Die casting aluminum part

A technology for casting aluminum parts and aluminum parts, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, and damage prevention measures of lighting devices, etc. The screws are rusted to the aluminum parts of the shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

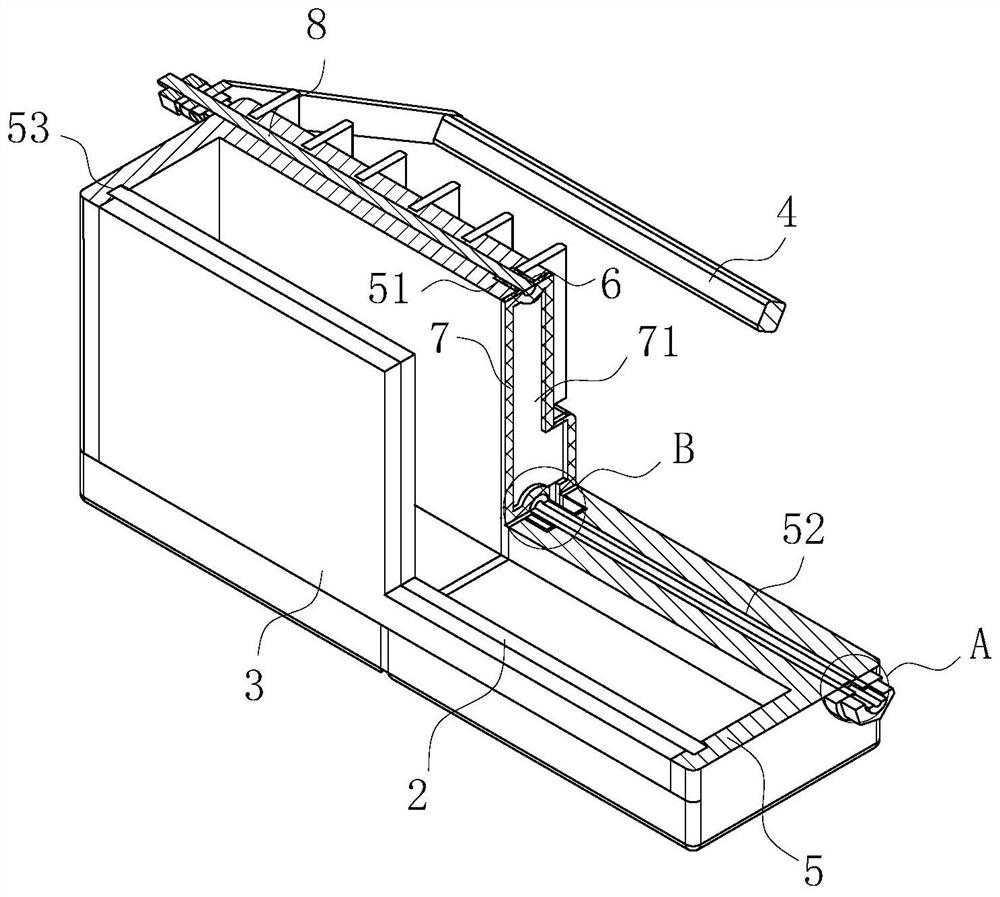

[0028] As an embodiment of the present invention, the rubber sealing strip 6 is provided with an expansion chamber 61, and the rubber sealing strip 6 is provided with a plurality of frosted convex films 62; There is a gap cavity 63 between them, and the gap cavity 63 is connected to the expansion cavity 61 through the air guide groove; the expansion cavity 61 communicates with the extrusion cavity 71; When shrinking, the gas inside the extrusion cavity 71 will enter the expansion cavity 61, and then enter the gap cavity 63 inside the frosted convex film 62 through the expansion cavity 61, so that the frosted convex film 62 is expanded and squeezed to fit In the insertion cavity 51 , the frictional resistance between the rubber sealing strip 6 and the insertion cavity 51 is further improved, and the insertion stability of the rubber sealing strip 6 inserted into the insertion cavity 51 is further improved.

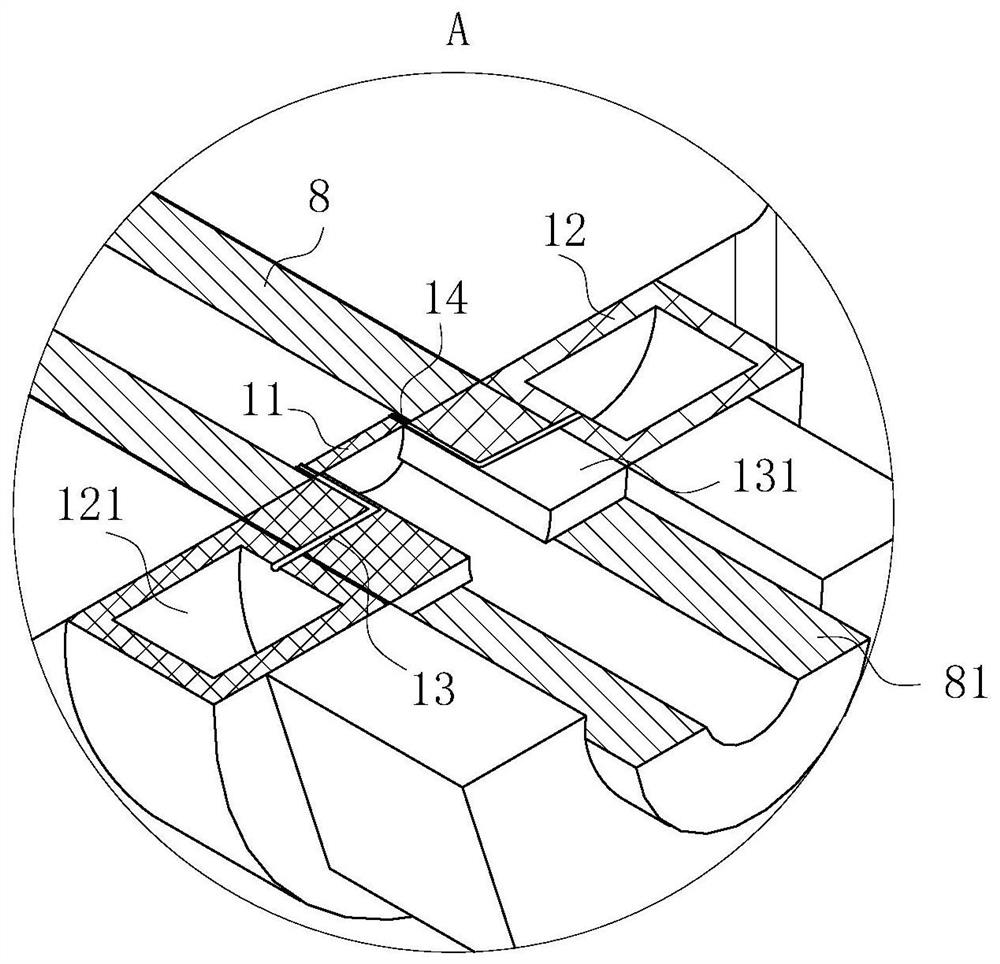

[0029] As an embodiment of the present invention, the connection betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com