Harvester

A harvester and harvesting part technology, applied in the field of harvesters, can solve the problems of hooking on the bumps or clods on the ground, easy to act on the sensor support parts such as ground sensors, etc., to avoid the action. bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

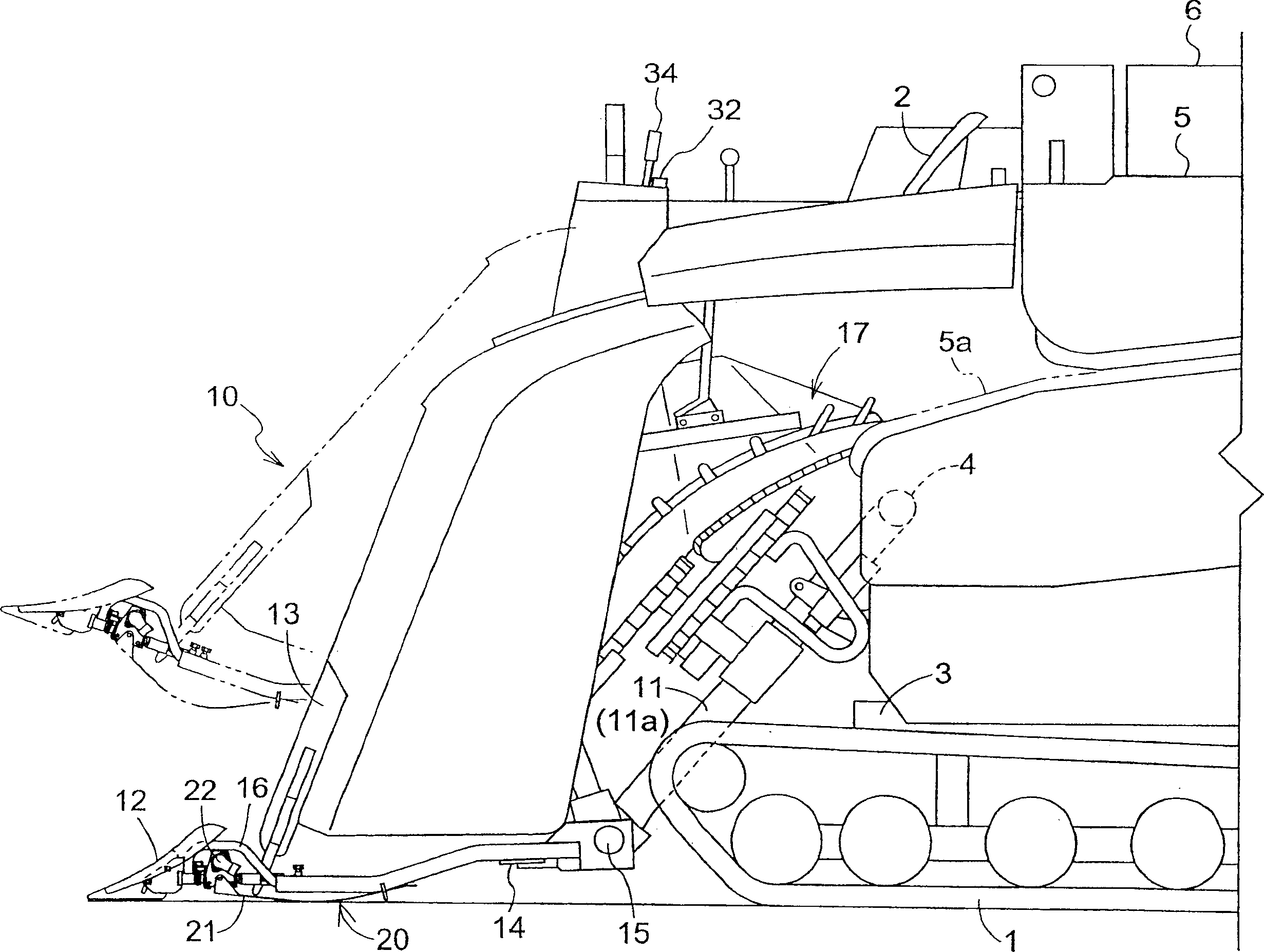

[0042] Such as figure 1 As shown, this Combine harvester consists of a ride-on driver's part equipped with a driver's seat 2 and an engine (the Not shown) of the prime mover constituted. On the support part 4 positioned at the front part of the body frame 3, the base end part of the pretreatment part frame 11 of the harvesting part 10 is connected freely around the horizontal axis. On the rear end side of the body frame 3, a threshing device 5 and a grain tank 6 for storing grains such as rice and wheat after threshing are provided.

[0043] A piston rod of a hydraulic lifting cylinder (corresponding to a hydraulic cylinder) 8 is connected to the above-mentioned preprocessing part frame 11 . By telescopically operating the lifting cylinder 8, the pre-processing unit frame 11 swings in the up and down direction, thereby lowering the harvesting unit 10 to a working position close to the ground and lifting the harvesting unit 10 from the ground to a non-working position. Betw...

no. 2 Embodiment approach

[0066] Figure 10 The harvesting part 10 of the Combine harvester which concerns on 2nd Embodiment of this invention is shown. In this harvesting section 10, except for the location and the number of installations of the harvesting section's height-to-ground detection device 20, the rest of the structure is the same as that of the above-mentioned Kangbaiying harvester in the first embodiment. Below, only the differences will be described. point.

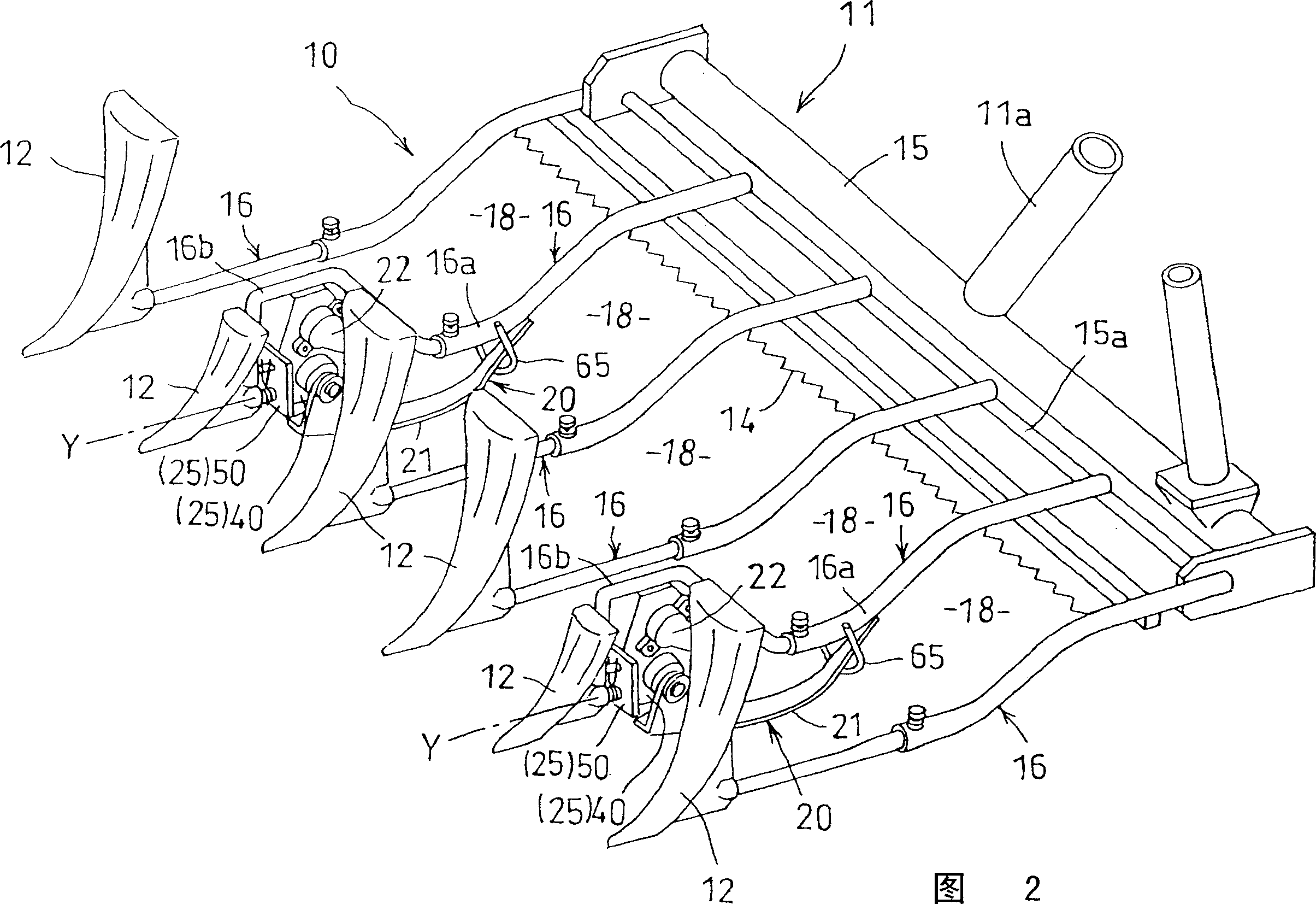

[0067] That is, the height detection device 20 of the harvesting section to the ground is arranged in a plurality of grass-distributing frames 16 arranged in the lateral direction of the body, and is also a plurality of grass-distributing frames inside the body than the two outermost grass-distributing frames 16 positioned in the lateral direction of the body. 16 on the front end.

[0068] In this way, if a plurality of detection devices 20 for the height of the harvesting section to the ground are installed, even if the ground sen...

no. 3 Embodiment approach

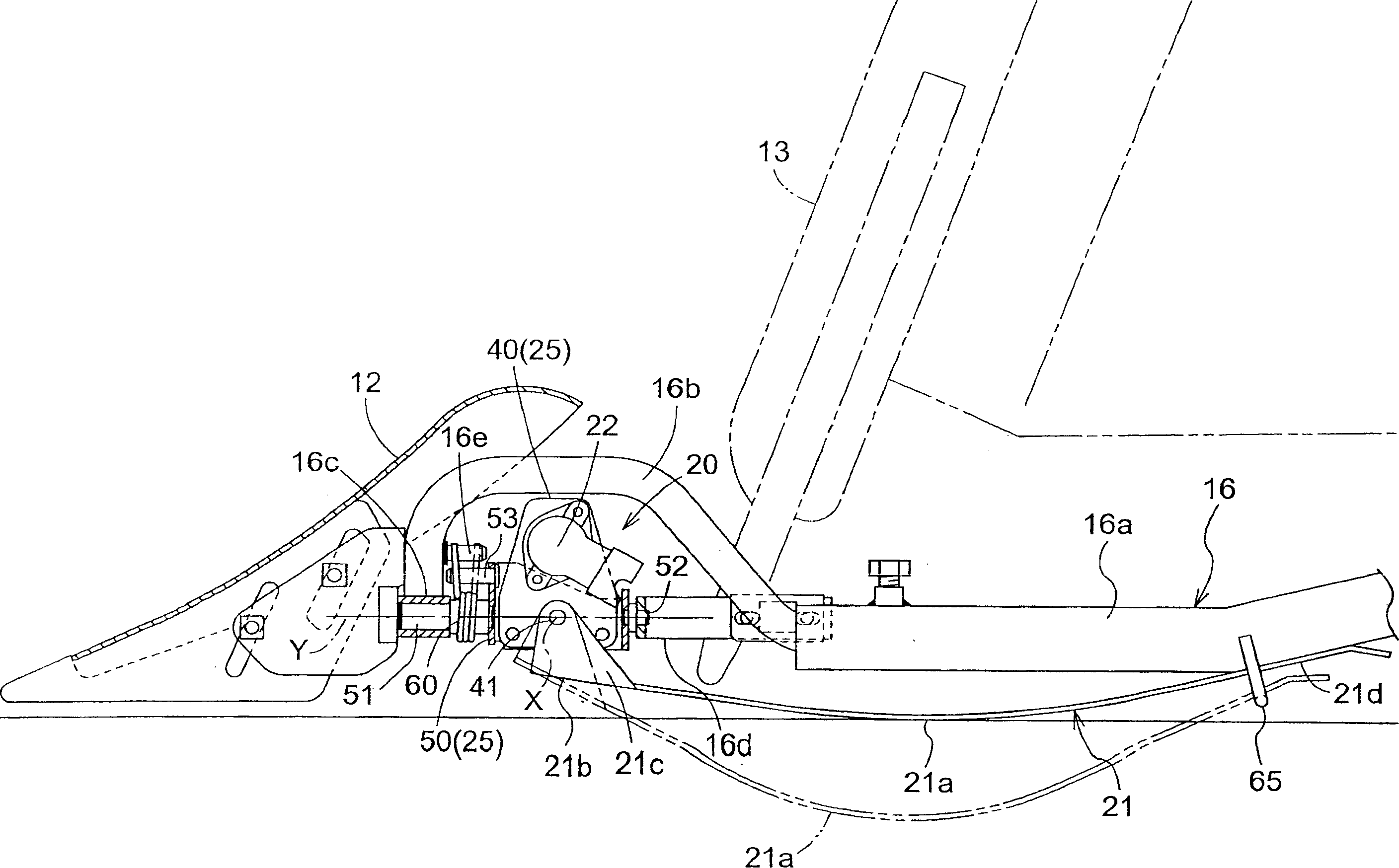

[0070] Figure 11 , FIG. 12 has shown the main part of the harvesting part height detection apparatus 20 in the Combine harvester which concerns on 2nd Embodiment of this invention. Among them, a brake bolt (an example of a stopper) 55 is attached to the bearing portion 40a of the gear box 40 supporting one end side of the input shaft 41 . The stop bolt 55 plays a blocking role relative to the flat portion 41 a provided at the end of the input shaft 41 inside the gearbox 40 . Thereby, a structure is formed in which the lowering limit of the ground contact sensor 21 can be freely adjusted and set so that the ground contact sensor 21 becomes the lowering limit when the detection unit 22 reaches the operation limit.

[0071] That is to say, even in the state where the ground sensor 21 is still grounded, the operating force that makes the automatically traveling body retreat and swing downward continues to act on the ground sensor 21, and as the ground sensor 21 descends and swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com