A full-face rock formation construction method in which the mud-water shield develops cracks

A technology of mud-water shield and construction method, which is applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve problems such as operation affecting the safety of tunnels, increase the cost of human, property, and water leakage of tunnel segments, and achieve enhanced Waterproof effect, increase the mud circulation flow, reduce the driving speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

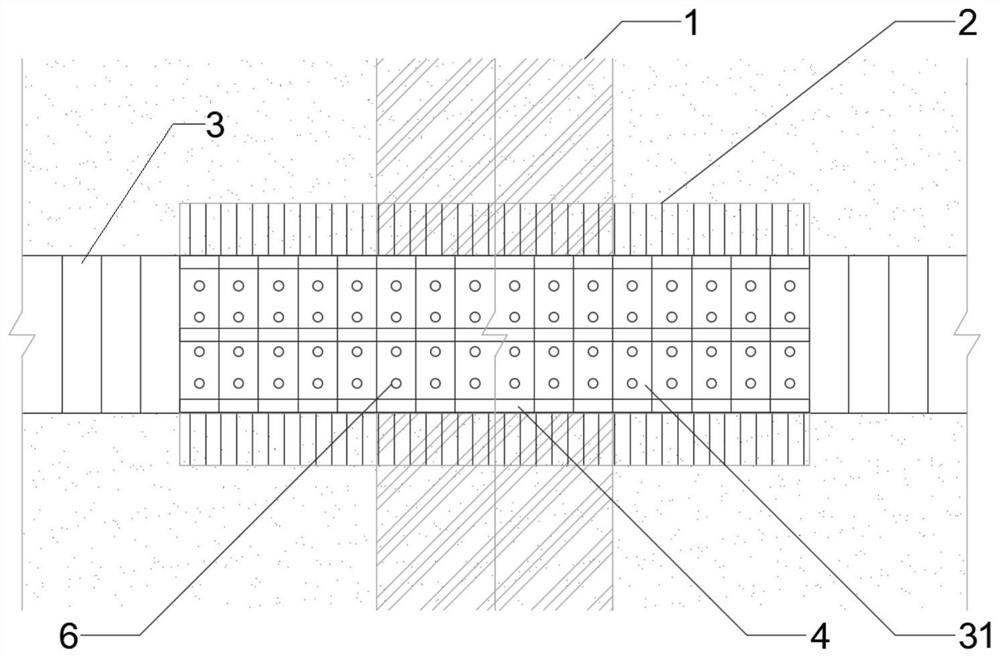

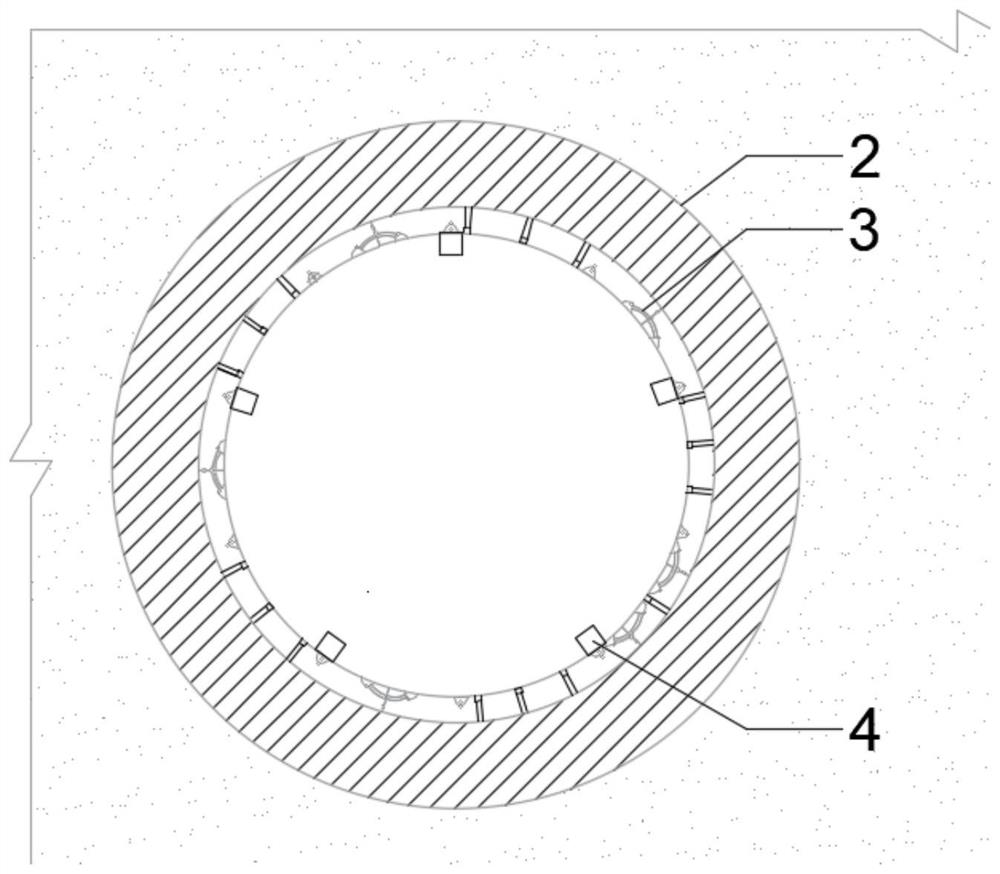

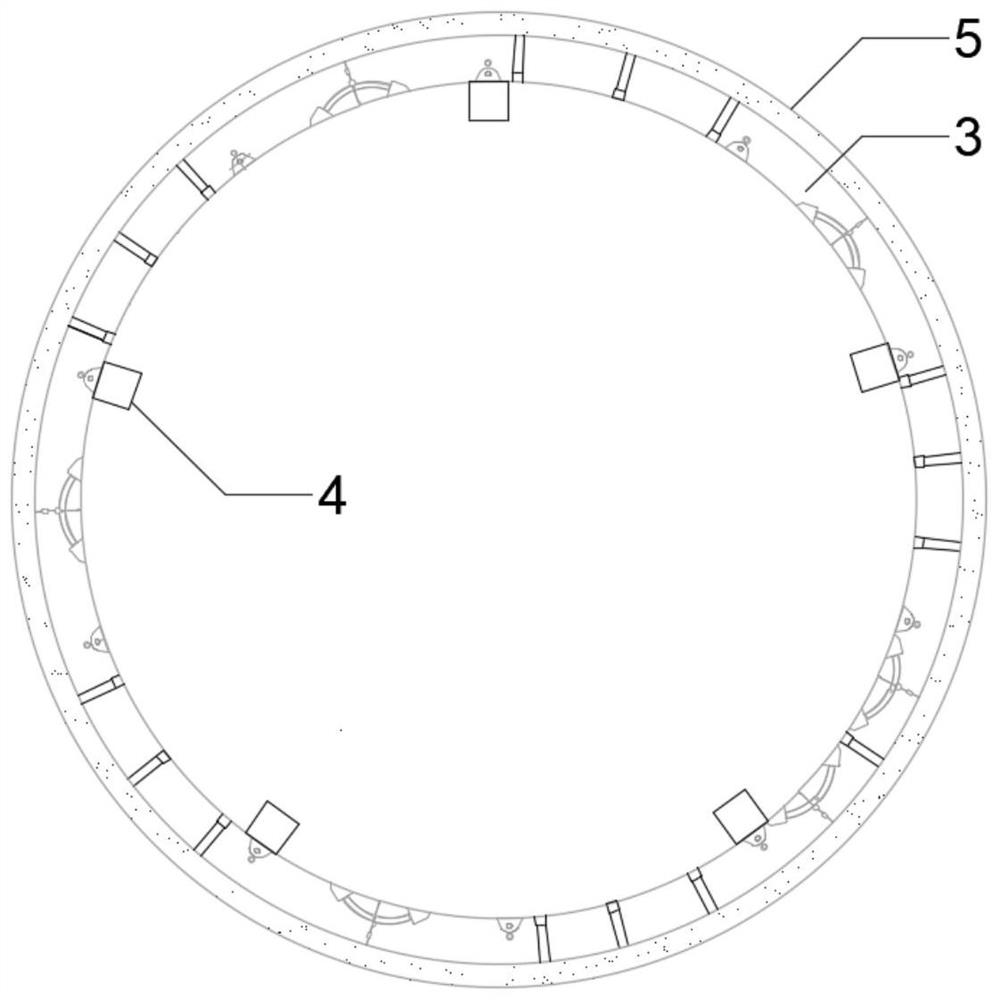

[0057] Such as Figure 1-3 , the construction method of the full-section rock strata in which the mud-water shield develops in the crack; comprises the following steps:

[0058] Step 1, preset the water stop hoop:

[0059] The cutter head of the shield machine (not shown in the figure) is stopped 2-5m away from the fissure zone area 1, and the optimal distance area is 3m. At least three annular water-stop hoops 5 are successively arranged at the tail of the shield machine to prevent shield When the mechanism passes through the fracture zone area, the groundwater passes through the fracture zone area to dilute the mortar on the back of the segment 3, causing the segment 3 to float up and be damaged.

[0060] Step 2, the shield machine passes through the fissure zone area:

[0061] Step 2.1, according to the actual situation of the formation, appropriately reduce the speed of the shield machine cutterhead and the tunneling speed, reduce the cutterhead speed: 1.7r / min→1.2r / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com