Overturning clamp for packaging chip

A technology for flipping jigs and chips, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., and can solve problems such as low effect, easily damaged leads, and heavy workload of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

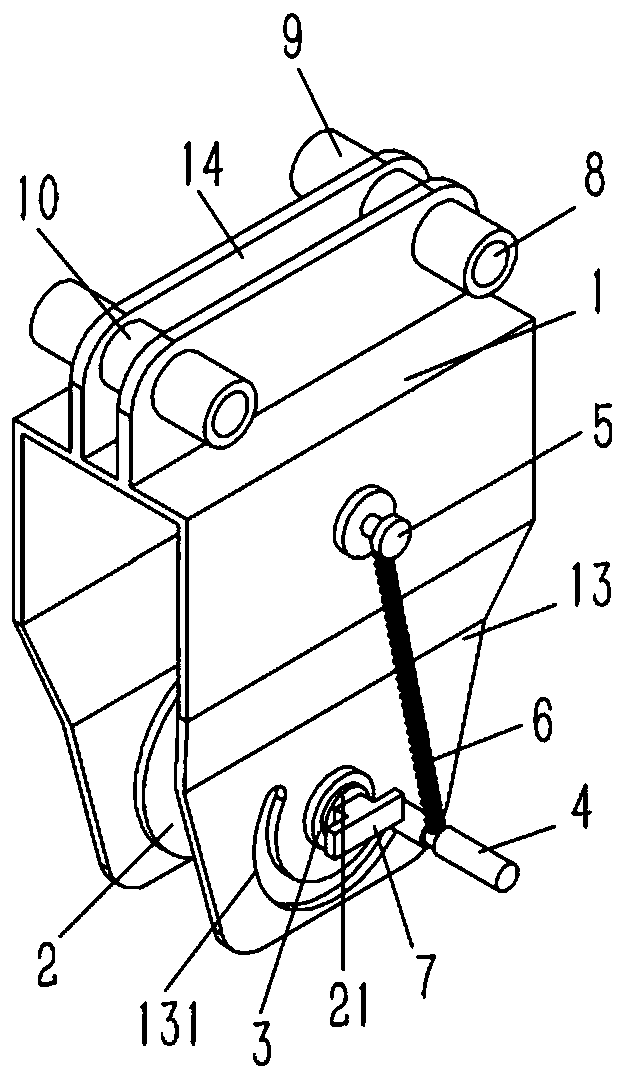

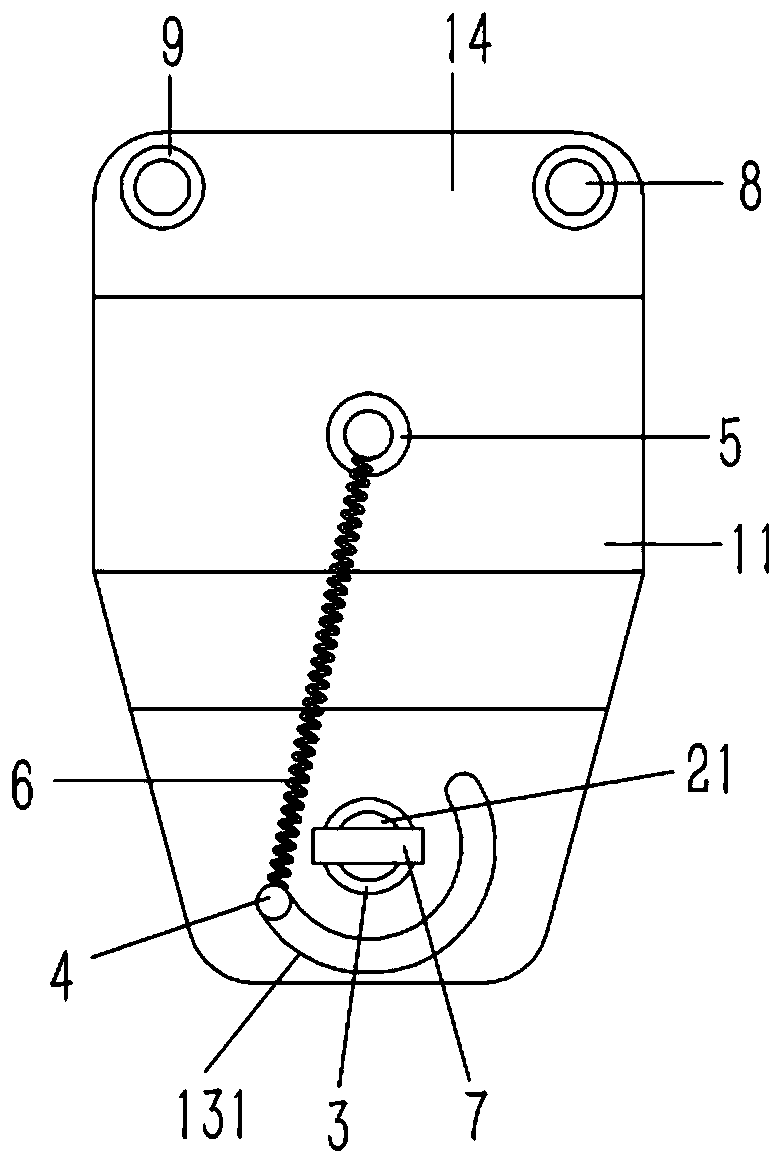

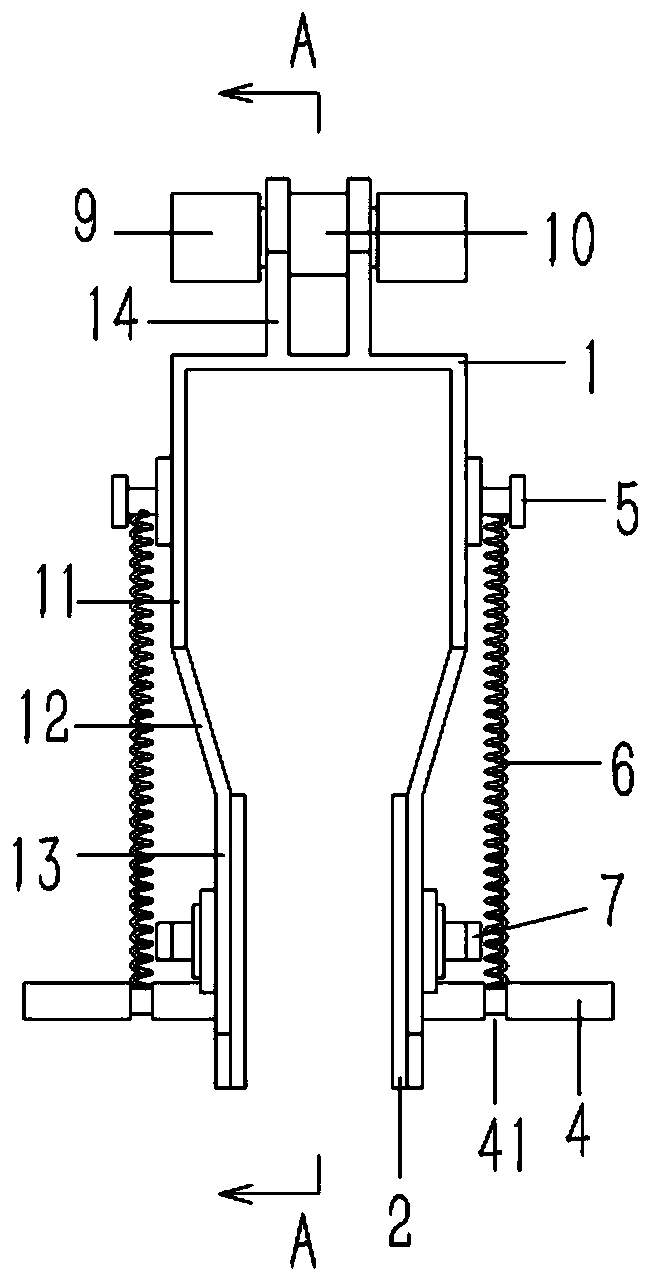

[0019] Example: see Figures 1 to 4 As shown, a flipping jig for packaged chips includes a horizontal top plate 1, the two sides of the top plate 1 are bent and formed with vertical side plates 11, and the lower side of the side plate 11 is bent and formed with an inwardly inclined oblique elastic Plate 12, the lower side of the inclined elastic plate 12 is bent to form a vertical splint 13, the inner wall of the splint 13 is against a circular support plate 2, and the middle part of the outer wall of the support plate 2 is formed with a fulcrum 21, The supporting shaft 21 passes through the splint 13 and fixes the limit sleeve 3. The splint 13 on the lower side of the supporting shaft 21 is formed with an arc-shaped guide groove 131, and a cylindrical driving rod 4 is inserted in the guiding groove 131. The inner end of the driving rod 4 is fixed on the support plate 2; the spring 6 is fixedly connected to the driving rod 4, the other end of the spring 6 is fixed on the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com