Environmentally-friendly anticorrosive treatment method for household wood slab

A technology of anti-corrosion treatment and wood board, applied in wood treatment, wood treatment details, machine tools suitable for grinding workpiece plane, etc. Service life, improved anti-corrosion effect, improved bonding adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

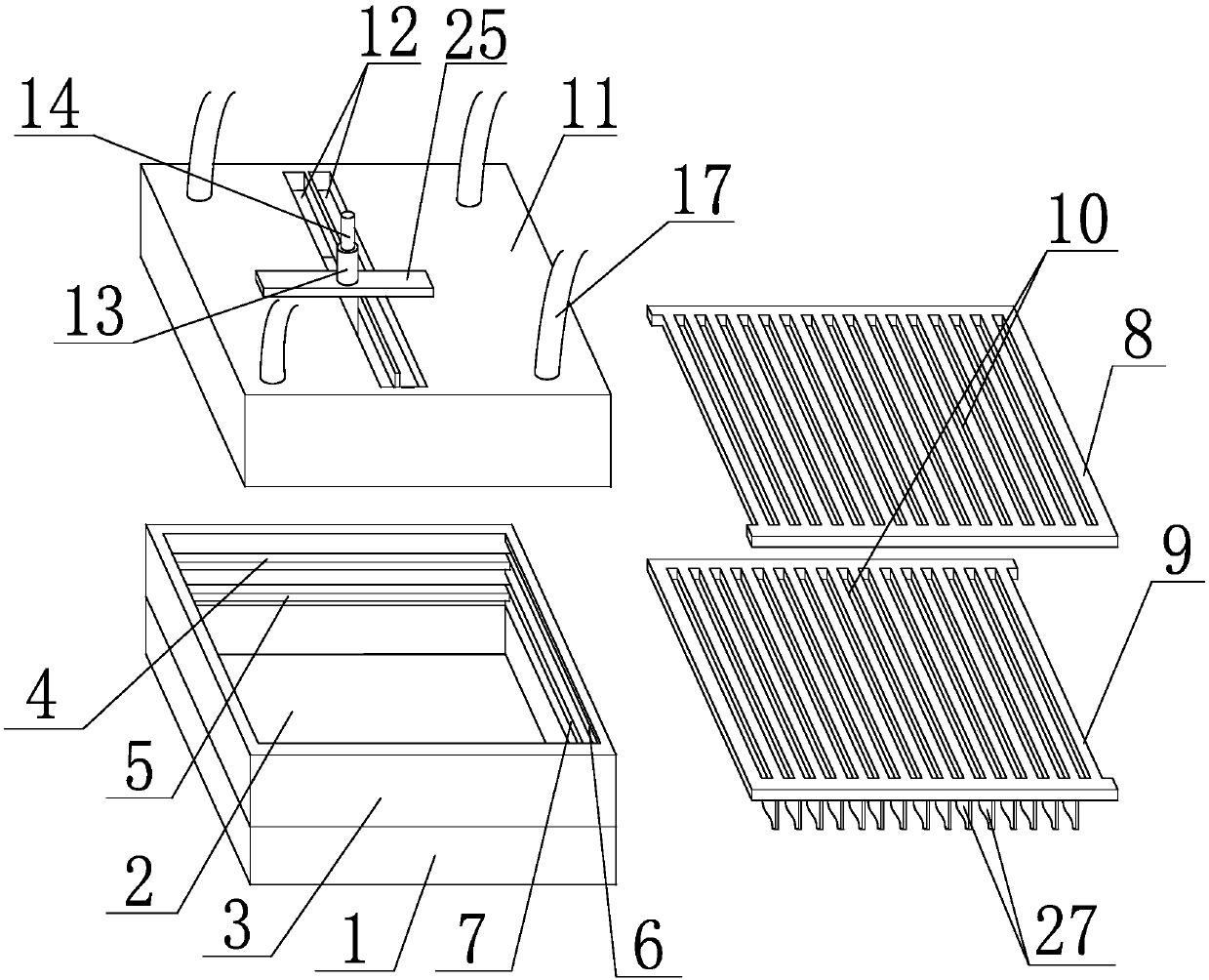

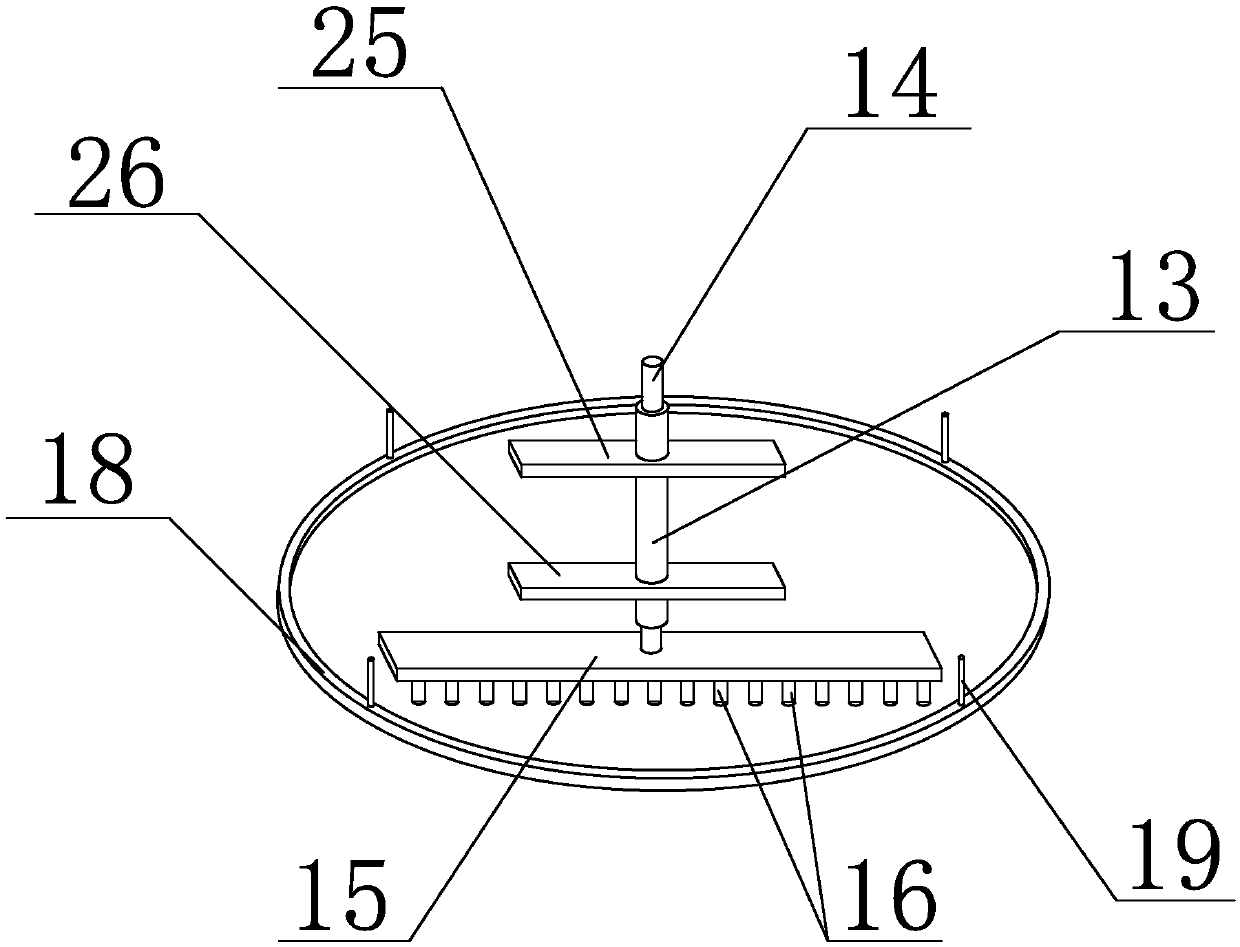

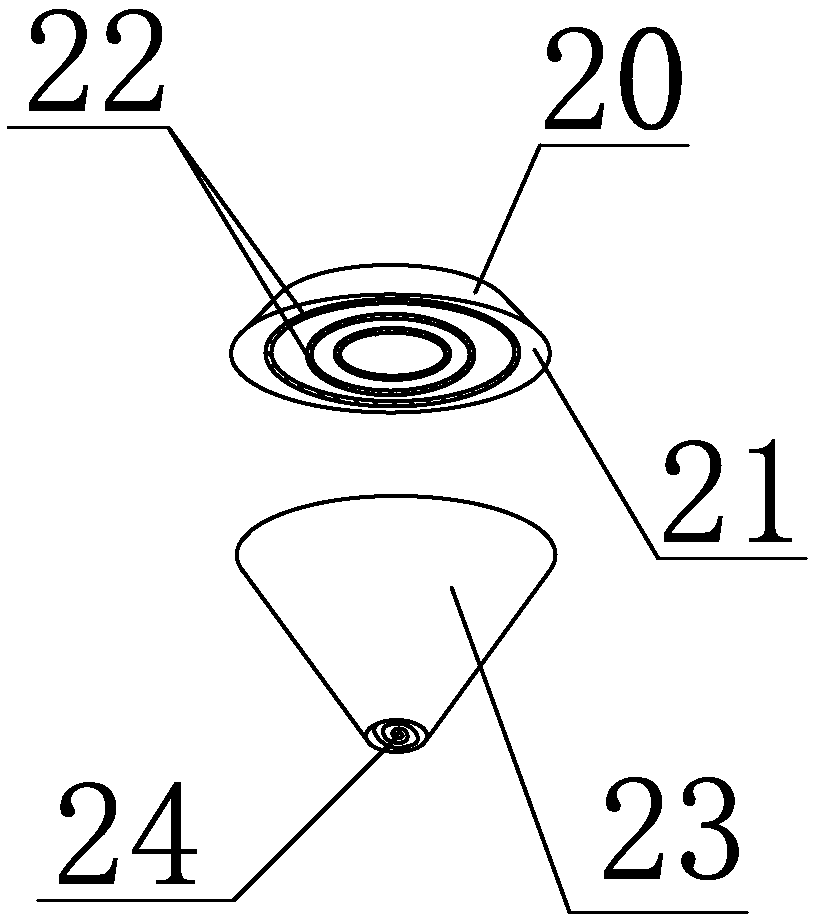

[0026] The environmental protection anti-corrosion treatment method for household wooden boards of the present invention includes the following steps: 1) cutting the wooden board to a suitable size, and polishing the surface until smooth; 2) dipping the wood wax oil with a cloth and rubbing a layer on the surface of the wooden board, Place it to dry at room temperature; 3) Use a spraying device to spray the anticorrosive coating on the surface of the wood. After spraying, the wood is taken out and placed at a temperature of 35-40℃ for drying, and then the surface of the wood is covered with a fresh-keeping film. And evenly poke small holes on the fresh-keeping film layer; then put the wooden board covered with the fresh-keeping film layer into the steam chamber, pass high-temperature steam into the steam chamber, and heat it to 110-115°C for 30-45 minutes after processing. Stop the high-temperature steam and let it stand in the steam room to cool down to 40-45℃. Take out the woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com