High-voltage transmission line deicing device

A high-voltage transmission line and ice-melting technology, applied in the installation of cables, electrical components, overhead installation, etc., can solve problems such as affecting the transmission efficiency of high-voltage lines, scratches and cracks in high-voltage lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

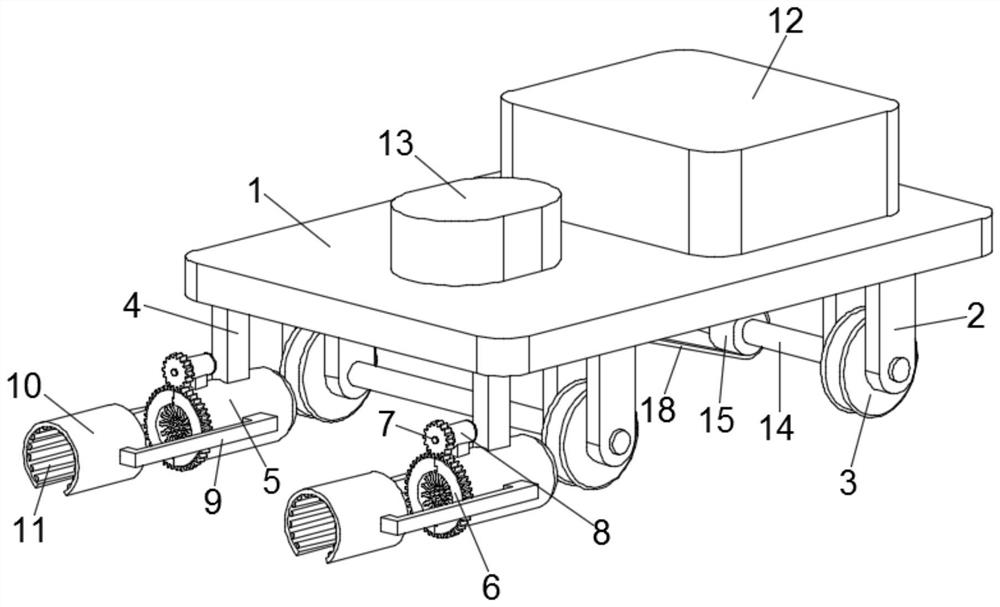

[0029] see figure 1 , a high-voltage transmission line deicing device, including a platform 1, the four corners of the lower end surface of the platform 1 are installed with rollers 3 through the rotation of the support 2, and the deicing mechanism is symmetrically installed on both sides of the front end of the platform 1, and the deicing mechanism It includes an ice-melting assembly and a cleaning assembly, and the ice-melting assembly and the cleaning assembly are fixedly connected through a connecting frame 9;

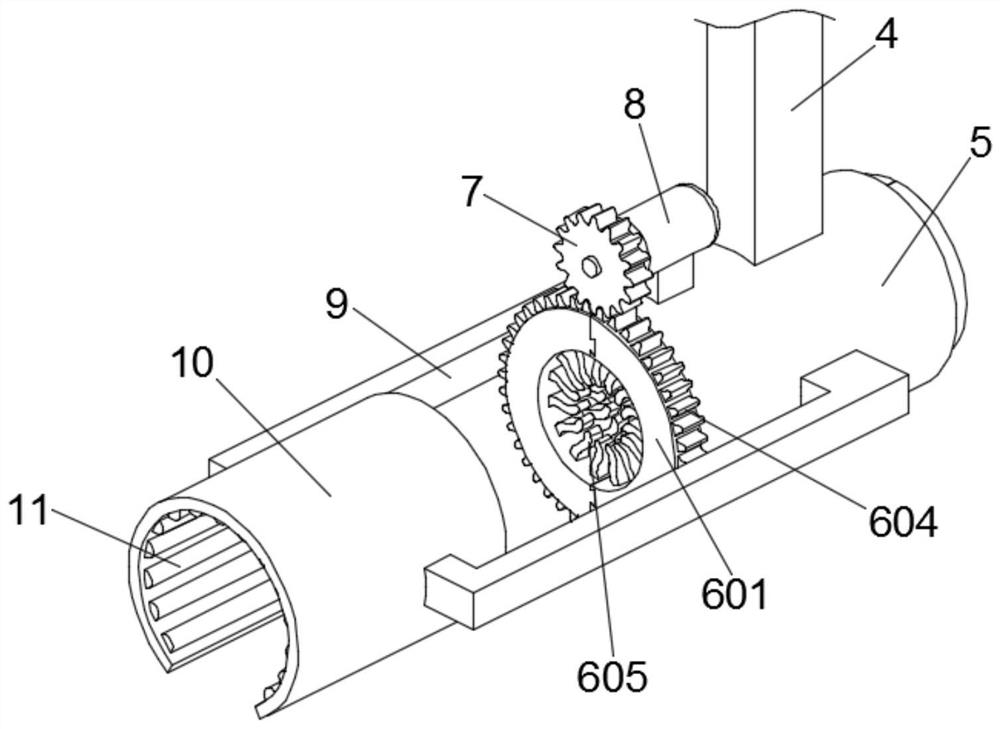

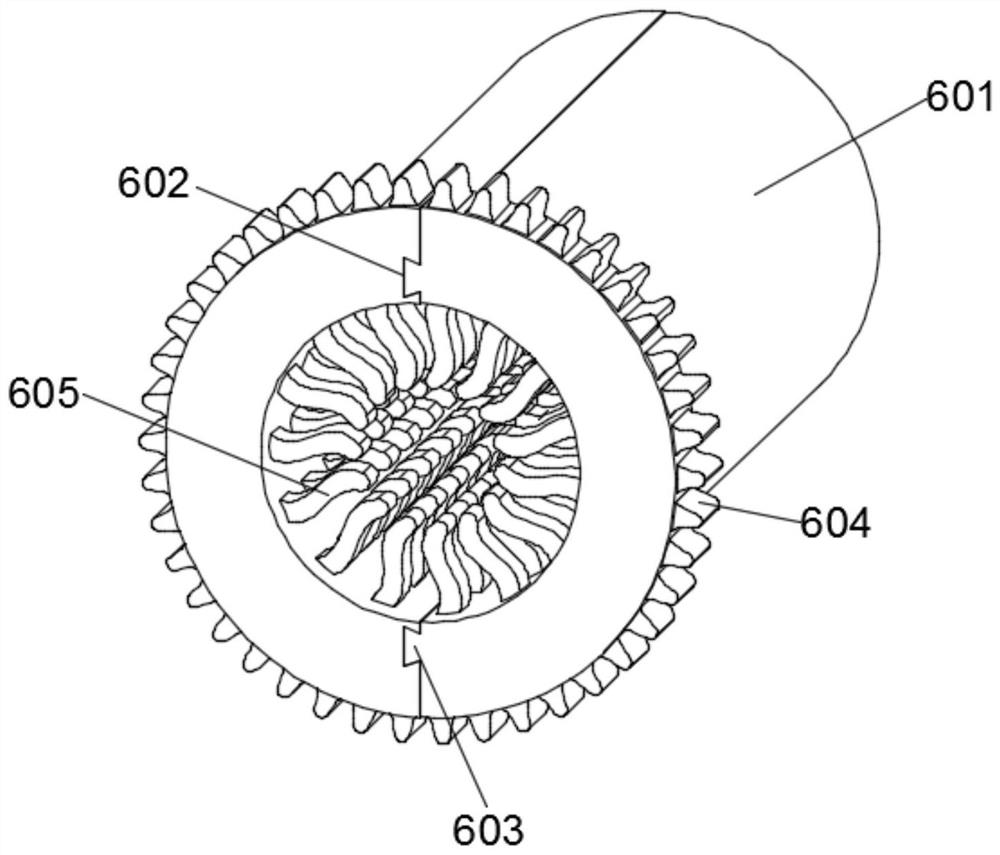

[0030] see Figure 2-3 , the ice-melting assembly includes a heating mantle 10, and a plurality of heating strips 11 are annularly arranged on the inner wall of the heating mantle 10; Fixedly installed on the lower end surface of the platform 1, the fixed sleeve 5 is rotatably provided with a cleaning cylinder 6, the cleaning cylinder 6 is formed by splicing two half cylinders 601, and the outer wall of one end of the cleaning cylinder 6 is provided with teeth Ri...

Embodiment 2

[0040] A high-voltage transmission line deicing device, including a platform 1, the four corners of the lower end surface of the platform 1 are rotated by a support 2, and rollers 3 are installed, and the two sides of the front end of the platform 1 are symmetrically installed with a deicing mechanism, and the deicing mechanism includes An ice-melting assembly and a cleaning assembly, the ice-melting assembly and the cleaning assembly are fixedly connected through a connecting frame 9;

[0041]The ice-melting assembly includes a heating cover 10, and a plurality of heating strips 11 are annularly arranged on the inner wall of the heating cover 10; the cleaning assembly includes a fixing sleeve 5 and a cleaning cylinder 6, and the fixing sleeve 5 is fixed by a fixing column 4 Installed on the lower end surface of the platform 1, the fixed sleeve 5 is rotatably provided with a cleaning cylinder 6, the cleaning cylinder 6 is formed by splicing two half cylinders 601, and a ring ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com