A non-metal bulletproof board

A bulletproof board and non-metallic technology, which is applied in the direction of protective equipment, armor plate structure, offensive equipment, etc., can solve the problems of high bulge height and weight reduction of non-metallic bulletproof board, so as to reduce the height of bulge and reduce the risk of injury , to meet the effect of bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

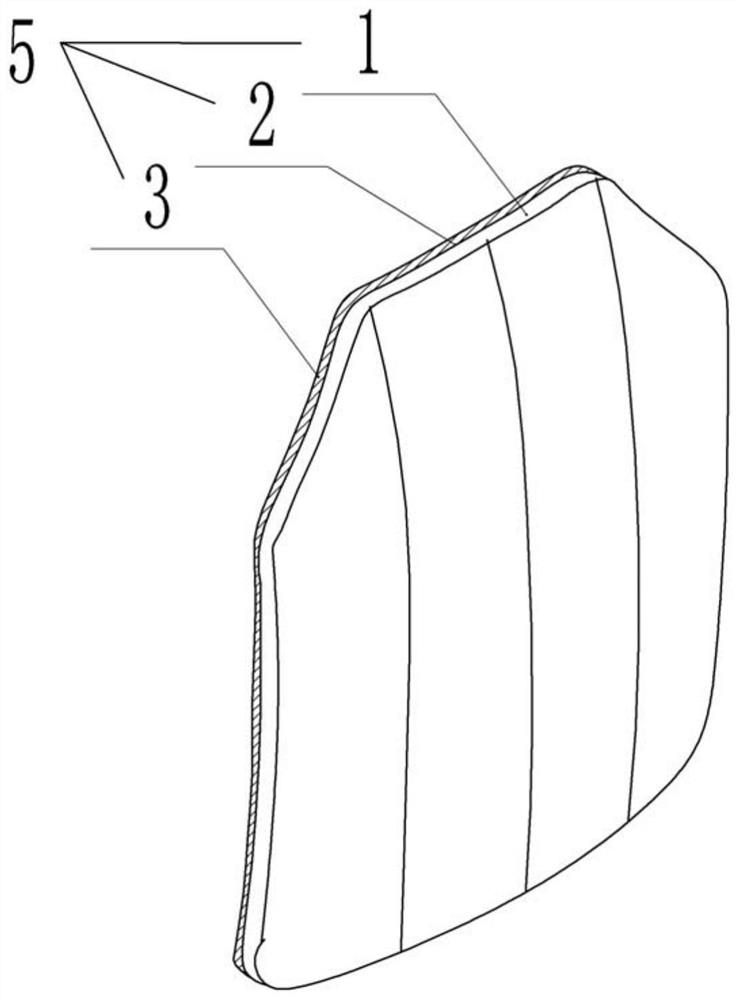

[0026] Basic as attached figure 1 Shown: a non-metallic bulletproof board, including a board body 5, the board body 5 sequentially includes an anti-bulge layer 1 and an adhesive layer 2 from the inside (the part close to the chest) to the outside (the part away from the chest) And the buffer layer 3, the anti-bulging layer 1, the adhesive layer 2 and the buffer layer 3 are thermocompressed and compositely formed. The adhesive layer 2 in this embodiment is a hot-melt adhesive film, and the anti-bulge cladding layer 1 and buffer layer 3 are formed by several layers of high-strength and high-modulus polyethylene non-weft fabrics by hot pressing. The high-strength and high-modulus polyethylene non-weft fabrics can be selected from Sinopec Yizheng Chemical Fiber Co., Ltd. manufactures. In this embodiment, the thickness of the anti-bulging layer 1 of the board body 5 is 9 mm, the thickness of the buffer layer 3 is 18 mm, and the surface density of the high-strength high-modulus pol...

Embodiment 2

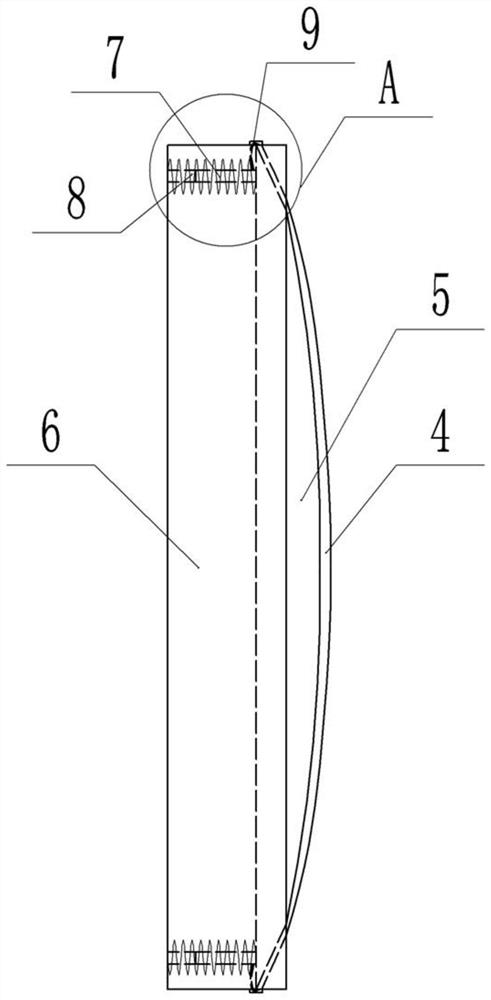

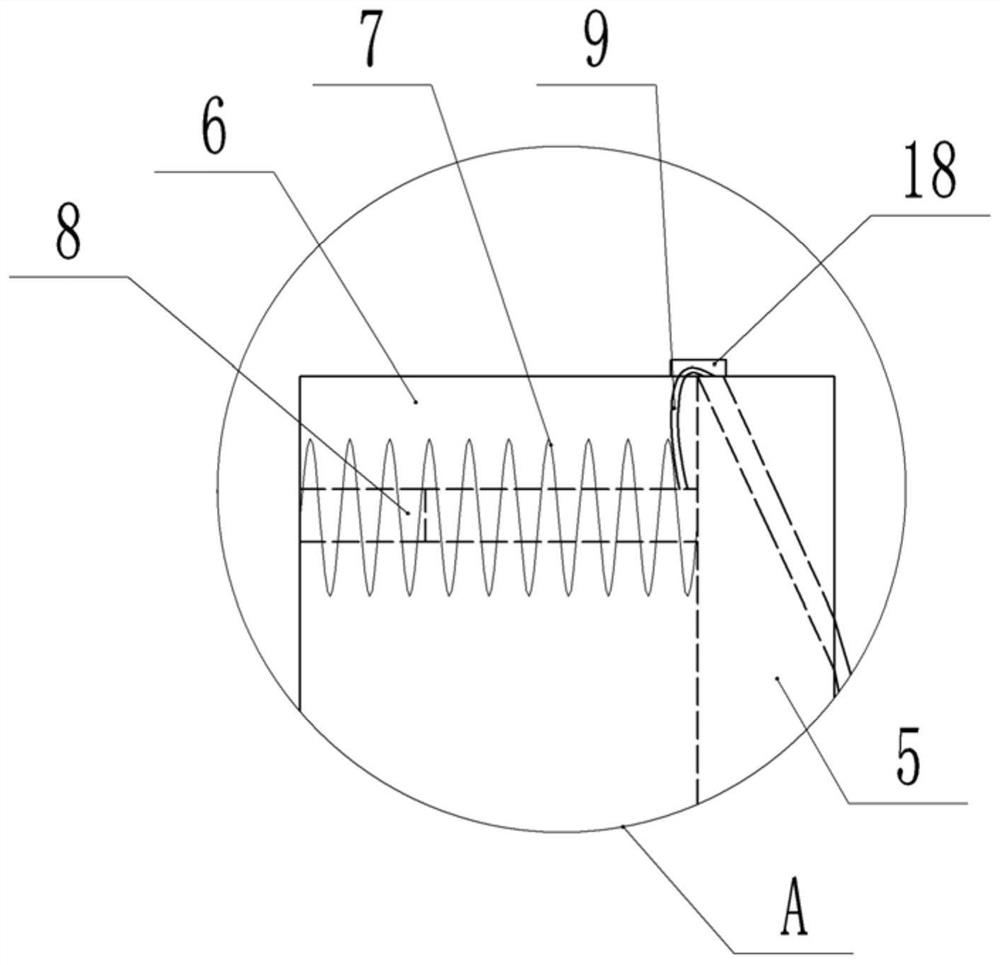

[0038] combine Figure 2-Figure 4 As shown, the non-metal bulletproof board in this embodiment also includes an outer shell 6, the outer shell 6 is a pentahedron, the inside of the outer shell 6 is provided with a cavity, and the right side of the outer shell 6 is provided with an opening communicating with the cavity , the body formation and size of the cavity inside the outer casing 6 match the board body 5, so that the board body 5 can be completely inserted into the cavity, the board body 5 is located in the cavity, and the buffer layer 3 of the board body 5 faces The outer side of outer casing 6 ( figure 2 The middle is the right side), the left side of the board body 5 and the bottom of the cavity are connected with a telescopic piece 8 and an elastic piece 7, and the telescopic piece 8 is provided with a locking unit, combined with image 3 and Figure 4 As shown, the telescopic member 8 in this embodiment includes a first sliding tube 11 and a second sliding tube 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com