Steel structure outer wall convenient to install for architectural engineering, and method

A construction engineering and steel structure technology, applied in building components, building structures, buildings, etc., can solve the problems of time-consuming, labor-intensive, low installation efficiency, and difficult alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

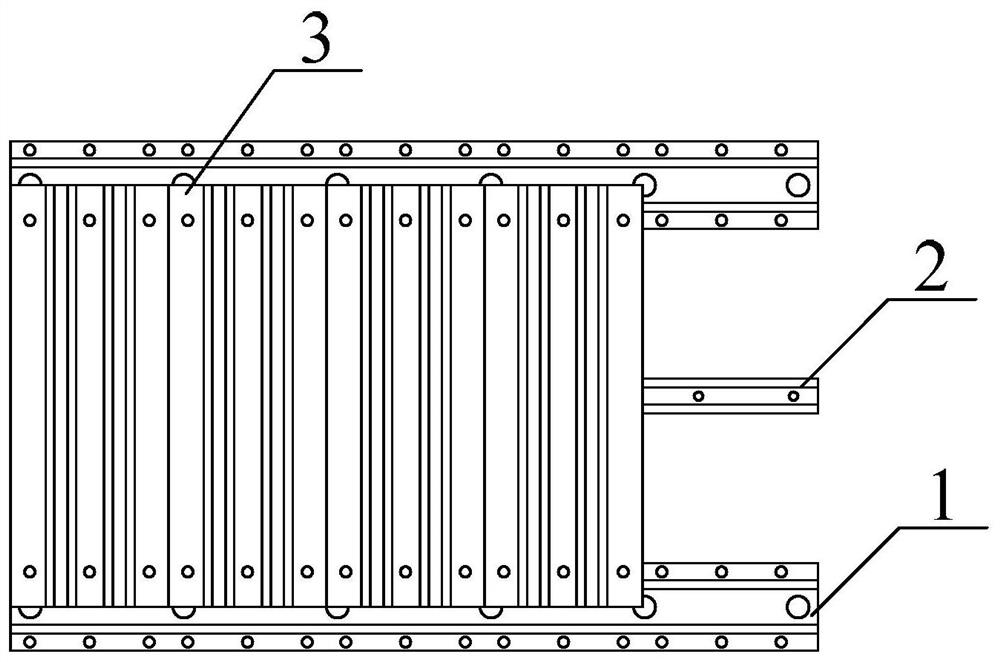

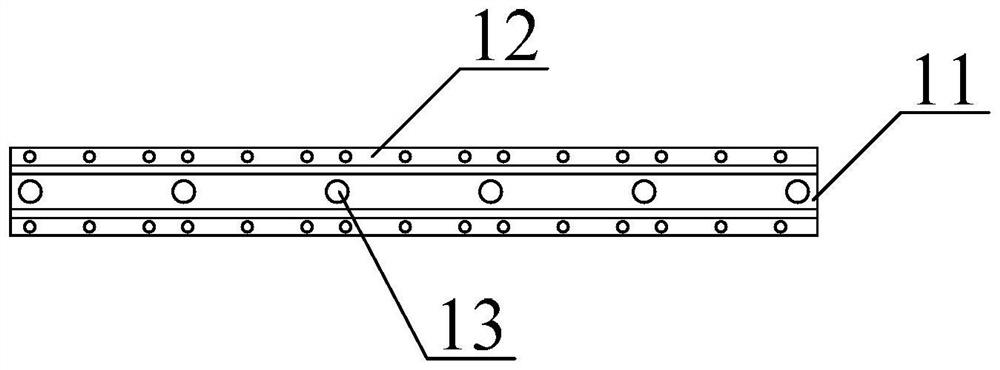

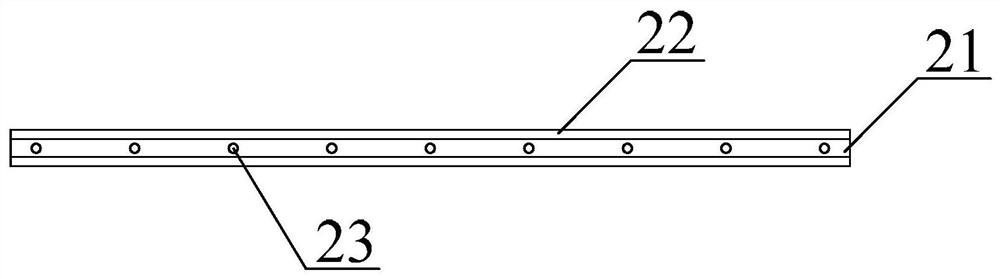

[0031] as attached figure 1 to attach Image 6 shown

[0032] The present invention provides an easy-to-install steel structure exterior wall for construction engineering, which includes a steel structure component 1, a guide plate component 2 and a wall panel component 3. There are multiple steel structure components 1, and the steel structure component 1 is installed on the wall Above, the steel structure components 1 are arranged in parallel, wherein the steel structure components 1 are arranged at equal intervals; the guide plate components 2 are multiple, and the guide plate components 2 are installed on the wall, and the guide plate components 2 are located between the steel structure components 1 Intermediate position; multiple wall panel assemblies 3 are used, and the wall panel assemblies 3 are installed on the front side of the steel structure assembly 1 and the guide plate assembly 2;

[0033] The steel structure component 1 includes a steel plate 11, a mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com