Road and bridge deicing machine

A deicer, road technology, used in snow surface cleaning, construction, cleaning methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

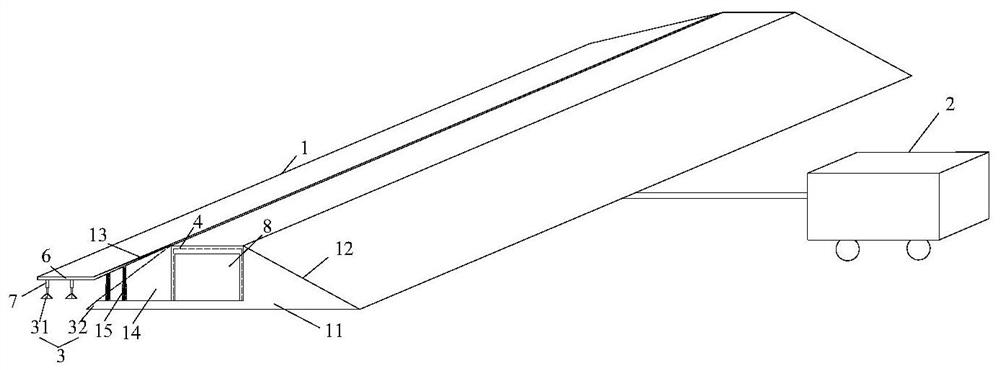

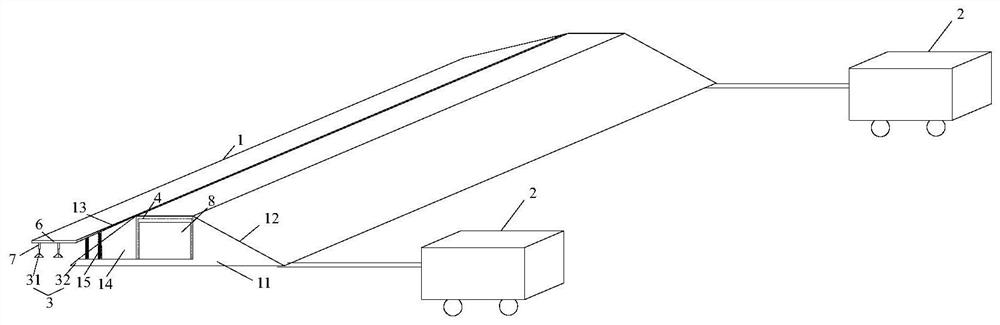

[0039] A kind of road bridge deicing machine provided by the present invention comprises:

[0040] The arch bridge structure 1 is used to meet the normal traffic of vehicles while deicing;

[0041] The moving mechanism 2 is used to make the arch bridge structure move along the length direction of the road bridge;

[0042] The deicing mechanism 3 is used to remove ice and snow on the road surface;

[0043] Described arch bridge structure 1 comprises:

[0044] Support body 11;

[0045] The upslope surface 12 is fixed on the supporting body 11 parallel to the width direction of the road bridge;

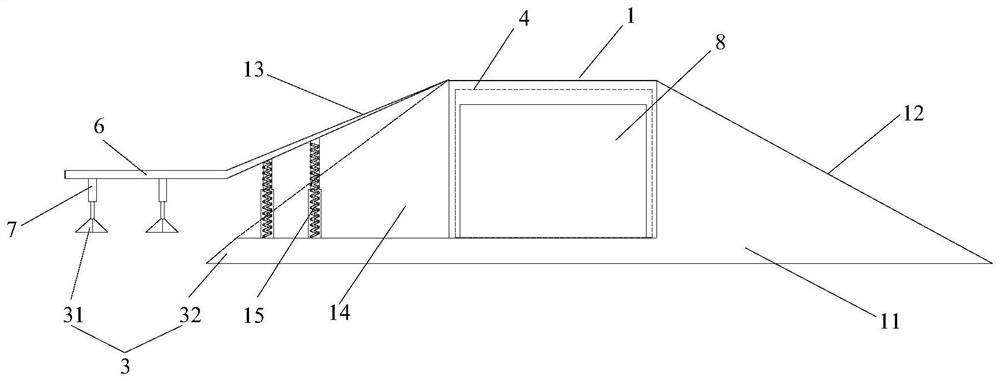

[0046] Downslope 13, the top of which is hinged on the opposite side of support body 11 to upslope 12;

[0047] The accommodating cavity 14 is arranged in the supporting body 11, and the side close to the downhill surface 13 is an open end;

[0048] The first elastic support member 15 is arranged between the downslope surface 13 and the bottom of the accommodation chamber 14, and th...

Embodiment 2

[0054] The deicing mechanism 3 includes:

[0055] The crampons 31 are arranged at the bottom of the downhill surface 13 close to the ground;

[0056] The deicing shovel 32 is arranged on the outer edge of the supporting body 11 close to the downhill surface 13 , and is used for shoveling the ice cubes broken by the crampons 31 and storing them in the receiving chamber 14 .

[0057] The deicing mechanism 3 of this embodiment can realize efficient deicing by combining ice breaking and ice shoveling.

Embodiment 3

[0059] An ice pusher 4 is provided inside the accommodation chamber 14 of this embodiment, and the ice pusher 4 is connected with a driving device 5 for driving the ice pusher 4 to reciprocate. Outlet 8 for ice cube discharge.

[0060]When working, the ice-breaking claws 31 break the ice in front, which can destroy the structure of the ice layer, increase the friction between the de-icing blade 32 and the ice surface, and improve the ice-shoveling efficiency. The crushed ice will be received into the accommodation chamber 14, and will be discharged through the outlet 8 when the crushed ice accumulates a lot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com