Patents

Literature

34results about How to "Improve the tightness of use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improved charging pile for electric vehicles

InactiveCN108471017AAvoid enteringExtended service lifeVehicle connectorsCharging stationsEngineeringElectric vehicle

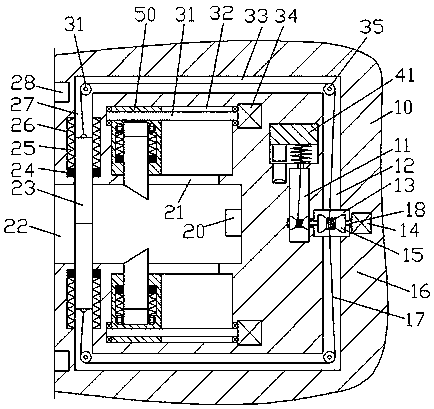

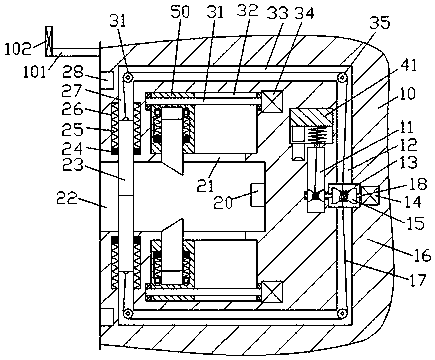

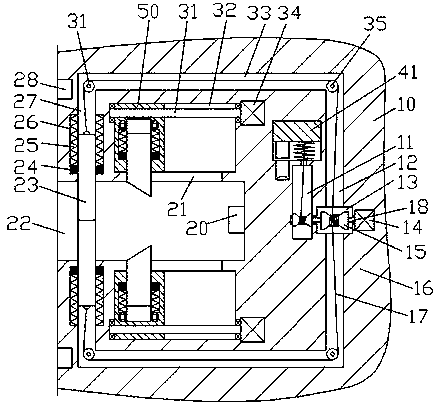

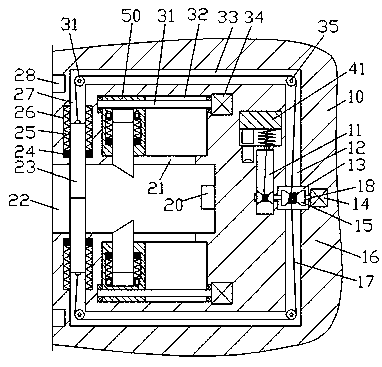

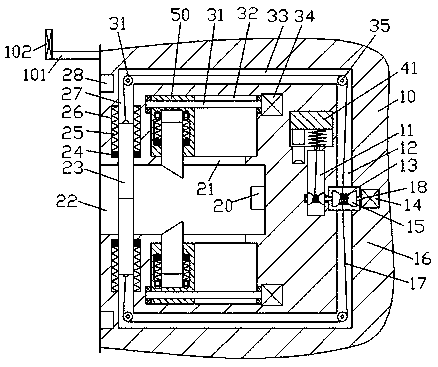

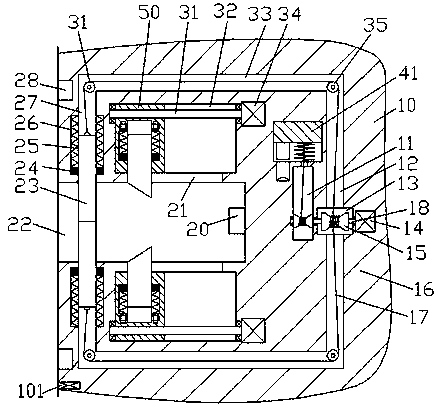

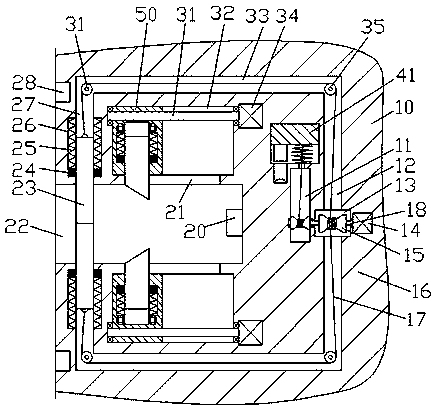

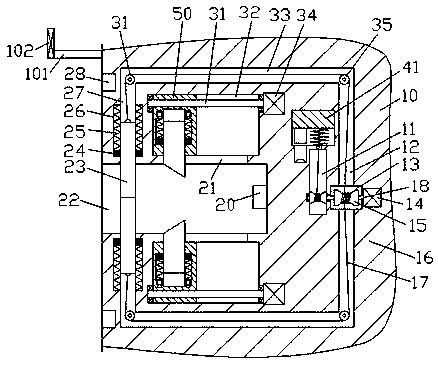

The invention discloses an improved charging pile for electric vehicles. The improved charging pile comprises a charging pile body and a charging gun connected to the charging pile body in a pluggingmatching manner, wherein a plugging cavity is formed in the left side end surface of the charging pile body, a power connection block is fixedly arranged on the right inner wall of the plugging cavity, first sliding slots are symmetrically formed in the upper and lower inner walls of the plugging cavity, stopping blocks are mounted in the first sliding slots in the sliding fit manner, first guiding and sliding slots are symmetrically are formed in the left and right inner walls of each first sliding slot, first guiding and sliding blocks fixedly connected with the stopping blocks are mounted in the first guiding and sliding slots in a sliding fit manner, a first ejection spring is connected to one side, away from the plugging cavity, of each first guiding and sliding block in an ejection manner, and the tail end of one side, away from the plugging cavity, of each sliding slot extends rightwards to form a second sliding slot.

Owner:江苏卓燃高新科技有限公司

Improved charging pile for electric vehicles

InactiveCN108471018AAvoid enteringExtended service lifeVehicle connectorsCharging stationsElectric vehicleElectrical and Electronics engineering

The invention discloses an improved charging pile for electric vehicles. The improved charging pile comprises a charging pile body and a charging gun connected to the charging pile body in a pluggingmatching manner, wherein a plugging cavity is formed in the left side end surface of the charging pile body, a power connection block is fixedly arranged on the right inner wall of the plugging cavity, first sliding slots are symmetrically formed in the upper and lower inner walls of the plugging cavity, stopping blocks are mounted in the first sliding slots in the sliding fit manner, first guiding and sliding slots are symmetrically are formed in the left and right inner walls of each first sliding slot, first guiding and sliding blocks fixedly connected with the stopping blocks are mounted in the first guiding and sliding slots in a sliding fit manner, a first ejection spring is connected to one side, away from the plugging cavity, of each first guiding and sliding block in an ejection manner, and the tail end of one side, away from the plugging cavity, of each sliding slot extends rightwards to form a second sliding slot.

Owner:江苏卓燃高新科技有限公司

Novel charging pile for electric vehicles

InactiveCN108437844AAvoid enteringExtended service lifeCharging stationsElectric vehicle charging technologyElectric vehicleElectrical and Electronics engineering

The invention discloses a novel charging pile for electric vehicles. The novel charging pile comprises a charging pile body and a charging gun connected on the charging pile body in an inserting and matching manner, wherein an inserting cavity is arranged in the end surface of the left side of the charging pile body; a power connecting block is fixedly arranged on the inner wall of the right sideof the inserting cavity; first sliding grooves are symmetrically arranged in the upper inner wall and the lower inner wall of the inserting cavity; stoppers are arranged in the first sliding grooves in a sliding-matching manner; first guiding and sliding grooves are symmetrically arranged in the inner walls of the left sides and the right sides of the first sliding grooves; the first guiding and sliding grooves are internally provided with first guiding and sliding blocks fixedly connected with the stoppers in a sliding-matching manner; one side of each first guiding and sliding block, separated from the inserting cavity, is connected with a first jacking spring in a jacking-matching manner; the tail end of one side of each first sliding groove, is provided with a second sliding groove ina manner of extending rightwards.

Owner:江苏卓燃高新科技有限公司

Improved electric vehicle charging pile

InactiveCN108482178AAvoid enteringExtended service lifeVehicle connectorsCharging stationsElectric vehicleElectrical and Electronics engineering

The invention discloses an improved electric vehicle charging pile. The electric vehicle charging pile comprises a charging pile body and a charging gun which is cooperatively inserted and connected to the charging pile body. An insertion cavity is formed in the left end surface of the charging pile body, a power receiving block is fixedly arranged on the inner wall of the right side of the insertion cavity, first sliding grooves are symmetrically formed in the upper and lower inner walls of the insertion cavity, and stopping blocks are slidingly and cooperatively mounted in the first slidinggrooves; first guide sliding grooves are symmetrically formed in the left and right inner walls of the first sliding grooves, and first guide sliding blocks fixedly connected with the stopping blocksare slidingly and cooperatively mounted in the first guide sliding grooves. First jacking pressing springs are cooperatively connected to the sides, away from the insertion cavity, of the first guidesliding blocks in a jacking pressing mode, and second sliding grooves extending rightwards are formed in the tail ends of the sides, away from the insertion cavity, of the first sliding grooves.

Owner:江苏卓燃高新科技有限公司

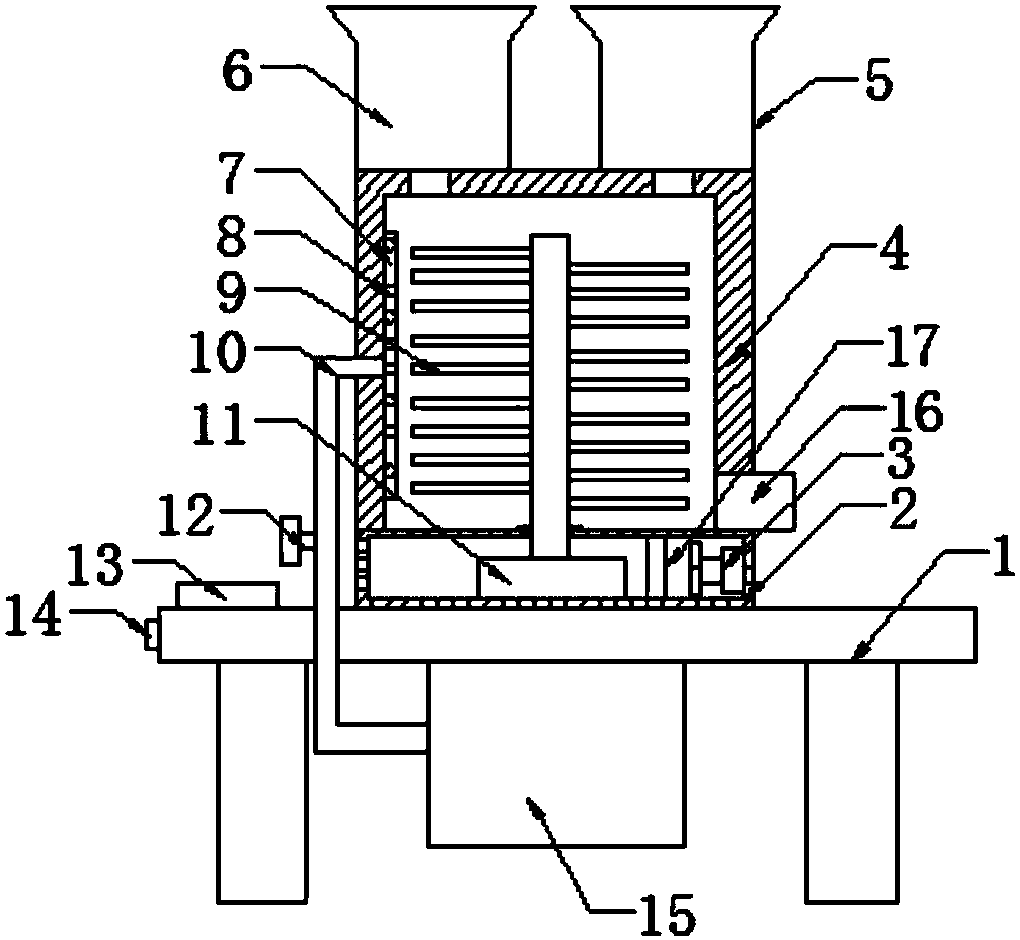

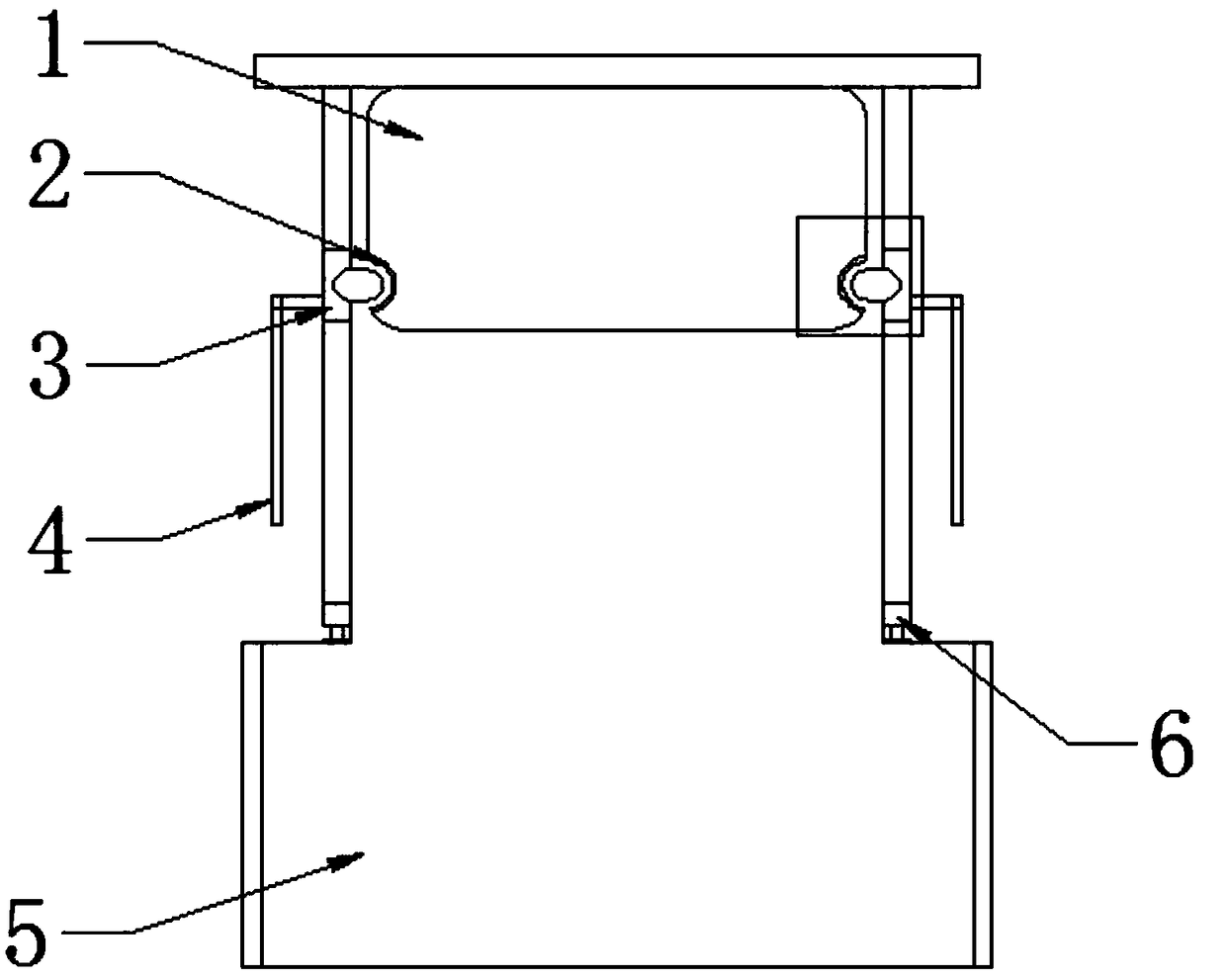

Sand mixing machine for casting

PendingCN107661961AImprove cooling effectClean in timeMould handling/dressing devicesWater storageWater storage tank

The invention provides a sand mixing machine for casting. The sand mixing machine comprises a work table, an inner cavity, a sand mixing box, an old sand cabin and a new sand cabin, wherein the sand mixing box is arranged at the upper end surface of the work table; the old sand cabin is arranged at the right side of the upper end surface of the sand mixing box; the new sand cabin is arranged at the left side of the upper end surface of the sand mixing box; an inner cavity is formed in the bottom position of the sand mixing box; a rotating motor is assembled in the middle position inside the inner cavity; a stirring blade is arranged inside the sand mixing box; a water storage box is assembled right under the work table; the left end surface of the water storage box is connected with a first water outlet pipe; a water pumping pump is arranged at the left end surface of the first water outlet pipe; a second water outlet pipe is arranged at the inner wall of the sand mixing box; a plurality of groups of high-pressure spray heads are assembled on the outer surface of the second water outlet pipe; the first water outlet pipe is connected with the second water outlet pipe. Through the design, the residues on the outer surface of the stirring blade can be conveniently cleaned in time; the influence on the stirring efficiency caused by the residue attached onto the stirring blade can be prevented. The structure is reasonable; the installation is convenient; the reliability is high.

Owner:六安市鸿圣铸造有限责任公司

Electric vehicle charging pile

InactiveCN108528260AAvoid enteringExtended service lifeCharging stationsElectric vehicle charging technologyElectricityEngineering

The invention discloses an electric vehicle charging pile which comprises a charging pile body and a charging gun connected with the charging pile body in an inserted and matched manner. An insertingcavity is formed in the end surface of the left side of the charging pile body, an electricity connecting block is fixedly arranged on the inner wall of the right side of the inserting cavity, first sliding grooves are symmetrically formed in the upper inner wall and the lower inner wall of the inserting cavity, stoppers are slidably mounted in the first sliding grooves in a matched manner, firstguide sliding grooves are symmetrically formed in the inner walls of the left sides and the right sides of the first sliding grooves, first guide sliders fixedly connected with the stoppers are slidably mounted in the first guide sliding grooves in a matched manner, a first top pressing spring is connected on one side, far away from the inserting cavity, of each first guide slider in a top pressing and matched manner, and the tail end of one side, far away from the inserting cavity, of each first sliding groove extends rightwards and is provided with a second sliding groove.

Owner:江苏卓燃高新科技有限公司

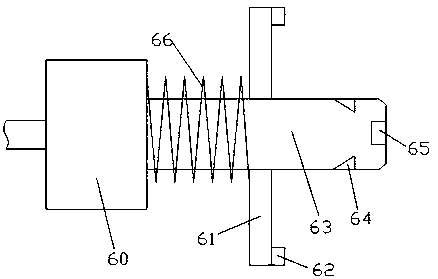

Air purifier

InactiveCN109038059AAvoid enteringExtended service lifeLighting and heating apparatusCouplings bases/casesAir purifiersMechanical engineering

The invention discloses an air purifier, which comprises a case body and a clamping connector connected with the case body in an insertion matching mode, An insertion cavity is arranged in the end surface of the left side of the case body, A power feed block is fixedly arrange on the inner wall of the right side of the insertion cavity, A first sliding cavity is symmetrically arranged within the upper and lower inner walls of the insertion cavity, A shield plate is arranged is mounted in the first sliding cavity in sliding fit, first guide grooves are symmetrically arranged in the inner wallsof the left and right sides of the first sliding cavity, A first guide block fixedly connected with the shield plate is mounted in the first guide grooves in sliding fit, a first elastic piece is connected in top press fit with one side of the first guide block which is far away from the insertion cavity, and a second sliding cavity is arranged on the tail end of one side of the first sliding cavity which is far away from the insertion cavity and extending rightward.

Owner:广州上同环保科技有限公司

Control system of 3D laser carving machine

InactiveCN108817704AAvoid enteringExtended service lifeCouplings bases/casesLaser beam welding apparatusControl systemEngineering

The invention discloses a control system of a 3D laser carving machine. The control system comprises a base and a connecting part connected to the base in an inserted and matched mode. The end face ofthe left side of the base is provided with an insertion cavity. An electric connecting block is fixedly arranged on the inner wall of the right side of the insertion cavity. The upper and lower innerwalls of the insertion cavity are internally and symmetrically provided with first sliding grooves. Cover plates are mounted in the first sliding grooves in a sliding fit mode. The inner walls of theleft and right sides of each first sliding groove are internally and symmetrically provided with first guide grooves. First guide blocks fixedly connected with the cover plates are mounted in the first guide grooves in a sliding fit mode. The sides, far away from the insertion cavity, of the first guide blocks abut against and are connected with first compression springs in a matched mode. The tail end of the side, far away from the insertion groove, of each first sliding groove extends rightwards to be provided with a second sliding groove.

Owner:广州广林科技有限公司

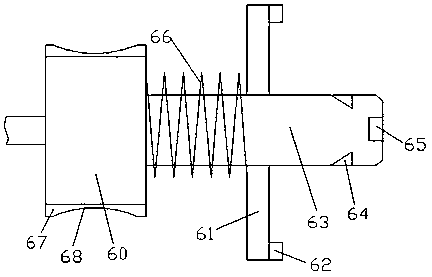

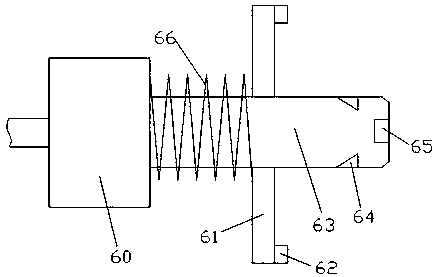

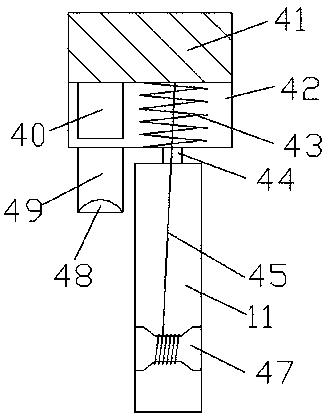

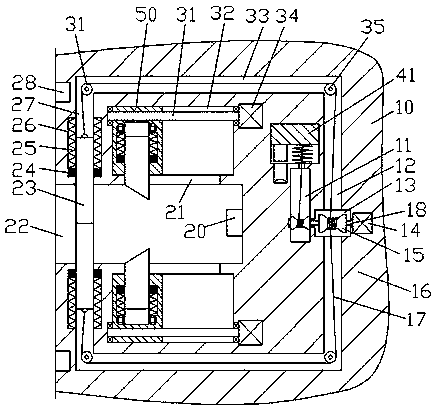

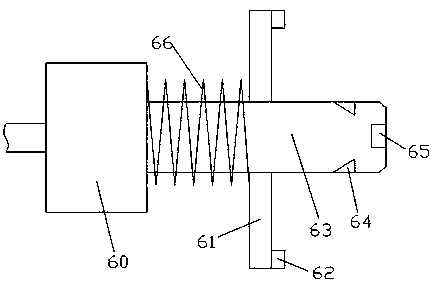

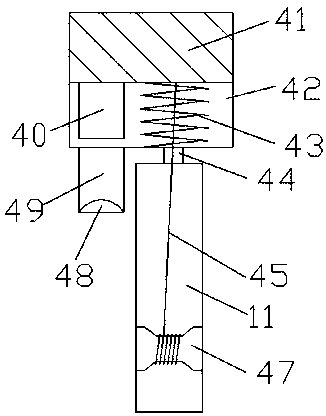

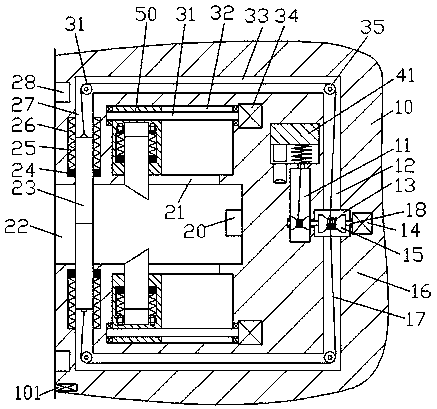

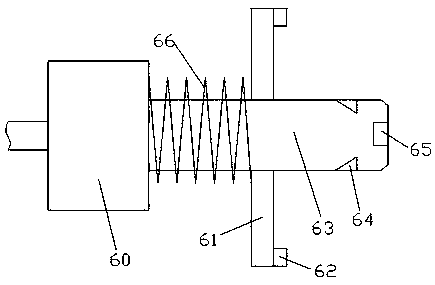

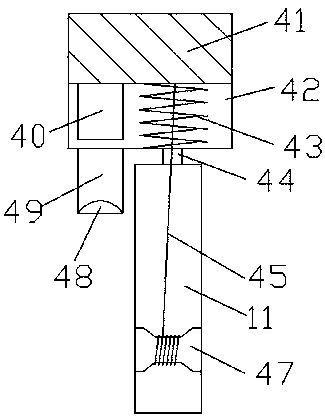

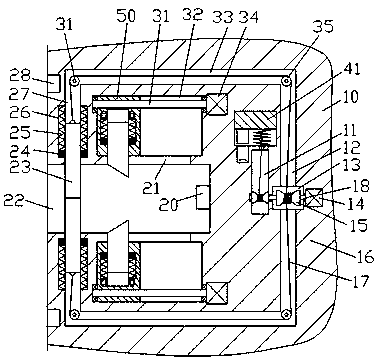

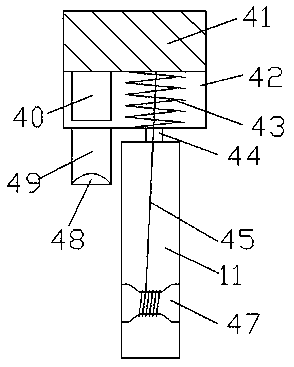

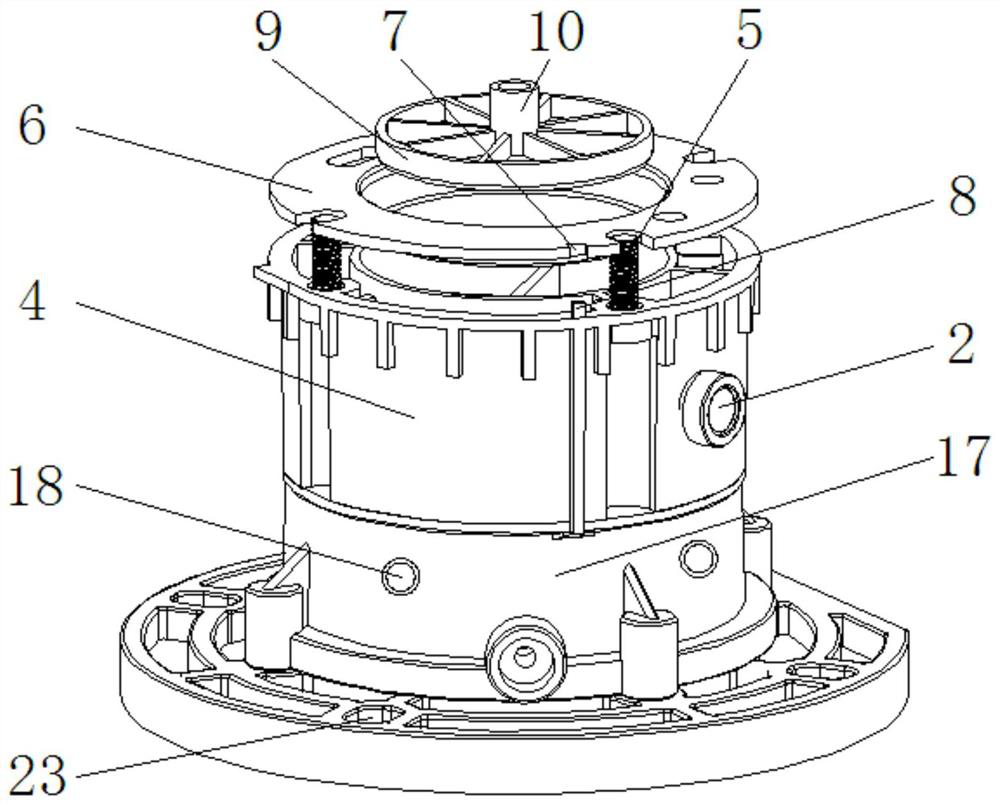

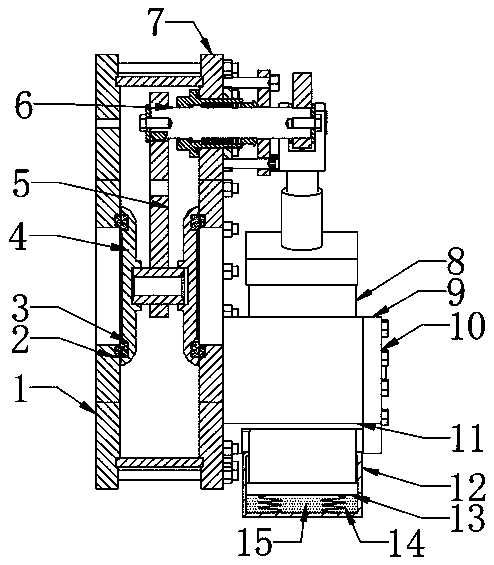

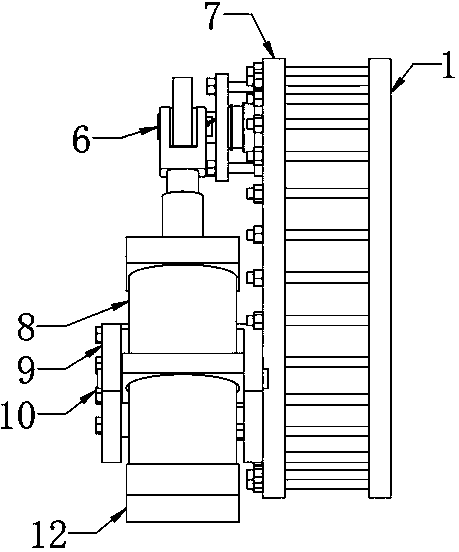

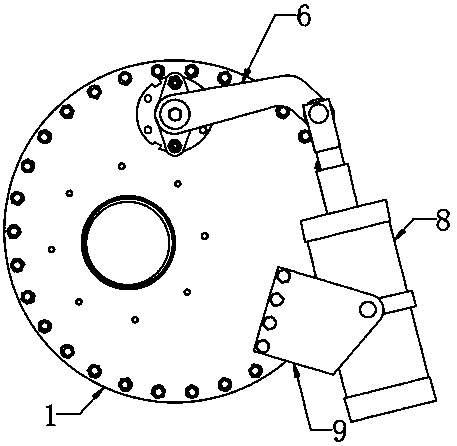

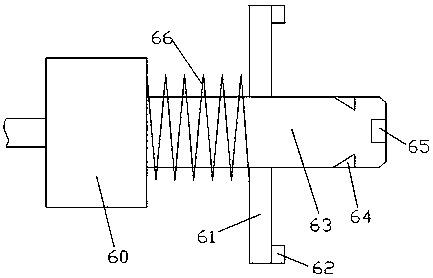

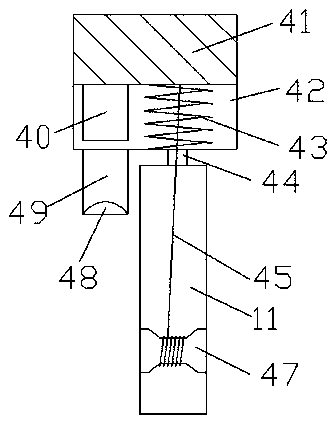

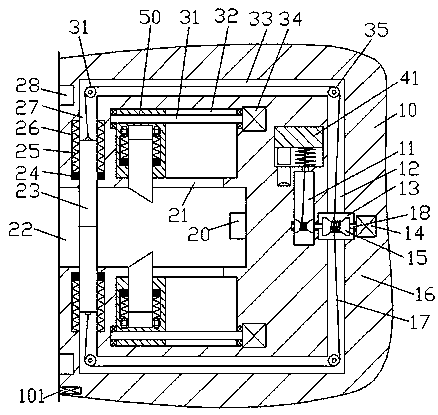

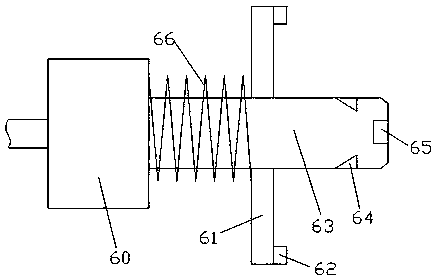

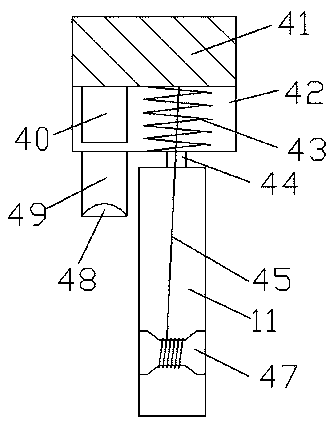

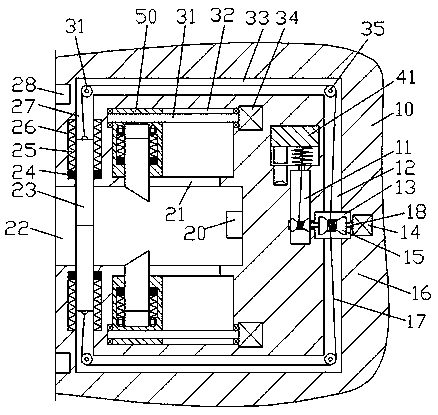

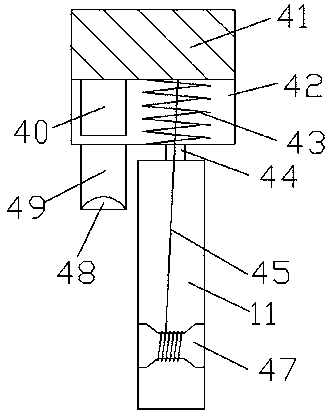

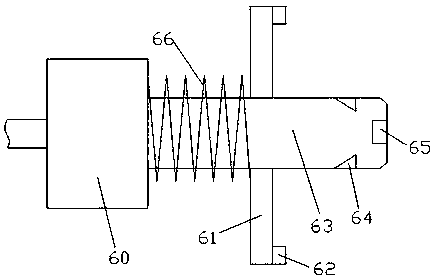

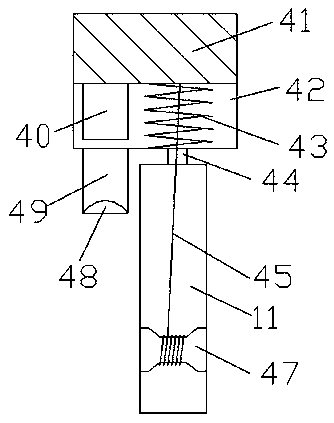

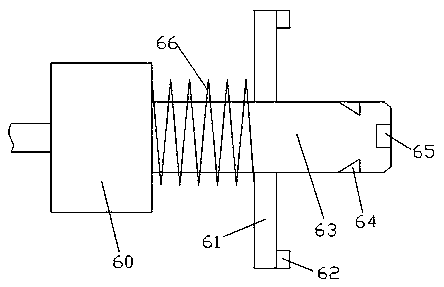

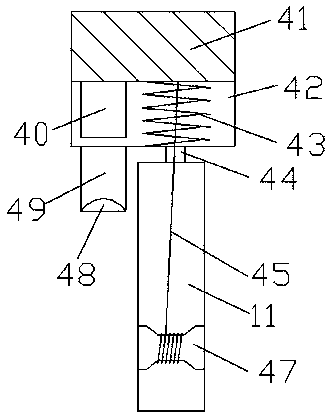

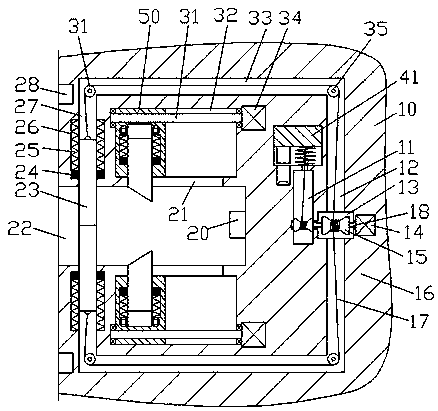

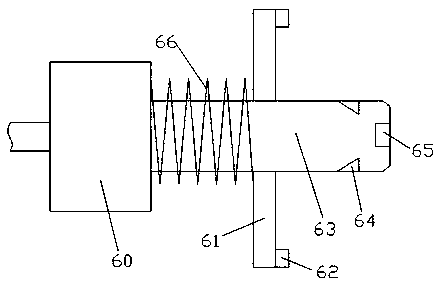

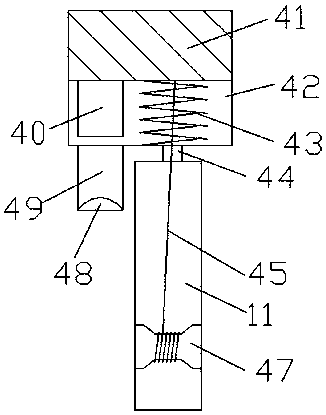

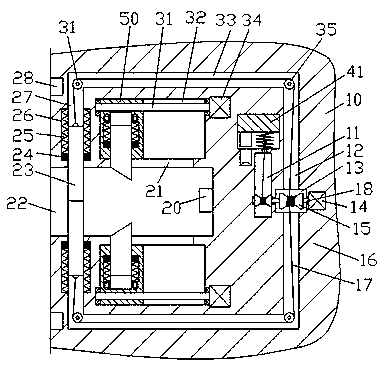

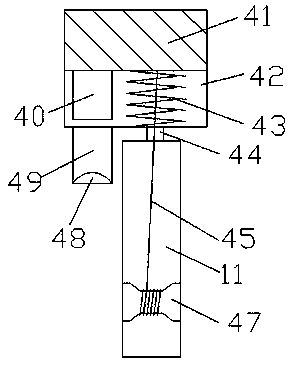

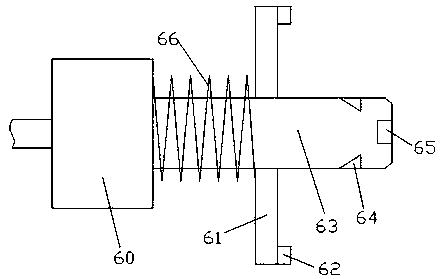

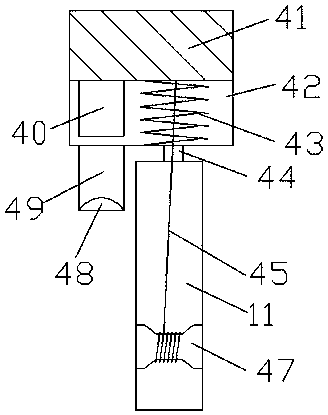

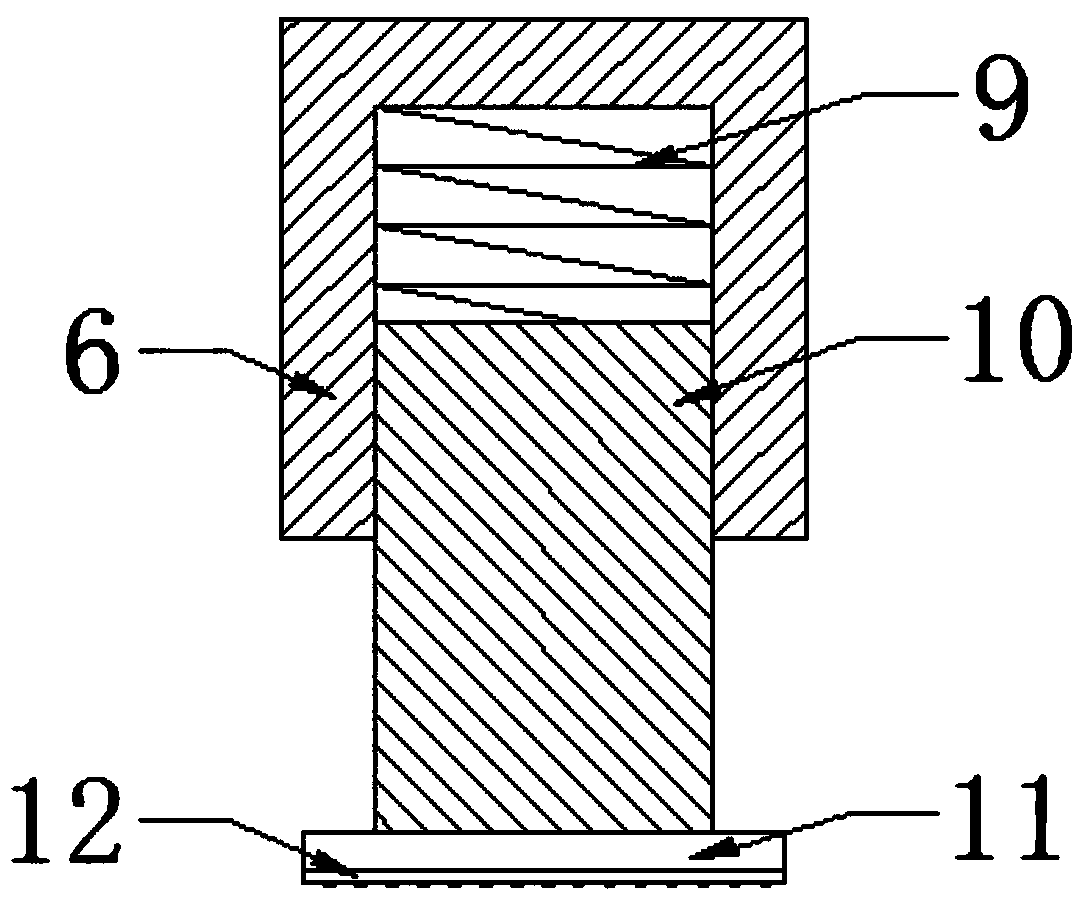

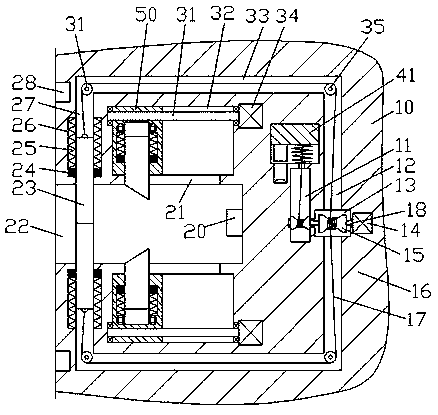

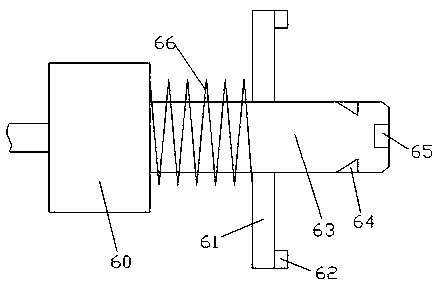

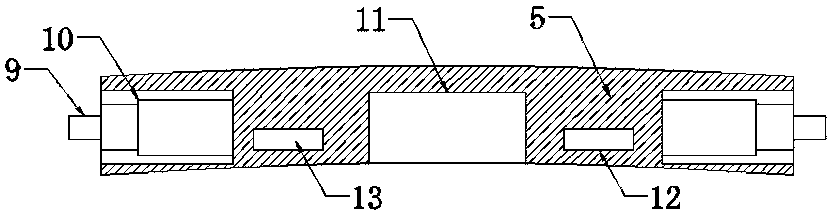

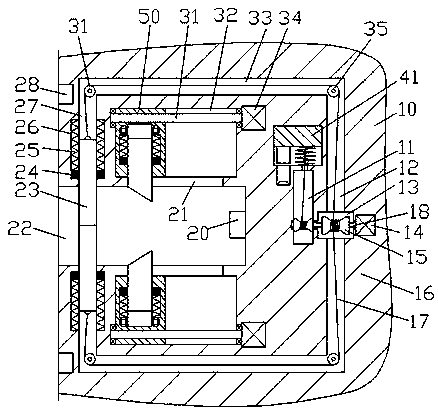

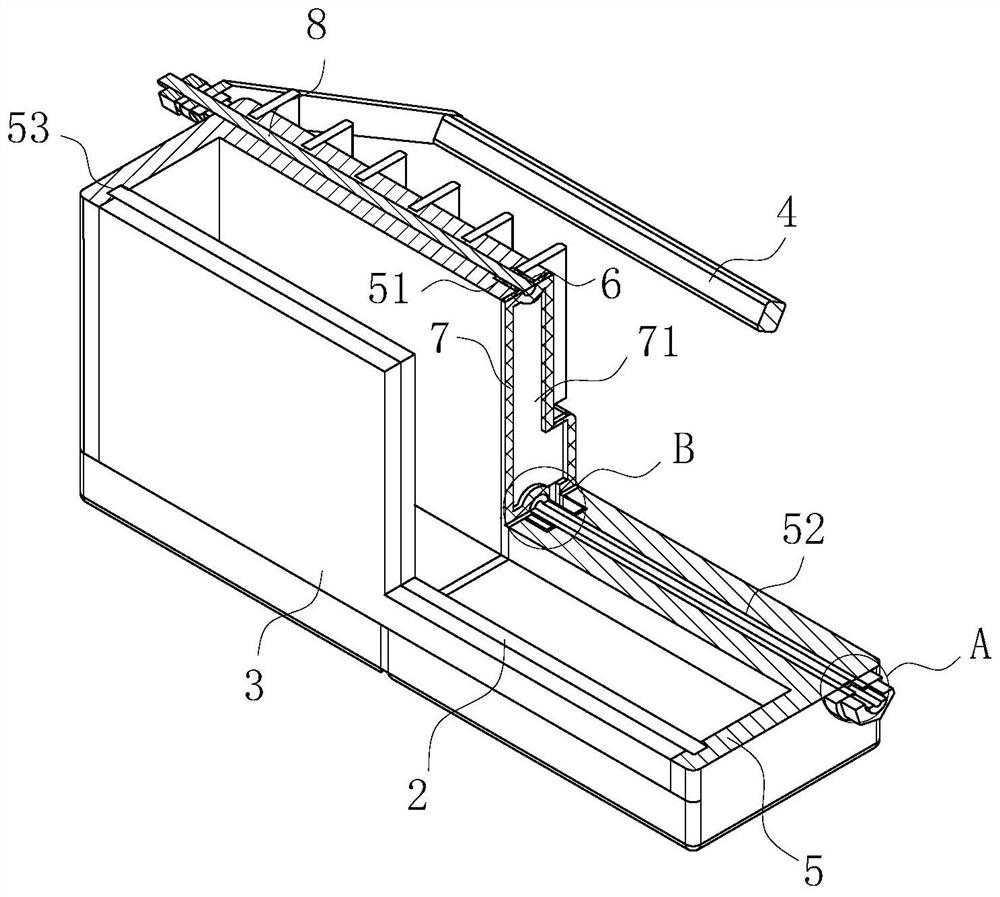

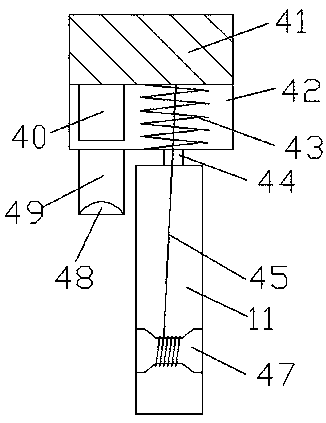

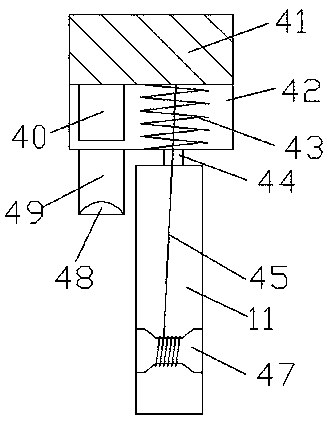

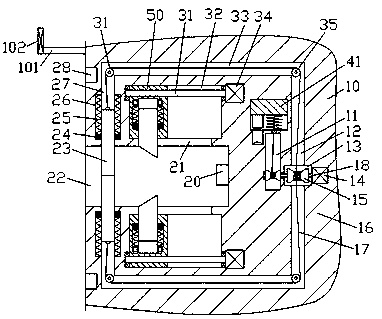

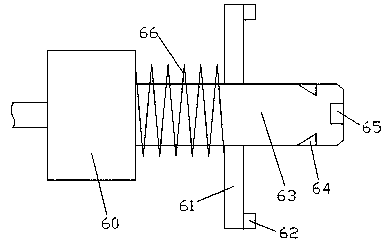

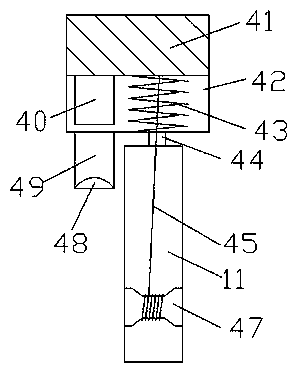

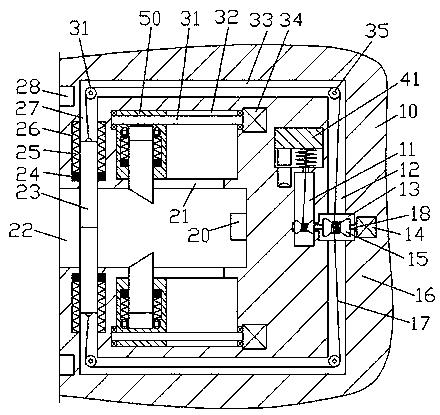

Actuating mechanism

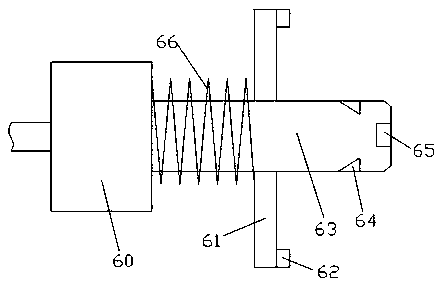

PendingCN112124499AImprove the tightness of useImprove the safety of useEngine sealsCabin closetsDrive shaftBolt connection

The invention discloses an actuating mechanism. The actuating mechanism comprises an actuating mechanism body, a mounting gas chamber, a side rubber gasbag and a blocking rod, wherein a damping plug is in bolt mounting on the actuating mechanism body; a drive shaft is movably connected on the actuating mechanism body; a mounting plate is in bolt connection in the mounting gas chamber; the top endof the mounting plate is in bolt connection to a main rubber gasbag; a connecting hose is in bolt mounting on the main rubber gasbag; the top end of the connecting hose is in bolt mounting with the side rubber gasbag; and the side rubber gasbag is in bolt connection in the mounting gas chamber. The actuating mechanism is equipped with the side rubber gasbag, the drive shaft drives a fixed top plate to extrude the main rubber gasbag downwards in the mounting gas chamber; and under extrusion effect of the main rubber gasbag, gas is conveyed into the side rubber gasbag through the connecting hosewhile the side rubber gasbag can conveniently and quickly extrude, package and seal the fixed top plate, so that use sealing property of the actuating mechanism is effectively improved.

Owner:ZHEJIANG JIANJIANG SHIP TECH CO LTD

Novel stainless steel tableware washing device

InactiveCN108903877AAvoid enteringExtended service lifeTableware washing/rinsing machine detailsCleaning equipmentEngineeringMechanical engineering

The invention discloses a novel stainless steel tableware washing device which comprises a main seat and a connecting part which is in plug-in fit connection onto the main seat. A slot is arranged inthen left end face of the main seat, a transmission block is fixedly arranged on the right inner wall of the slot, first sliding grooves are symmetrically arranged in the upper and lower inner wall ofthe slot, a retaining plate is slidably and fittingly mounted in the first sliding grooves, first guiding slots are symmetrically arranged on left and right inner walls of each first sliding groove,a first guiding block fixedly connected with the retaining plate is fittingly mounted in each first guiding slot slidably, a first elastic piece is fittingly connected to on side of the first guidingblock away from the slot in a top pressure manner, and second sliding grooves extending rightwards are arranged at tail ends of one ends of the first sliding grooves and away from the slot.

Owner:广州吉和电子商务有限公司

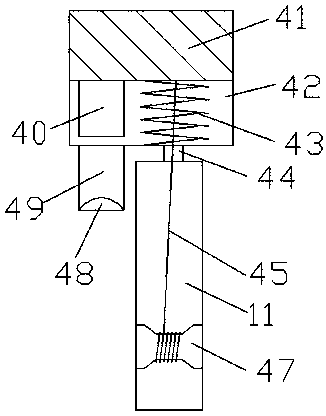

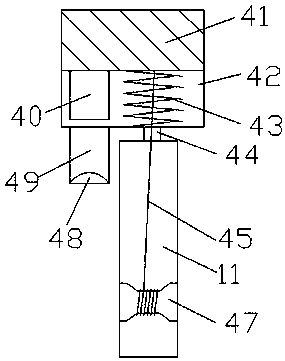

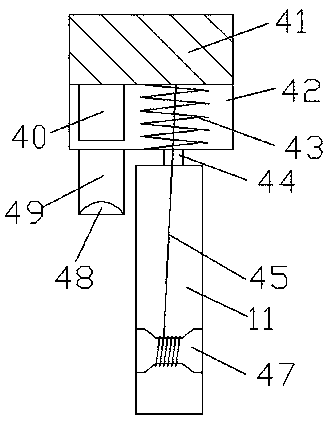

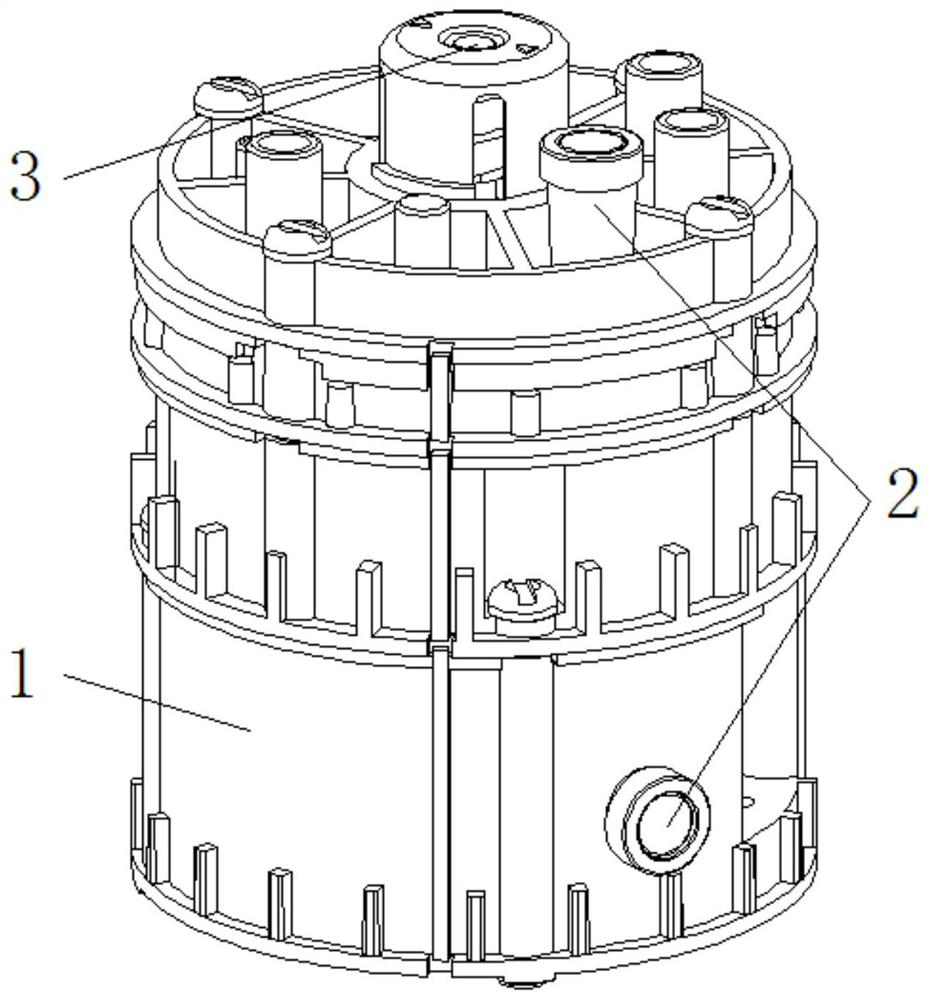

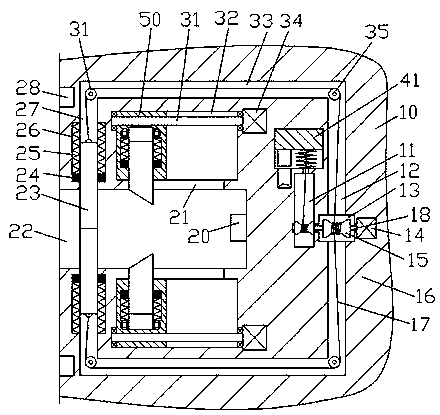

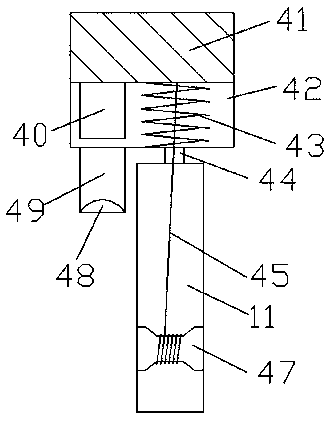

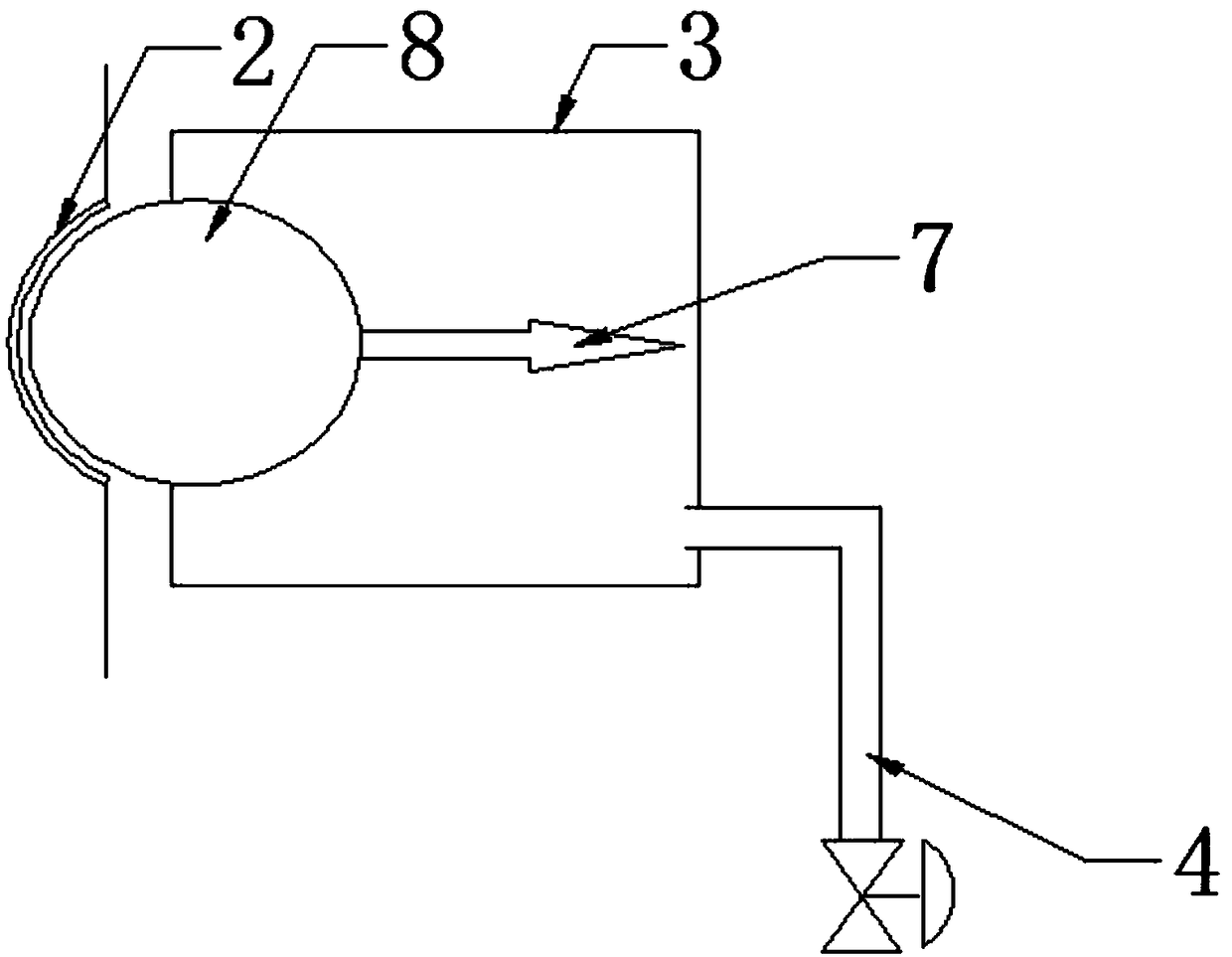

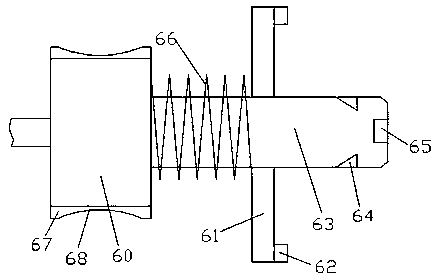

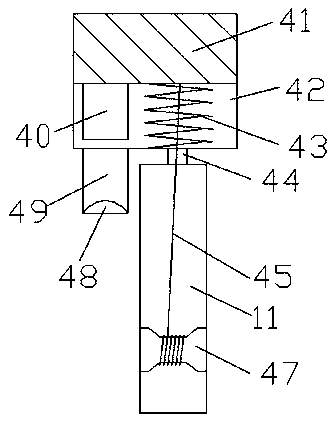

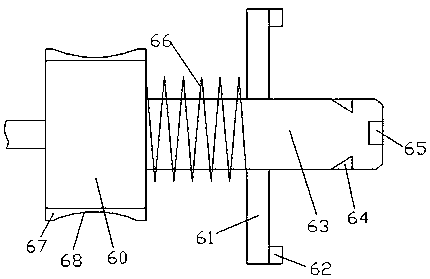

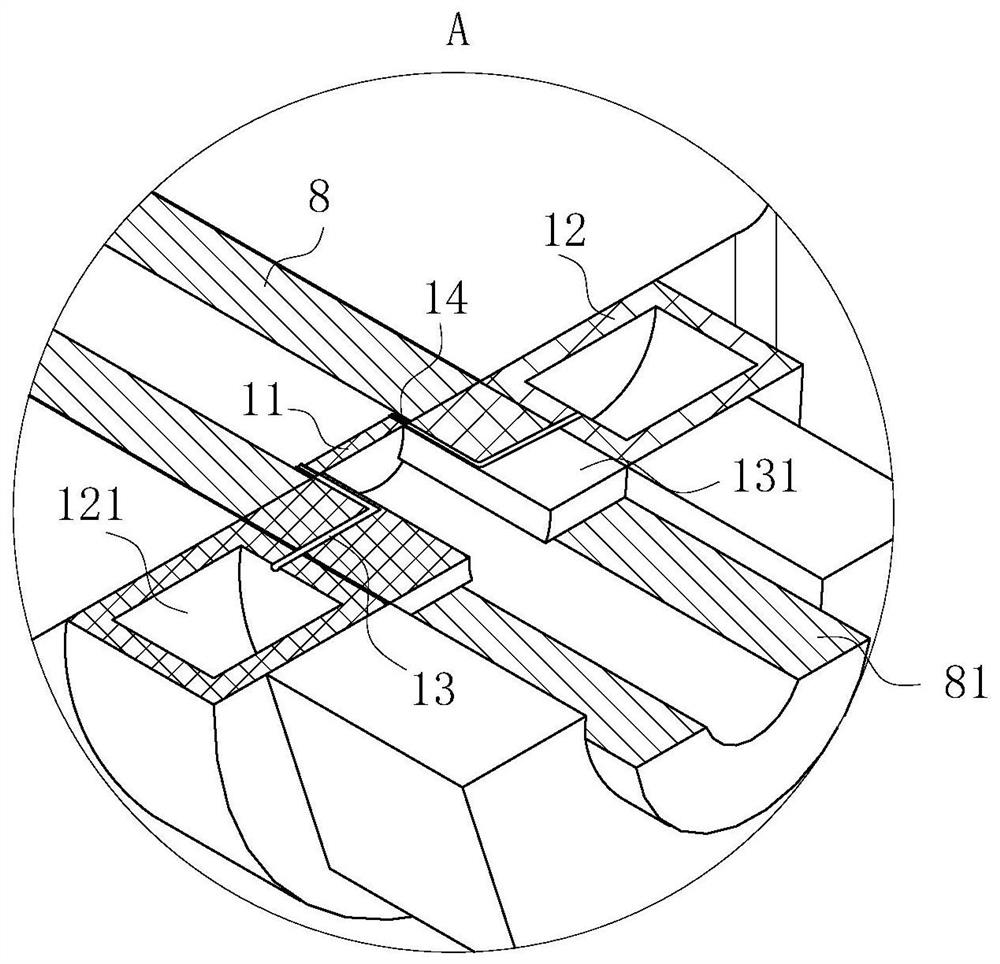

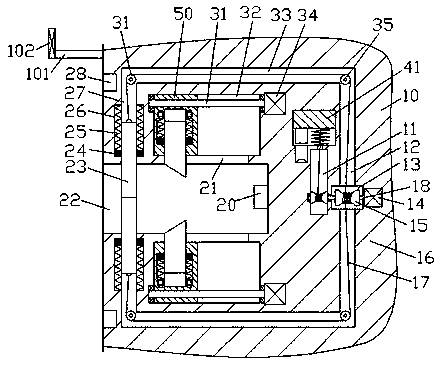

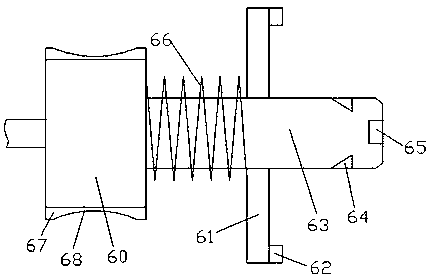

Ceramic disc valve

PendingCN108708982AImprove the tightness of useExtended service lifeOperating means/releasing devices for valvesValve members for absorbing fluid energyWear resistanceMuffler

The invention provides a ceramic disc valve. The ceramic disc valve comprises a valve body, a ceramic valve seat, a sealing ring, a ceramic valve plate, a swing rod, a valve rod, a driving device, a locking screw, a spring and muffler cotton; the ceramic valve seat is mounted in the valve body, the sealing ring is mounted in the ceramic valve seat, the ceramic valve plate is mounted on the right side of the valve body, and the swing rod is mounted on the right side of the ceramic valve plate; and the valve rod is mounted on the upper side of the swinging rod, and the driving device is mountedon the upper side of the valve rod. By means of the ceramic disc valve, the problem of poor sealing performance and wear resistance of a ceramic disc valve during using is solved, the locking screw ismounted on the right end surface of a guarding sheet, the spring is mounted on the lower end surface of a moving plate, and the muffler cotton is filled in the lower side of the interior of a base, the problem that a ceramic disc valve is not stable during using is solved, and the ceramic disc valve is reasonable in structure, high in sealing performance, high in stability and fast and convenientto adjust.

Owner:HENAN SHENGYU IND

Device for candy product packaging

InactiveCN109018473AAvoid enteringExtended service lifeIndividual articlesEngineeringMechanical engineering

The invention discloses a device for candy product packaging. The device for candy product packaging comprises a base frame and a joint part connected onto the base frame in a plug-in matching way, wherein a plug-in cavity is arranged in the left side end surface of the base frame; a power connection block is fixedly arranged on the inner wall of the right side of the plug-in cavity; first slidingchutes are symmetrically formed in the upper inner wall and the lower inner wall of the plug-in cavity; shielding plates are arranged in the first sliding chutes in a sliding fit way; first guide slots are symmetrically formed in the inner walls of the left sides and the right sides of the first chutes; first guide blocks fixedly connected with the shielding plates are arranged in the first guideslots in a sliding fit way; first elastic strips are connected to one sides, far away from the plug-in cavity, of the first guide blocks in a top-pressing fit way; and the tail ends of one sides, faraway from the plug-in cavity, of the first sliding chutes rightwards extend to be provided with second sliding chutes.

Owner:广州上成科技有限公司

Improved stainless steel tableware flushing device

InactiveCN108742420AAvoid enteringExtended service lifeTableware washing/rinsing machine detailsEngineering

The invention discloses an improved stainless steel tableware flushing device. The device comprises a main base body and a connecting part which is in inserted fit connection with the main base body,an inserting groove is formed in the left side end face of the main base body, and a power transmission block is fixedly arranged on the inner wall of the right side of the inserting groove; first sliding grooves are symmetrically formed in the upper inner wall and the lower inner wall of the inserting groove, baffles are slidably arranged in the first sliding grooves, and first guide grooves aresymmetrically formed in the inner wall of the left side and the inner wall of the right side of the first sliding grooves; first guide blocks which are fixedly connected with the baffles are slidablyarranged in the first guide grooves; the sides, away from the inserting groove, of the first guide blocks are in pressed fit connection with first elastic pieces; the tail ends of the sides, away fromthe inserting groove, of the first sliding grooves extend rightwards to be provided with second sliding grooves.

Owner:广州吉和电子商务有限公司

Improved stainless-steel-tableware washing device

InactiveCN108814491AAvoid enteringExtended service lifeTableware washing/rinsing machine detailsEngineering

The invention discloses an improved stainless-steel-tableware washing device. The improved stainless-steel-tableware washing device comprises a main base and a connecting part connected on the main base through inserting matching, an inserting groove is formed in the end face of the left side of the main base, a power transmission block is fixedly arranged on the inner wall of the right side of the inserting groove, first sliding grooves are symmetrically formed in the upper inner wall and the lower inner wall of the inserting groove, baffles are in sliding fit in the first sliding grooves, first guiding grooves are symmetrically formed in the left inner walls and the right inner walls of the first sliding grooves, first guiding blocks fixedly connected with the baffles are in sliding fitin the first guiding grooves, first elastic sheets are in abutting fit to the sides, away from the inserting groove, of the first guiding blocks, and second sliding grooves extend from the tail ends of the sides, away from the inserting groove, of the first sliding grooves rightwards.

Owner:广州吉和电子商务有限公司

Packaging device for candy products

The invention discloses a packaging device for candy products. The packaging device comprises a base frame and a joint part connected to the base frame in an inserted fit mode; an inserting cavity isformed in the left side end face of the base frame, an electricity connecting block is fixedly arranged on the inner wall of the right side of the inserting cavity, first sliding grooves are symmetrically formed in the upper inner wall and the lower inner wall of the inserting cavity, and shielding plates are mounted in the first sliding grooves in a sliding fit mode; first guiding grooves are symmetrically formed in the inner walls of the left sides and the right sides of the first sliding grooves, first guiding blocks fixedly connected with the shielding plates are mounted in the first guiding grooves in a sliding fit mode, and first elastic strips are connected to the sides, away from the inserting cavity, of the first guiding blocks in a jacking fit mode; and second sliding grooves areformed in the tail ends of the sides, away from the inserting cavity, of the first sliding grooves in a rightward extending mode.

Owner:广州上成科技有限公司

Improved air purifier

InactiveCN108695643AAvoid enteringExtended service lifeCouplings bases/casesTwo-part coupling devicesMating connectionAir purifiers

The invention discloses an improved air purifier, and the air purifier comprises a case body and a clamping connector which is connected to the case body in a manner of plugging connection cooperation. A left end face of the case body is provided with an insertion cavity, and the right inner wall of the insertion cavity is fixedly provided with a power incoming block. The upper and lower inner walls of the insertion cavity are symmetrically provided with first sliding cavities, and the interior of each first sliding cavity is provided with a shielding plate in a sliding fit manner. The left and right inner walls of each first sliding cavity are symmetrically provided with first guide grooves, and the interior of each first guide groove is provided with a first guide block in fixed connection with the corresponding shielding plate in a sliding fit manner. One side, far from the insertion cavity, of each first guide block is connected with a first elastic piece in a jacking fit manner, and the tail end of one side, far from the insertion cavity, of each first sliding cavity extends towards the right to be provided with a second sliding cavity.

Owner:广州上同环保科技有限公司

Novel three-dimensional laser engraving machine control system

InactiveCN108788478AAvoid enteringExtended service lifeLaser beam welding apparatusElectricityMachine control

The invention discloses a novel three-dimensional laser engraving machine control system which comprises a base and a connecting part, wherein the connecting part is connected onto the base in an inserting and matching manner; an inserting cavity is arranged in the left end surface of the base; an electricity conduction block is fixedly arranged on the right inner wall of the inserting cavity; first sliding grooves are symmetrically arranged in the upper and lower inner walls of the inserting cavity; cover plates are mounted in the first sliding grooves in a sliding fit manner; first guiding grooves are symmetrically arranged in the left and right inner walls of the first sliding grooves; first guiding blocks which are fixedly connected with the cover plates are mounted in the first guiding grooves in a sliding fit manner; first compression springs are connected with the sides, far away from the inserting cavity, of the first guiding blocks in a top pressure fit manner; and second sliding grooves are arranged at the tail ends of the sides, far away from the inserting cavity, of the first sliding grooves in a rightward extending manner.

Owner:广州广林科技有限公司

Flushing device for stainless steel dining utensils

InactiveCN108784603AAvoid enteringExtended service lifeTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses a flushing device for stainless steel dining utensils. The flushing device comprises a main base and a connecting part connected to the main base in an insertion matched manner, wherein an insertion groove is arranged in the left end face of the main base, an electricity transmission block is fixedly arranged on the inner wall of the right side of the insertion groove, first sliding chutes are symmetrically arranged in upper and lower inner walls of the insertion groove, baffles are mounted in the first sliding chutes in a sliding matched manner, first guide grooves aresymmetrically arranged in inner walls of the left and right sides of the first sliding chutes, first guide blocks fixedly connected with the baffle plates are mounted in the first guide grooves in asliding matched manner, first elastic plates are connected to one sides, far away from the insertion groove, of the first guide blocks in a pushing-pressing matched manner, and the tail ends of one sides, far away from the insertion groove, of the first sliding chutes, are provided with second sliding chutes in a manner of extending rightwards.

Owner:广州吉和电子商务有限公司

Vertical-barrel cutting machine

InactiveCN108907868AAvoid enteringExtended service lifeMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses a vertical-barrel cutting machine. The vertical-barrel cutting machine comprises a main frame and a connecting part cooperatively connected to the main frame in an inserted manner and is characterized in that an insertion opening is arranged in the left end face of the main frame, a power supply block is fixedly arranged on the right inner wall of the insertion opening, first slide grooves are symmetrically arranged in the upper inner wall and the lower inner wall of the insertion opening, a blocking cover is mounted in the first slide grooves in a slide fit manner, first guide grooves are symmetrically arranged in the left inner walls and the right inner walls the first slide grooves, first guide blocks fixedly connected with the blocking cover are mounted in the first guide grooves in a slide fit manner, first elastic pressing pieces are connected to one sides, away from the insertion opening, of the first guide blocks in a press fit manner, and second slide grooves extend rightwards from the tail ends on one sides, away from the insertion opening, of the first slide grooves.

Owner:广州太牛科技有限公司

Novel vertical type barrel cutter

InactiveCN108746858AAvoid enteringExtended service lifeSolid waste disposalMechanical engineeringEngineering

The invention discloses a novel vertical type barrel cutter. The novel vertical type barrel cutter comprises a main frame body and a connecting part which is in splicing and matched connection onto the main frame body, wherein an insertion hole is formed in the left side end surface of the main frame body; the inner wall of the right side of the insertion hole is fixedly equipped with an electricfeeding block; first slip slots are symmetrically formed in upper and lower walls of the insertion hole; baffle covers are mounted in the first slip slots in a sliding fit mode; first guide slide slots are symmetrically formed in inner walls of left and right sides of each first slip slot; first guide slide blocks which are fixedly connected with the baffle covers are mounted in the first guide slide slots in the sliding fit mode; one side, away from the insertion hole, of each first guide slide slot is connected with a first elastic pressure sheet in a resisted and matched mode; and the tailend of one side, away from the insertion hole, of each first slip slot is equipped with a second slip slot in a rightward extending mode.

Owner:广州太牛科技有限公司

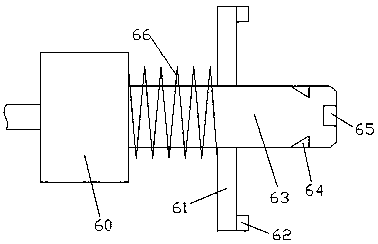

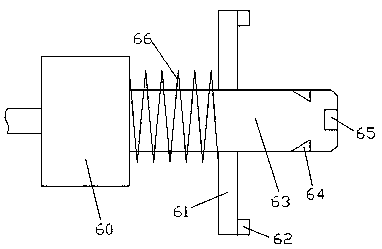

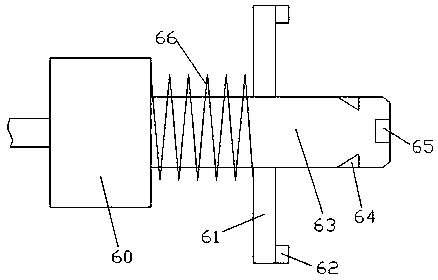

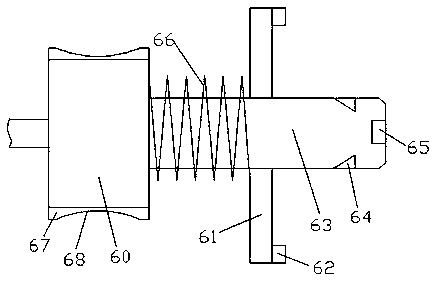

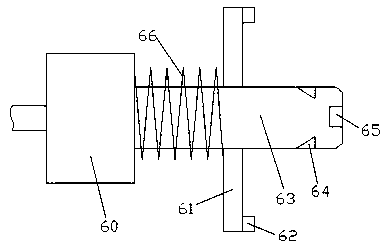

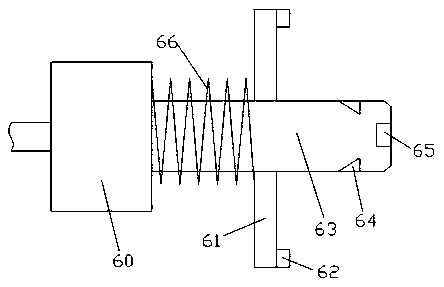

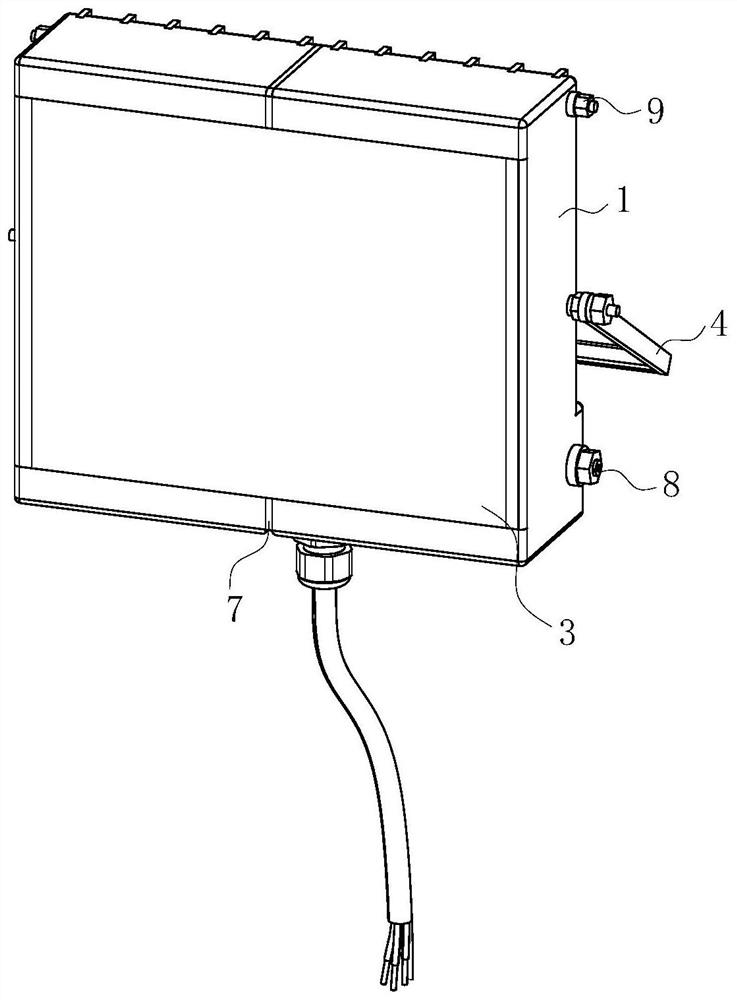

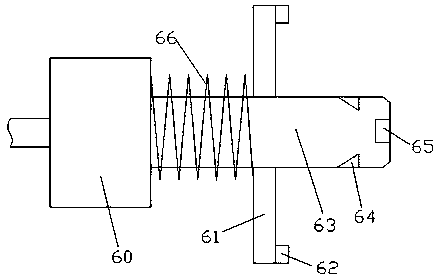

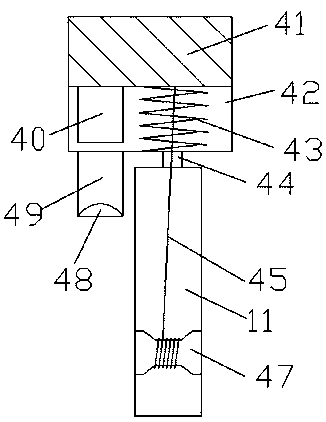

Air pressurization type sealing quick insertion gun head

InactiveCN108548090AEasy to seal and placeSolve the problem that cannot be completely sealedVessel mounting detailsContainer discharging methodsEngineeringPolytetrafluoroethylene

The invention provides an air pressurization type sealing quick insertion gun head. The air pressurization type sealing quick insertion gun head comprises insertion gun nozzle grooves, sealing gasketinner chambers, fixed rods, tension springs, polytetrafluoroethylene sealing balls, buffer springs, connecting rods, buffer plates and protective pads, the insertion gun nozzle grooves are symmetrically arranged in the left side and the right side of an insertion gun seat, the sealing gasket inner chambers are arranged at the left sides of the insertion gun nozzle grooves, the tension springs arearranged at the internal right sides of the sealing gasket inner chambers, the polytetrafluoroethylene sealing balls are arranged on the left end surfaces of the tension springs, and the above designsolves the problem of incomplete sealing storage of an original liquid charging gun. The fixed rods are arranged at the left side and the right side of the rear end surface of the liquid charging gun,the buffer springs are mounted at the internal rear sides of the fixed rods, the connecting rods are mounted on the front end surfaces of the buffer springs, the buffer plates are mounted on the front end surfaces of the connecting rods, and the protective pads are arranged on the front end surfaces of the buffer plates, and the above design solves the problem of very easy wearing of the originalliquid charging gun. The air pressurization type sealing quick insertion gun head has the advantages of reasonable structure, safety in use, wearing avoiding and good sealing effect.

Owner:歌思(天津)低温设备有限公司

Packing device for candy product

InactiveCN108995923AAvoid enteringExtended service lifePackaging machinesMating connectionEngineering

The invention discloses a packing device for a candy product. The packing device comprises a base frame and a joint part connected to the base frame in an inserting fit mode; an inserting cavity is formed in the end face of the left side of the base frame; and an electricity connecting block is fixedly arranged on the inner wall of the right side of the inserting cavity. First sliding grooves aresymmetrically formed in the upper inner wall and the lower inner wall of the inserting cavity; shielding plates are mounted in the first sliding grooves in a sliding fit mode; first guiding grooves are symmetrically formed in the inner walls of the left and right sides of the first sliding grooves; first guiding blocks fixedly connected with the shielding plates are mounted in the first guiding grooves in a sliding fit mode; the sides, away from the inserting cavity, of the first guiding blocks are connected with first elastic strips in a jacking fit mode; and the tail ends of the sides, awayfrom the inserting cavity, of the first sliding grooves rightwards extend to be provided with second sliding grooves.

Owner:广州上成科技有限公司

Improved three-dimensional laser engraving machine control system

InactiveCN108788479AAvoid enteringExtended service lifeLaser beam welding apparatusElectricityMachine control

The invention discloses an improved three-dimensional laser engraving machine control system which comprises a base and a connecting part, wherein the connecting part is connected onto the base in aninserting and matching manner; an inserting cavity is arranged in the left end surface of the base; an electricity conduction block is fixedly arranged on the right inner wall of the inserting cavity;first sliding grooves are symmetrically arranged in the upper and lower inner walls of the inserting cavity; cover plates are mounted in the first sliding grooves in a sliding fit manner; first guiding grooves are symmetrically arranged in the left and right inner walls of the first sliding grooves; first guiding blocks which are fixedly connected with the cover plates are mounted in the first guiding grooves in a sliding fit manner; first compression springs are connected with the sides, far away from the inserting cavity, of the first guiding blocks in a top pressure fit manner; and secondsliding grooves are arranged at the tail ends of the sides, far away from the inserting cavity, of the first sliding grooves in a rightward extending manner.

Owner:广州广林科技有限公司

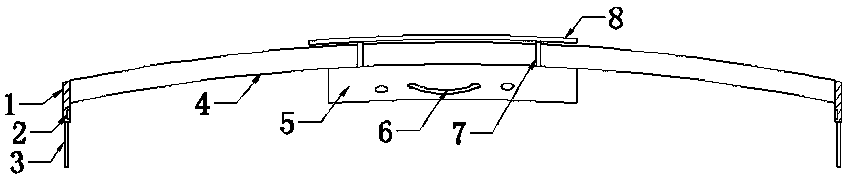

Car sun shield

InactiveCN108146210ASolve the problem that requires the user to stretch from one side of the car to the other to fix itImprove ease of useBatteries circuit arrangementsRemovable external protective coveringsEngineering

The invention provides a car sun shield which comprises a sun shield body, an arc-shaped fixed plate, a handle and a flexible solar panel. The arc-shaped fixed plate is mounted on the lower end surface of the sun shield body, the handle is mounted on the front end surface of the arc-shaped fixed plate, the flexible solar panel is mounted in the middle of the upper end surface of the sun shield, and two groups of fixed bolts are assembled on the upper end of the arc-shaped fixed plate, penetrate the sun shield body and are fixed with the bottom of the flexible solar panel. According to the design, energy saving properties and environmental protection properties of the sun shield are improved, fixed blocks are arranged on the left side and the right side of the sun shield body, grooves are formed in the left side and the right side of the arc-shaped fixed plate, pushing rod motors are assembled in the grooves, fixing rods are assembled at the left ends of the pushing rod motors, and thedesign solves the problem that an original car sun shield needs a user to draw the sun shield to the other side from one side to fix the car sun shield. The car sun shield is reasonable in structure,convenient to use and strong in functionality.

Owner:海宁市硖石迅奇科技信息咨询服务部

Improved vertical barrel cutting machine

InactiveCN108818430AAvoid enteringExtended service lifeCoupling contact membersCouplings bases/casesEngineeringPower transmission

The invention discloses an improved vertical barrel cutting machine. The improved vertical barrel cutting machine comprises a main rack body and a connecting portion connected to the main rack body inan inserted fit manner. An inserting opening is formed in the end face of the left side of the main rack body. A power transmission block is fixedly arranged on the inner wall of the right side of the inserting opening. First sliding grooves are symmetrically arranged in the upper inner wall and the lower inner wall of the inserting opening. A blocking cover is mounted in each first sliding groove in a sliding fit manner. First guide grooves are symmetrically formed in the inner walls of the left side and the right side of each first sliding groove. A first guide block fixedly connected withthe corresponding blocking cover is mounted in each first guide groove in a sliding fit manner. The side, away from the inserting opening, of each first guide block is connected with a first spring clip in a jacking-pressing fit manner. The tail end of the side, away from the inserting opening, of each first sliding groove extends rightwards to be provided with a second sliding groove.

Owner:广州太牛科技有限公司

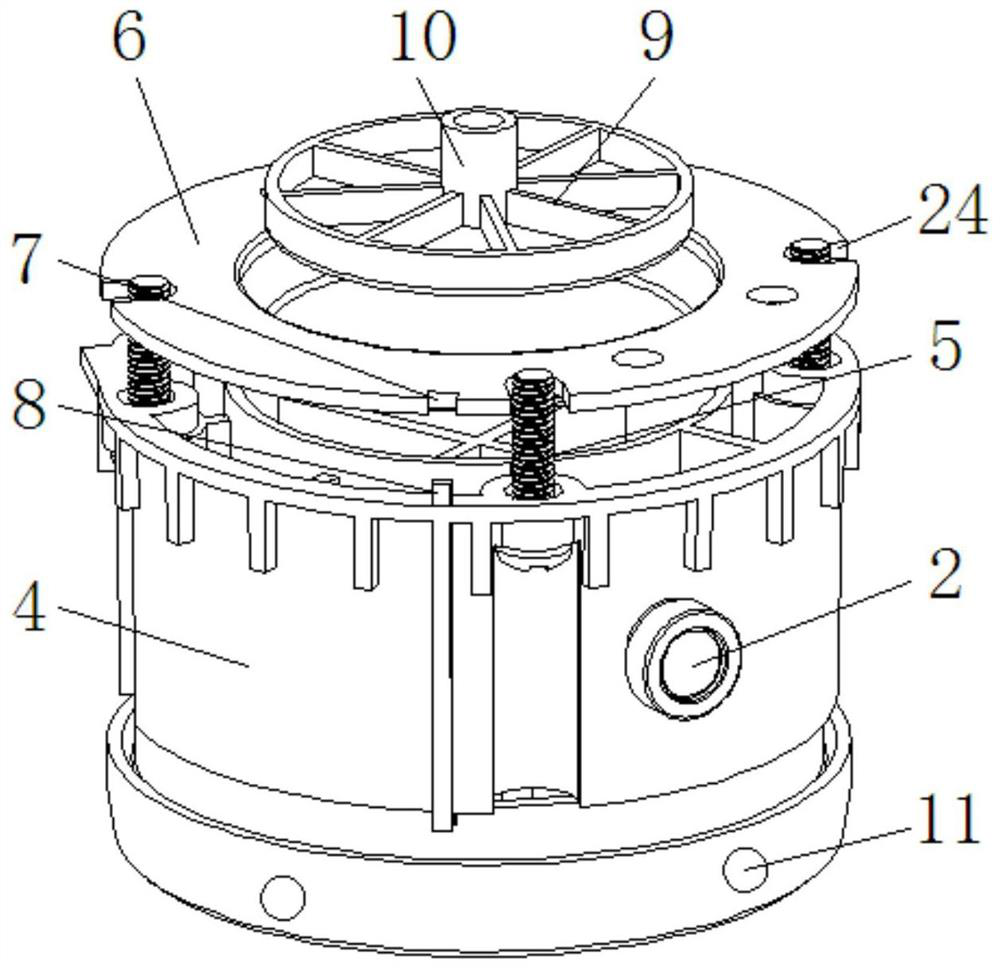

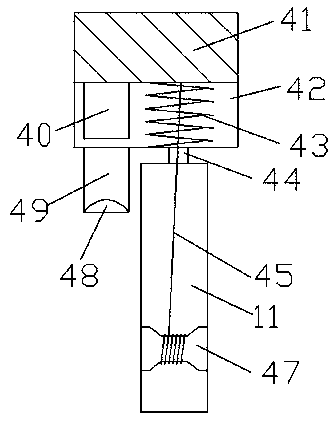

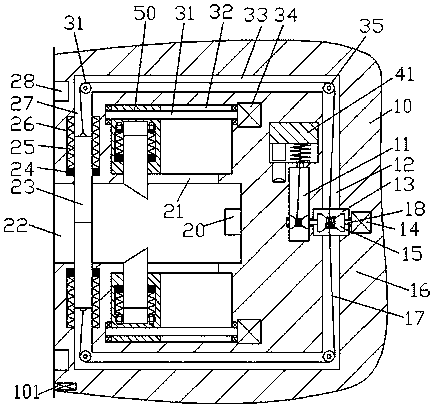

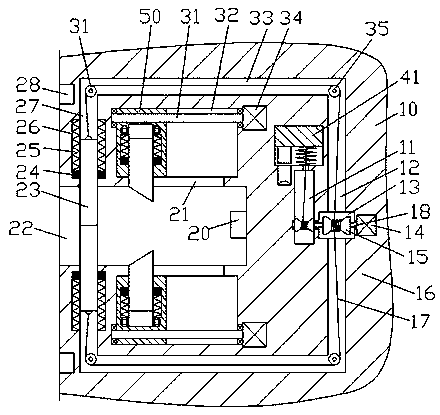

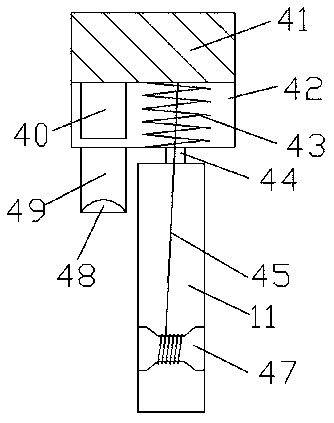

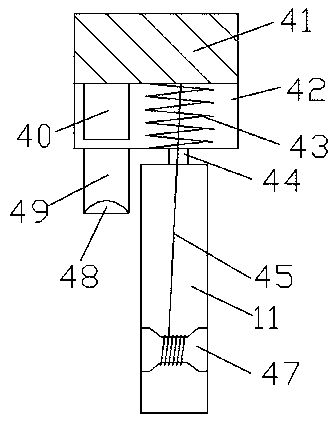

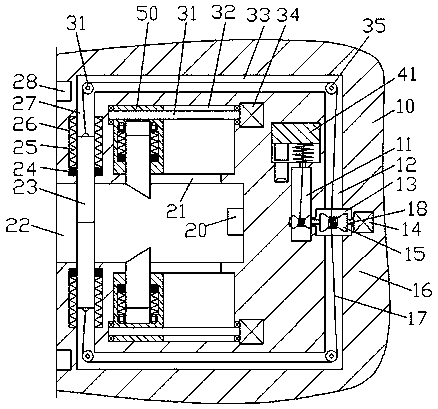

Die casting aluminum part

PendingCN111810920AImprove the tightness of useQuick fixProtective devices for lightingGas-tight/water-tight arrangementsDie castingLED lamp

The invention belongs to the technical field of die casting, and particularly relates to a die casting aluminum part. The die casting aluminum part comprises a housing aluminum part; the housing aluminum part and a supporting frame are both formed through die casting; the housing aluminum part is formed by mutually splicing two die-casting frames; rubber sealing strips are inserted into symmetrically arranged insertion cavities, and the two rubber sealing strips are mutually connected through a rubber clamping strip; a plurality of connecting holes are vertically formed in the inner side wallsof the two die-casting frames, and threaded rods are inserted into the connecting holes; nuts are in threaded connection with the two ends of the multiple threaded rods; the two ends of the threadedrod located in the middle of the die-casting frames are provided with the supporting frame, and the supporting frame is adjustably fixed on the threaded rod through nuts; inner cavity walls of the twodie-casting frames are provided with insertion sliding grooves respectively, and an LED lamp panel is slidably inserted into the insertion sliding grooves; and a lampshade is arranged on the outer side of the LED lamp panel. Holes do not need to be punched on the housing aluminum part, and the LED lamp panel is mounted on the housing aluminum part through screws, so that the use sealing effect ofthe housing aluminum part is improved.

Owner:苏强

Novel air purifier

InactiveCN108758812AAvoid enteringExtended service lifeMechanical apparatusLighting and heating apparatusEngineeringAir purifier

The invention discloses a novel air purifier. The novel air purifier comprises a case body, and a blocking head which is in spliced and matched connection on the case body, wherein an insertion cavityis arranged in the left side end surface of the case body; the inner wall of the right side of the insertion cavity is fixedly equipped with an electric feeding block; first slide cavities are symmetrically arranged in upper and lower inner walls of the insertion cavity; shielding plates are mounted in the first slide cavities in a sliding fit mode; first guide slots are symmetrically formed in inner walls of left and right sides of each first slide cavity; first guide blocks which are fixedly connected with the shielding plates are mounted in the first guide slots in a sliding fit mode; sides, away from the insertion cavity, of the first guide blocks abut against and are in matched connection with first elastic sheets; and the tail ends of sides, away from the insertion cavity, of the first slide cavities are equipped with second slide cavities in a rightward extending mode.

Owner:广州上同环保科技有限公司

Improved vertical barrel cutting machine

InactiveCN108942373AAvoid enteringExtended service lifeMaintainance and safety accessoriesEngineeringMechanical engineering

The invention discloses an improved vertical barrel cutting machine. The improved vertical barrel cutting machine comprises a main frame and a connecting part connected to the main frame in inserted and matched modes. An insertion opening is formed in the end face of the left side of the main frame. A power supply block is fixedly arranged on the inner wall of the right side of the insertion opening. First sliding grooves are symmetrically formed in the upper inner wall and the lower inner wall of the insertion opening. A cover is mounted in the first sliding grooves in a sliding fit mode. First guide grooves are symmetrically formed in the inner walls of the left side and the right side of each first sliding groove. First guide blocks fixedly connected with the cover are mounted in the first guide grooves in a sliding fit mode. A first elastic pressing piece is connected to the side, away from the insertion opening, of each first guide block in an abutting fit mode. A second sliding groove which extends rightwards is formed in the tail end of the side, away from the insertion opening, of each first sliding groove.

Owner:广州太牛科技有限公司

Improved flushing device for stainless steel dining utensils

InactiveCN108784602AExtended service lifeAvoid Electric Shock AccidentsTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention discloses an improved flushing device for stainless steel dining utensils. The improved flushing device comprises a main base and a connecting part connected to the main base in an insertion matched manner, wherein an insertion groove is arranged in the left end face of the main base, an electricity transmission block is fixedly arranged on the inner wall of the right side of the insertion groove, first sliding chutes are symmetrically arranged in the upper and lower inner walls of the insertion groove, baffles are mounted in the first sliding chutes in a sliding matched manner,first guide grooves are symmetrically arranged in the inner walls of the left and right sides of the first sliding chutes, first guide blocks fixedly connected with the baffle plates are mounted in the first guide grooves in a sliding matched manner, first elastic plates are connected to one sides, far away from the insertion groove, of the first guide blocks in a pushing-pressing matched manner,and the tail ends of one sides, far away from the insertion groove, of the first sliding chutes are provided with second sliding chutes in a manner of extending rightwards.

Owner:广州吉和电子商务有限公司

Improved air purifier

InactiveCN108736240AExtended service lifeAvoid Electric Shock AccidentsCouplings bases/casesLive contact access preventionEngineeringAir purifiers

The invention discloses an improved air purifier. The improved air purifier comprises a machine case body and a clamping head which is connected with the machine case body in an inserting and connecting mode, wherein an inserting cavity is formed in the left side end plane of the machine case body, and a power inlet block is fixedly arranged on the inner wall of the right side of the inserting cavity; first sliding cavities are symmetrically formed in the upper inner wall and the lower inner wall of the inserting cavity, and a shielding plate is mounted in each first sliding cavity in a sliding fit mode; first guide grooves are symmetrically formed in the inner walls of the left side and the right side of each first sliding cavity; a first guide block which is fixedly connected with the shielding plate is arranged in the corresponding first guide groove in a sliding fit mode; a first elastic piece is connected with one side, far away from the inserting cavity, of each first guide blockin a pressed fit mode; and a second sliding cavity is formed in the tail end of one side, far away from the inserting cavity, of the first sliding cavity in a rightward extension manner.

Owner:广州上同环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com