High-precision hydraulic balance detection supporting table

A hydraulically balanced, high-precision technology that can be used in static/dynamic balance testing, measuring devices, machine/structural component testing, etc., and can solve problems such as unstable adjustment amplitudes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

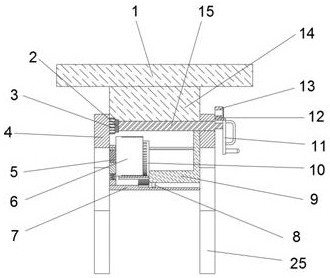

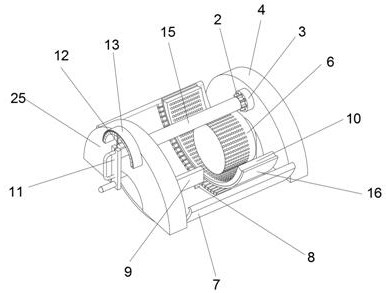

[0027] Reference Figure 1-3 with Figure 5 , A high-precision hydraulic balance detection support table, including a connecting table 14, the top outer wall of the connecting table 14 is connected with a table plate 1 through bolts, a support shaft 15 is inserted into the wall of the connecting table 14, and a rotating mechanism is fixed on one side of the support shaft 15 , The other side of the support shaft 15 is fixed with the limit mechanism, the outer walls on both sides of the connecting platform 14 are respectively connected by sliding legs with leg one 4 and leg two 25, and there is a tooth groove between the leg one 4 and the leg two 25 through bolts. The arc plate 7 is provided with a card slot in the wall of the tooth slot arc plate 7, a measuring mechanism is fixed on one side of the second leg 25, a slow motion mechanism is fixed on the outer wall of the tooth slot arc plate 7, and a locking mechanism is fixed on the outer wall of the support shaft 15.

[0028] In ...

Embodiment 2

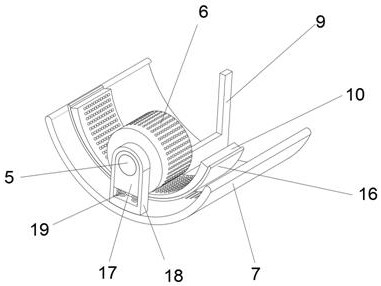

[0036] Reference Figure 4 with Figure 5 , A high-precision hydraulic balance detection support table. Compared with the first embodiment, this embodiment also includes a movable rod 22 plugged into the top of the first leg 4 and the second leg 25, and the top outer wall of the movable rod 22 is connected by bolts. The roller 21, and the top of the roller 21 is in contact with the outer wall of the bottom of the table board 1, and the inner walls of the legs 4 and 25 are connected with a transmission hose 23 by sliding. The outer wall of the transmission hose 23 is connected by a bolt with an extension support The inner walls of the plate 20, the first leg 4 and the second leg 25 are all connected to the extension support plate 20 by a return spring 26 through bolts.

[0037] When in use, when the adjustment range of the table board 1 is too large, the center of gravity of the table board 1 will move to one side when the table board 1 is loaded. At this time, the roller 21 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com