Lens driving structure, photographic device and electronic product

A lens driving and driving device technology, applied in the field of motors, can solve the problems of high production cost, excessive volume and high control difficulty, and achieve the effects of reducing the structure, realizing the zoom function and high-precision focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

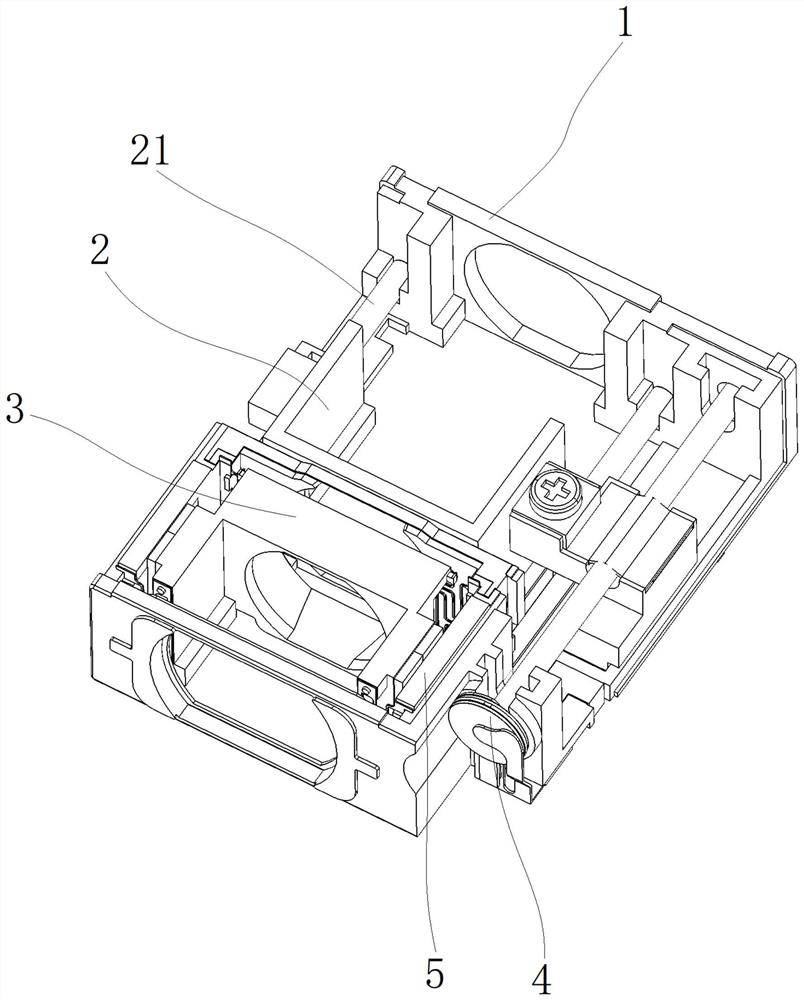

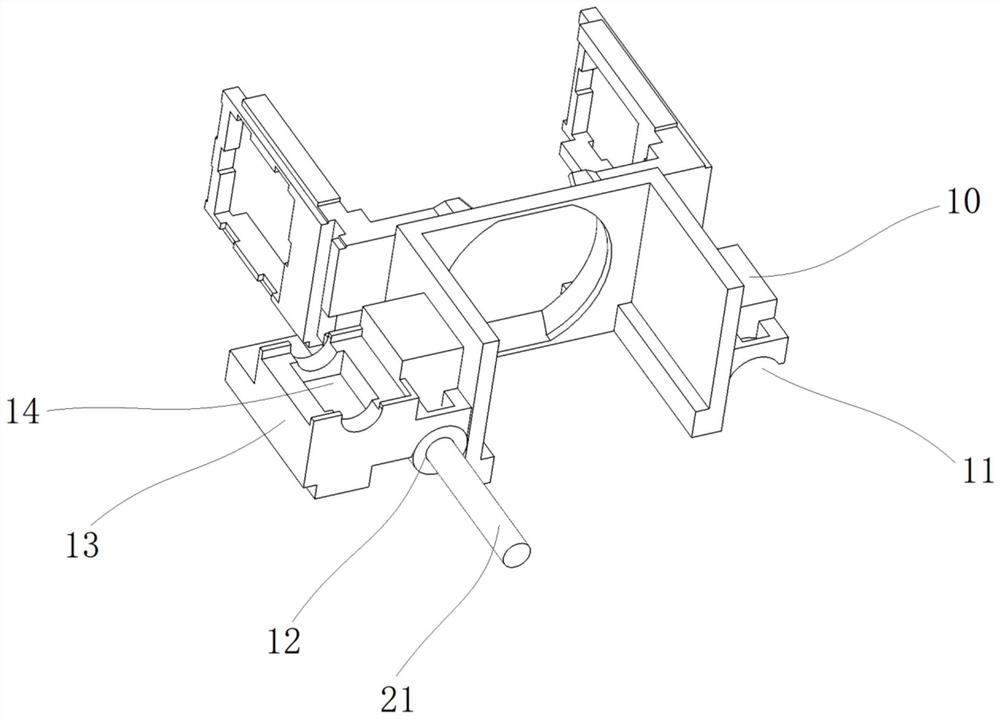

[0036] A lens driving structure, comprising a frame (1), a first carrier (2), a second carrier (3), a first driving device (4) and a second driving device (5) arranged in the frame (1) ;

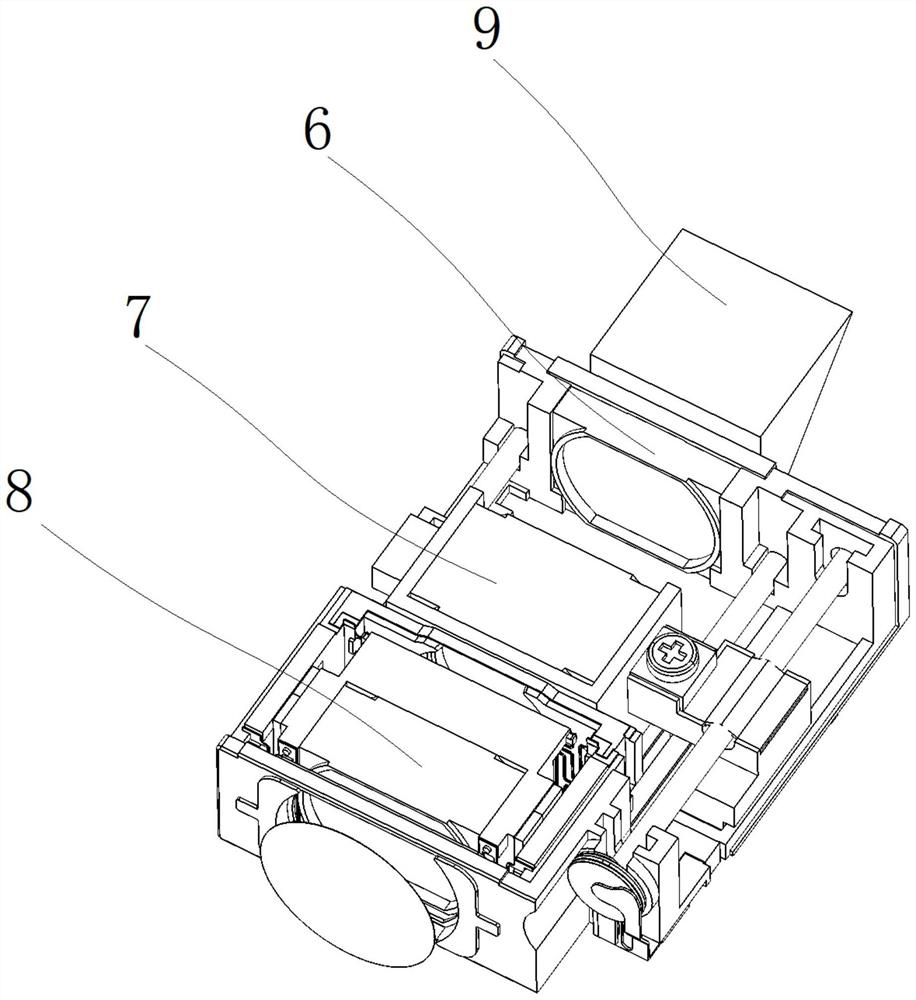

[0037] see figure 2 , In this embodiment, the installation position of the prism (9) is set as the front side, and the installation position of the third lens mounting body (8) is set as the rear side.

[0038] Both ends of the front side of the first carrier (2) are respectively movably arranged in the frame (1) through a slide rail (21), and a first driving device (4) is installed at one end of the front side of the first carrier (2). , the first driving device (4) connects and drives the first carrier (2) to move along the slide rail (21) in the frame (1);

[0039] The rear side of the first carrier (3) is provided with a second carrier (3) and a second driving device (5), and the second driving device (5) connects and drives the second carrier (3) on the first carrier (2) ) to the re...

Embodiment 2

[0050] A driving device has the lens driving structure as described in Embodiment 1. In this embodiment, other structures of the driving device are the same as those of the prior art, so no detailed description is given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com