Dustproof heat dissipation system and method for subway vehicle-mounted controller cabinet

A vehicle-mounted controller and heat dissipation system technology, which is applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the unsatisfied safety requirements of subway operations, and the lack of attention to dust-proof and heat-dissipating systems, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

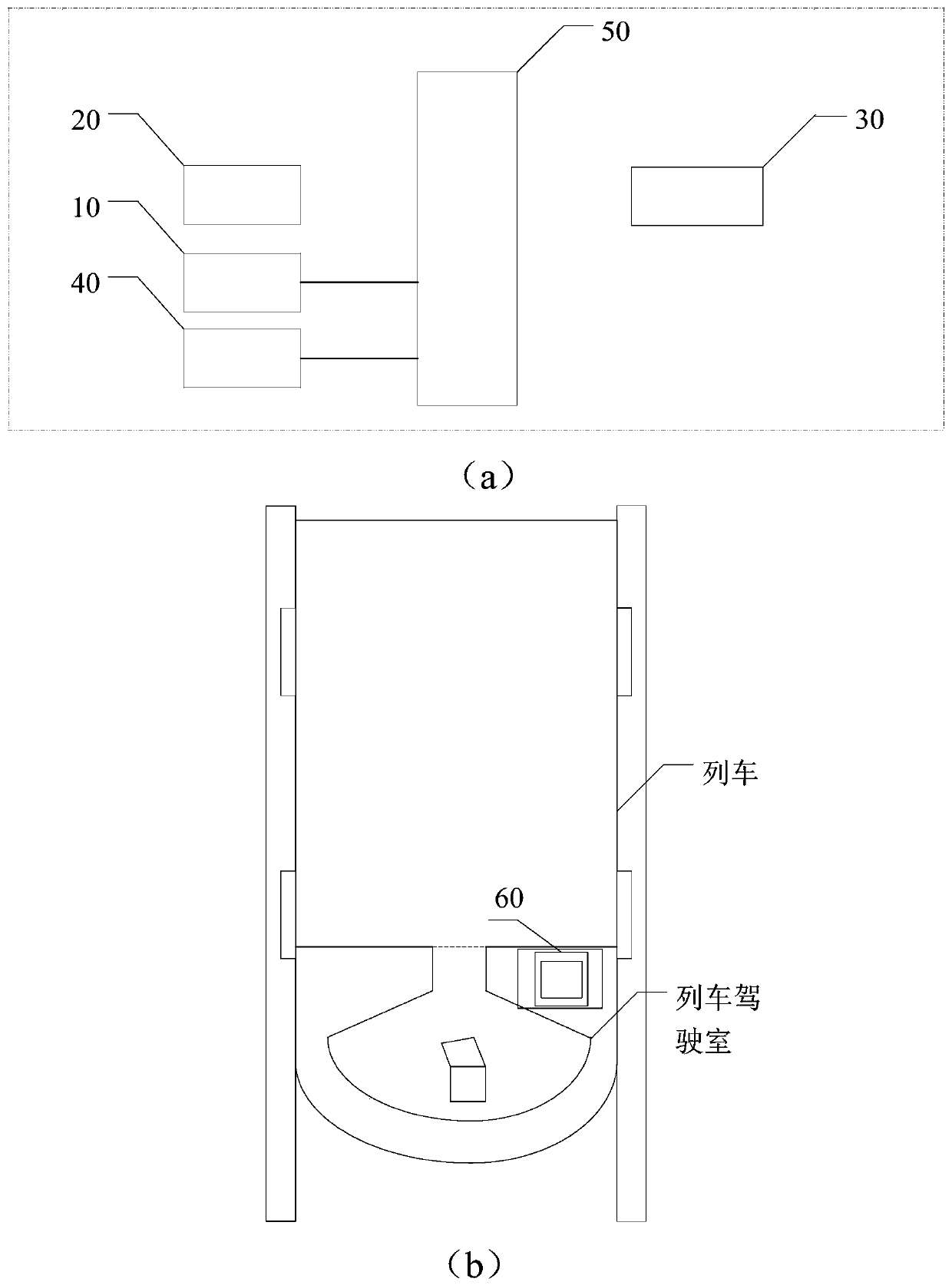

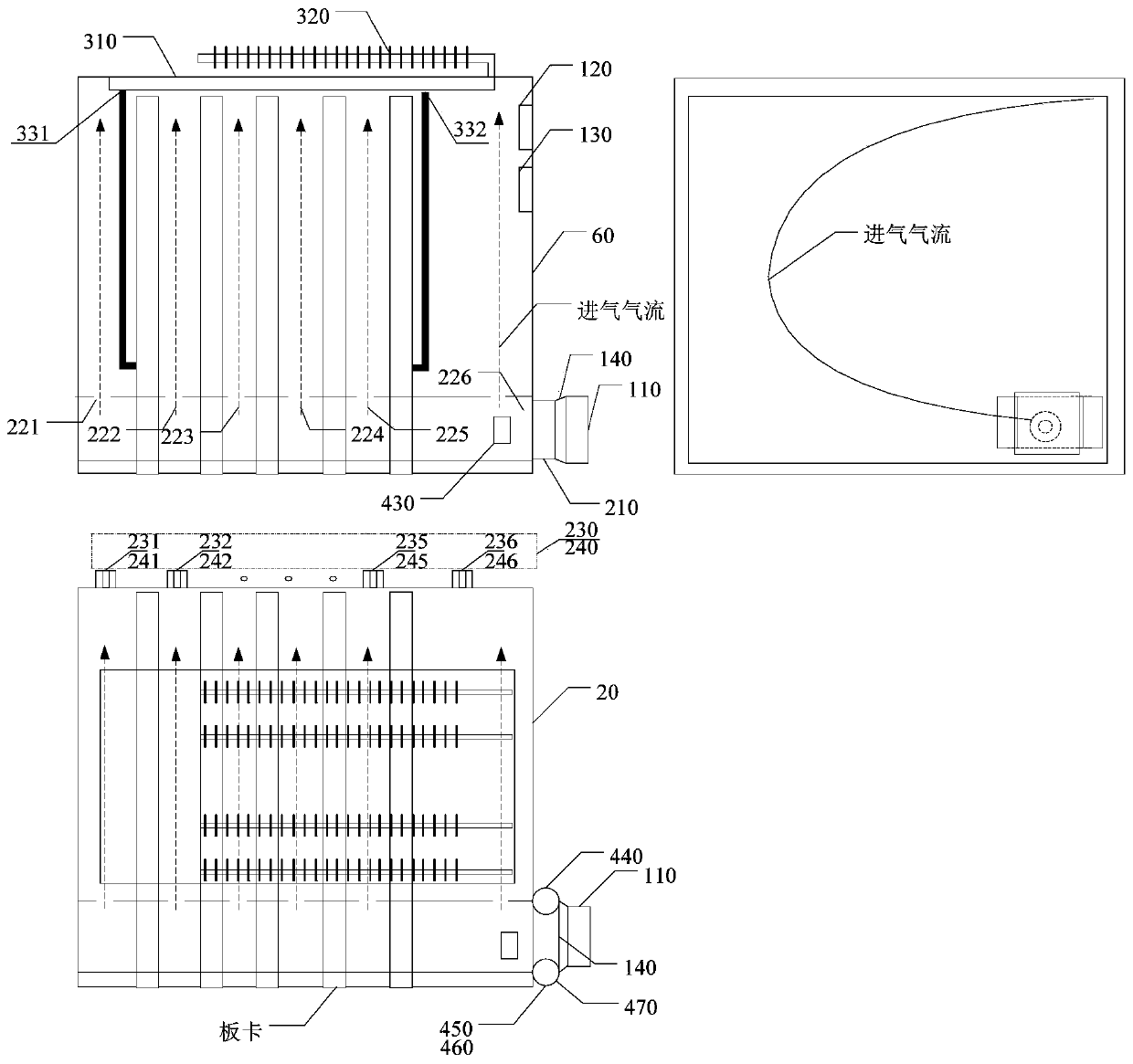

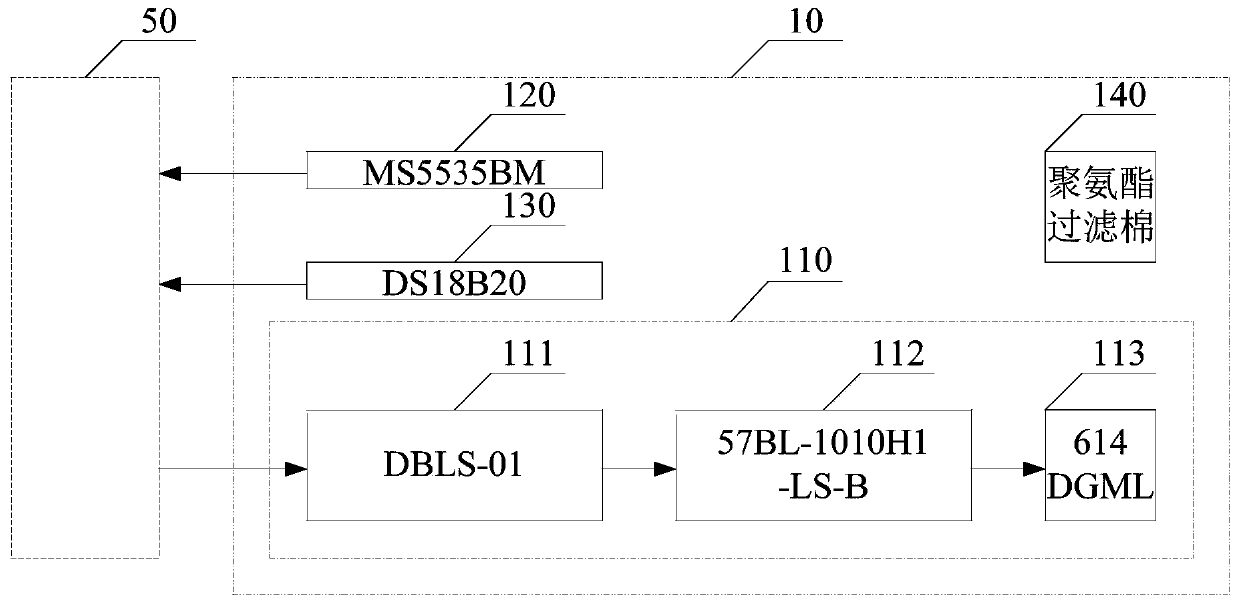

[0105] Such as figure 1 (a), figure 1 (b), figure 2 As shown, the dust-proof and heat-dissipating system of the subway vehicle-mounted controller cabinet is composed of a positive-pressure dust-proof and heat-dissipating unit 10 for filtering the air intake and outlet air through the fan dust-proof filter, an air-flow organization heat-dissipating unit 20 for separating hot and cold air and orderly flow, and a heat pipe Composed of heat dissipation unit 30, dust-proof filter automatic update unit 40, and signal processing main control unit 50, the dust-proof and heat-dissipation system is embedded and installed in the cabinet 60 of the subway vehicle controller; The unit 10 is connected to the dust-proof filter screen automatic update unit 40;

[0106] Under the control of the signal processing main control unit 50, the positive pressure dust-proof heat dissipation unit 10 sucks the cooling air filtered through the dustproof filter; The heat generated by the on-board contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com