Shield Digging Safety and Fast Combination Light Pillow

A technology of shield and sleeper, which is applied in the field of shield tunneling, safe and quick combination of light sleepers, can solve the problems of laborious installation of sleepers, time-consuming maintenance, and labor-consuming dismantling, so as to improve work efficiency, reduce operation and maintenance, and achieve flexible and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

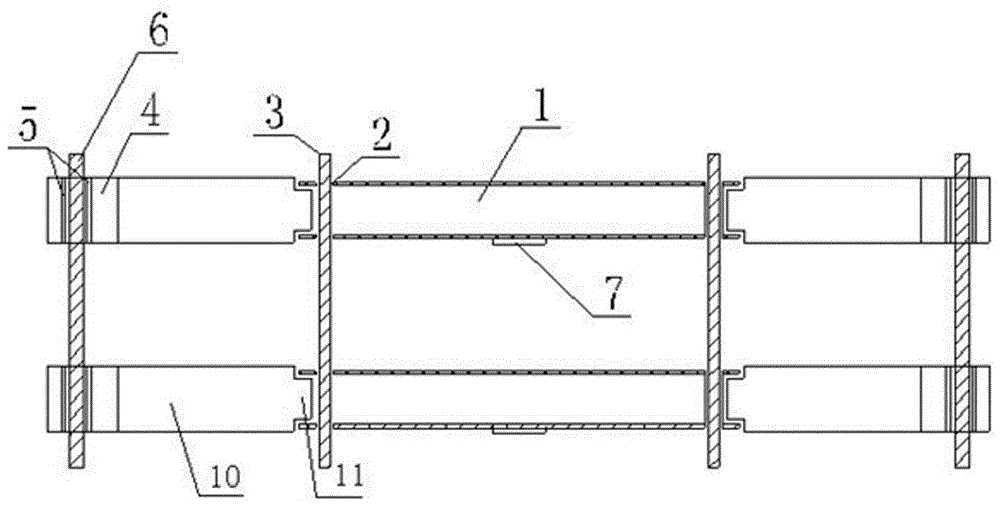

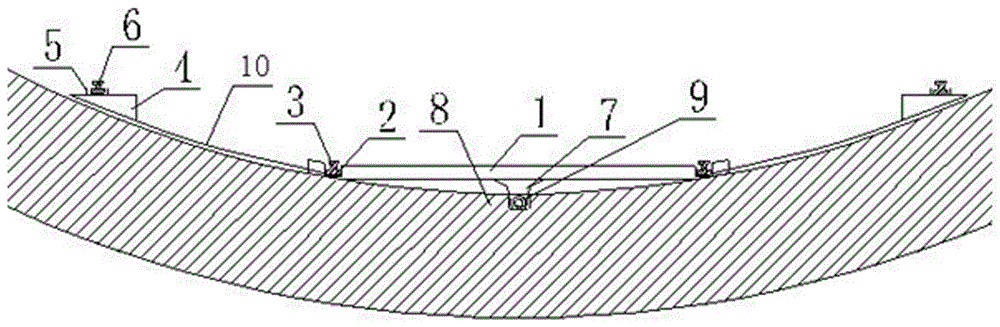

[0017] Safe and fast combination of light sleepers for shield tunneling, such as figure 1 , 2 As shown, it includes transport vehicle channel sleepers 1 arranged at intervals along the tunnel excavation direction and located in the middle of the tunnel bottom segment 8, and shield tunneling sleepers assembled with the two ends of the transport vehicle channel steel sleepers respectively, and adjacent transport vehicle channel steel sleepers Both ends are provided with U-shaped grooves 2 at the same position, and the transport vehicle rails 3 are placed in the U-shaped grooves on both sides of each transport vehicle channel steel sleeper; shaped steel plate 10 and the arc-shaped step sleeper 4 fixed at the high end of the arc-shaped steel plate, the low end of the arc-shaped steel plate is provided with a convex part 11 plugged with the channel steel sleeper of the transport vehicle, and the arc-shaped step sleeper is provided with two positions opposite to each other. The rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com