Rapid Trenching Method of Deep One-shot Blasting for the Whole Segment of Small Block Section in Open-pit Mine with Large Water Influx Depression

A water inflow and open-pit mine technology, applied in blasting, drainage, mining equipment, etc., can solve problems such as limited wading depth, large drilling clamping, and narrow working face, so as to reduce the number of pumping and drainage operations and improve blasting efficiency. Effect, the effect of increasing the tunneling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

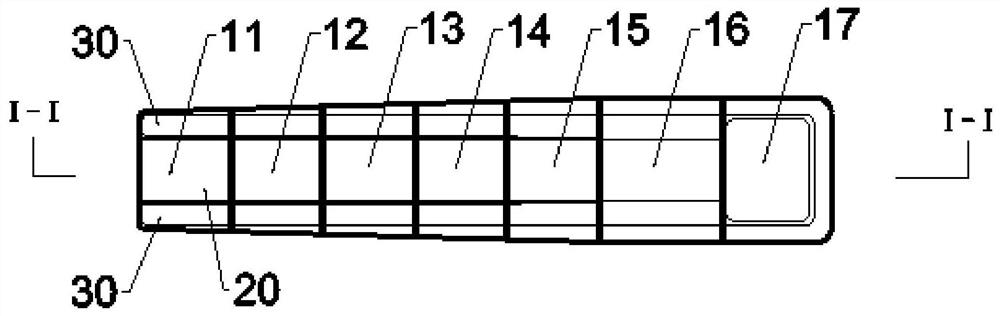

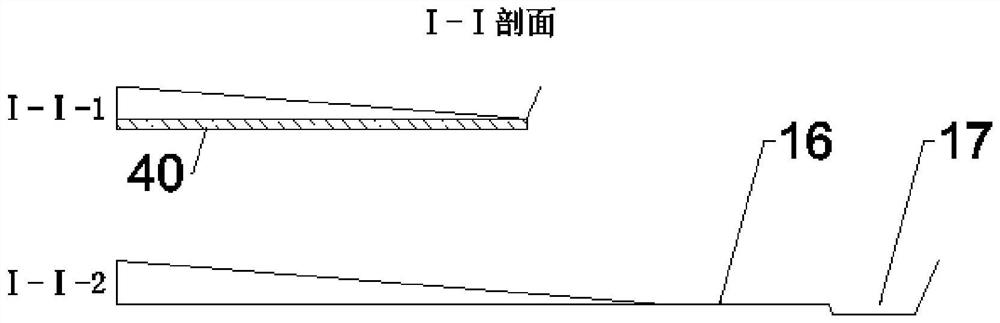

[0019] like Figure 1-2 As shown in the present invention, a deep one-time blasting rapid ditching method for the whole section of a large water inflow depression open-pit mine section is selected to arrange the entrance and exit ditches in the area with a small water inflow according to the hydrogeological conditions of the mine site, and the entrance and exit ditches are divided into Five sub-sections [11-15], carrying out blasting and shoveling operations one by one, forming normal trenching in the middle of the plot [20], surrounding advance blasting expansion [30] and bottom blasting pile water collection layer [40] , with the development of the advance blasting expansion[30], the follow-up ditch[16] and the initial sump[17] are completed, which can effectively reduce the impact of water inflow on the excavation of new level depressions, reduce the transportation distance of ore and rock, and release The ore volume of the next level ensures the balance of the secondary or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com