Basement bottom plate post-cast strip reserved drainage well rear sealing structure

A basement floor, closed structure technology, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve problems such as leakage of drainage wells, and achieve the improvement of work and life comfort, practicability, and operational procedures. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

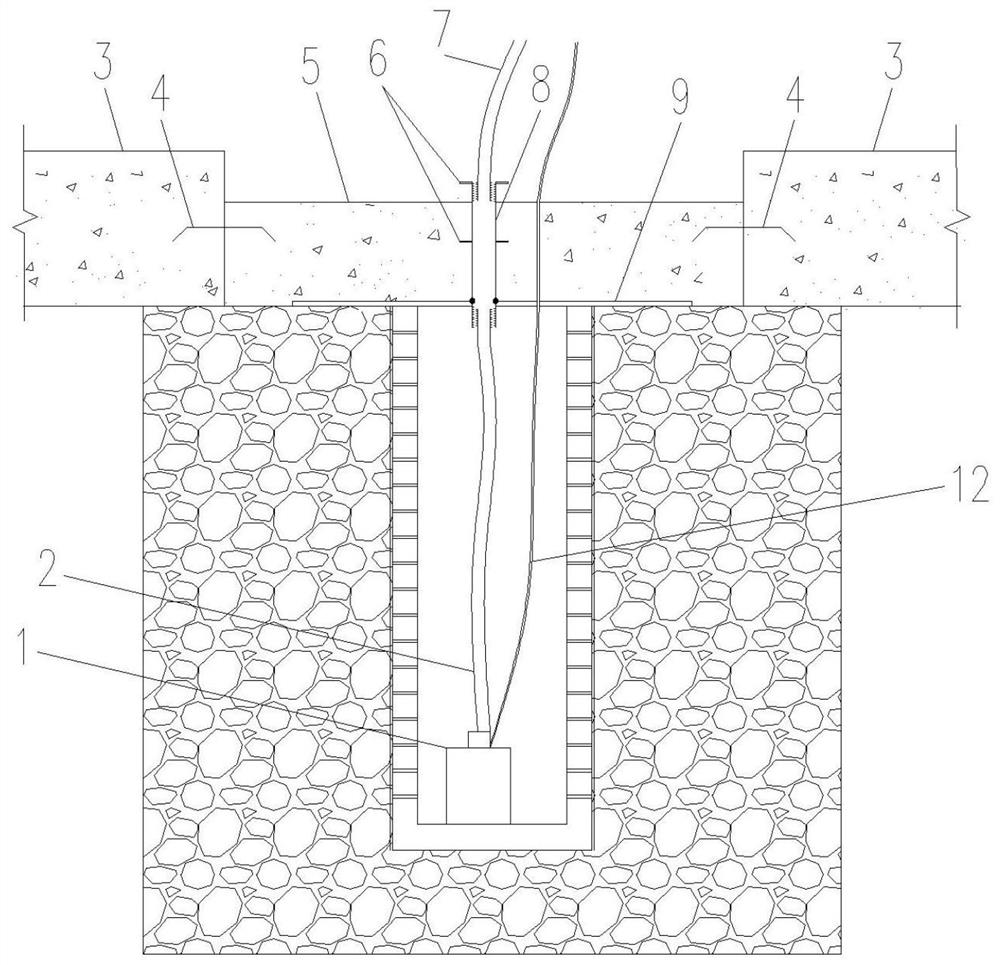

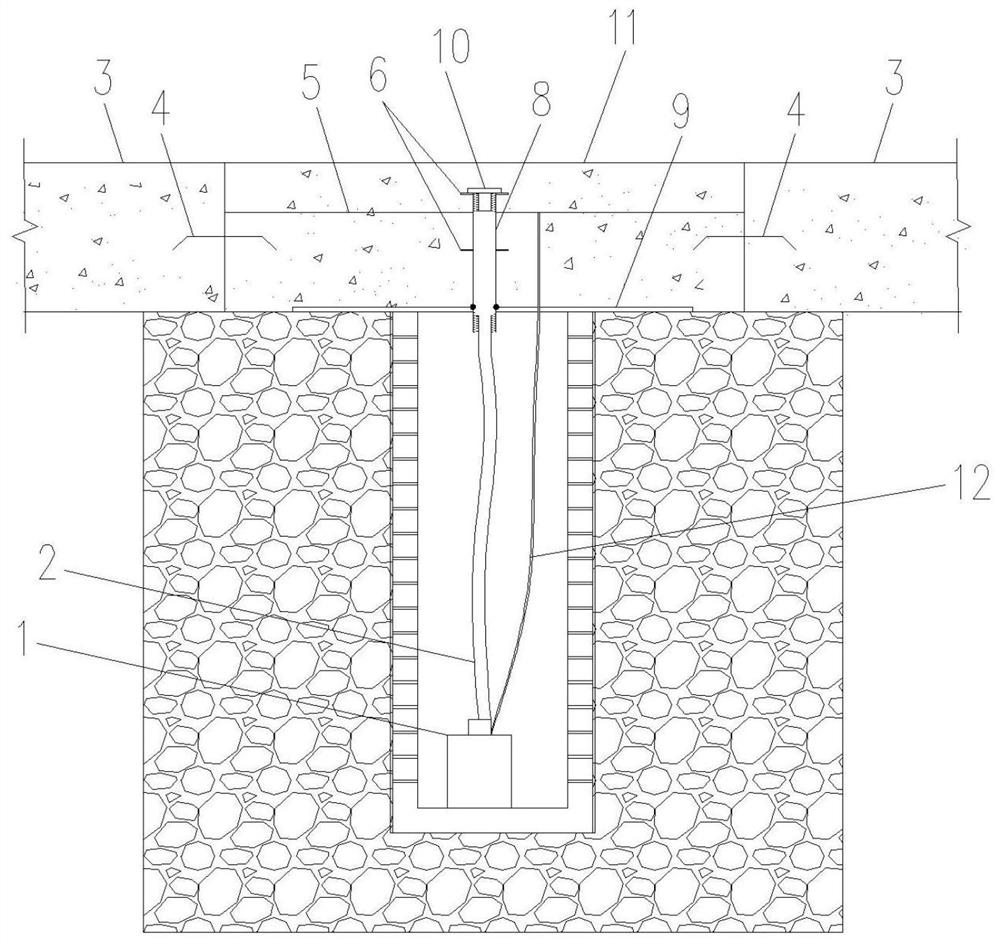

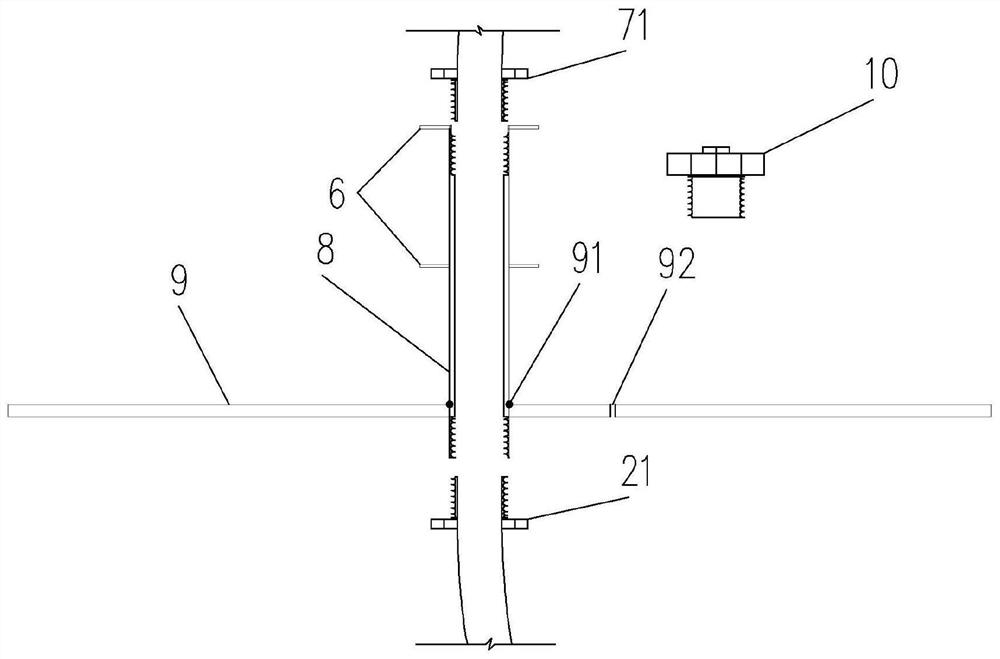

[0018] refer to Figure 1 to Figure 4 , the present embodiment provides a basement basement post-casting belt to reserve a closed structure behind the drain well, the upper end of the drain well is closed by a steel plate 9 covered, the steel plate 9 adopts a 20 mm thick steel plate, and the steel plate 9 is provided with a steel pipe hole 91 with a diameter of 50 mm The galvanized steel pipe 8 passes through the steel plate 9 through the steel pipe hole 91, and the periphery is fully welded. At the same time, a cable hole 92 with a diameter just enough to accommodate a 12-core cable is opened on the steel plate 9, so that the cable 12 connected to the water pump 1 is drawn out to the The external power supply supplies power to the water pump 1. The water pump 1 is permanently placed in the drainage well. The water inlet of the water pump 1 is wrapped with a filter screen. The water pump 1 is connected to one end of the water pipe 2 in the well. The water pipe joint 21 is thre...

Embodiment 2

[0036] Based on the method of closing the drain well after the basement floor post-pouring belt in the first embodiment, the improvement of this embodiment lies in:

[0037] When the groundwater level is high, the water volume is abundant, and the discharge wells have a lot of water, two or more water pumps 1 can be permanently embedded for pumping water, and one or more galvanized steel pipes 8 are correspondingly added to the steel plate 9 for pumping water. The principle of plugging is the same as that of Embodiment 1. The pumping rate is increased to ensure that the groundwater level is below the floor, which meets the construction requirements for anti-floating, and the quality of plugging can also be guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com