Metal electroplating climbing production line

A production line and hardware technology, applied in the field of hardware electroplating climbing production line, can solve the problems of inability to react with wax, workpiece falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

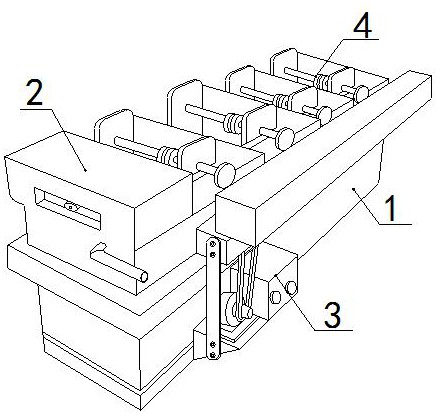

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The invention provides a hardware electroplating climbing production line, the structure of which includes a body 1, a cleaning tank 2, a distribution box 3, and a clamping device 4. The cleaning tank 2 is arranged on the top of the body 1, and the distribution box 3 is installed on the The front of the body 1 is on the left bottom, and four clamping devices 4 are respectively fixed on the top of the cleaning tank 2 .

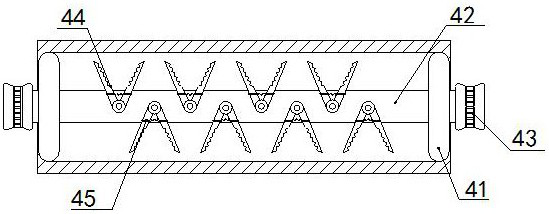

[0029] The clamping device 4 is provided with a fixed block 41, a bearing 42, a chain 43, a workpiece holder 44, and a wax removal device 45. The fixed block 41 is fixed on the inner walls of both sides of the clamping device 4, and the bearing 42 runs through the fixed block 41. The middle parts on both sides are movably matched with the chains 43 , and the workpiece clamps 44 are provided with eight pieces that are evenly distributed outside the bearing 42 , and the wax removal device 45 is sle...

Embodiment 2

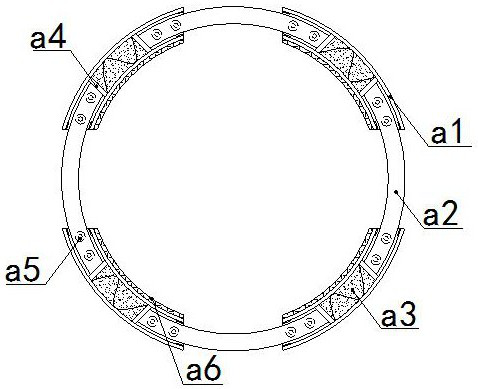

[0036] as attached Figure 6 to attach Figure 8 Shown:

[0037] Wherein, the baffle a4 is provided with a supporting spring e1, a stopper e2, a main rotating rod e3, a secondary rotating rod e4, and a slideway e5, and the supporting spring e1 respectively runs through the left and right sides of the baffle a4 and cooperates with the stopper e2. , the main rotating rod e3 is respectively installed on the four corners of the baffle a4, and the secondary rotating rod e4 is respectively installed on the surface and the inner bottom of the baffle a4 between the left side and the right side of the main rotating rod e3. The slideways e5 are respectively recessed on the top of the baffle a4 and opened at the inner bottom, the secondary rotating rods e4 are respectively located on the tops of both sides of the slideway e5, and the stopper e2 is provided with two symmetrically distributed on both sides of the baffle a4, with It is conducive to full contact with the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com