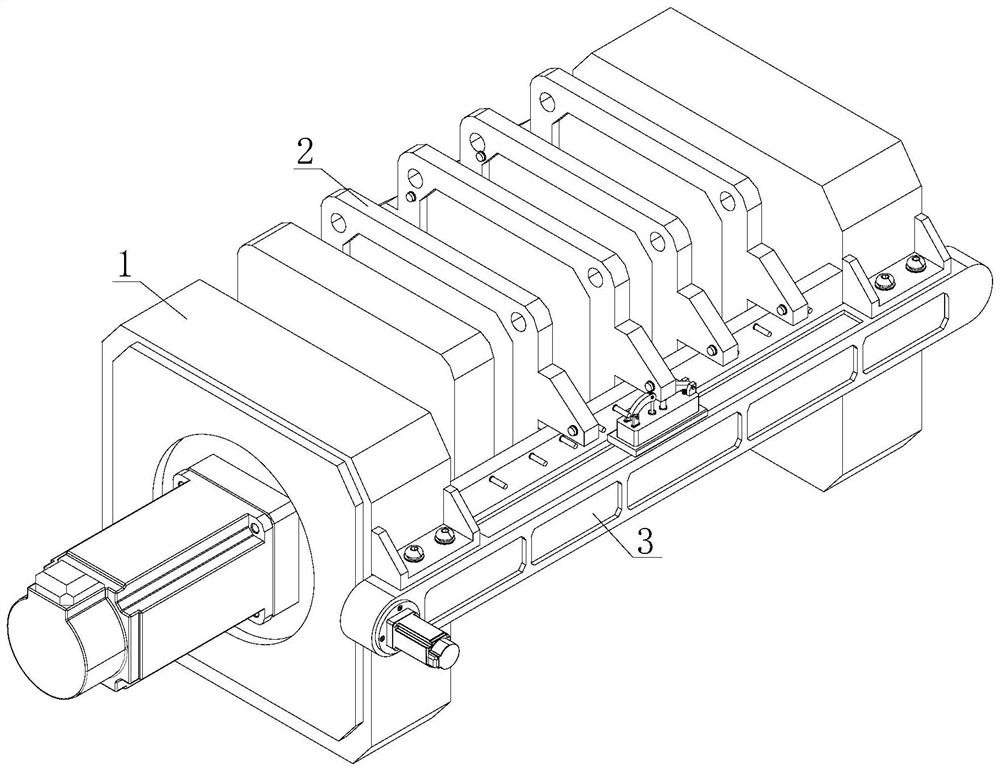

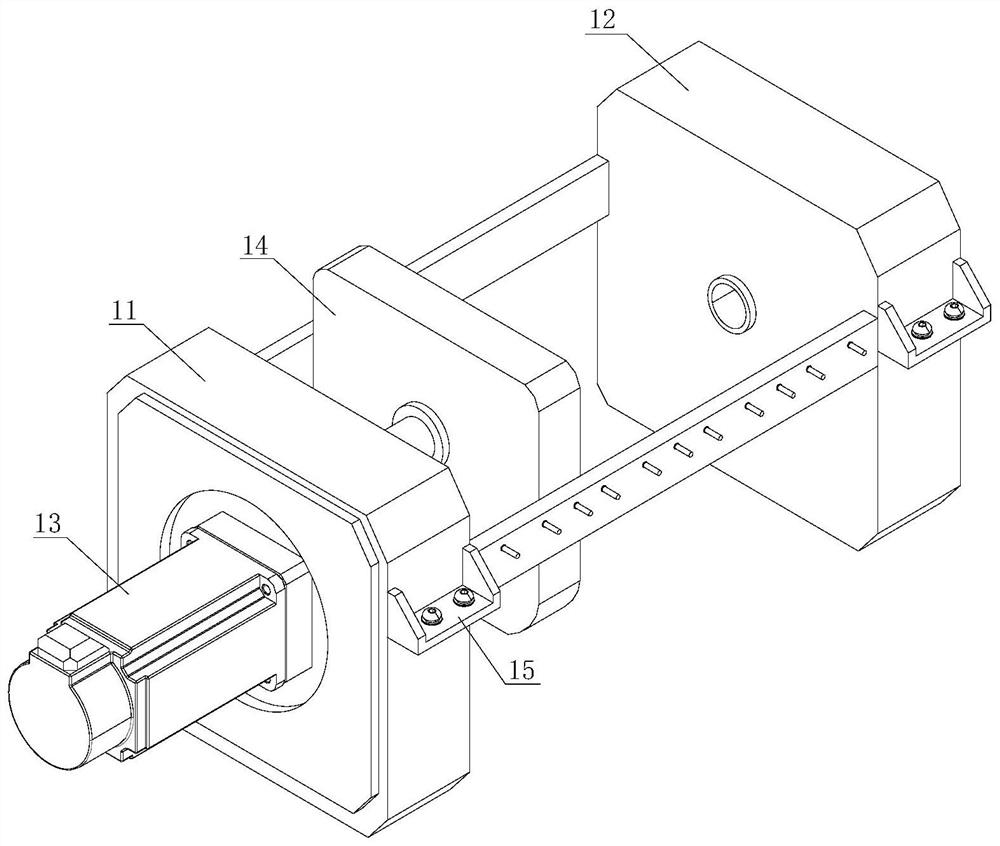

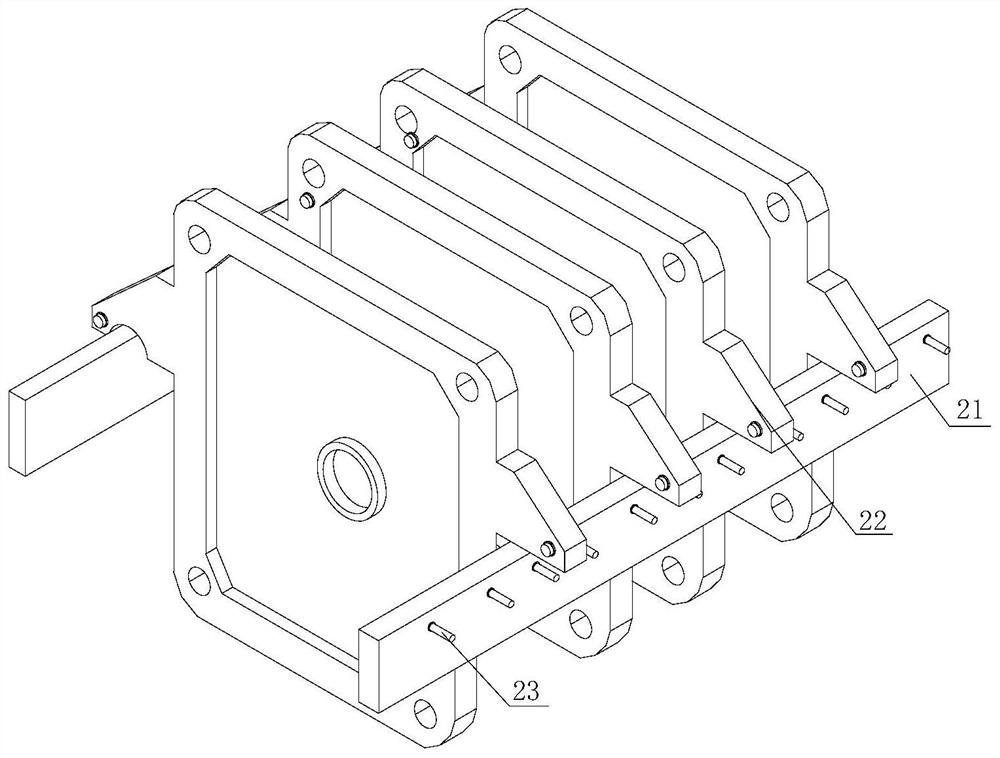

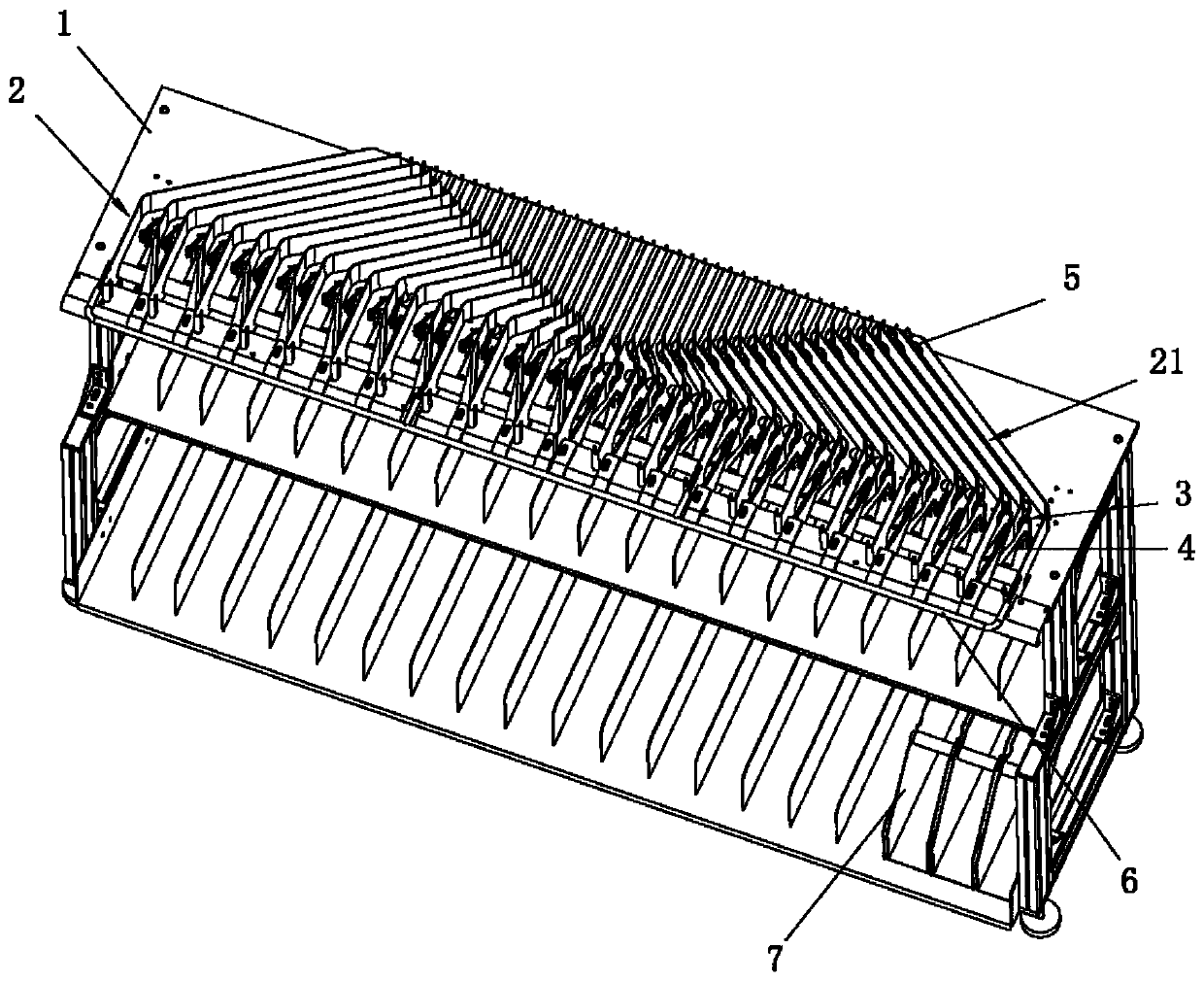

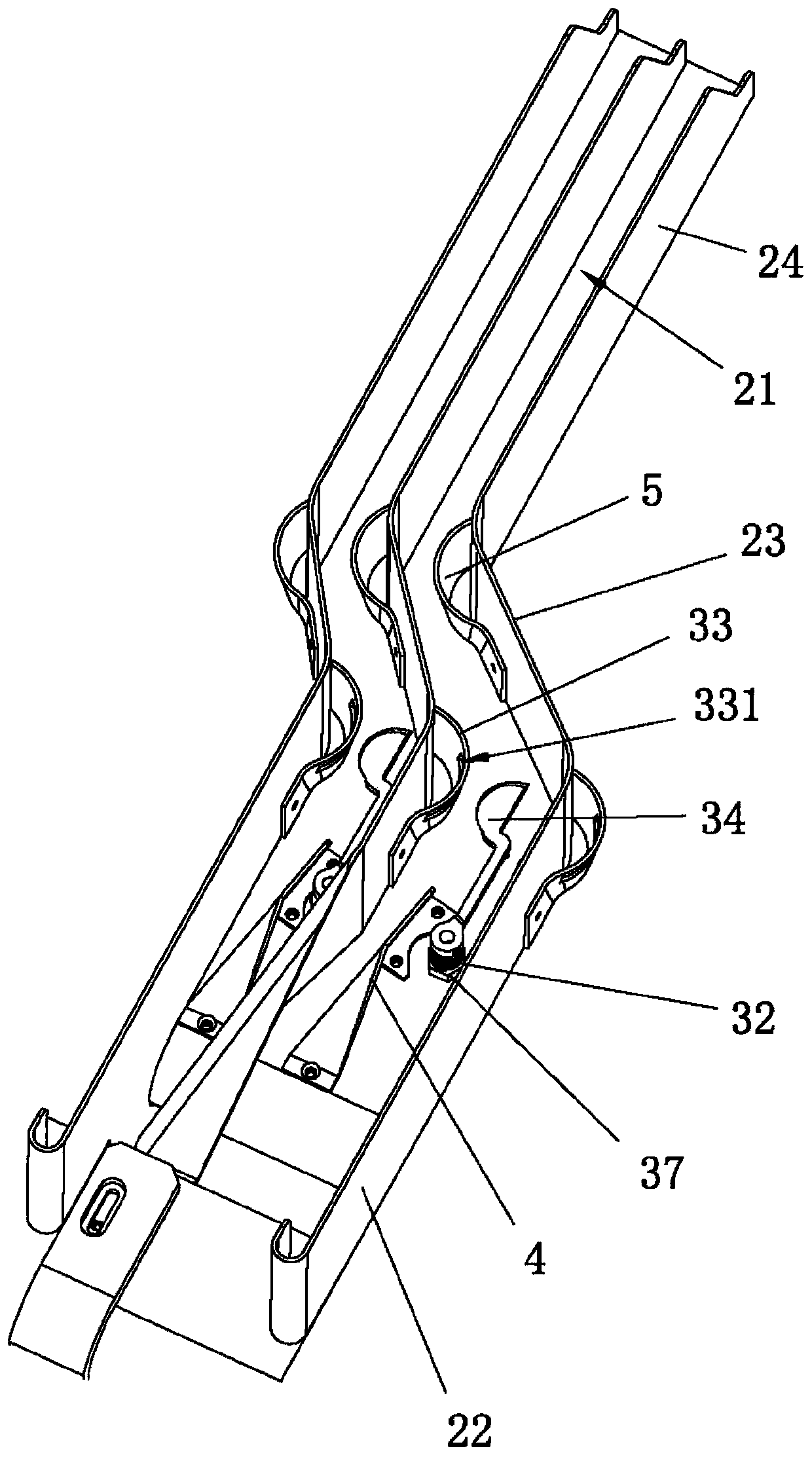

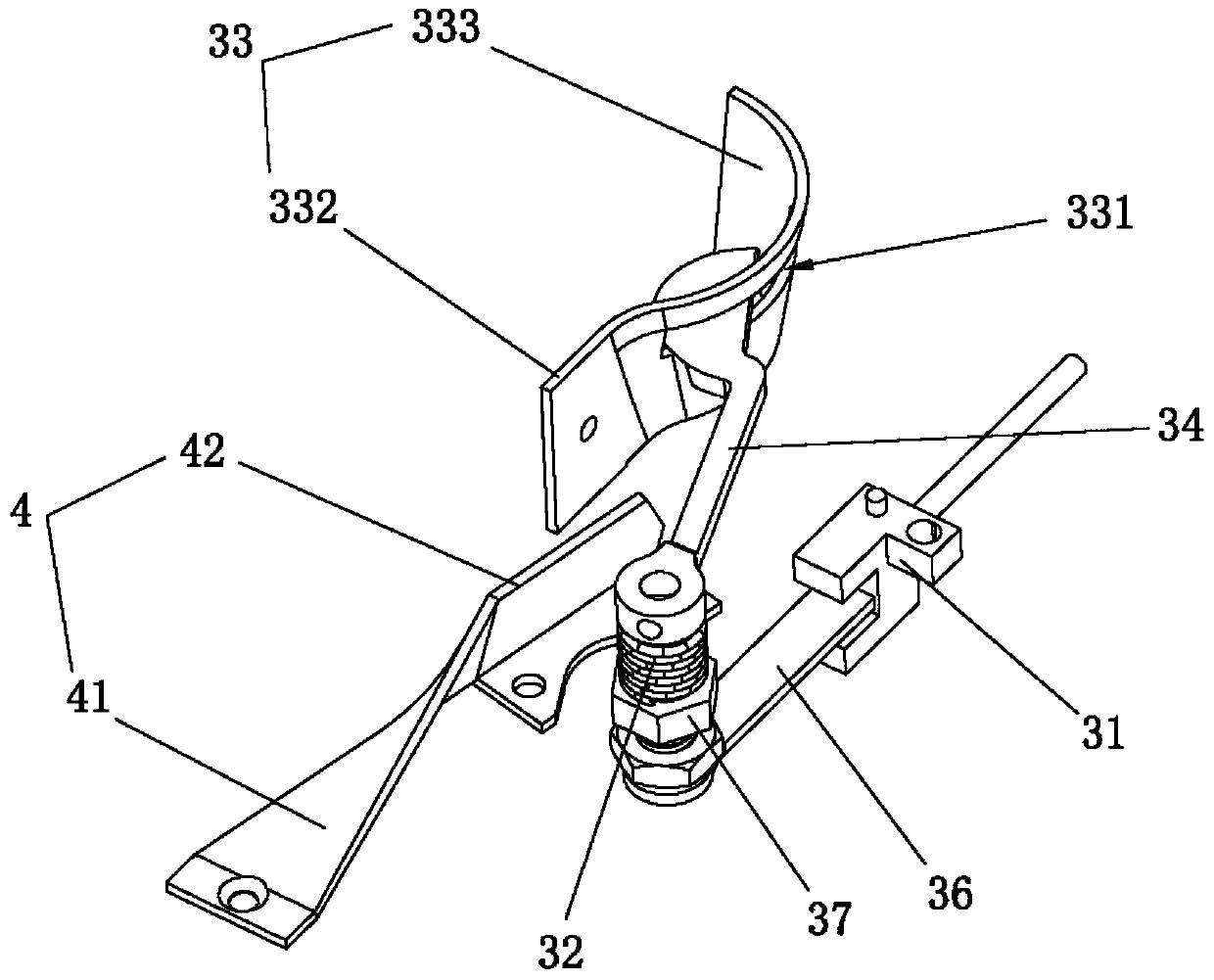

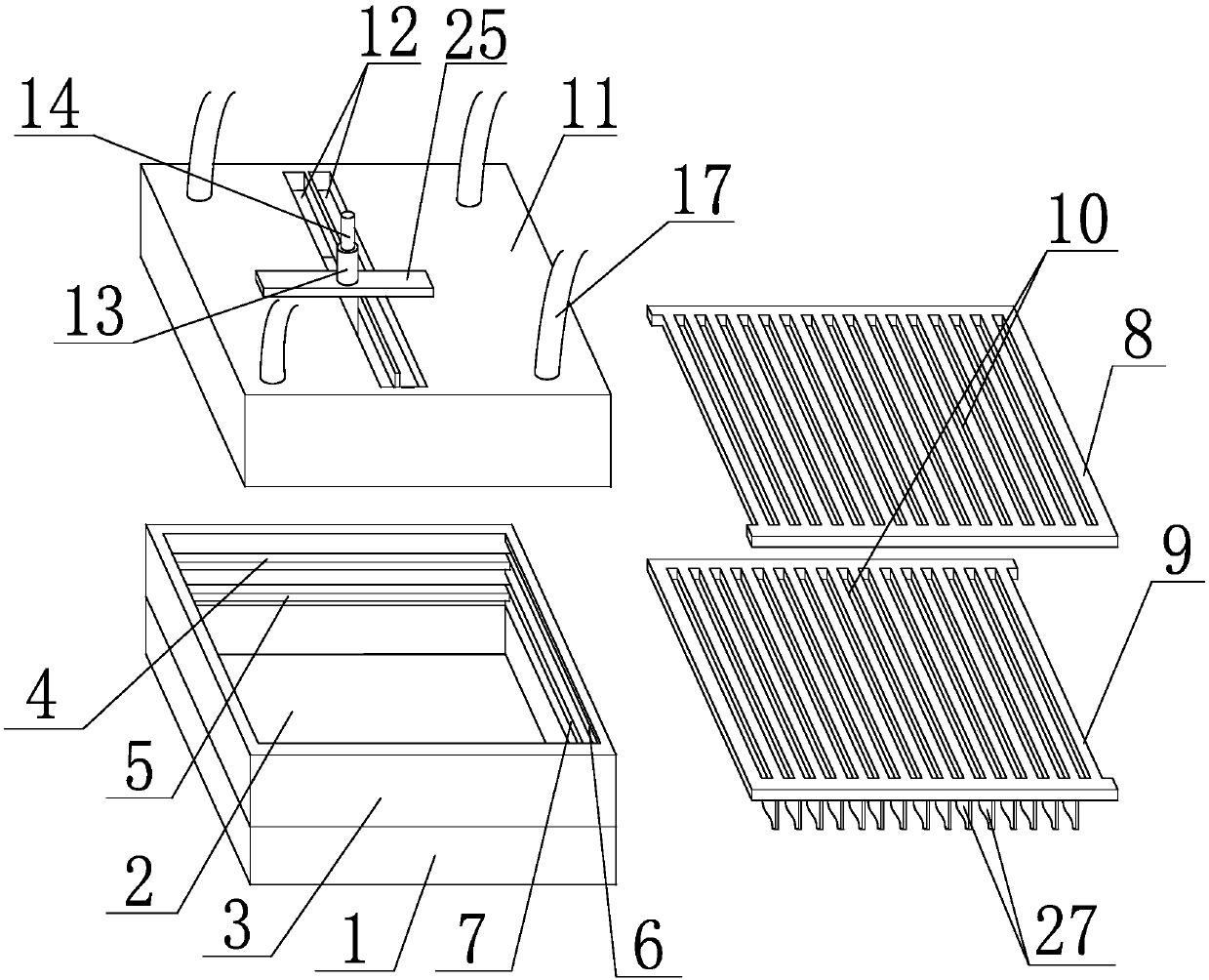

Sludge treatment, separation and filter-pressing device for sewage treatment plant and operation method of device

The invention discloses a sludge treatment, separation and filter-pressing device for a sewage treatment plant. The device comprises a filter-pressing fixed driving mechanism, a filter-pressing platemechanism and a movable hook mechanism; the filter-pressing plate mechanism and the movable hook mechanism are both fixedly arranged on the filter-pressing fixed driving mechanism. Meanwhile, the invention further discloses an operation method of the sludge treatment, separation and filter-pressing device for the sewage treatment plant; when the movable hook mechanism pulls a filter plate body toone end of a supporting guide rail batten, and an arc-shaped curved bar passes through a height limiting column, the height limiting column presses the arc-shaped curved bar, so that a pressing columnpresses one end of a warping plate downwards, and the warping plate jacks up the other end of a pushing column; the pushing column pushes a first limiting lug to push up the filter plate body; afterthe arc-shaped curved bar moves over the height limiting column, a second reset spring is reset, the pushing column moves downwards, the filter plate body falls down, and the process is repeated, so that vibration of the filter plate body is realized, and mud cakes adhered to the surface of the filter plate body are vibrated to fall down.

Owner:肖正新

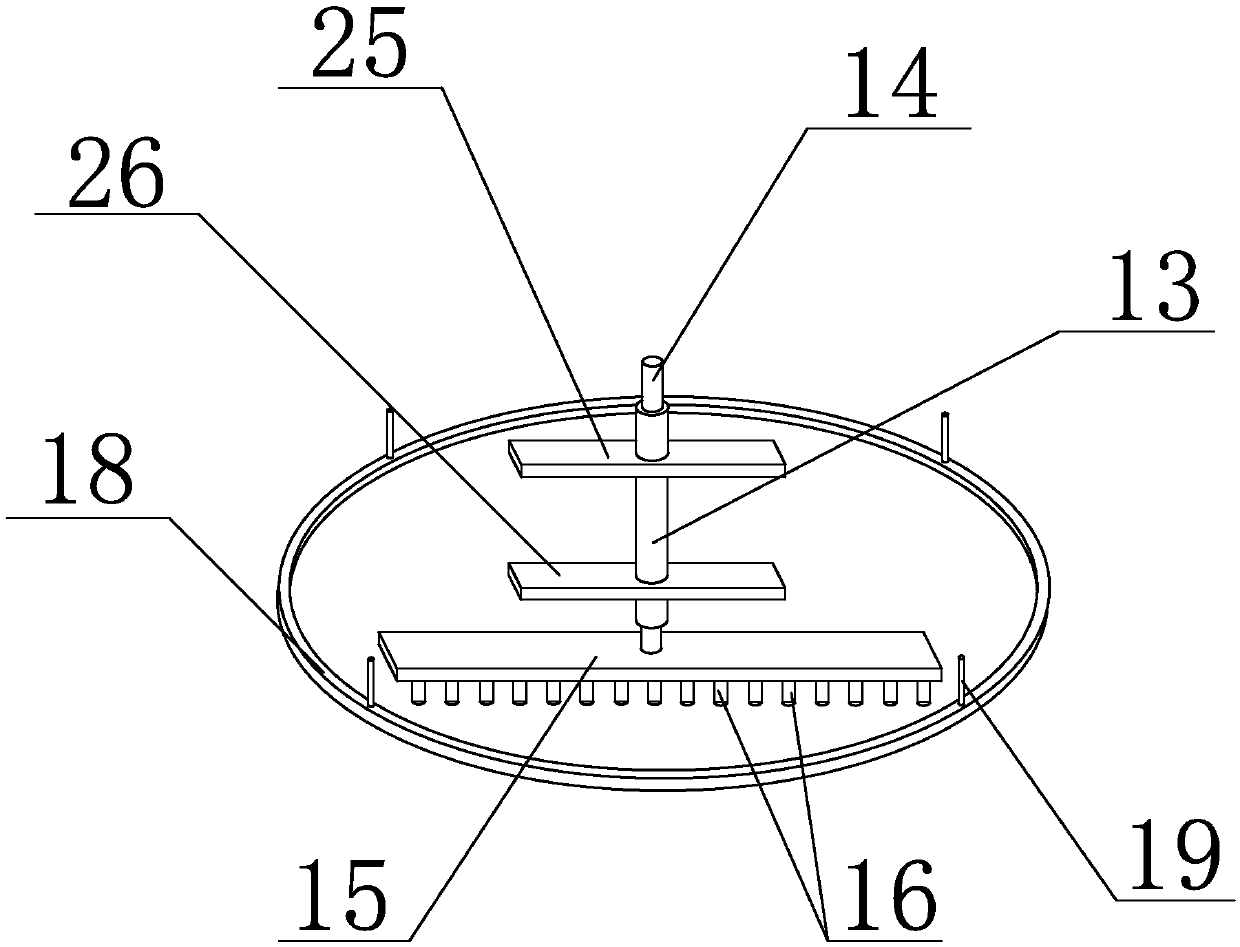

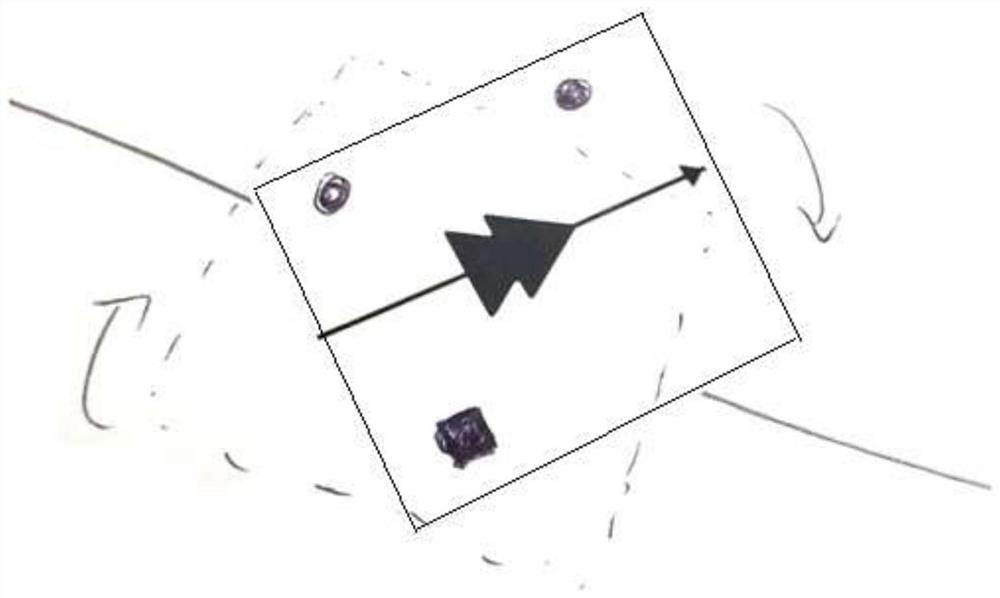

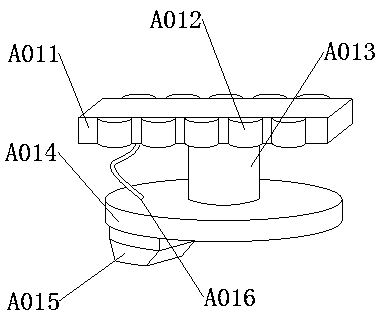

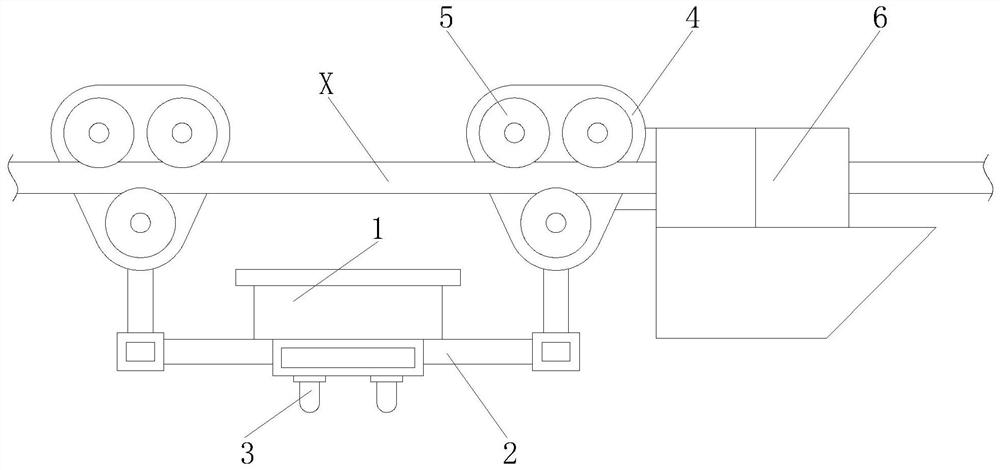

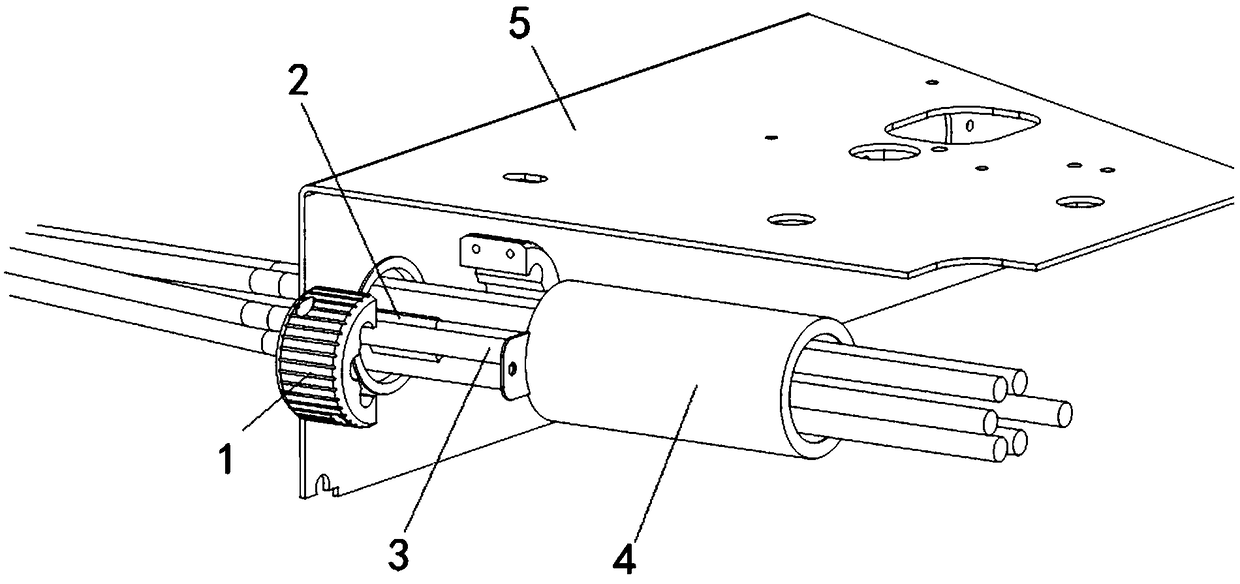

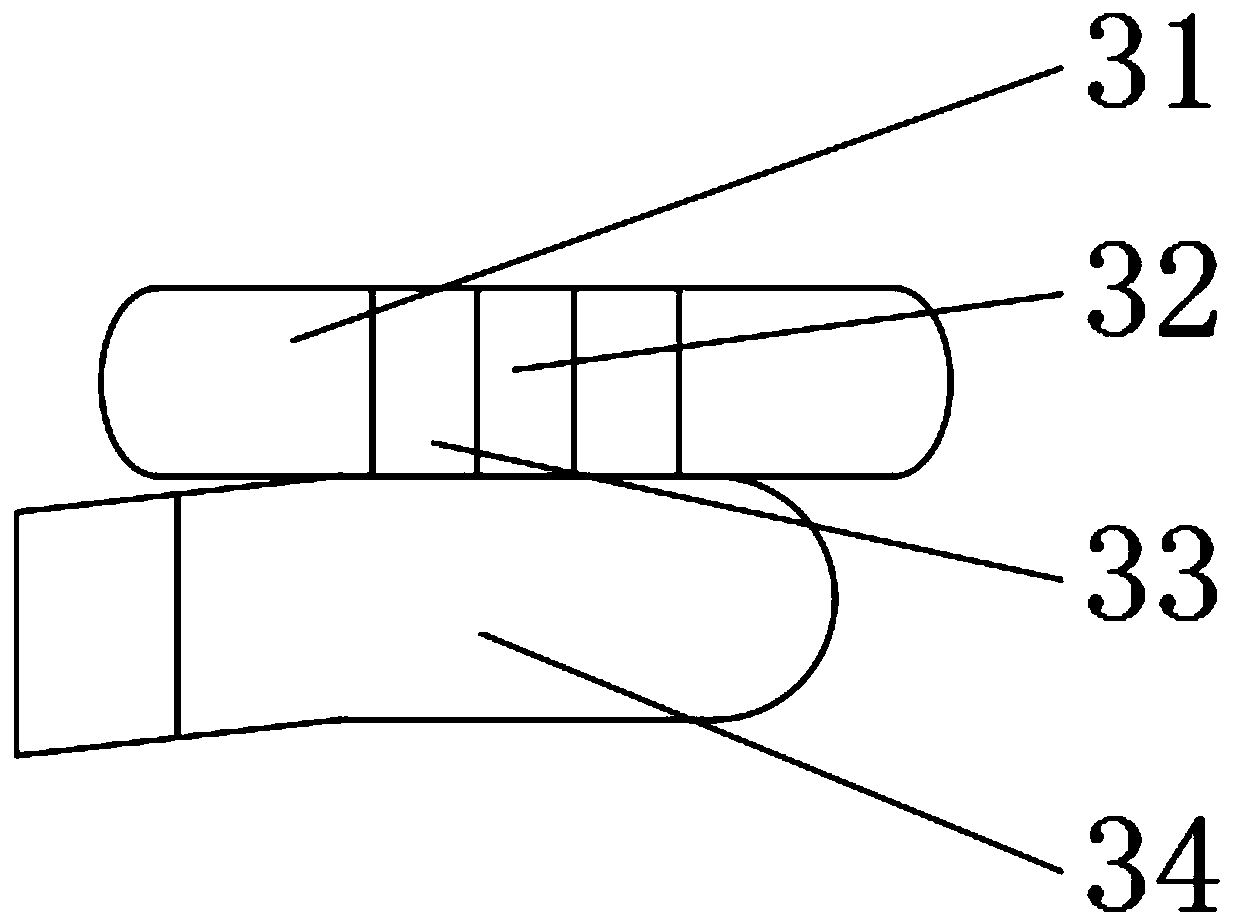

Material guide device

The invention relates to the technical field of a plugin machine, in particular to a material guide device. The material guide device comprises a support rack and a material guide disc, wherein the material guide disc is arranged at the support rack and comprises a plurality of material guide rails, the plurality of material guide rails are used for guiding a moving direction of a material belt, aprop-against induction mechanism is arranged in each material guide rail and is used for propping against the material belt and inducting the material belt in the material guide rail, a front material guide piece and a rear material guide piece are arranged in the material guide rail, and the prop-against induction mechanism is arranged between the front material guide piece and the rear materialguide piece. The material guide device is simple in structure, the material guide rails, the front material guide piece and the rear material guide piece are used for guiding the material belt, the prop-against induction mechanism is used for propping against and inducting the moving material belt, the material belt is enabled to smoothly and stably move, and a phenomenon that the moving materialbelt swings, jumps or turns over to affect normal working of the equipment is prevented

Owner:广东岩田智慧机电有限公司

Environmentally-friendly anticorrosive treatment method for household wood slab

ActiveCN109093800AExtended service lifeLiquidWood treatment detailsCoating impregnationWaxWood plank

Owner:MIANYANG FEIYUAN TECH CO LTD

Dismounting device

InactiveCN105822335AAchieve supportPrevent fallingMine roof supportsEngineeringMechanical engineering

Owner:SHANDONG MINING MASCH GRP CO LTD

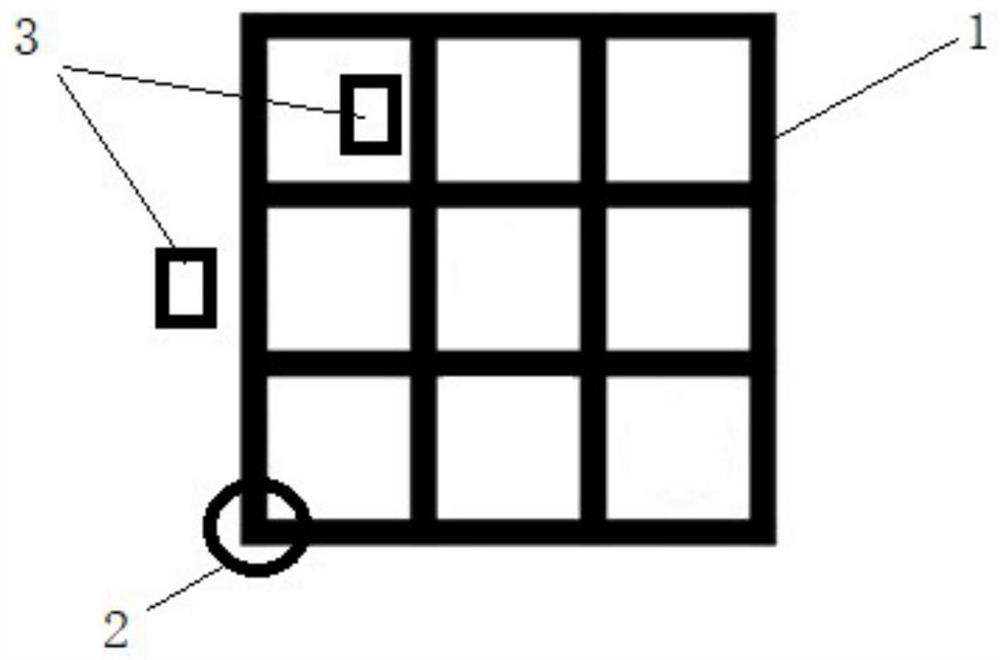

Mobile robot toy and method of use thereof

ActiveCN111625003BFreedom from programming workChild friendlyPosition/course control in two dimensionsVehiclesInformation transmissionMan machine

Owner:SHANGHAI BLOKS TECH CO LTD

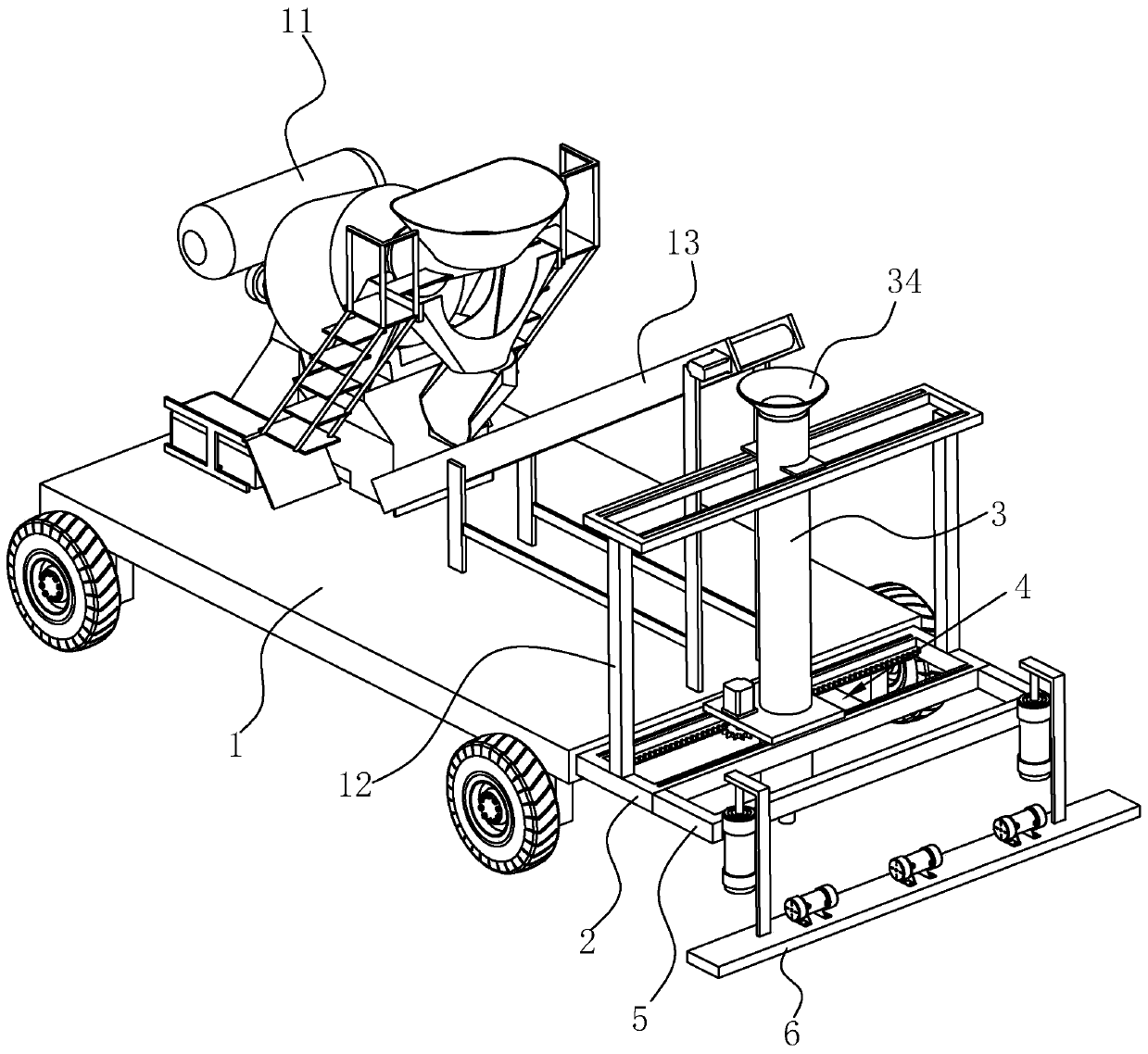

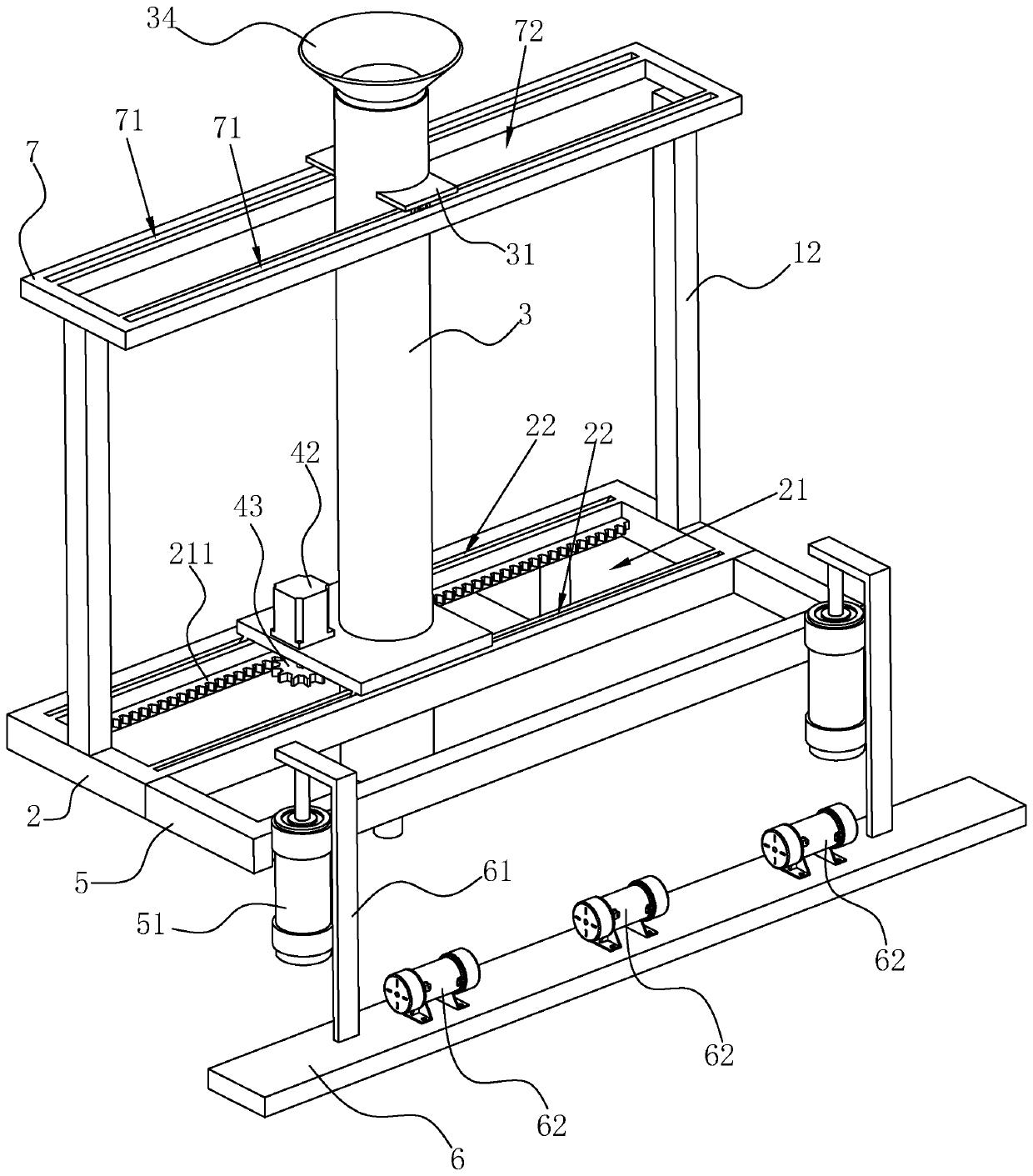

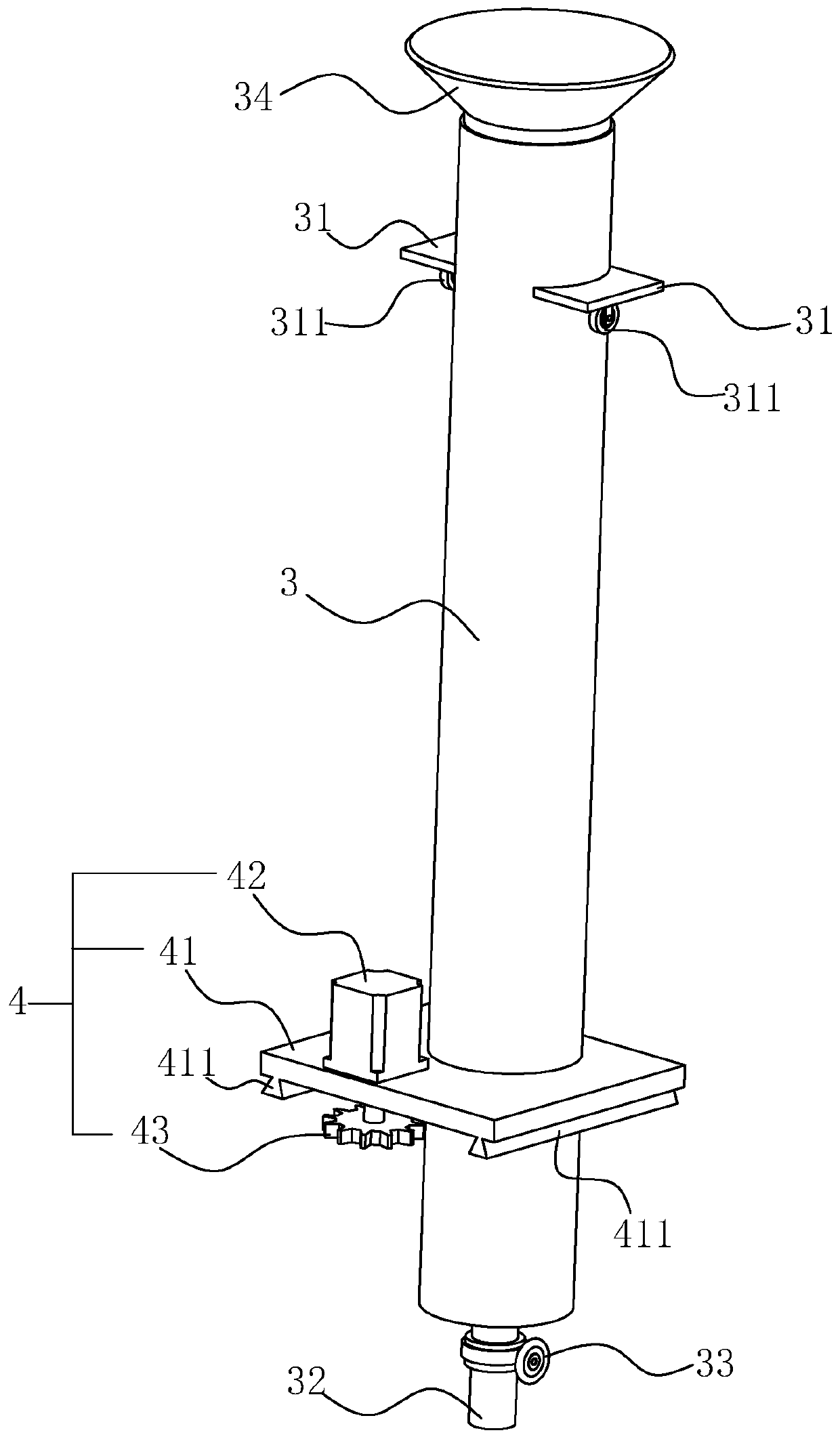

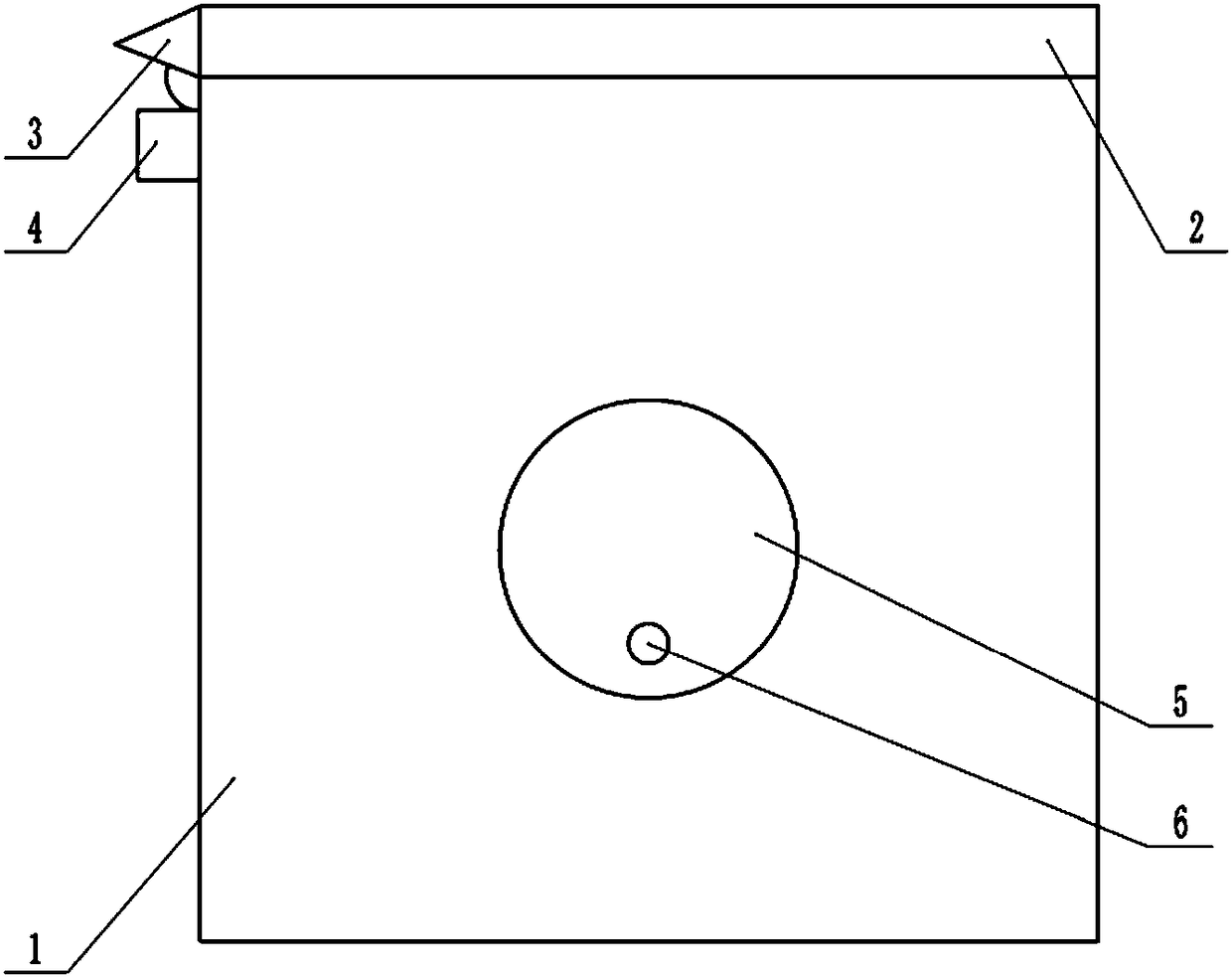

Cement laying device for mountainous road with flat laying function

InactiveCN110904789AImprove flatnessReduce labor intensityRoads maintainenceTrackwayStructural engineering

The invention relates to a cement laying device for a mountainous road with a flat laying function, and belongs to the technical field of road construction equipment. The device comprises a movable seat, a cement stirring tank is arranged on the movable seat; a rail is arranged at the edge of the movable seat; the length direction of the track is consistent with the width direction of the roadbed;a cement spraying cylinder is movably arranged on the rail; a nozzle of the cement spraying cylinder is over against the roadbed surface; a moving assembly used for driving the cement spraying cylinder to move in the length direction of the rail is arranged on the rail; an extension frame is arranged on one side, deviating from the moving seat, of the rail; a leveling plate is arranged on the extending frame, a lifting assembly used for driving the leveling plate to ascend and descend in the vertical direction is arranged on the extending frame, a vibrating piece used for driving the levelingplate to vibrate is arranged on the leveling plate, and the device has the advantages that cement conveyed to a roadbed can be leveled conveniently, and therefore the labor intensity of workers is reduced.

Owner:四川鸥鹏建筑工程公司

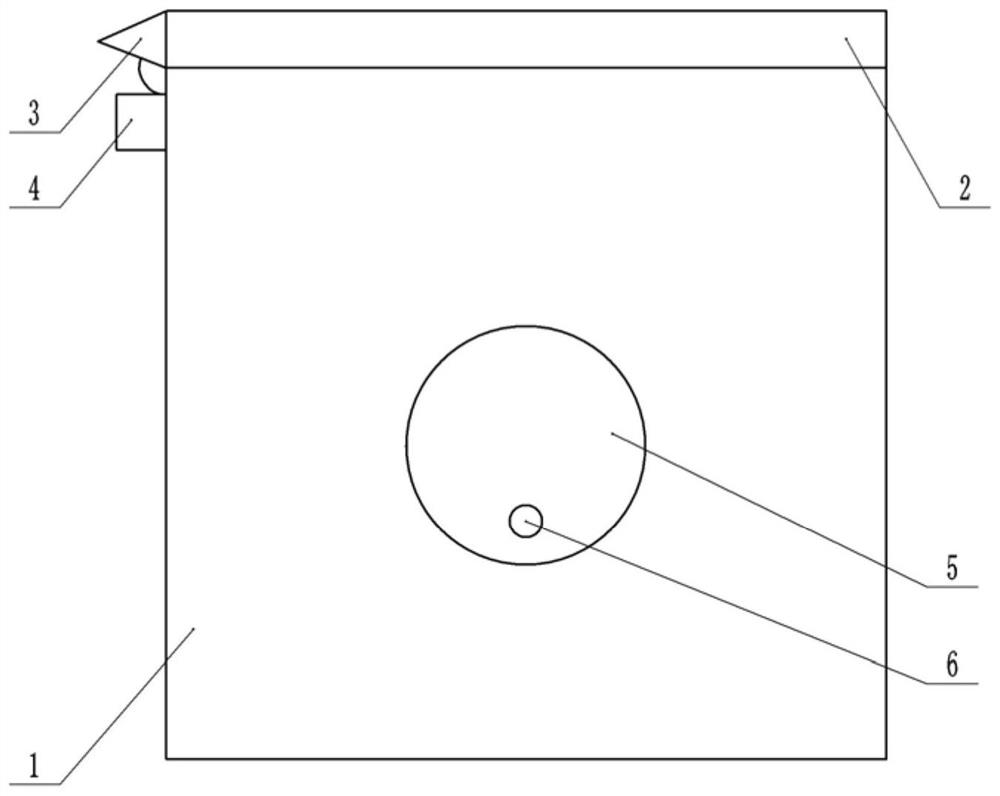

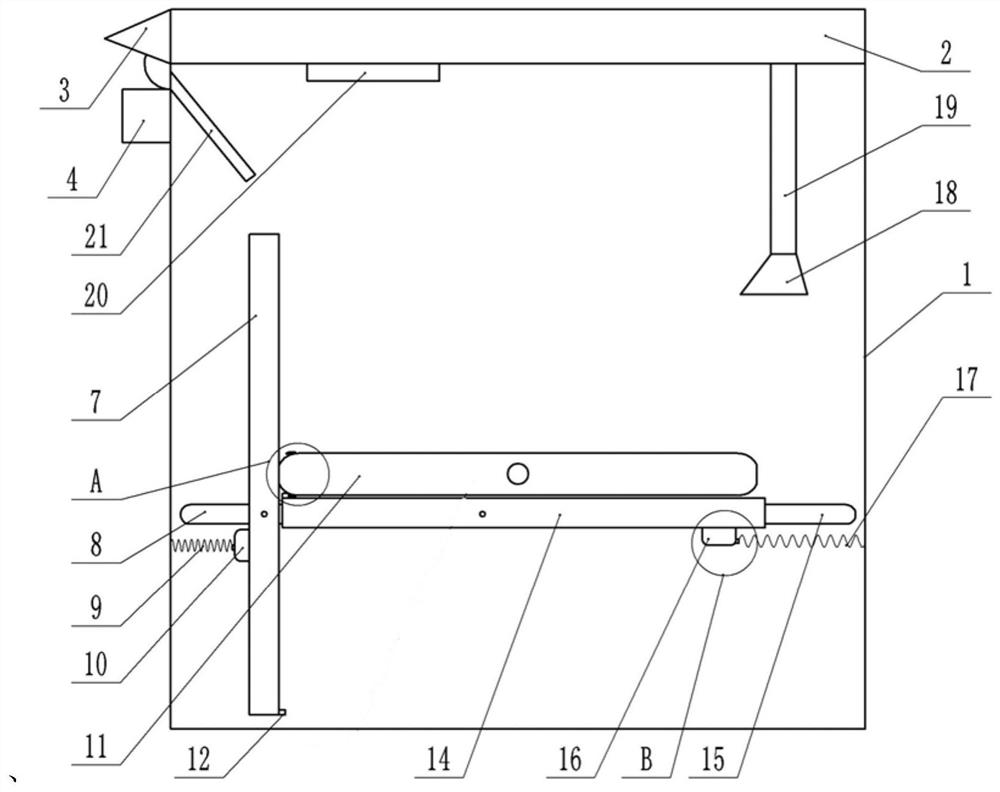

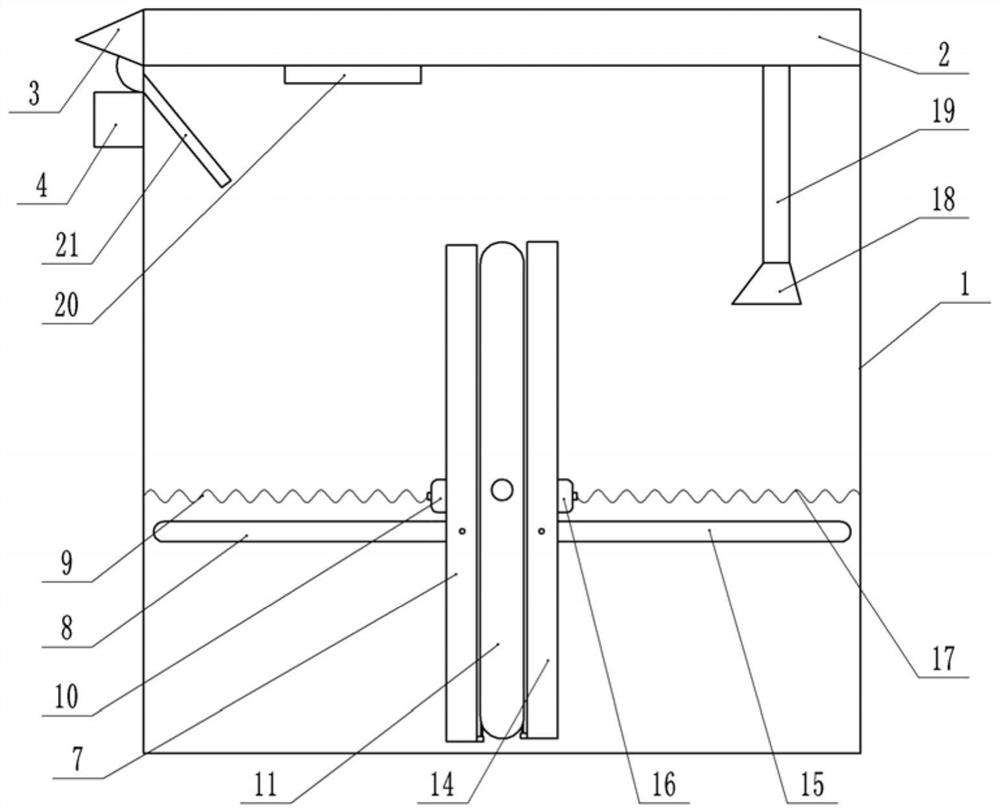

Beekeeping device

The invention relates to the field of beekeeping, in particular to a beekeeping device. The beekeeping device comprises a beehive, a frame is arranged in the beehive and rotationally connected in thebeehive, two sides of one end of the frame are provided with hooks, an operating mechanism for controlling the frame to rotate is arranged on the beehive, and two identical butting mechanisms are arranged in the beehive. Each butting mechanism comprises a butting plate movably connected in the beehive, the frame is positioned between the two butting plates, hang blocks matched with the hooks are arranged at ends of the butting plates, and sliders are slidably connected to lateral sides, away from the frame, of the butting plates and slidably connected with connection blocks. Springs are connected between the connection blocks and the inner wall of the beehive, and guide mechanisms enabling movement of the two butting plates are arranged on the beehive. By adoption of the scheme, larvae, honeydew and pollen are prevented from falling from honeycombs in turning of the frame.

Owner:临沭县独沭一帜富华商贸有限公司

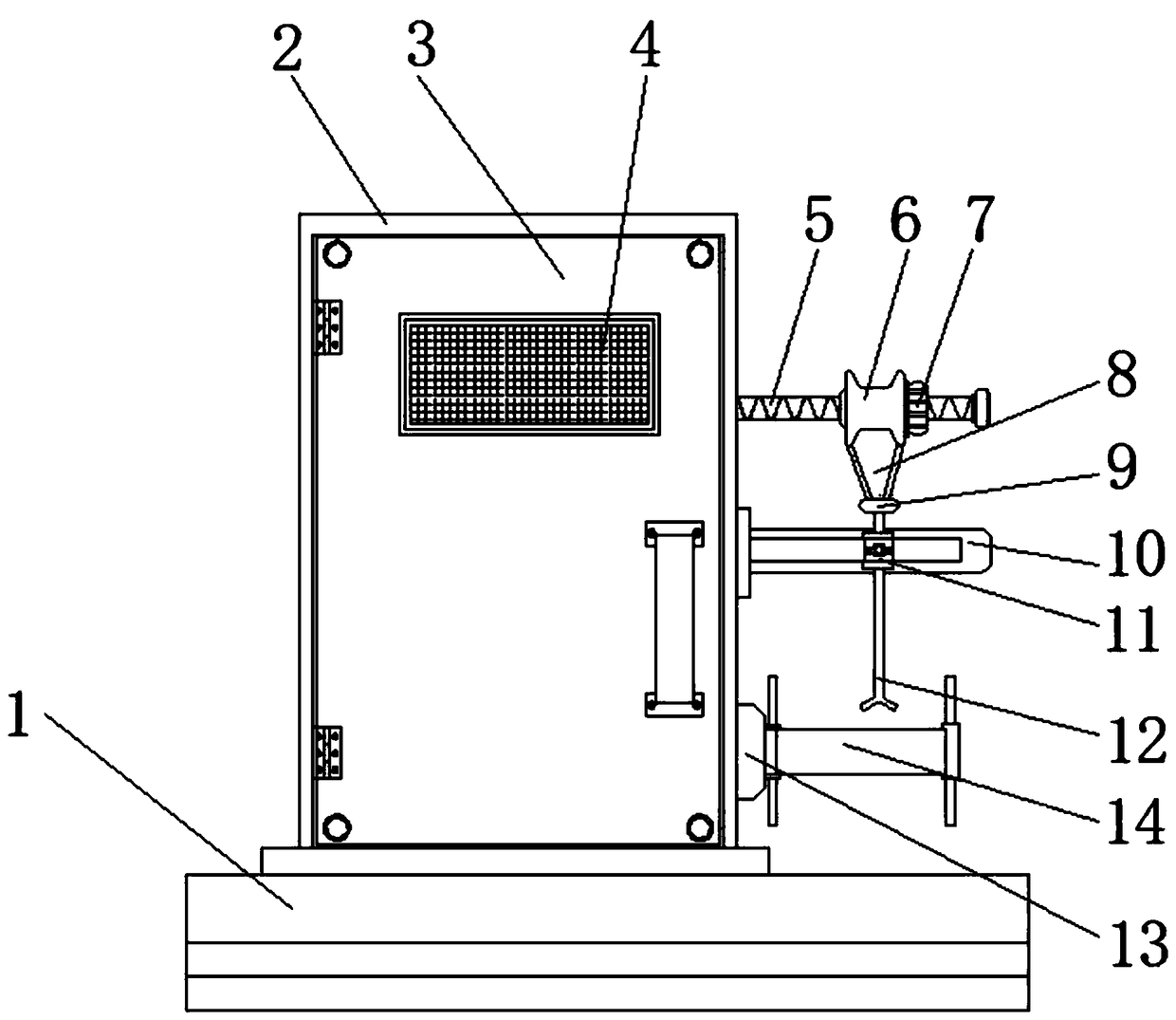

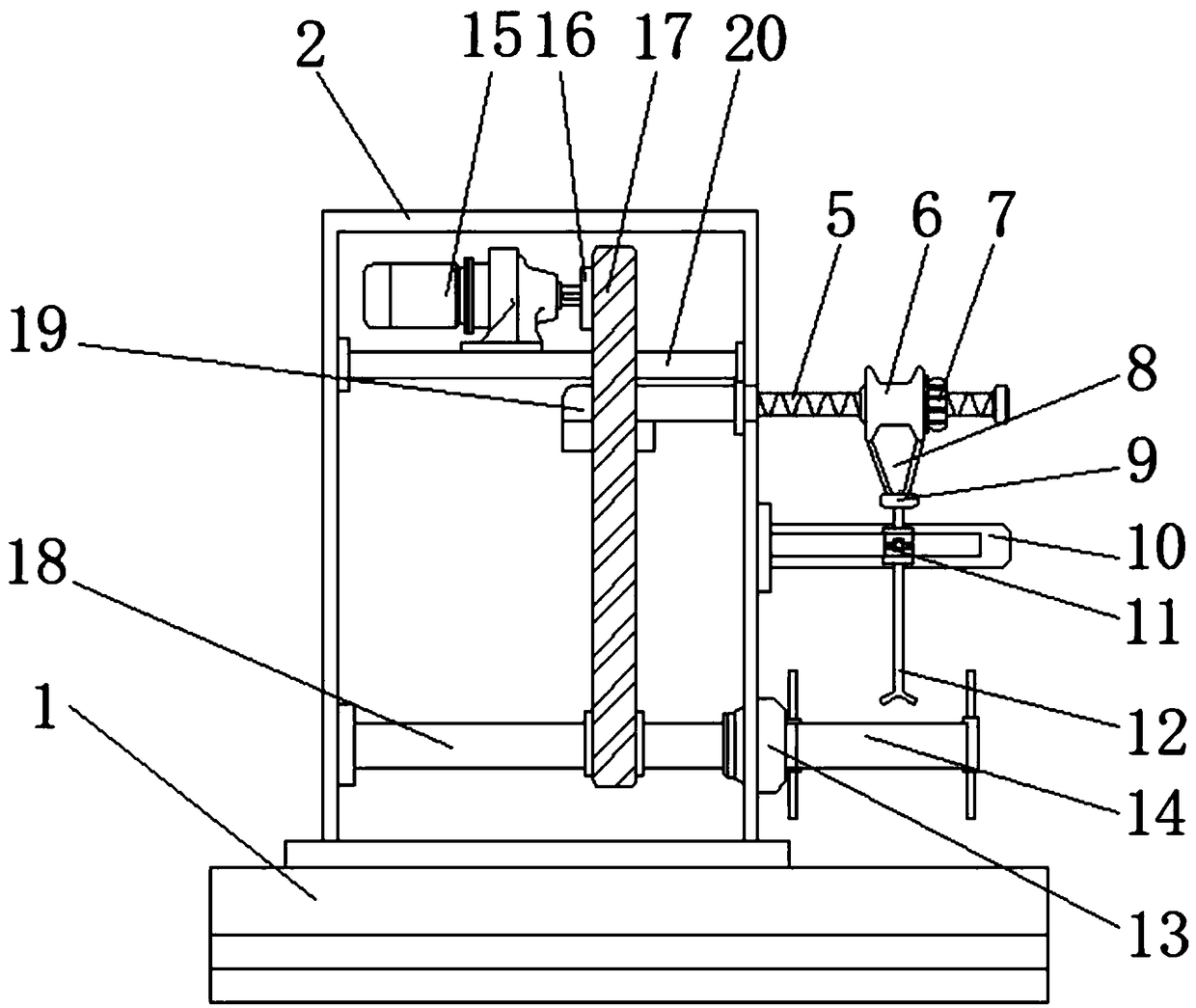

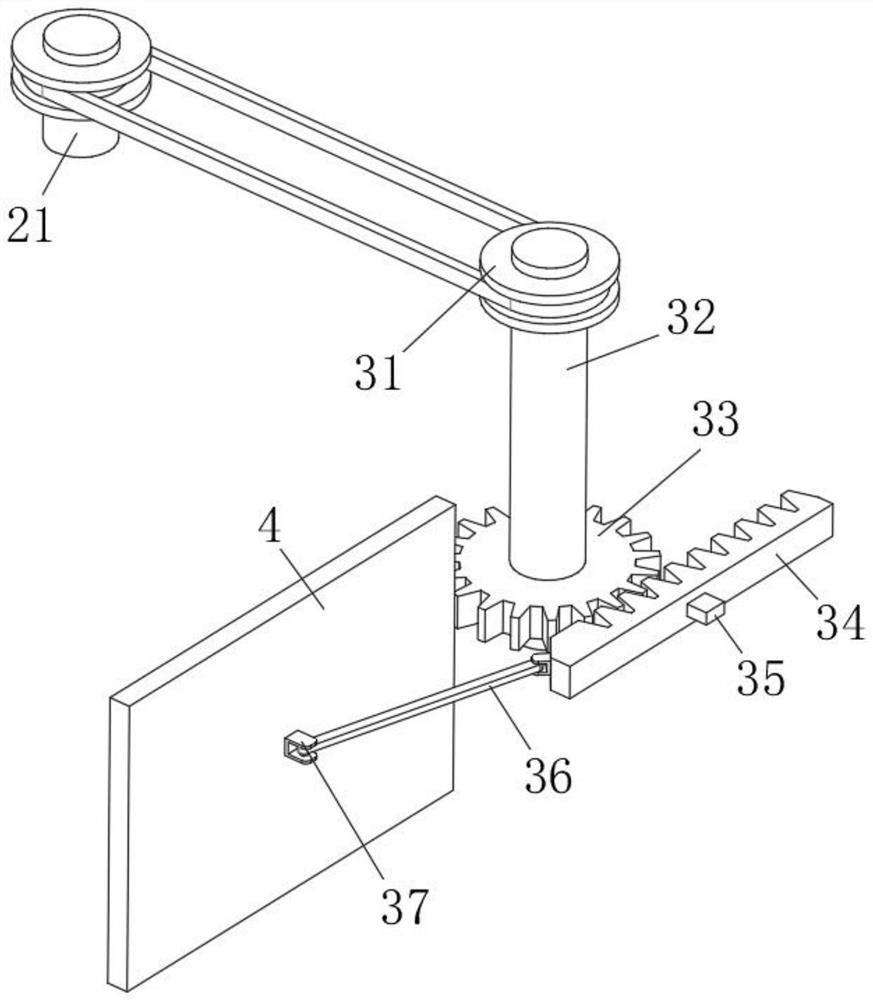

Cutting path adjustable numerical control laser cutting machine

ActiveCN107649791AMove normallyEasy to controlLaser beam welding apparatusNumerical controlGear wheel

The invention provides a cutting path adjustable numerical control laser cutting machine. The machine comprises a placing table and a moving machine, wherein an anti-skid pad is fixedly arranged at the middle end of the top of the placing table; the moving machine is movably arranged at the upper end of the placing table; a storage box is fixedly connected to the front end of the moving machine; adata transmission line is embedded into the right side of the storage box; built-in rolling wheels are movably connected to the bottom ends of two sides of the moving machine separately. According tothe numerical control laser cutting machine, a circular-ring-shaped laser bearing plate is arranged and an inner ring is gear-shaped, so that when linkage gears are embedded into the laser bearing plate through the gear-shaped inner ring, the linkage gear at the upper part transfers the rotary power to the linkage gear at the lower part through a telescopic column, and the linkage gear at the lower part then transfers the rotary power to the laser bearing plate through the gear-shaped inner ring, and therefore, the laser bearing plate can perform rotation operation along with the linkage gears synchronously.

Owner:唐山市利众精密制造有限公司

High-altitude operation robot and method

InactiveCN113161920AEfficient removalAvoid scratchesOverhead installationApparatus for overhead lines/cablesElectrical connectionStructural engineering

The invention discloses a high-altitude operation robot and method. Thehigh-altitude operation robot structurally comprises a detection box, a connecting base, an indicator light, a driver, moving wheels and a deicing mechanism, wherein the middle end of the detection box is fixedly installed on the connecting base, the indicator light is arranged at the bottom of the detection box and electrically connected with the detection box, and the moving wheels are fixedly installed on the front surface of the driver. In the moving process, an ice layer on the outer surface of the high-altitude electric wire is cut in a sliding mode through the three transverse cutters, then the ice layers on the three faces obtained after sliding cutting are stripped from the outer surface of the high-altitude electric wire through the three push plates, the ice layer on the outer surface of the high-altitude electric wire is effectively removed, what is ensured is that the moving wheels normally move on the high-altitude electric wire, a sponge mat on the extrusion mechanism moves on the outer surface of the high-altitude electric wire, residual water on the outer surface of the high-altitude electric wire is sucked dry, pressing plates on the two sides extrude the sponge mat under the hinging action of a fixing shaft, the water absorbed by the sponge mat is extruded out, and the phenomenon that moving wheels slip in the moving process is prevented.

Owner:BEIJING CHUNHE YULIN CONSTR ENG CO LTD

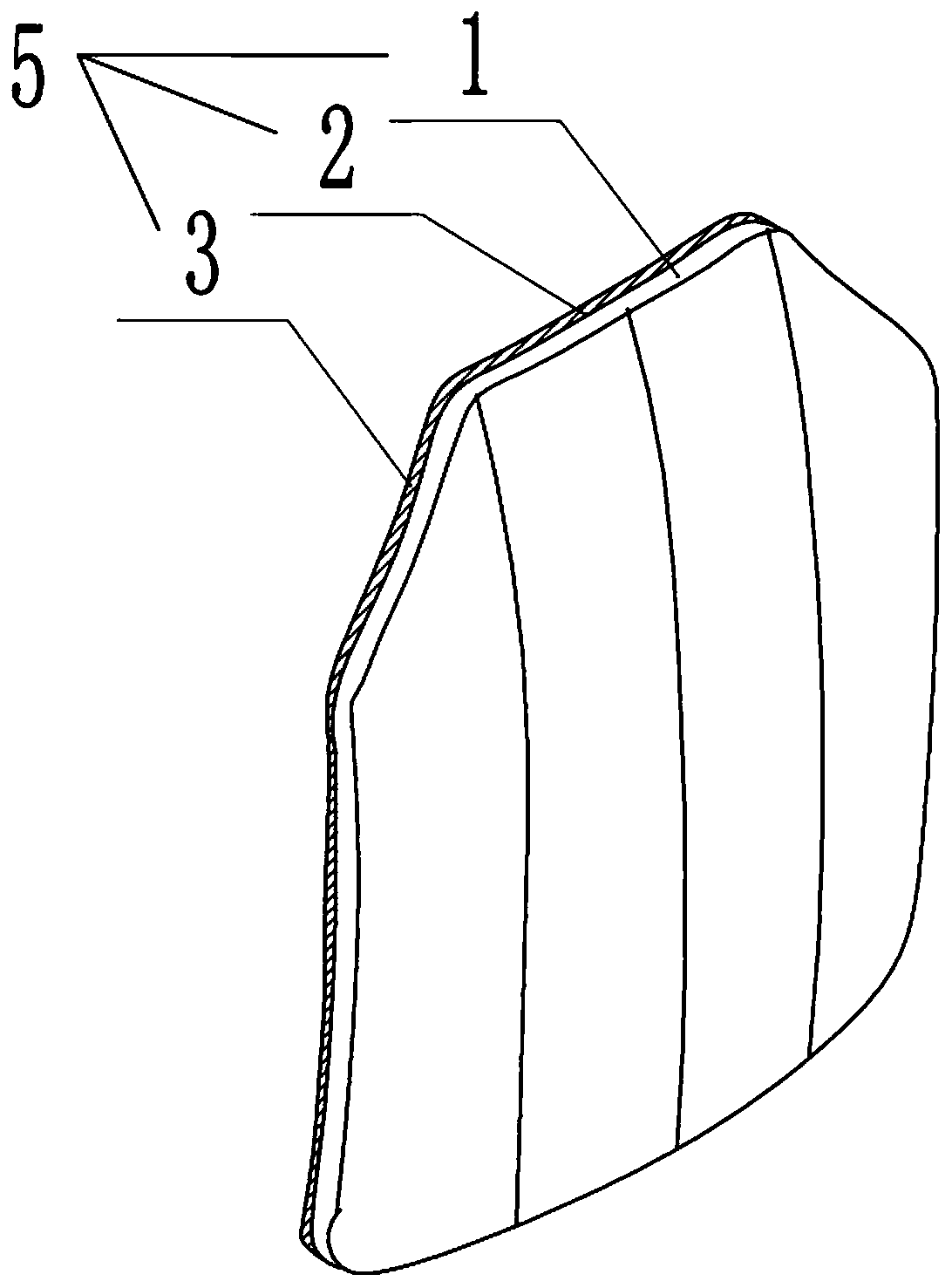

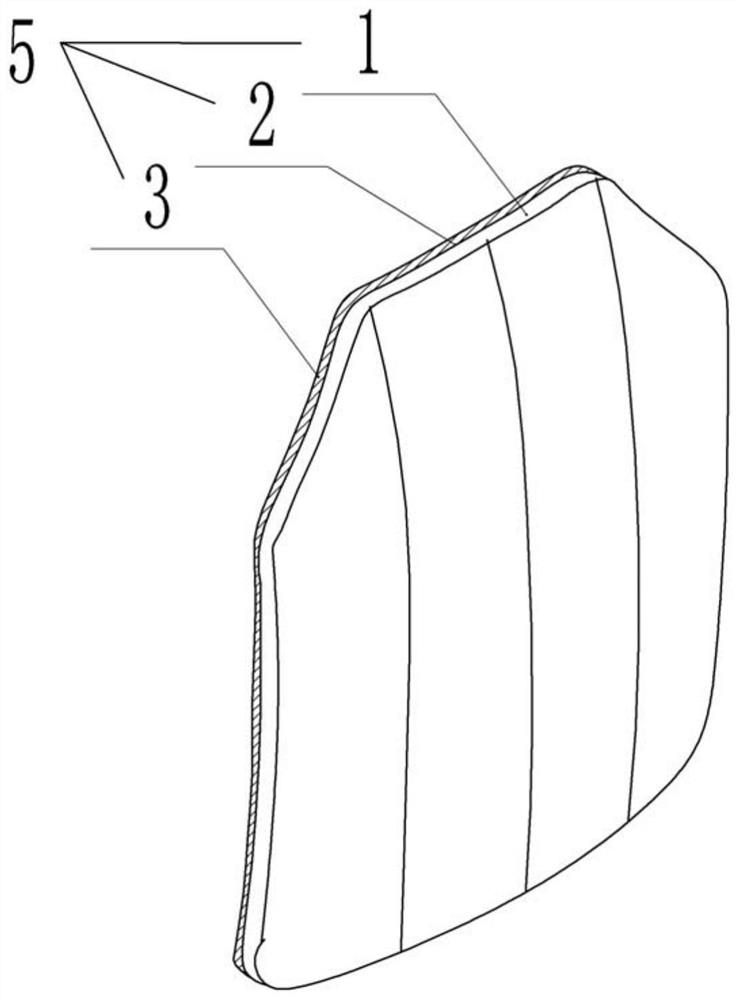

Non-metal bulletproof insertion plate

The invention relates to the field of bulletproof insertion plates, and particularly relates to a non-metal bulletproof insertion plate. The non-metal bulletproof insertion plate comprises an insertion plate body, the insertion plate body sequentially comprises an anti-bulge layer, an adhesive layer and a buffer layer from inside to outside, the anti-bulge layer and the buffer layer comprise a plurality of layers of high-strength high-modulus polyethylene non-woven cloths, the adhesive layer comprises a hot melt adhesive film, the insertion plate body adopts an anti-bulge layer, the adhesive layer and the buffer layer to be subjected to hot-pressing composite molding, and phenolic resin is coated on the surfaces of the plurality of layers of high-strength high-modulus polyethylene non-woven cloths in the anti-bulge layer and the buffer layer. The non-metal bulletproof insertion plate and an existing non-metal bulletproof insert plate are compared under the condition of equal protectionarea, so that the weight of the non-metal bulletproof insertion plate is reduced, and meanwhile, the problem of large bulge height after bullet shooting is solved.

Owner:重庆盾之王安防设备技术研究院有限公司

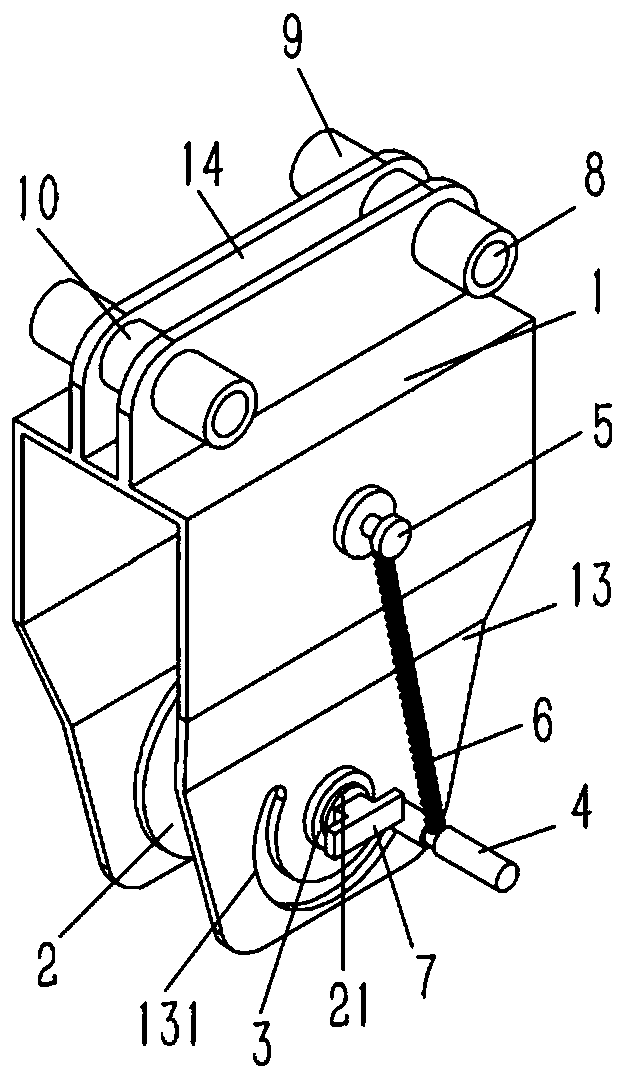

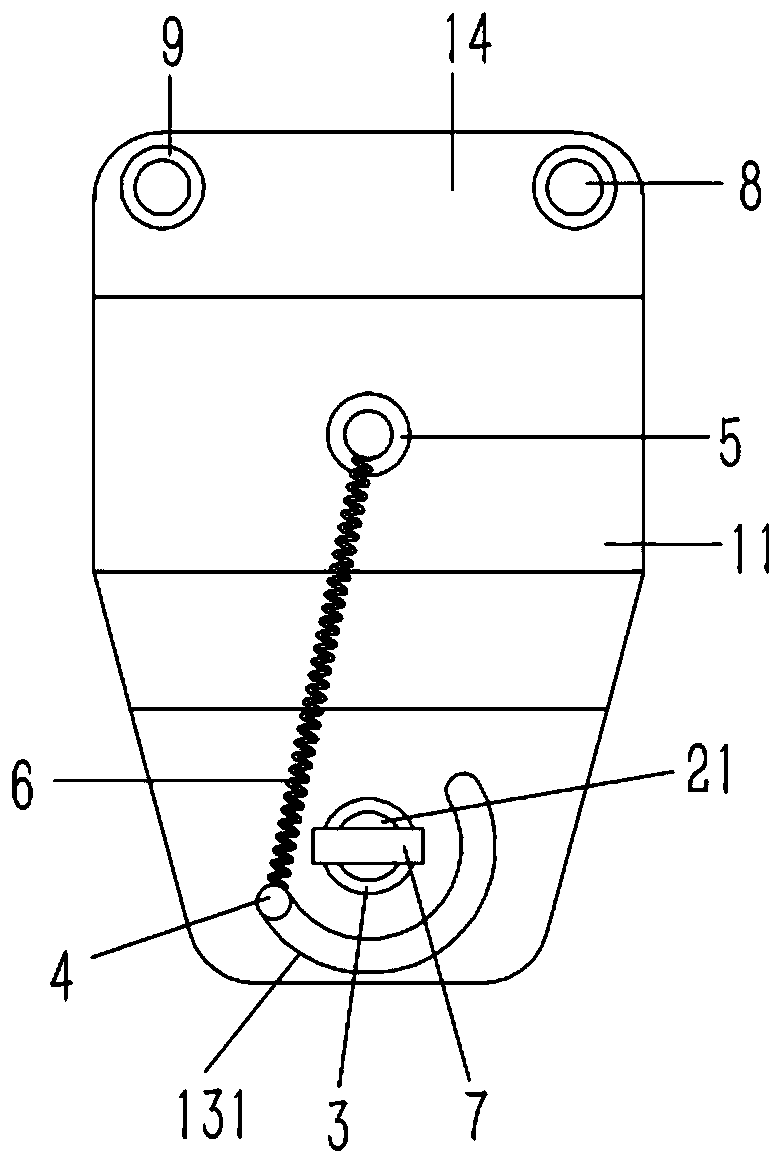

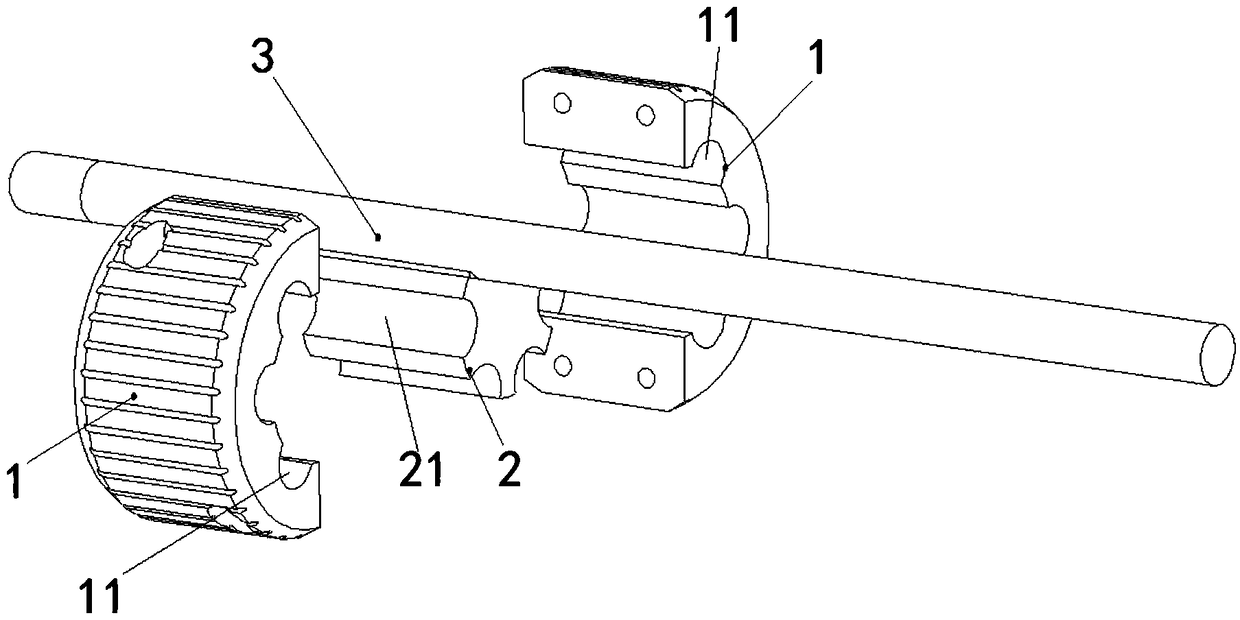

Overturning clamp for packaging chip

ActiveCN111162031AFlipMove normallySemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

The invention discloses an overturning clamp of a packaged chip. The overturning clamp comprises a horizontal top plate, and the two sides of the top plate are bent to form vertical side plates. The lower side edges of the side plates are bent to form inwards inclined elastic plates; the lower side edge of the inclined elastic plate is bent to form a vertical clamping plate; a circular supportingplate abuts against the inner side wall of the clamping plate, a supporting shaft is formed in the middle of the outer side wall of the supporting plate, the supporting shaft penetrates through the clamping plate to be inserted and sleeved with a fixed limiting sleeve, an arc-shaped guide groove is formed in the clamping plate on the lower side of the supporting shaft, a cylindrical shifting rod is inserted into the guide groove, and the inner end of the shifting rod is fixed to the supporting plate; a spring is fixedly connected to the shifting rod, the other end of the spring is fixed to a fixing block, and the fixing block is fixed to the outer wall of the side plate over the supporting shaft.

Owner:CHONGQING DABIAO ELECTRONICS SCI & TECH

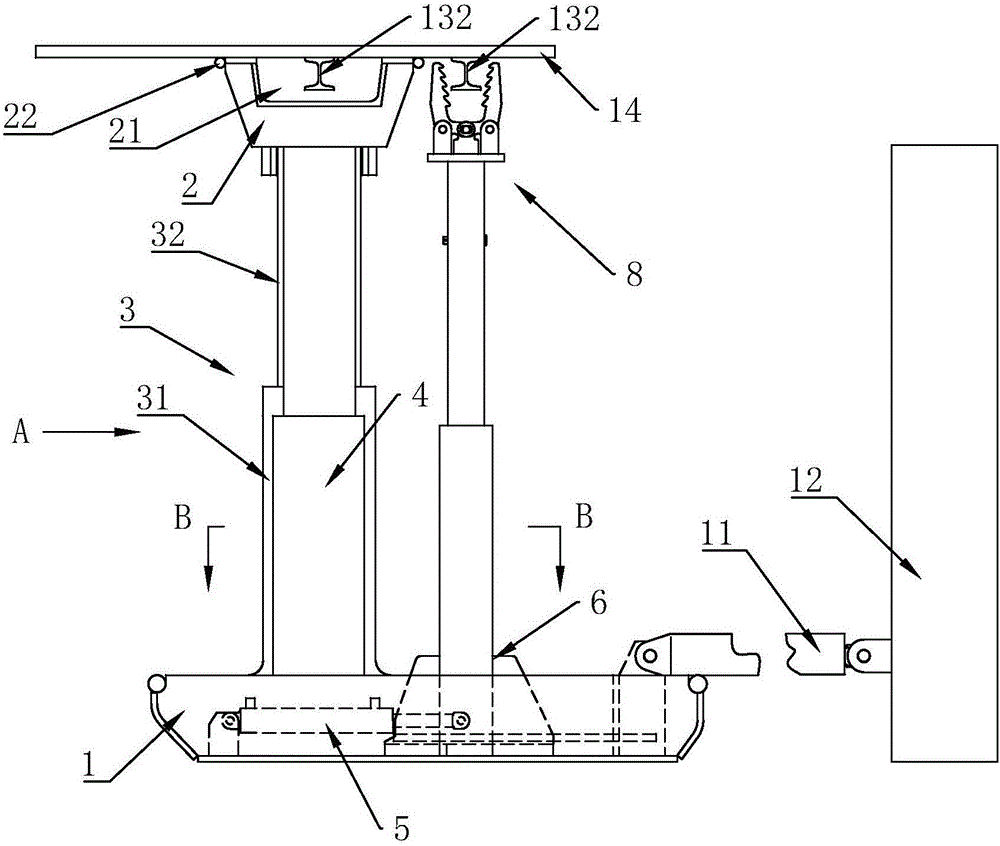

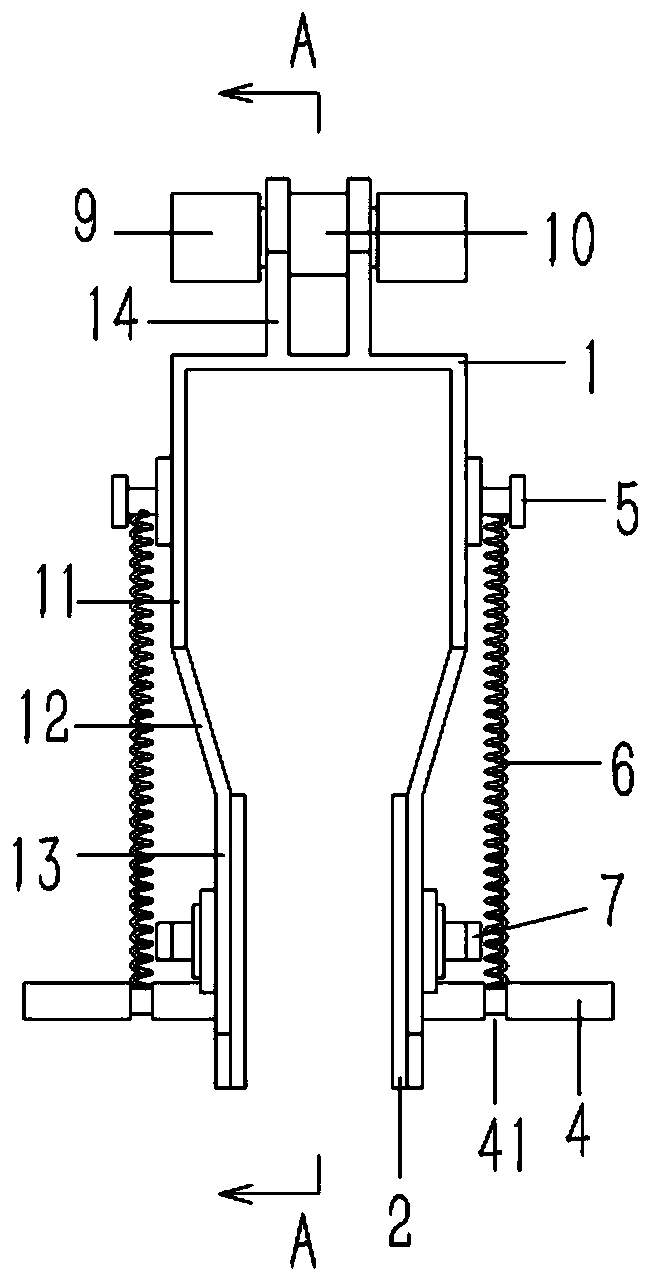

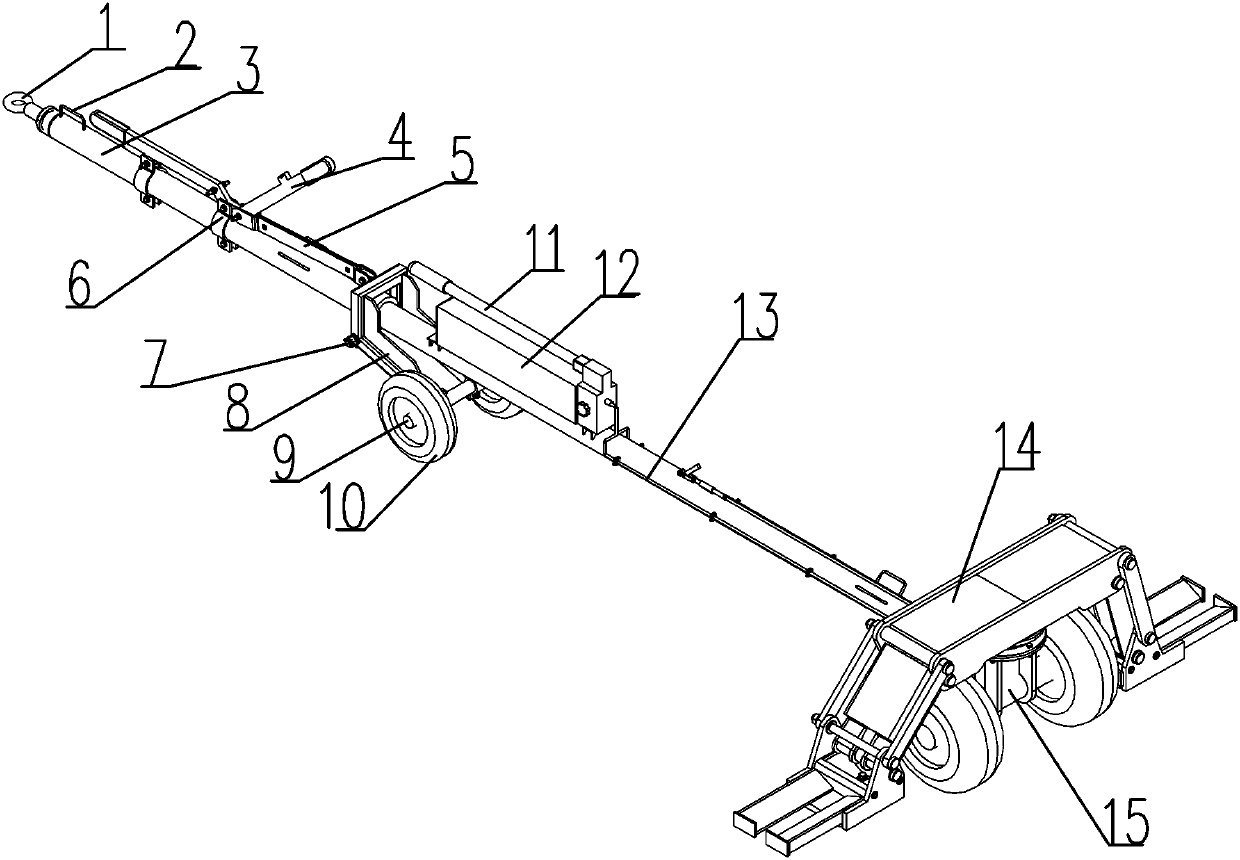

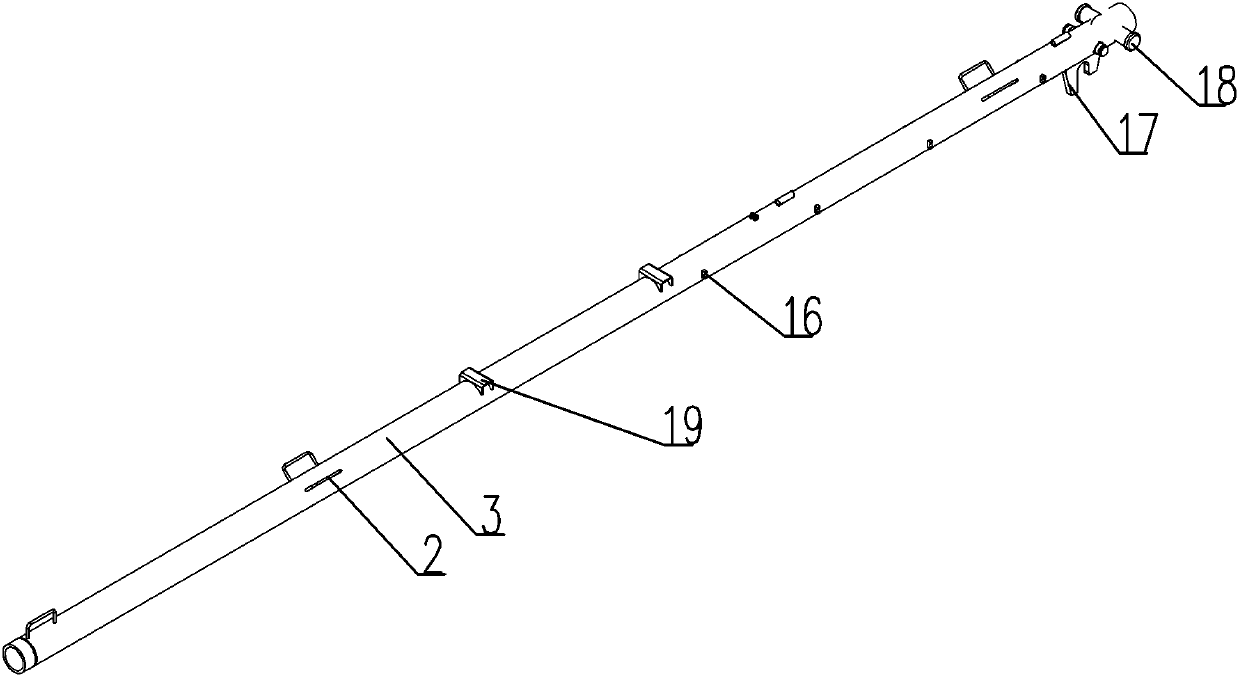

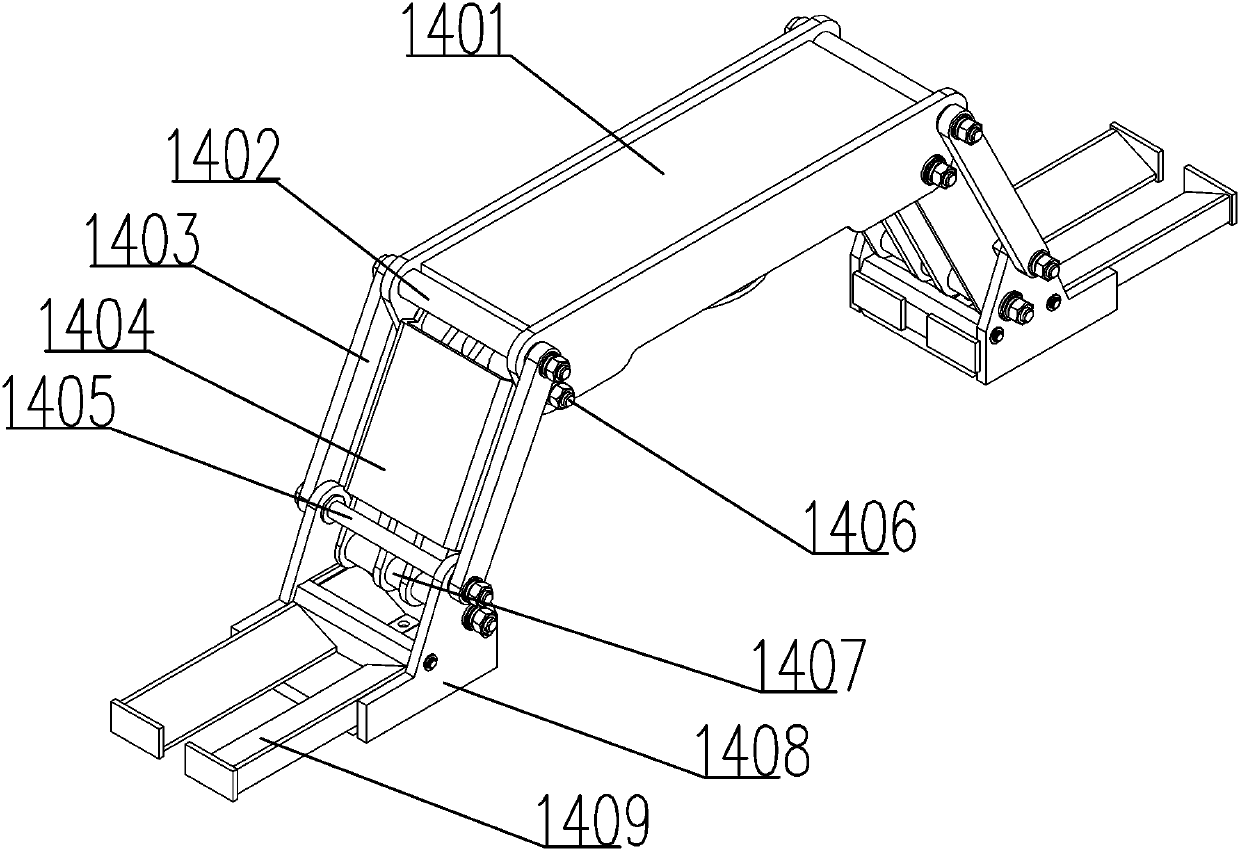

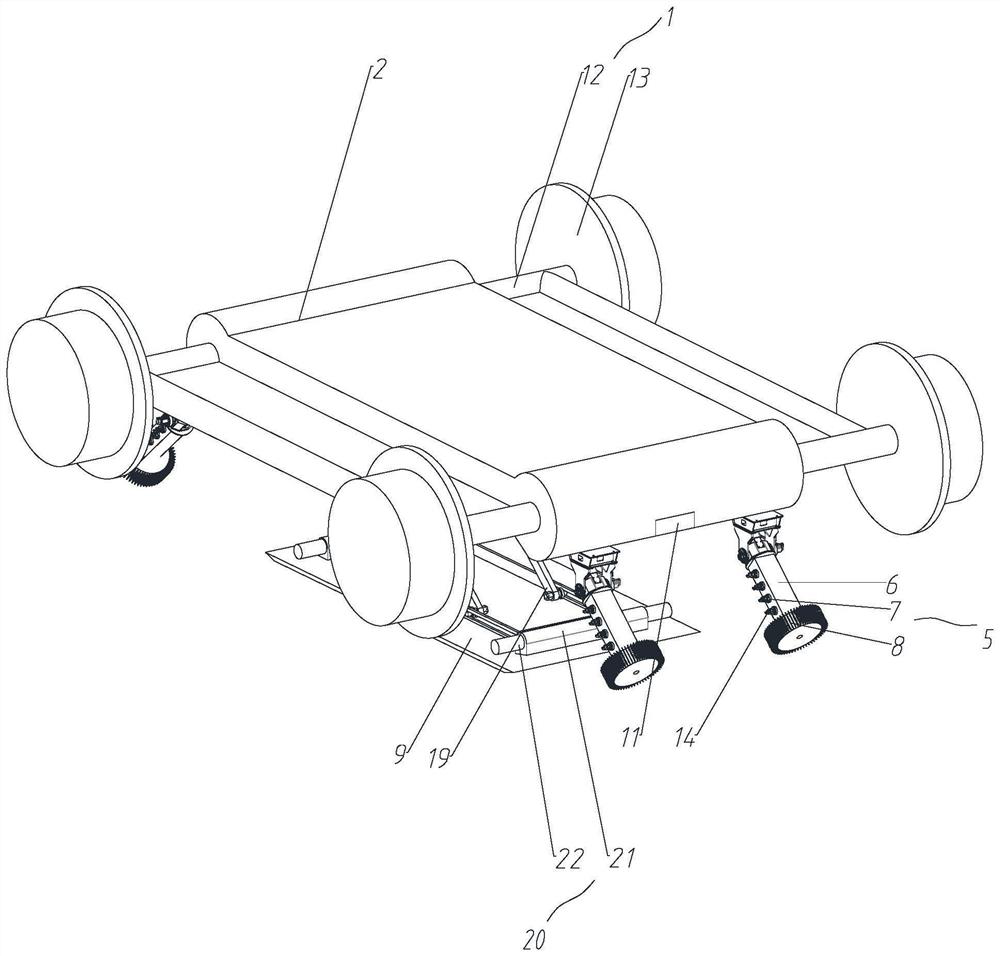

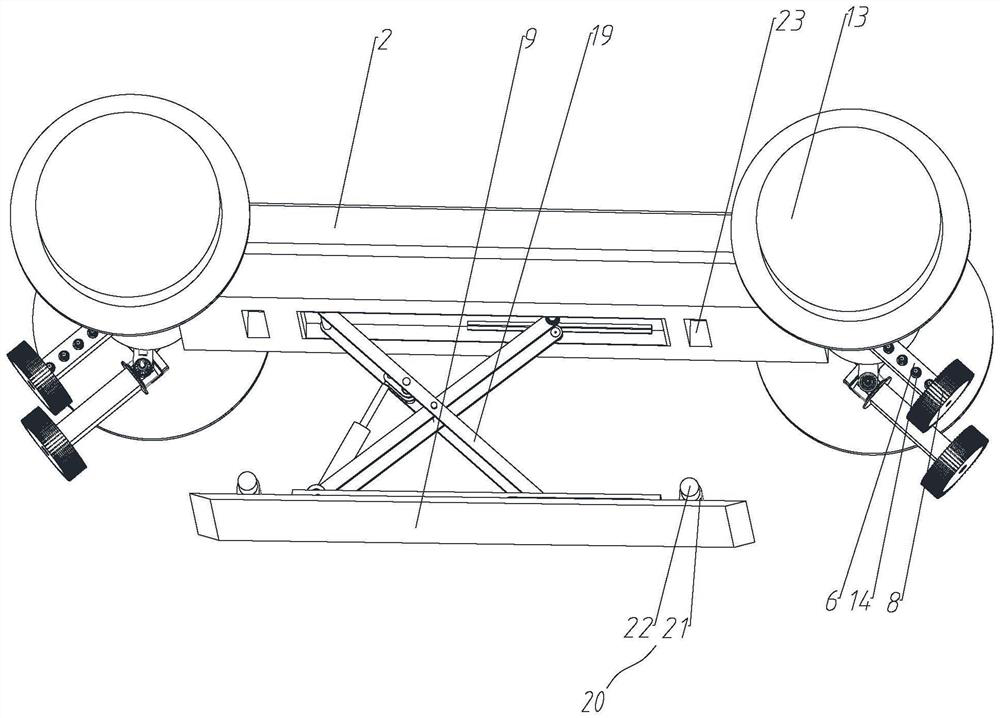

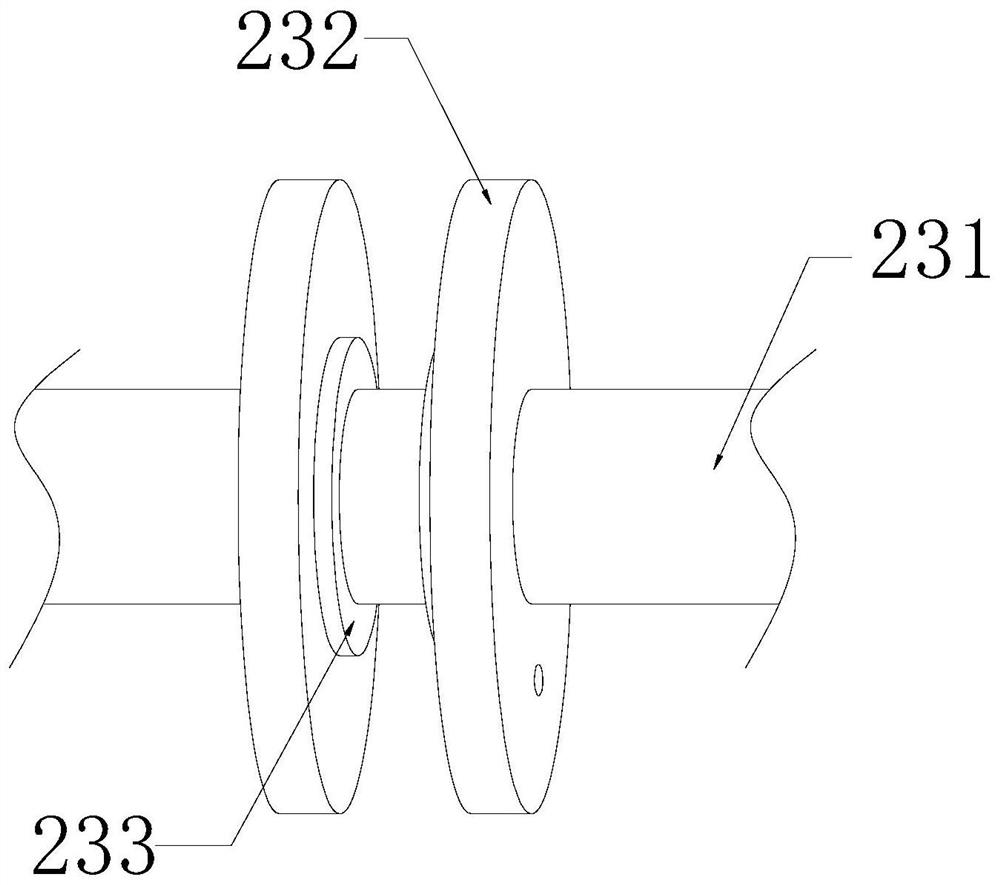

Towing vehicle structure for large scraped automobile and use method thereof

ActiveCN110588488AAvoiding Difficult Towing ProblemsMove normallyVehicle dissasembly recoveryTowing devicesTowing

The invention provides a towing vehicle structure for a large scraped automobile and a used method thereof. The towing vehicle structure for the large scraped automobile comprises a main towing bar, wherein one end of the main towing bar is connected with a travelling wheel structure through a hook hanging shaft and a hook hanging plate, a lifting mechanism is fixed at the top of the travelling wheel structure, and the lifting mechanism is connected with a power device for providing lifting power. The towing vehicle structure for the large scraped automobile can be used for automobile towing in the disassembling process of the large scraped automobile.

Owner:HUBEI LIDI MACHINE TOOL

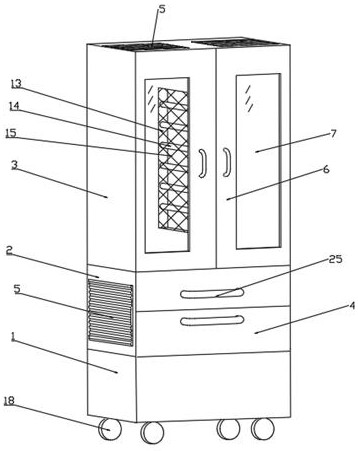

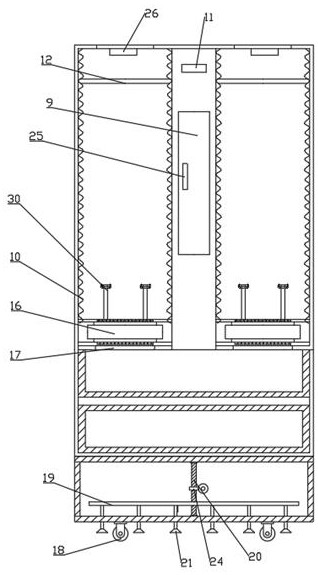

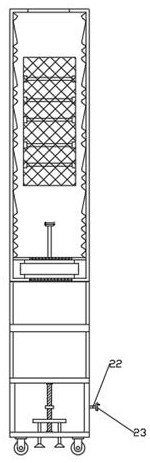

Intelligent electric power safety appliance cabinet with sterilization and peculiar smell absorption functions

InactiveCN111700408AAvoid enteringGuaranteed cleanlinessLighting elementsCabinetsUltraviolet lightsEngineering

The invention discloses an intelligent electric power safety appliance cabinet with sterilization and peculiar smell absorption functions. The cabinet comprises a base, and is characterized in that universal wheels are arranged at the bottom of the base. A first cabinet body is arranged at the top of the base; a second cabinet body is arranged at the top of the first cabinet body; drawers are arranged on the front side of the first cabinet body at equal intervals; shutter fans are arranged on the two sides of the first cabinet body and the top of the second cabinet body; an ultraviolet lamp isarranged on the side surface of the inner cavity of the second cabinet body; a heat insulation net is arranged on the front side of the ultraviolet lamp and matched with a wavy reflection plate arranged on the inner wall of the second cabinet body, electric power safety tools can be more effectively sterilized, damage of high temperature generated by the ultraviolet lamp to the electric power safety tools can be prevented, and meanwhile an air suction device is further arranged so that peculiar smells on the electric power safety tools can be removed.

Owner:STATE GRID CORP OF CHINA +1

A non-metal bulletproof board

Owner:重庆盾之王安防设备技术研究院有限公司

Shaping structure in aluminum rod continuous casting and rolling production line

InactiveCN110102574AMove normallyReduce blocking forceMetal rolling arrangementsProduction lineEngineering

The invention discloses a shaping structure in an aluminum rod continuous casting and rolling production line. The shaping structure comprises a bracket and a forming cylinder, the two sides of the top of the bracket are connected with protective covers in the length direction, the insides of the protective covers are hollow, a plurality of rotating shafts are rotatably mounted between the two protective covers, the two sides of the outer side of each rotating shaft are sleeved with limit rings, one side of each limit ring is connected with a fastening screw, one end of each fastening screw abuts against the corresponding rotating shaft, the opposite sides of every two corresponding limit rings are connected with a pressing plate, the pressing plates are movably mounted outside the rotating shafts, and a plurality of shock absorbing springs are connected between the side surfaces of the pressing plates and the limit rings. A plurality of pressing rollers simultaneously press the outside of an aluminum rod, the uneven and bending state of the outside of the aluminum rod can be adjusted, the aluminum rod passing through the inside the forming cylinder can be molded to be in a straight and round state, and subsequent use is facilitated. The shaping effect is good, the efficiency is high, integrated implementation can be achieved, and manual handling operation is not needed.

Owner:TONGLING JINGLONG ELECTRIC MATERIAL

Automatic wire harness equipment for wire cable production

InactiveCN109052005AImprove rigidityNot easy to break and collapseFilament handlingEngineeringElectric wire

The invention discloses an automatic wire harness device for wire cable production. The automatic wire harness device comprises a base, a dustproof net and a support, the upper end of the base is connected with a machine body, a door body is arranged on the inner side of the machine body, the door body is rotationally connected with the machine body, a dustproof net is embedded in the inner side of the door body, the dustproof net and the door body are connected in a bonding mode, the support is fixed to the upper end of the inner wall of the machine body, the support and the machine body areconnected in a welding mode, a motor is arranged on the left side of the top of the support, the motor is in threaded connection with the support, a belt wheel is connected to the right side of the motor. The automatic wire harness device is provided with the base, the base and the machine body are distributed in a vertical shape, the base and the machine body are made of stainless steel materials, the device has good rigidity and is not easy to break and collapse in use, meanwhile, the base is arranged in a horizontal shape, so that the whole device can be effectively ensured to operate in anormal state in use.

Owner:冯爱明

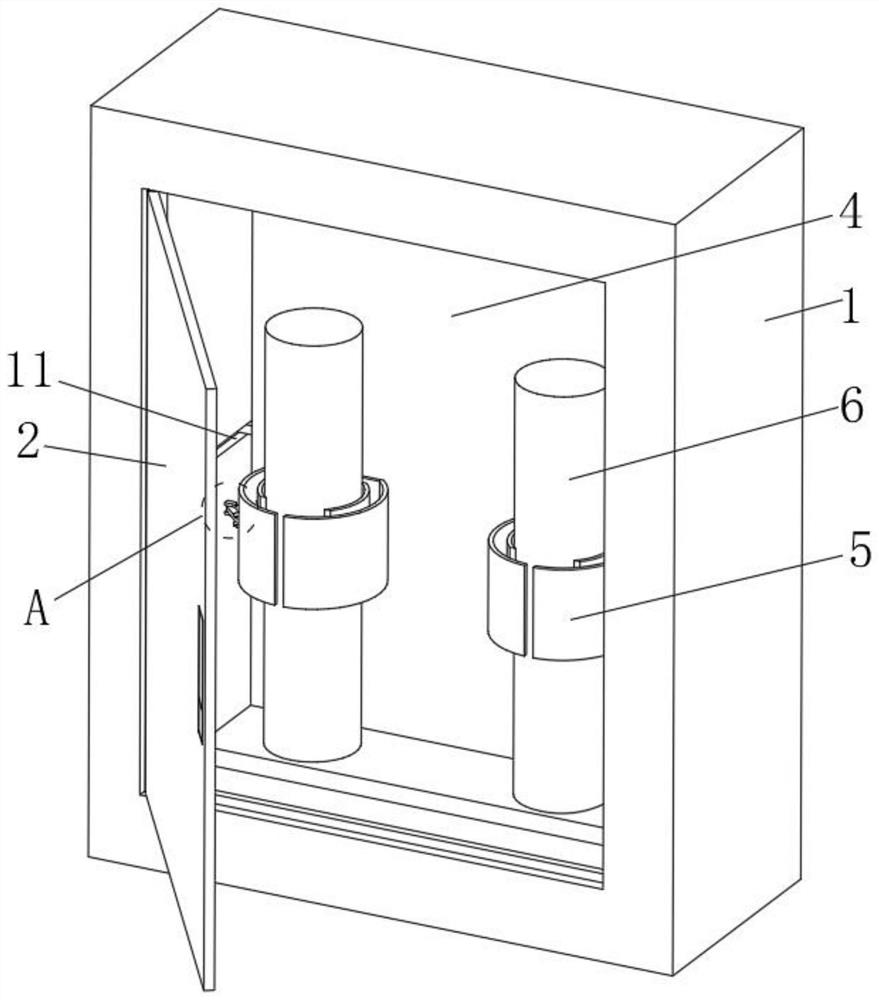

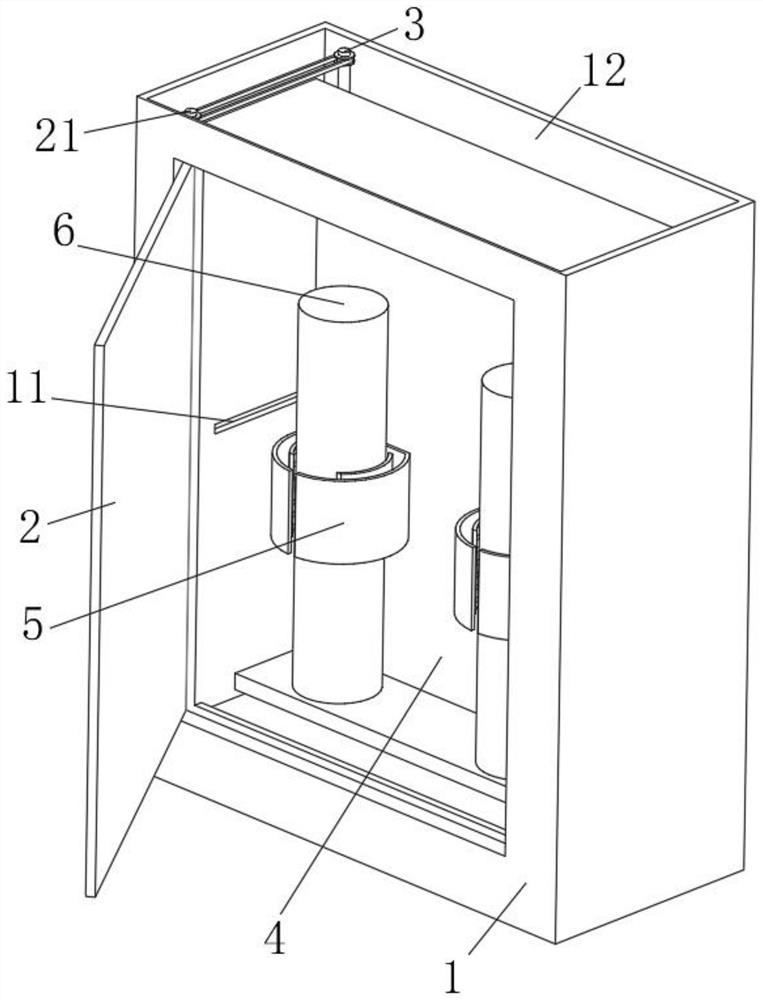

Fire-fighting equipment storage box convenient to store and take

ActiveCN114367073AExtended service lifeEasy to take out and useFire rescueStructural engineeringIndustrial engineering

The fire fighting equipment storage box comprises a storage box body, sliding grooves are symmetrically formed in the inner wall of the storage box body, a cavity is formed in the storage box body, a protective door is rotatably connected to the outer surface of the storage box body, and door shafts are fixedly connected to the upper end and the lower end of the protective door; a cavity is formed in the storage box body, two push-out assemblies are arranged in the cavity, a moving plate is arranged in the storage box body, two grooves are formed in the outer surface of the moving plate, and protection assemblies are arranged in the two grooves. Through cooperation of all the components, when the fire extinguisher needs to be used, the fire extinguisher can automatically move outwards when a protective door is opened, and meanwhile, a device for protecting the fire extinguisher can be automatically opened during moving, so that the fire extinguisher can be conveniently taken out for use, the fire extinguishing efficiency is improved, and the fire extinguisher can be fixed and protected when not used; therefore, the service life is prolonged.

Owner:天长市鹏展消防设备制造有限公司

Spraying equipment with rust removal mechanism

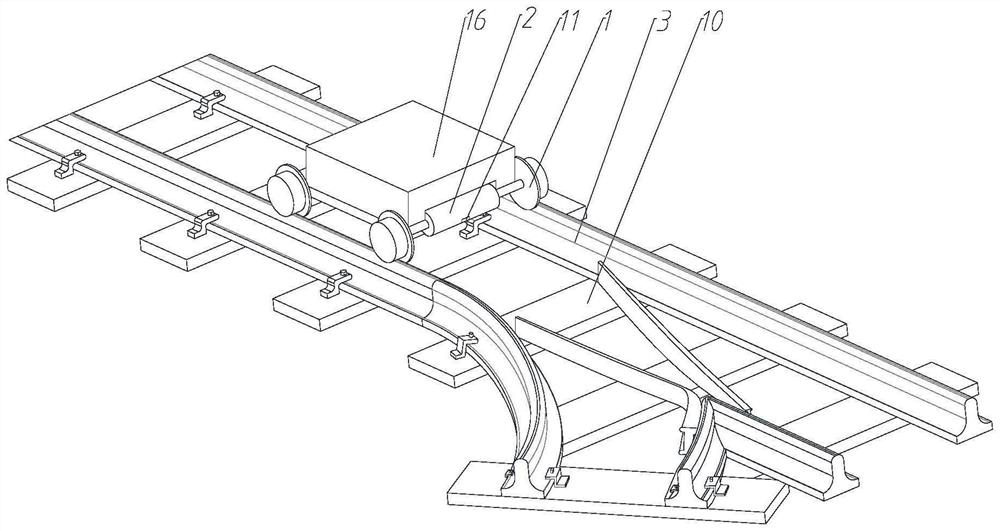

PendingCN114318974AEasy to remove rustEasy to moveSpraying apparatusRailway track constructionMechanical engineeringAutomotive engineering

The invention relates to the technical field of spraying equipment, and provides spraying equipment with a rust removal mechanism, the spraying equipment comprises a telescopic wheel body, a rack moves along a rail through the telescopic wheel body, the telescopic wheel body is provided with a step groove, after the telescopic wheel body stretches out and draws back, the step groove abuts against or cancels abutting against the rail, a rust removal device is arranged on the rack, and the rust removal mechanism is arranged on the rack. Comprising a rust removal part rotationally arranged on the rack, the rotating axial direction is perpendicular to the length direction of the rail, a rust removal spray head is rotationally arranged on the rust removal part, the rotating axial direction is perpendicular to the rotating axial direction of the rust removal part, and the rust removal spray head faces the inner side of the rail. By means of the technical scheme, the problems that in the prior art, a rail derusting vehicle occupies a rail and is inconvenient to separate from the rail, normal operation of other trains is affected, and due to the fact that the existing rail derusting vehicle cannot turn to different crossroads like the train, the rail derusting vehicle cannot work normally when passing through the crossroads are solved.

Owner:HEBEI UNIVERSITY

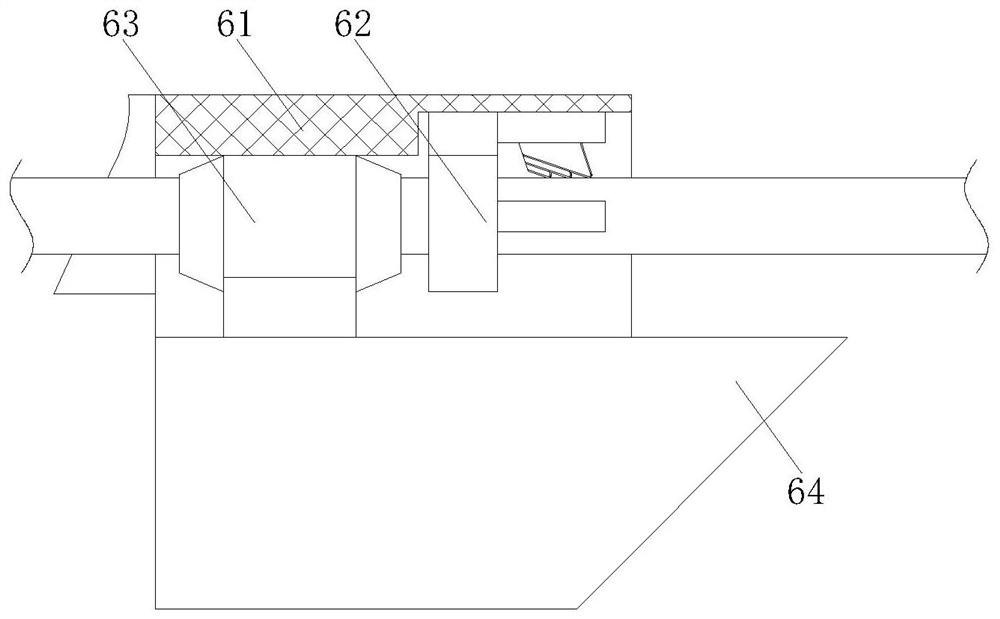

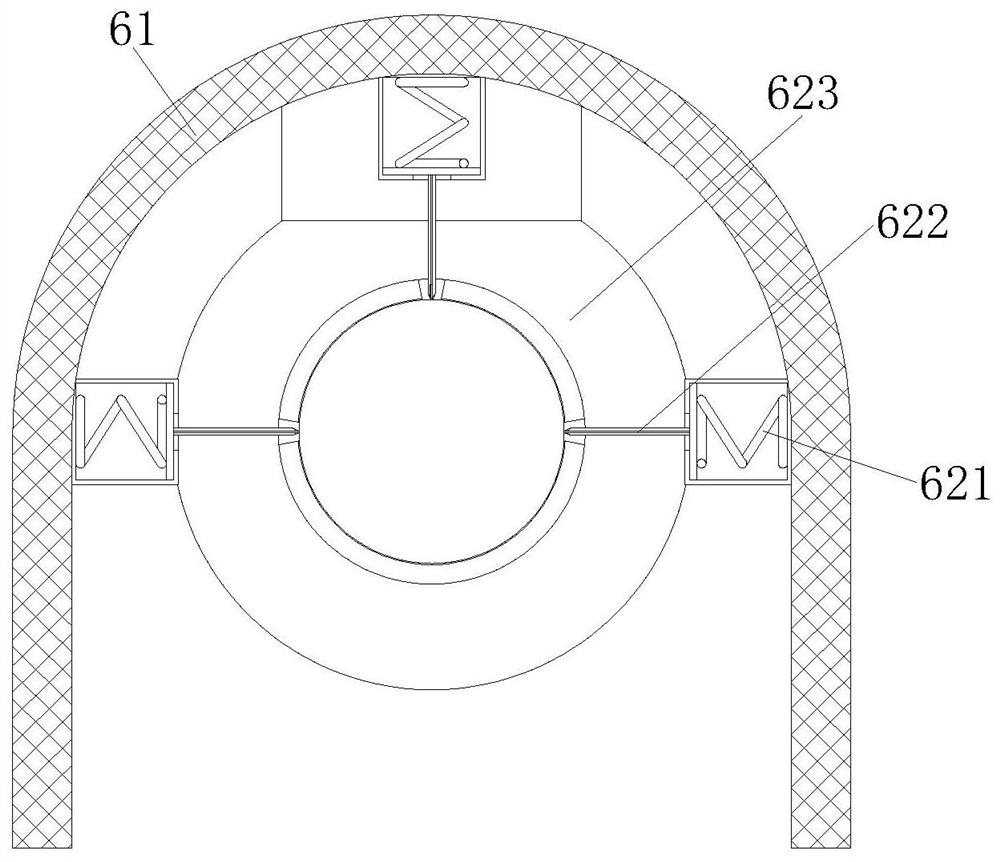

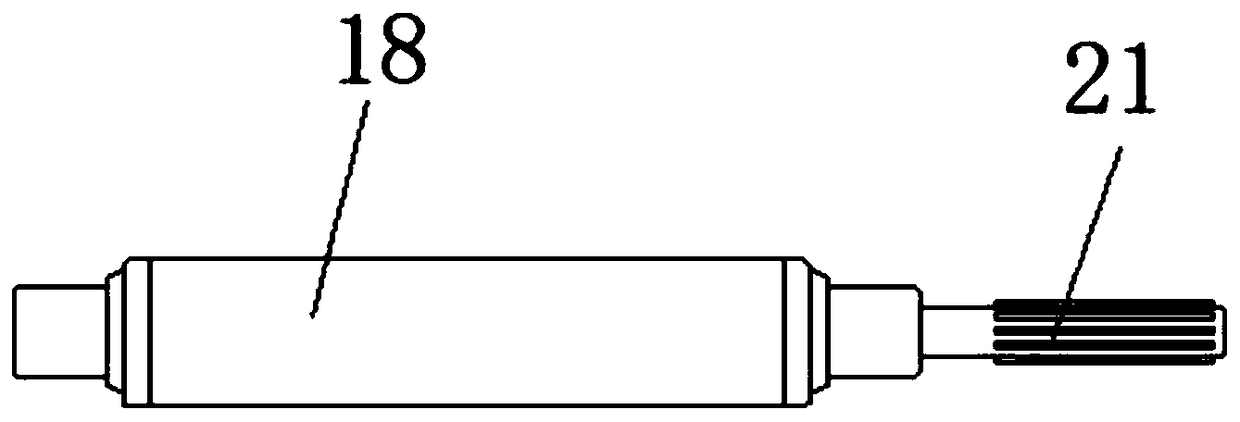

Plugging device, cab and engineering vehicle

PendingCN109318827AMove without getting in the wayMove normallyVehicle componentsEngineeringMechanical engineering

The invention provides a plugging device, a cab and an engineering vehicle, and relates to the technical field of engineering vehicles. The plugging device comprises a sleeve and a plugging assembly;the sleeve is for being arranged on the cab and penetrates through the cab; the plugging assembly is arranged in the sleeve and used for plugging the sleeve; and a through hole for a tubular product to pass is formed in the plugging assembly, and the tubular product can move in the axial direction of the sleeve. The sleeve is arranged on the cab and penetrates through the cab, the tubular productwhich needs to be movably arranged in the cab can stretch out of the cab through the sleeve and can move in the axial direction of the sleeve, the movement of the tubular product cannot be hindered, and the tubular product in the cab can move normally; and a gap between the inner wall of the sleeve and the tubular product is filled by the plugging assembly, air outside the cab can be prevented from entering into the cab, thus the influence of the air outside the cab on air inside the cab is reduced, appropriate temperature in the cab is kept, and the energy consumption is lowered.

Owner:SANY AUTOMOBILE MFG CO LTD

A kind of bee breeding device

The invention relates to the field of beekeeping, in particular to a beekeeping device. The beekeeping device comprises a beehive, a frame is arranged in the beehive and rotationally connected in thebeehive, two sides of one end of the frame are provided with hooks, an operating mechanism for controlling the frame to rotate is arranged on the beehive, and two identical butting mechanisms are arranged in the beehive. Each butting mechanism comprises a butting plate movably connected in the beehive, the frame is positioned between the two butting plates, hang blocks matched with the hooks are arranged at ends of the butting plates, and sliders are slidably connected to lateral sides, away from the frame, of the butting plates and slidably connected with connection blocks. Springs are connected between the connection blocks and the inner wall of the beehive, and guide mechanisms enabling movement of the two butting plates are arranged on the beehive. By adoption of the scheme, larvae, honeydew and pollen are prevented from falling from honeycombs in turning of the frame.

Owner:湖北集蜂堂生物有限公司

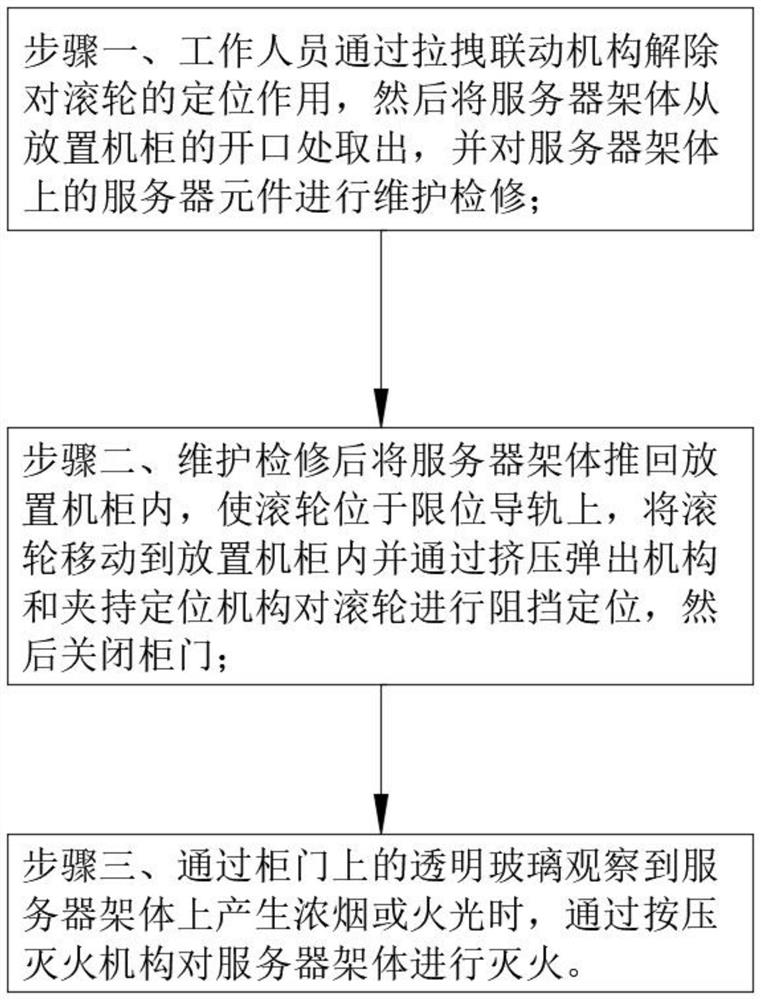

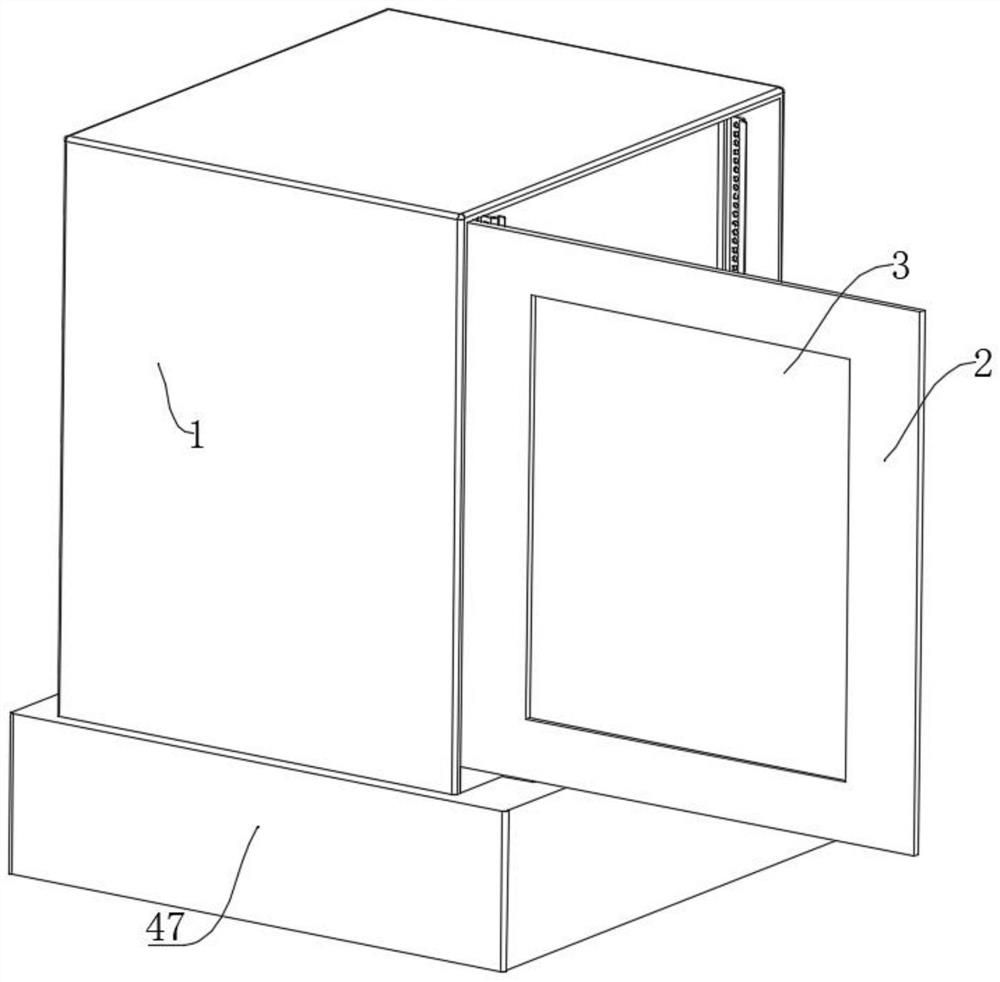

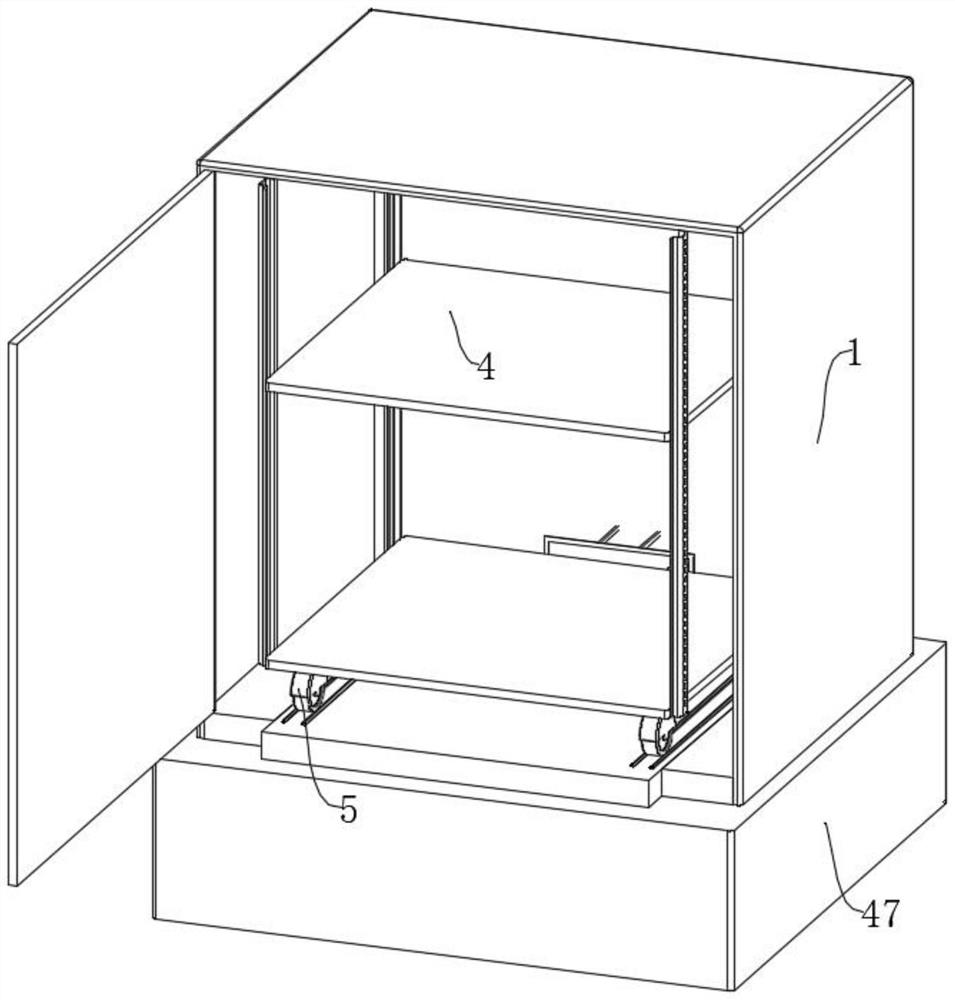

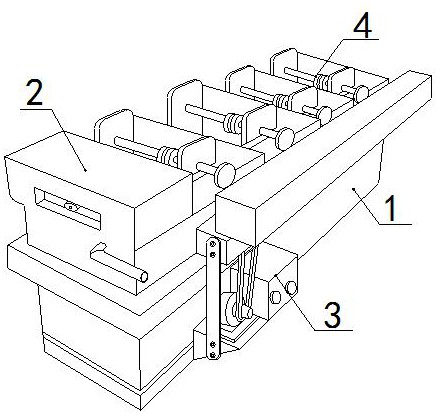

A device protection device for electronic information and its protection method

ActiveCN114245642BMove normallyAvoid shakingServersCasings/cabinets/drawers detailsEngineeringStructural engineering

The invention relates to the technical field of electronic information equipment protection, in particular to an equipment protection device for electronic information and a protection method thereof, comprising placing a cabinet, a cabinet door hinged on one side of the cabinet, and a transparent glass connected to the cabinet door, The server rack is placed in the placement cabinet, and the four ends of the bottom of the server rack are installed with rollers; they are positioned by the circular grooves on the rollers to prevent the server rack from shaking due to the movement of the rollers in the placement cabinet, and improve the server rack. When the server rack needs to be taken out, the staff releases the positioning through the positioning release mechanism, so that the positioning effect on the circular grooves on both sides of the roller is released, so that the roller at the bottom of the server rack can move normally, so that the server The frame body can be easily and quickly taken out to ensure the efficiency of maintenance and repair.

Owner:LANZHOU INST OF TECH

Metal electroplating climbing production line

The invention discloses a metal electroplating climbing production line. The structure comprises a machine body, a cleaning tank, a distribution box and a clamping device. The cleaning tank is arranged on the top of the machine body. The distribution box is installed at the bottom of the left front of the machine body. When the concentration of dewaxing water and cleaning solution in a cleaning pool is low, the dewaxing water and the cleaning solution can not react with wax, so that the melted wax floats on the surface of the cleaning solution due to low density. Wax blocks on the surface of aworkpiece clamp are pushed away by a wax removal device, wax solidification on the surface of the workpiece clamp is reduced, so that the surface of the workpiece clamp is smoothy, and the stabilityof the workpiece clamp is improved when a workpiece is clamped. When an inner binding ring moves inside an outer binding ring, due to the gap between the inner binding ring and the outer binding ring,the dewaxing water enters into the inner part of the outer binding ring and solidifies, so that the inner binding ring is stuck. Wax on the inner part of the outer binding ring can be brushed off andthe dewaxing water can be reduced through a baffle, inner wax is reduced, so that the inner binding ring can move normally, and the outer binding ring can be expanded and reduced normally.

Owner:广东稳帝机械科技有限公司

Template printing device with deviation rectifying mechanism

InactiveCN113844165AMove fastReduce mobility restrictionsRotary pressesOther printing apparatusStructural engineeringMechanical engineering

The invention discloses a template printing device with a deviation rectifying mechanism. The device structurally comprises a base, a machine body and a control panel, the bottom of the machine body is vertically welded to the surface of the top of the base, and the control panel is arranged on the surface of the right side of the machine body. Ink on the outer wall of a printing roller splashes to the outer wall of a limiting rod, with the extension of time, the ink is gradually solidified on the outer wall of the limiting rod, a clearing block is arranged in an opening of a limiting ring, ink solid particles on the outer wall of the limiting rod are impacted, crushed and fall off through a push plate, the situation that the movement position of the limiting ring is limited due to the fact that the movement of the limiting ring is hindered by small particles can be reduced, the limiting ring moves to a proper position, normal limiting of the template is facilitated, particles and part of dust after being crushed by the push plate remain on the outer wall of a rod body, and the dust remaining on the outer wall of the rod body after being crushed by the push plate can be cleared by arranging a clearing ring in a movable cavity so that the outer wall of the rod body can be kept clean and tidy, and the moving speed of the limiting ring is further accelerated.

Owner:李金彪

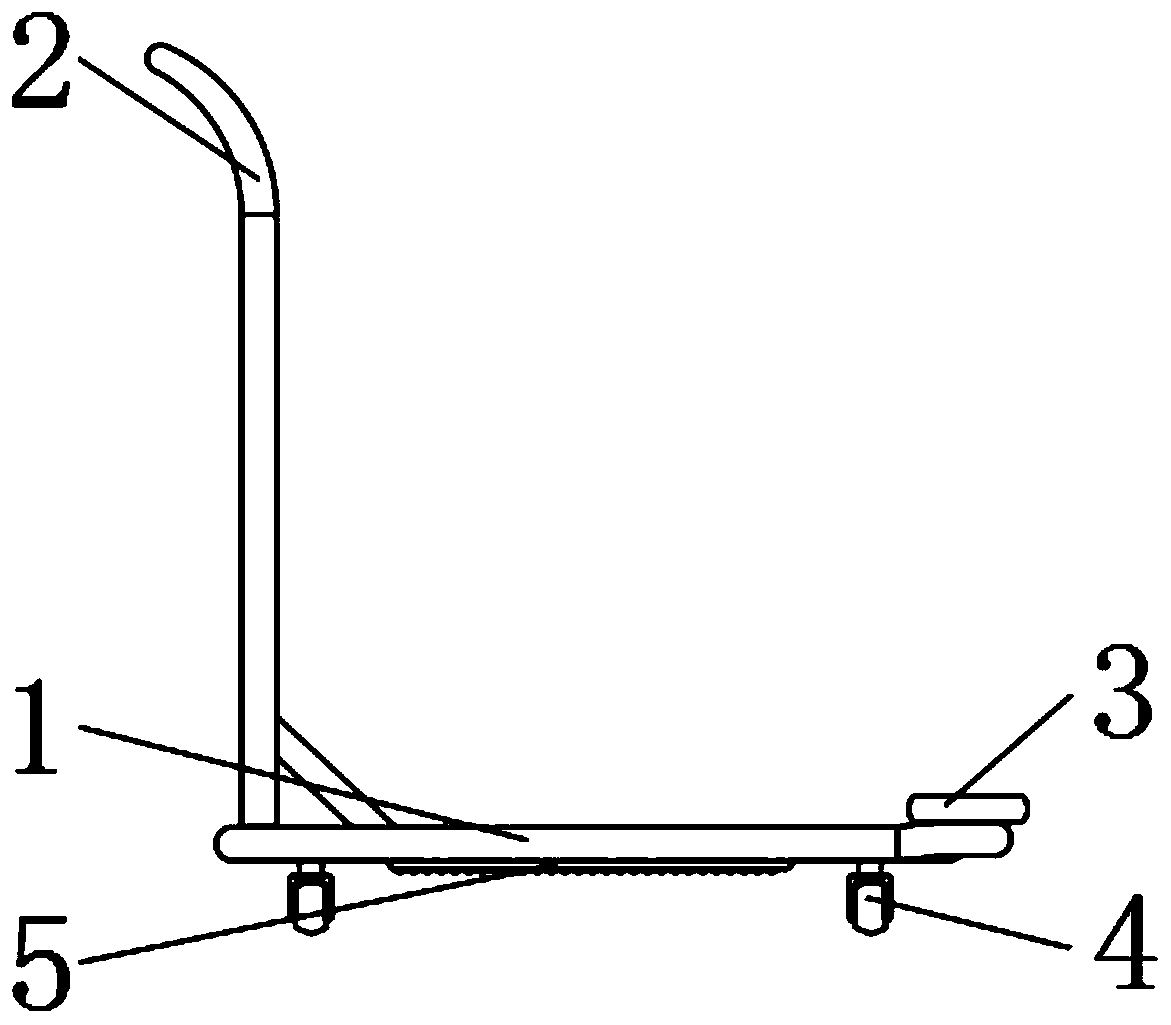

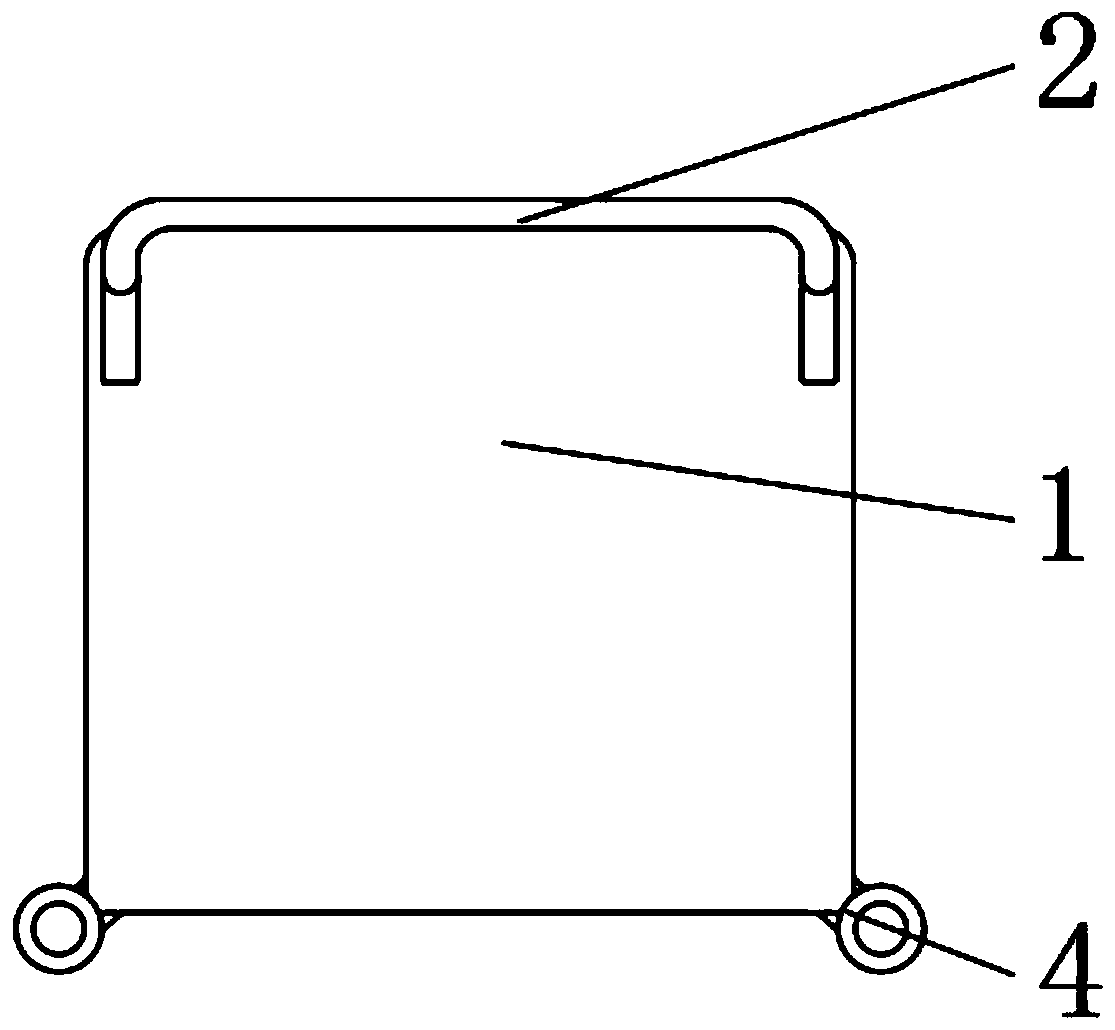

Turnover device

InactiveCN111232028ASimple structureEasy to operateHand carts with multiple axesHand cart accessoriesFriction reductionEngineering

The invention discloses a turnover device which comprises a turnover undercarriage, moving rollers are arranged on the outer surface of the lower end of the turnover undercarriage, a moving holding rod is fixedly connected to the outer surface of the upper end of the turnover undercarriage, and impact guide structures are arranged on the two sides of the turnover undercarriage. According to the turnober device, an impact guide structure and an anti-collision pad structure are arranged; when the turnover device is collided, the turnover device can rotate; the time for people to adjust the turnover device is reduced; people can conveniently and quickly adjust the movable turnover device to be straightened; the turnover efficiency of people is effectively improved; the turnover device is simple in structure and convenient to use, people can cross higher obstacles more conveniently, turnover of people is prevented from being hindered, sliding friction between the turnover chassis and the obstacles is effectively changed into rolling friction, friction is reduced, people can move the turnover device conveniently, use of people is facilitated, and better use prospects are brought.

Owner:杭州水力量科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com