Ditch excavation method for one-time blasting and layered shoveling of large-water-inflow sunken strip mine

A technology of water inflow and open-pit mines, applied in blasting, drainage, safety devices, etc., can solve the problems of long duration, reduction of mine production, and unfinished preparation for the new level of the lower part, so as to achieve the effect of improving efficiency and ensuring production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

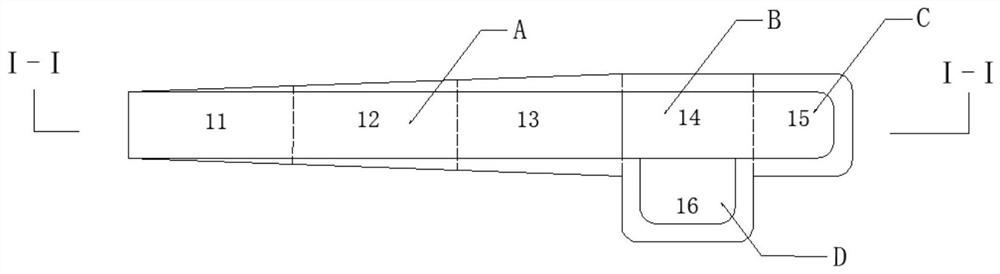

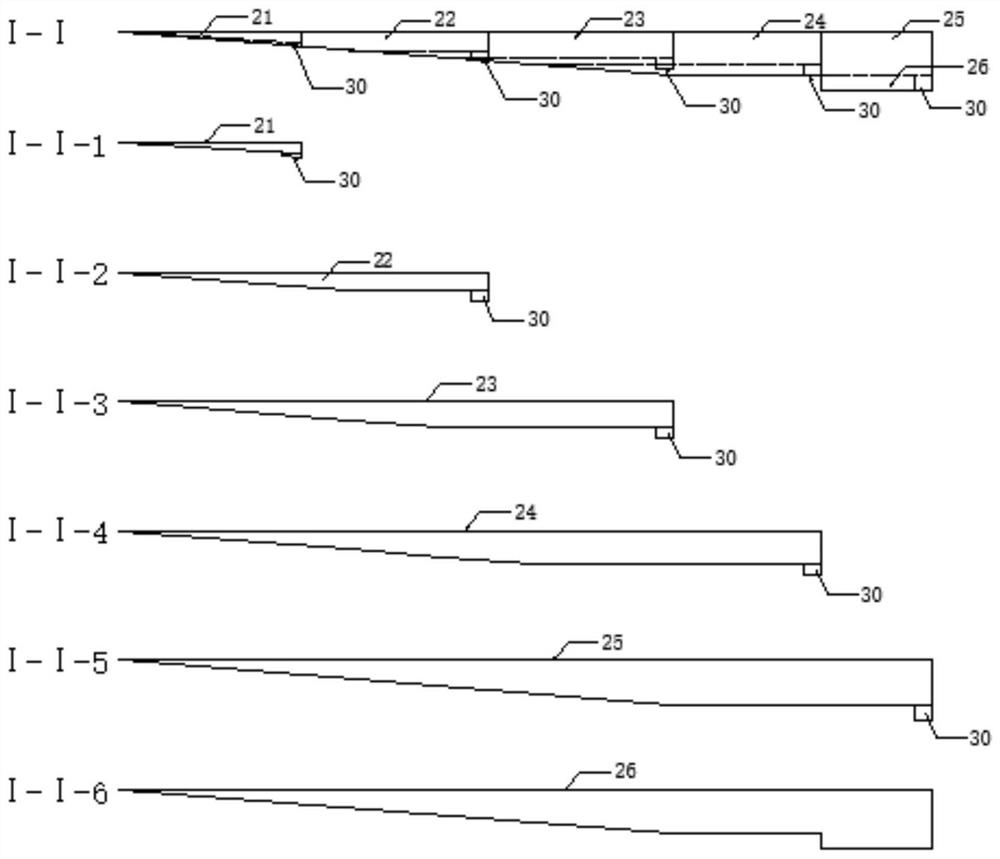

[0018] Such as Figure 1-2 As shown, the present invention proposes a trenching method for layered shoveling of primary blasting in a sunken open-pit mine with a large amount of water inflow, including trenching, blasting and shoveling operations, and is characterized in that the trenching operation includes arranging the entry and exit trenches [A] , open section ditch [B], short-term sump [C] and initial expansion [D]; piercing and blasting operation is divided into six sections and segmental piercing and blasting [11-16]; shoveling operation includes six times of shoveling [21 ~26], which can effectively reduce the impact of water inflow on the excavation of the new level sag, improve the progress of the new level of excavation, release the lower ore volume in time, and ensure the stable production of the mine.

[0019] The method of the present invention can further be

[0020] The entry and exit ditch [A] of the trench digging operation is divided into three sections, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com