Crop straw stubble and residual plastic film drip irrigation belt cutting and recycling machine

A technology of crop straws and drip irrigation belts, which is applied to cutters, collectors, harvesters, etc., can solve the problem that the residual film cannot be separated from crop stubble and soil debris, soil debris cleaning, and crop stubble cleaning work. good solution to the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

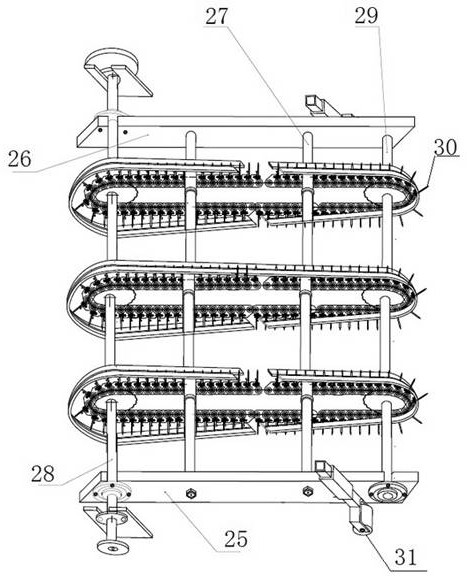

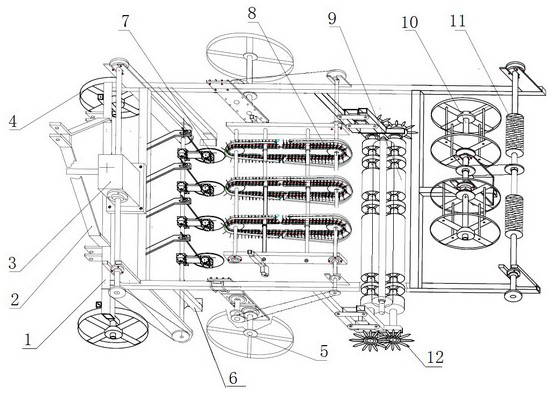

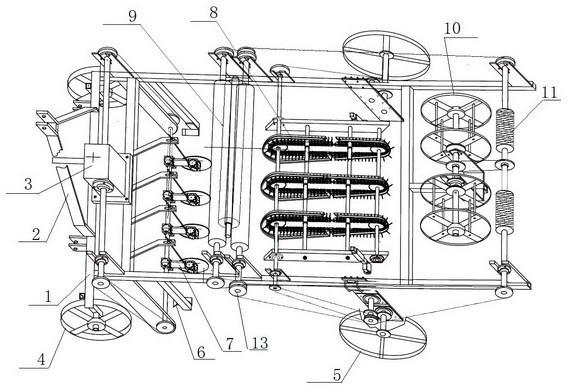

[0008] A crop straw stubble cutting residual film drip irrigation belt recovery machine, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, a suspension frame 2 is arranged at the front end of the frame 1 with the depth gauge wheel 4 and the ground wheel 5, and the gearbox 3 connected to the power output shaft of the tractor is arranged on the frame 1, behind the gearbox 3 On the frame at the bottom, there are arranged in sequence a symmetrical film lifting shovel 6 or an integral film lifting shovel, a disc knife set 7 for cutting residual film of straw stubble, a sprocket type film collecting component group 8, a residual film retracting component 9, The drip irrigation belt take-up pulley set 10 and the drip irrigation belt discharge roller assembly 11, the output shaft of the gearbox 3 works through the mechanical transmission of the disc kn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap