Plugging device, cab and engineering vehicle

A technology for blocking device and cab, applied in vehicle parts, transportation and packaging, etc., can solve the problem of low cab temperature, and achieve the effect of reducing energy consumption and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

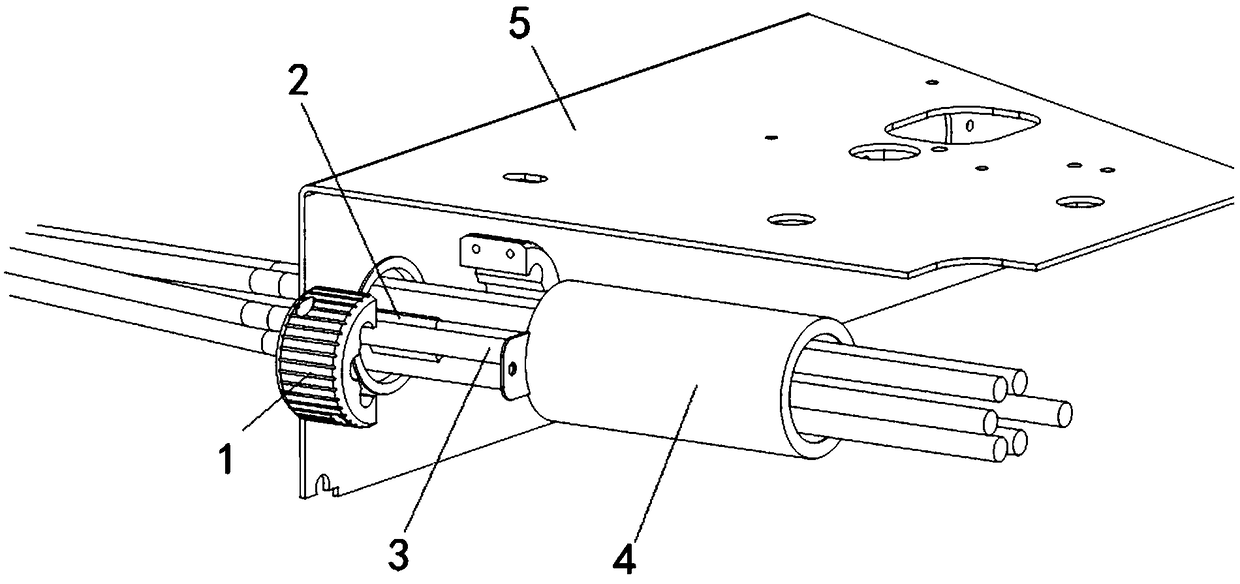

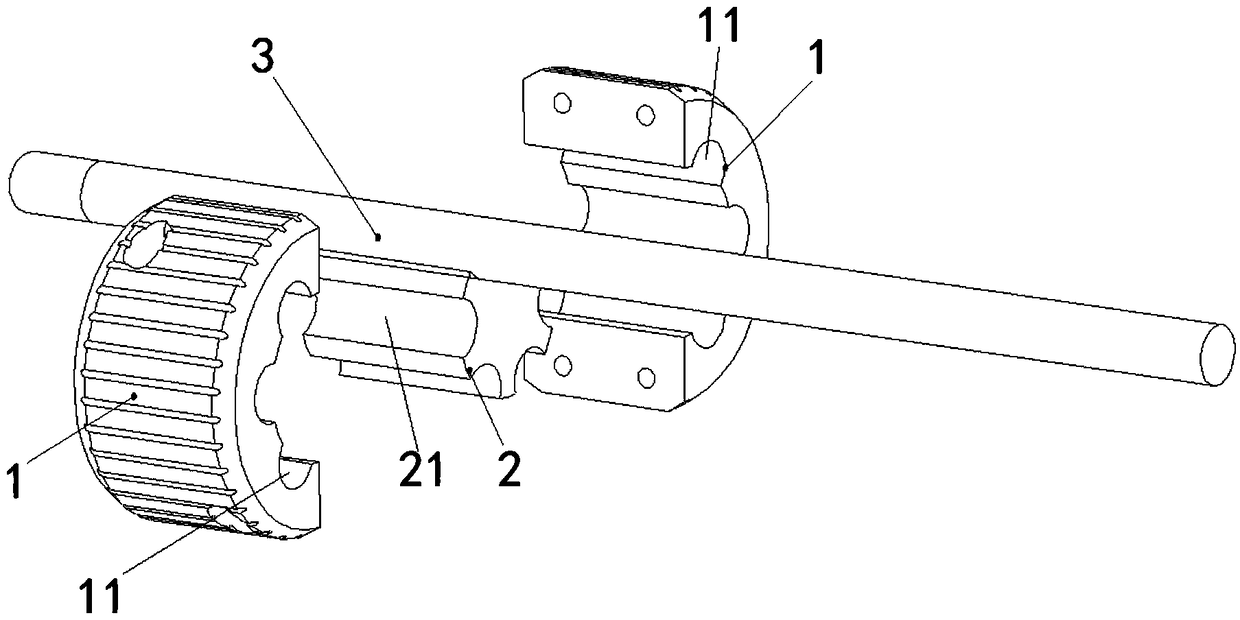

[0033] The blocking device provided in this embodiment, such as Figure 1 to Figure 2 As shown, it includes a sleeve 4 and a blocking assembly; the sleeve 4 is used to be arranged on the cab, and the sleeve 4 is arranged through the cab; the blocking assembly is arranged in the sleeve 4 for blocking the sleeve; A through hole for the pipe to pass is formed in the blocking assembly, and the pipe can move along the axial direction of the sleeve 4 .

[0034] Wherein, the shape of the sleeve 4 can be cylindrical, cubical, or any suitable shape such as elliptical cylindrical, and the outer contour of the plugging assembly can be cylindrical, cubical, or elliptical cylindrical, etc. Any suitable shape, as long as the plugging component can fill the gap between the inner wall of the sleeve 4 and the pipe material 3 .

[0035] The sleeve 4 is arranged on the cab and penetrates the cab. The pipe 3 that needs to be moved and installed in the cab (such as the hydraulic oil pipe connecte...

Embodiment 2

[0068] The cab provided in this embodiment includes the blocking device provided in Embodiment 1.

[0069] Wherein, the sleeve 4 runs through the outer wall of the cab and is fixedly connected with the outer wall of the cab, the pipe material 3 that needs to be moved and installed in the cab can extend out of the cab through the sleeve 4, and the pipe material 3 can move along the axial direction of the sleeve 4, The blocking assembly will not hinder the movement of the pipe material 3, so that the pipe material 3 in the cab can move normally, and the blocking assembly fills the gap between the inner wall of the sleeve 4 and the pipe material 3, which can prevent the air outside the cab from entering the interior of the cab, thereby Reduce the impact of external air on the air inside the cab, help maintain a suitable temperature inside the cab, and reduce energy consumption.

[0070] Specifically, the floor 5 of the driver's cab is provided with a through hole, the bottom plat...

Embodiment 3

[0074] The engineering vehicle provided in this embodiment includes the blocking device provided in Embodiment 1 or the cab provided in Embodiment 2.

[0075] Wherein, the sleeve 4 is arranged on the driver's cab and is arranged through the driver's cab. The pipe material 3 in the driver's cab can protrude out of the driver's cab through the sleeve 4, and the pipe material 3 can move along the axial direction of the sleeve 4. The plugging assembly will not The assembly of the pipe 3 hinders the normal movement of the pipe 3 in the cab, and the plugging assembly fills the gap between the inner wall of the sleeve 4 and the pipe 3, which can prevent the air outside the cab from entering the interior of the cab, thereby reducing the impact of external air on the driver. The influence of the air inside the cabin helps maintain a suitable temperature inside the cab, helps engineering vehicles maintain a suitable working condition, and reduces energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com