Patents

Literature

49results about How to "Prevent signal leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

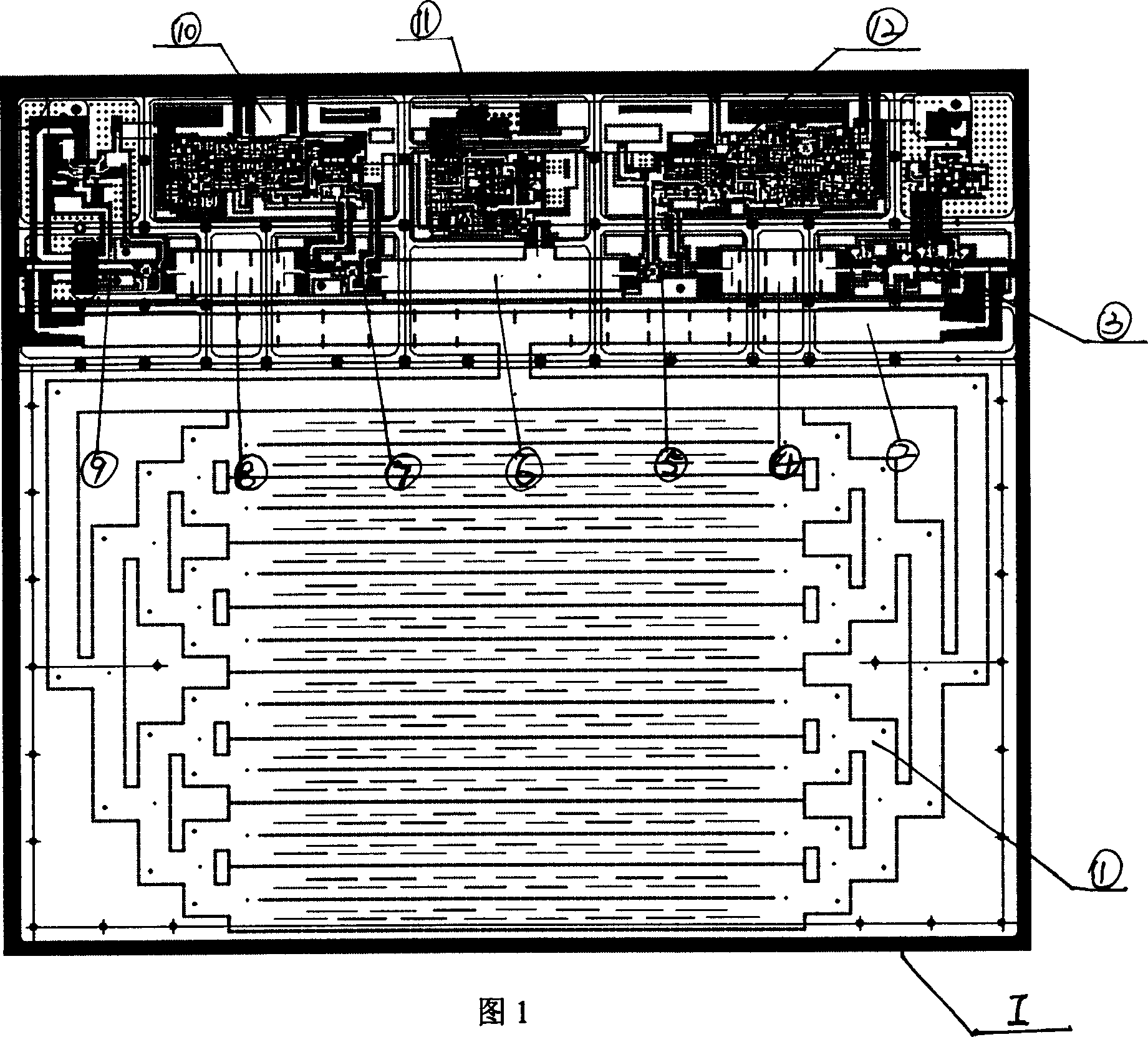

X wave band substrate integrated waveguide single board radio frequency system

This invention relates to a single-board RF system used in microwaves and millimeter waves, especially to an X band chip integrated waveguide single-board RF system including a medium chip set with an antenna, a duplexer, a RF receive noise amplifier, a RF receive filter, a lower converter, a local power splitter, an upper converter, a RF emission filter, an emission power amplifier, an IF emission circuit, a RF local phase lock loop and an IF receiving circuit.

Owner:南京易太可通信技术有限公司

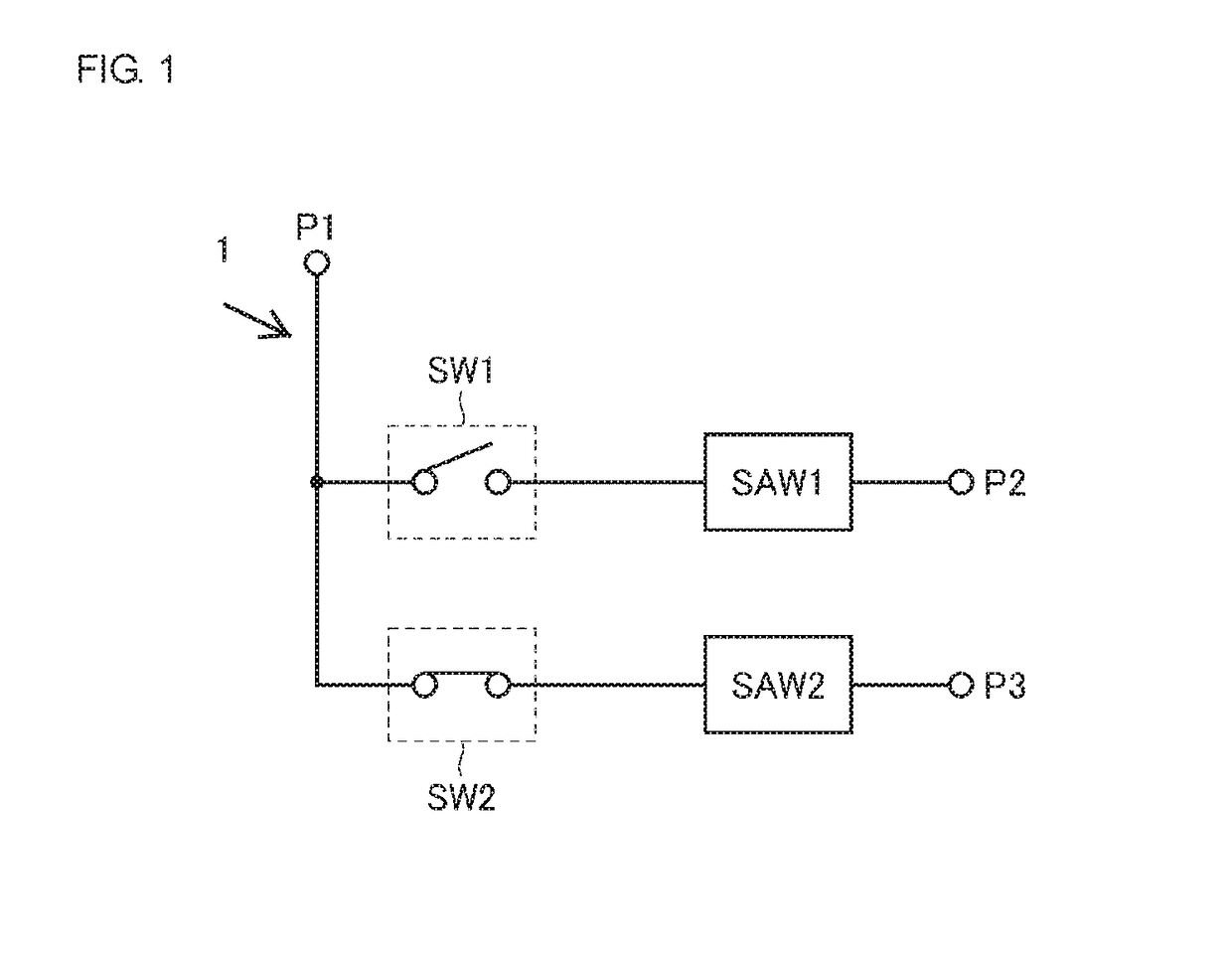

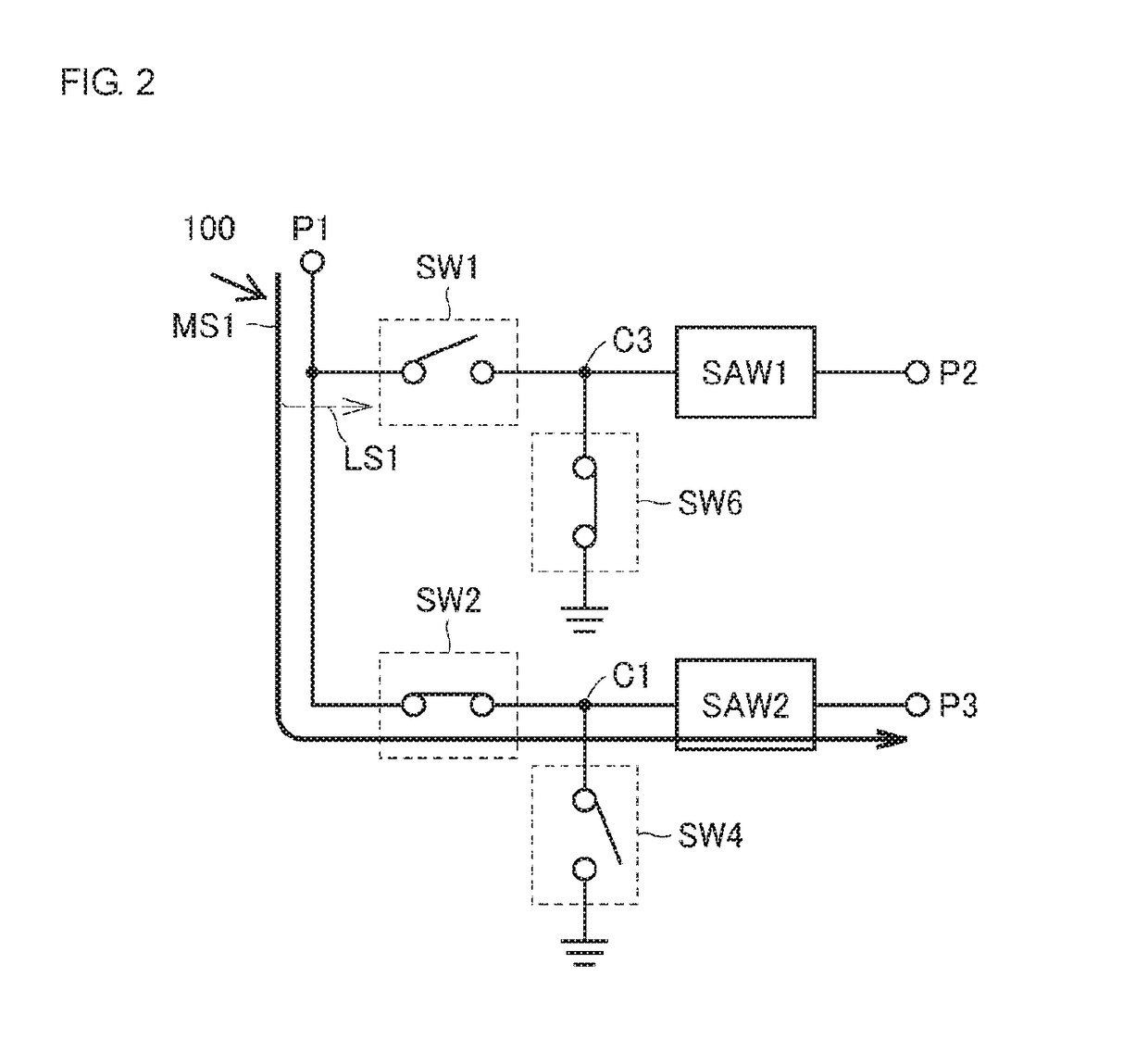

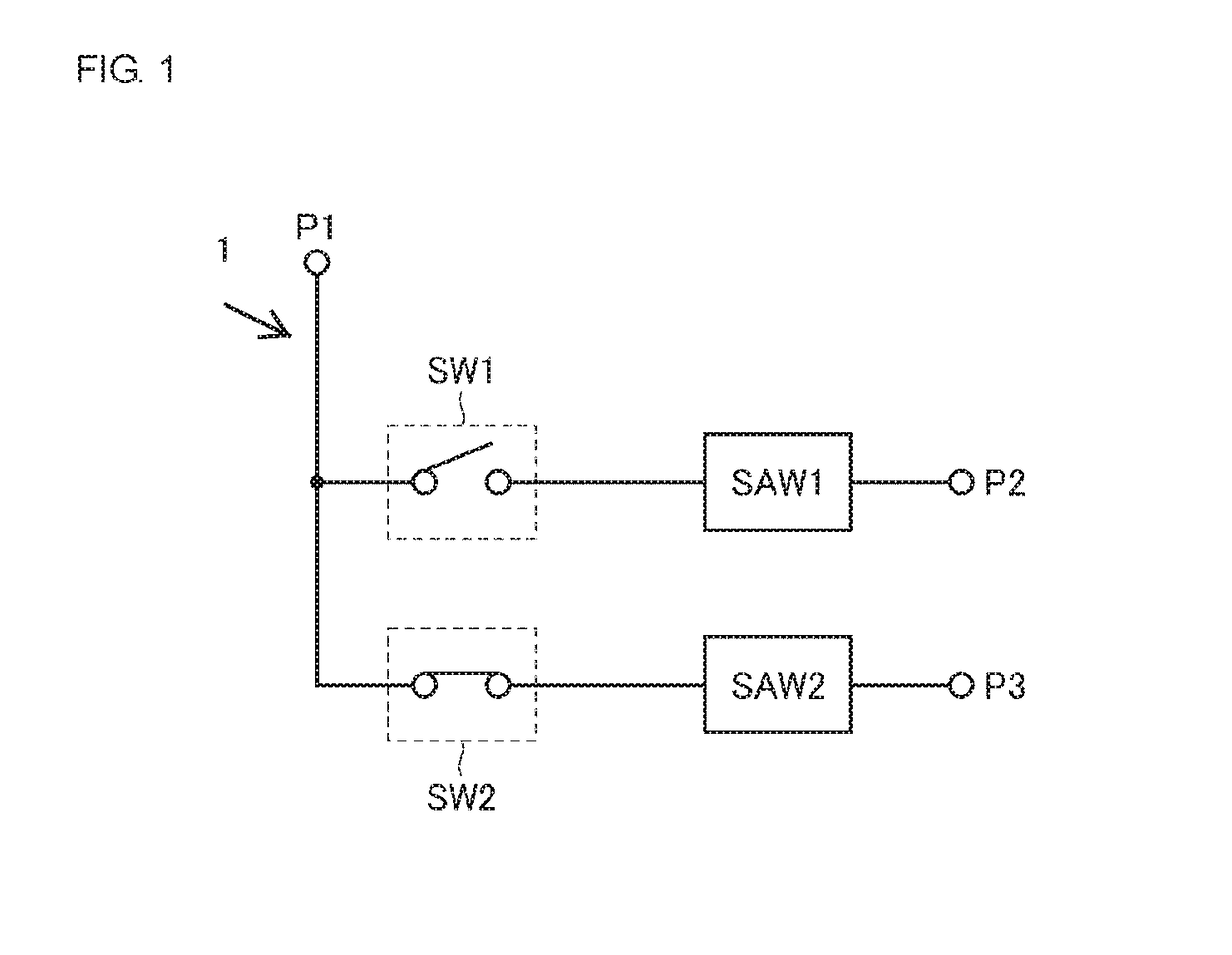

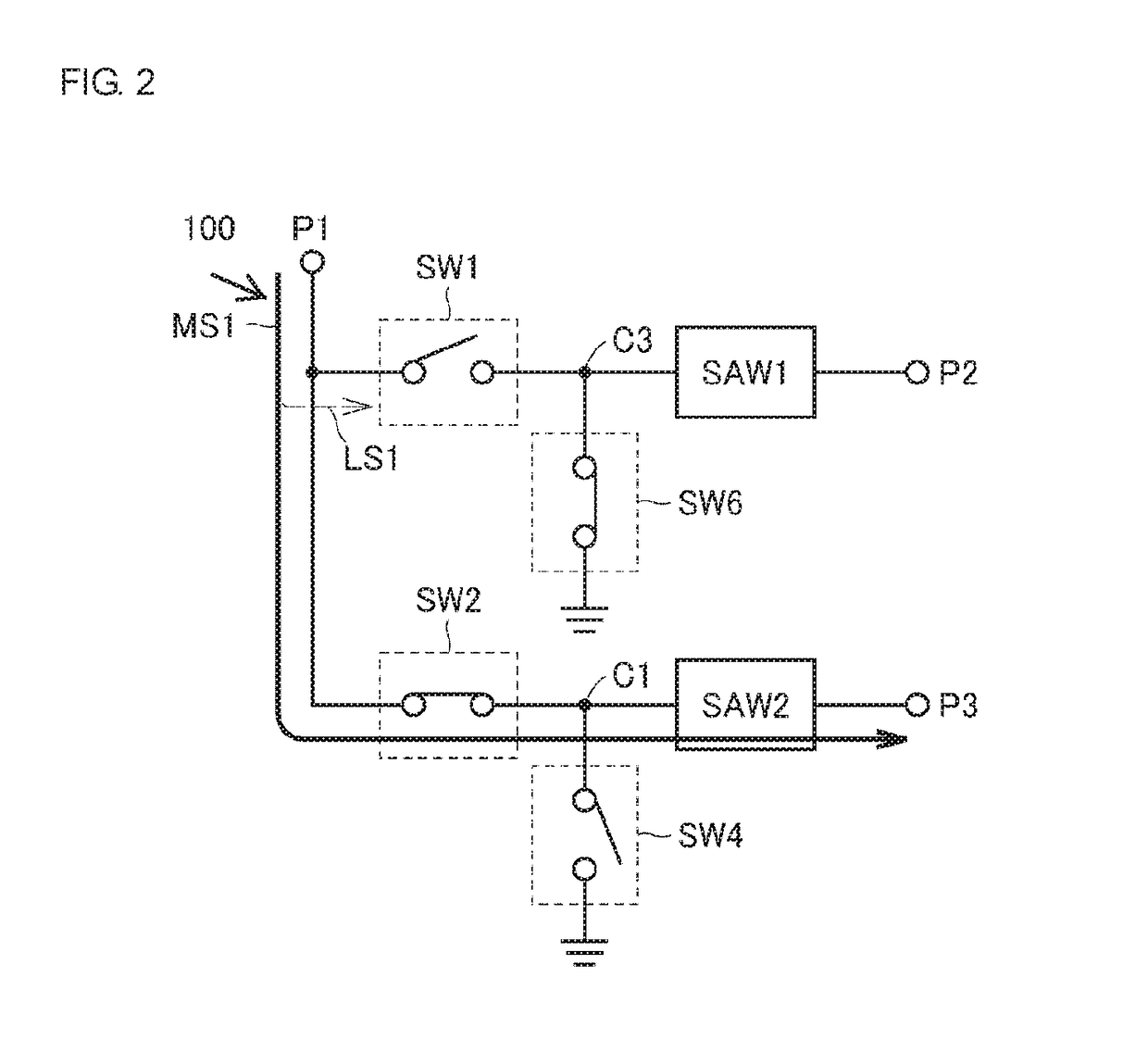

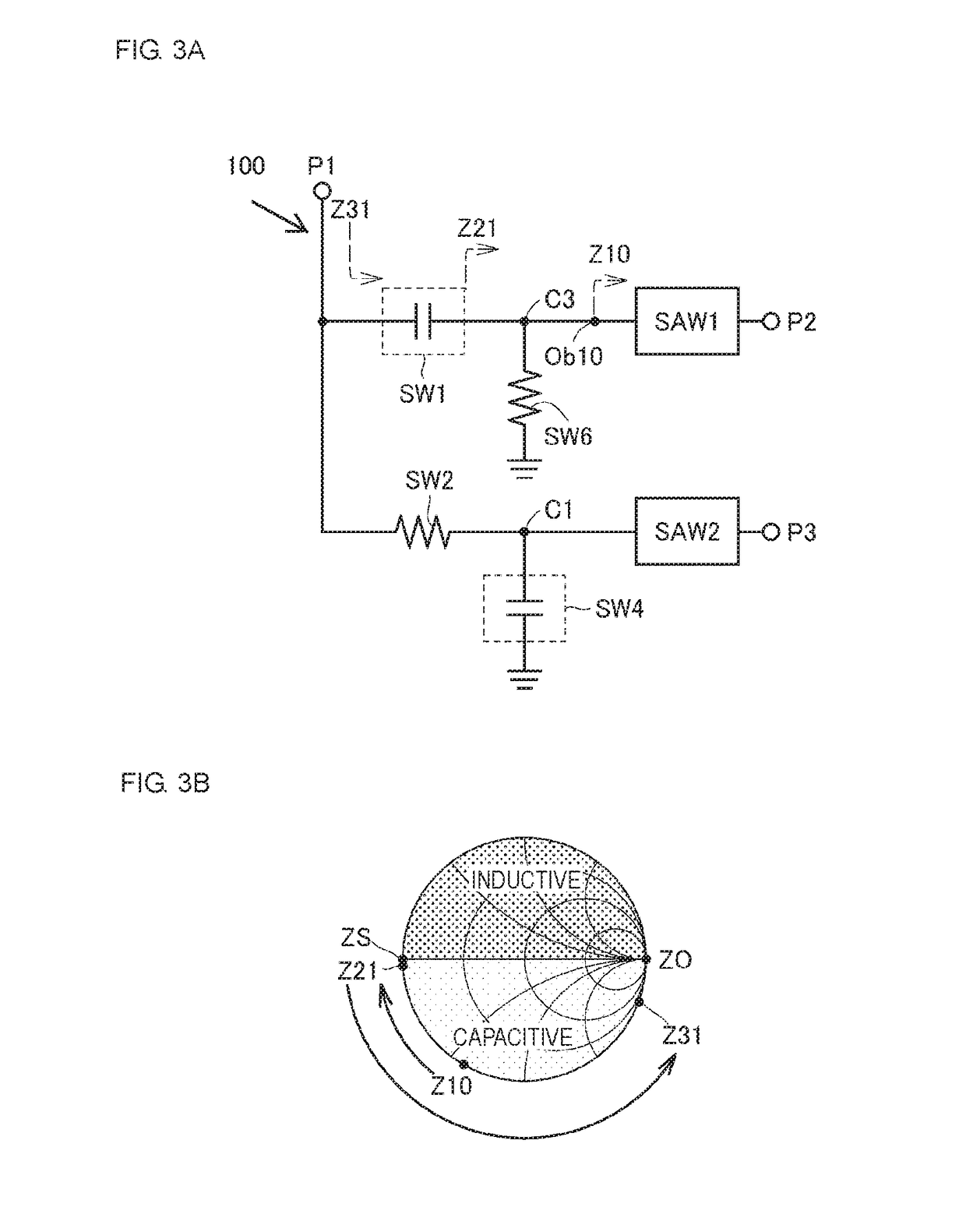

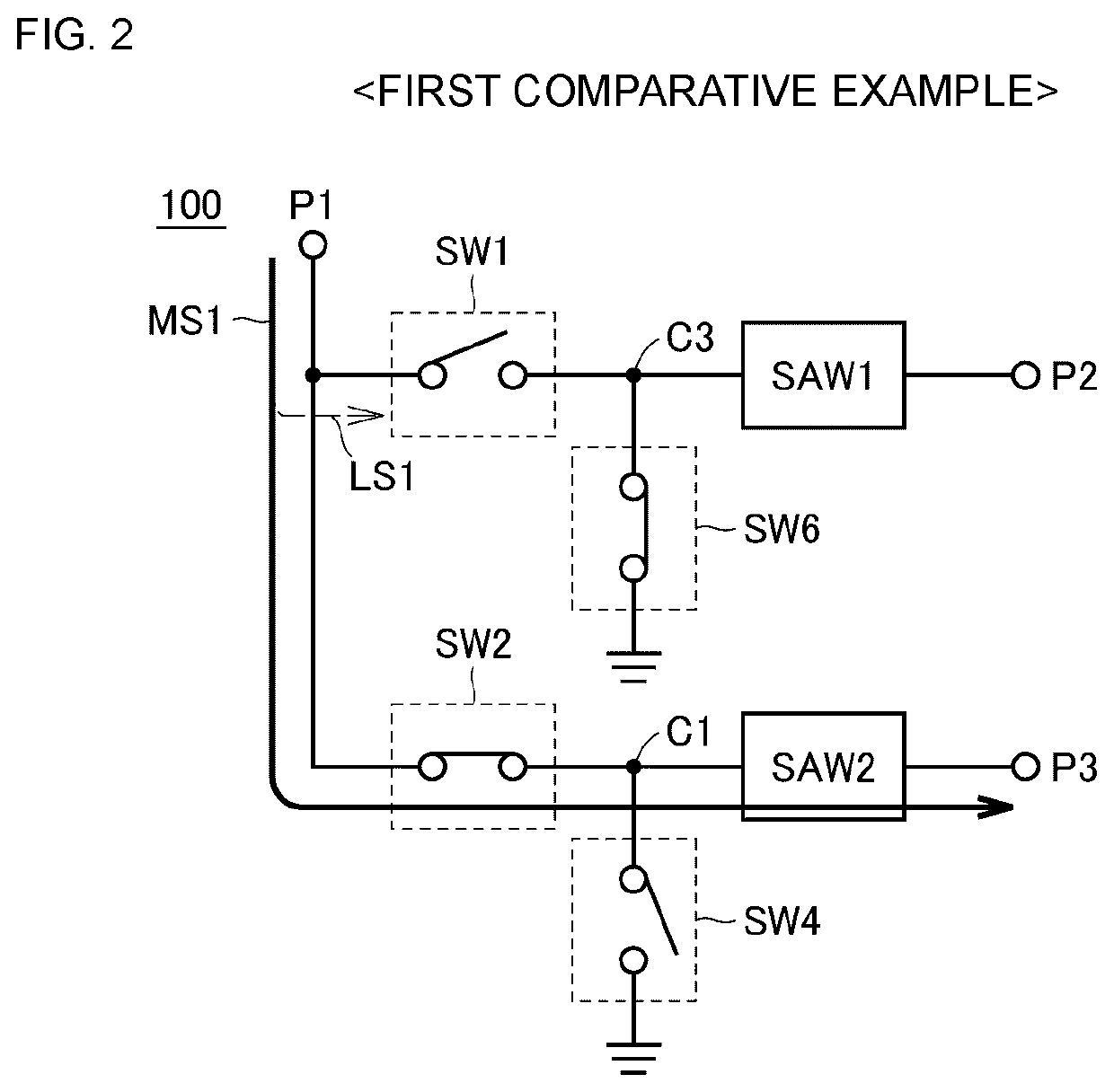

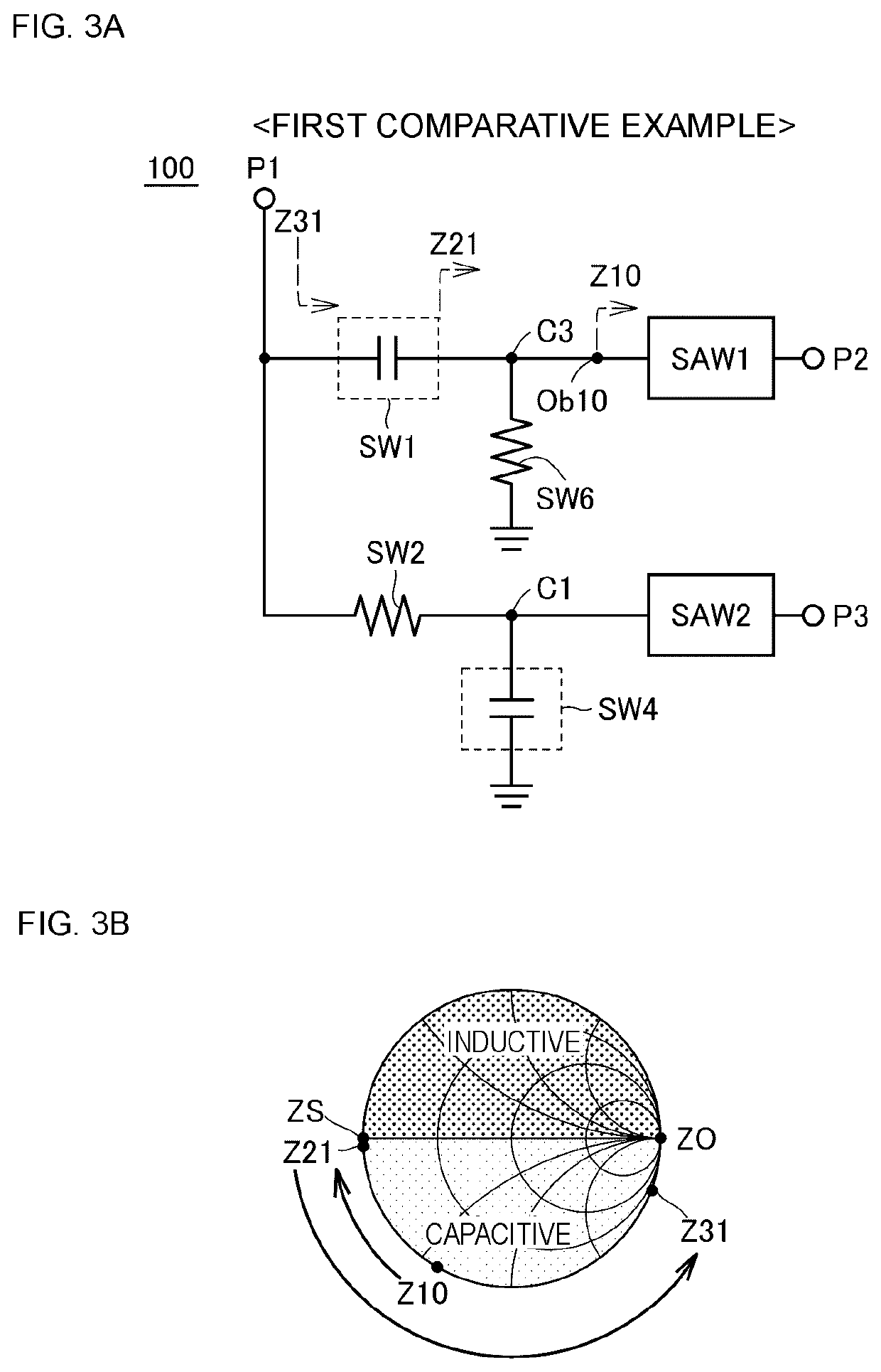

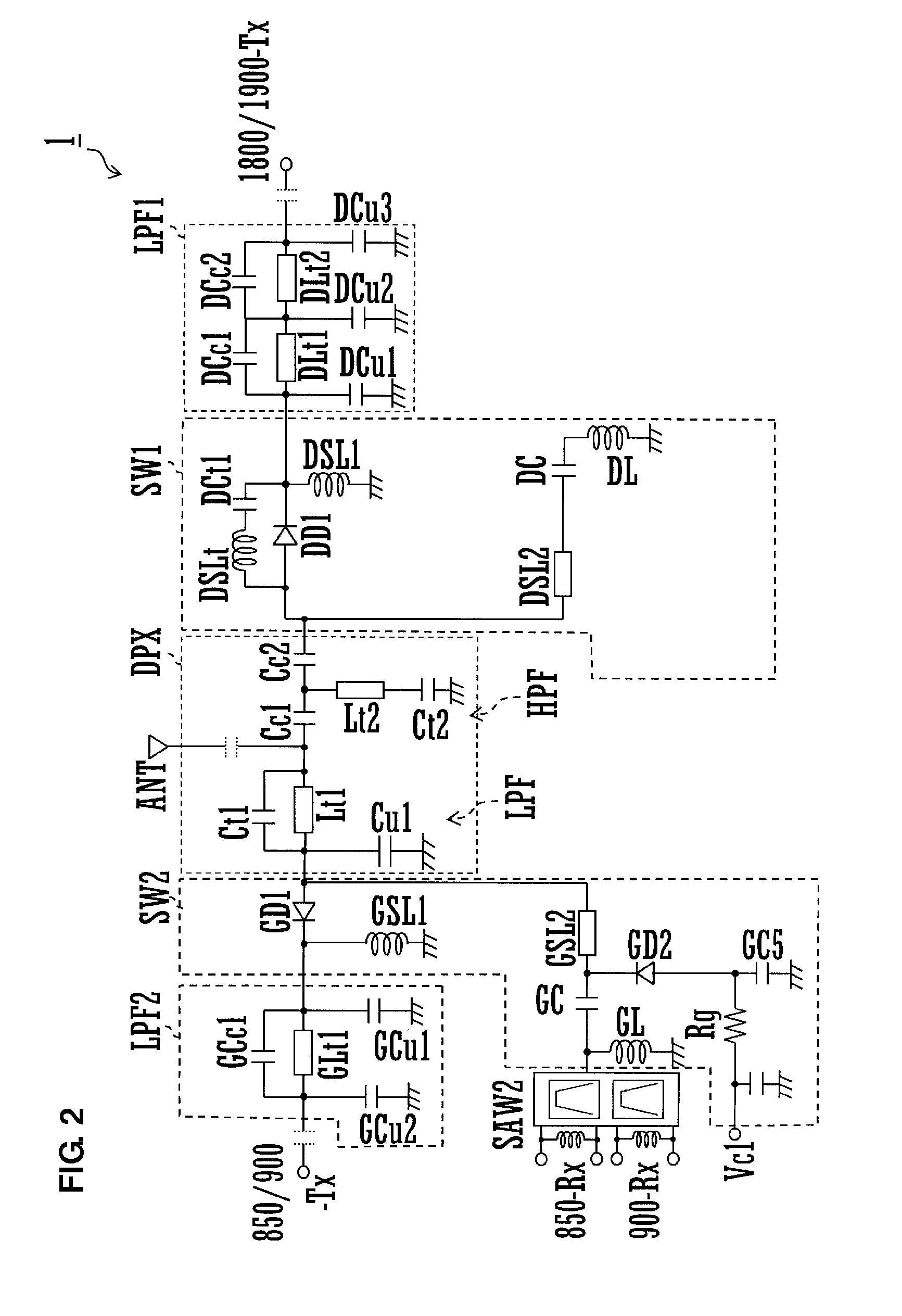

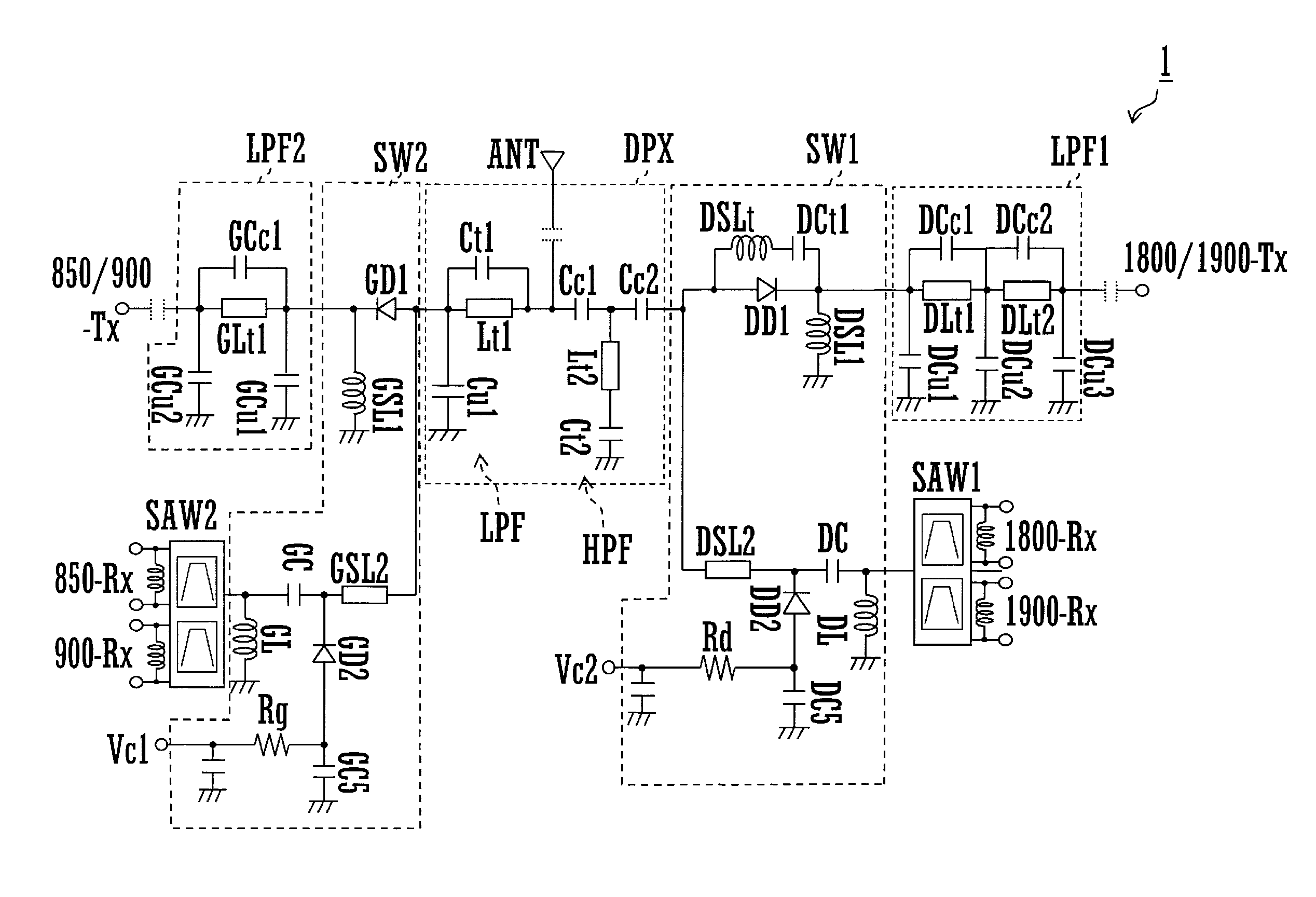

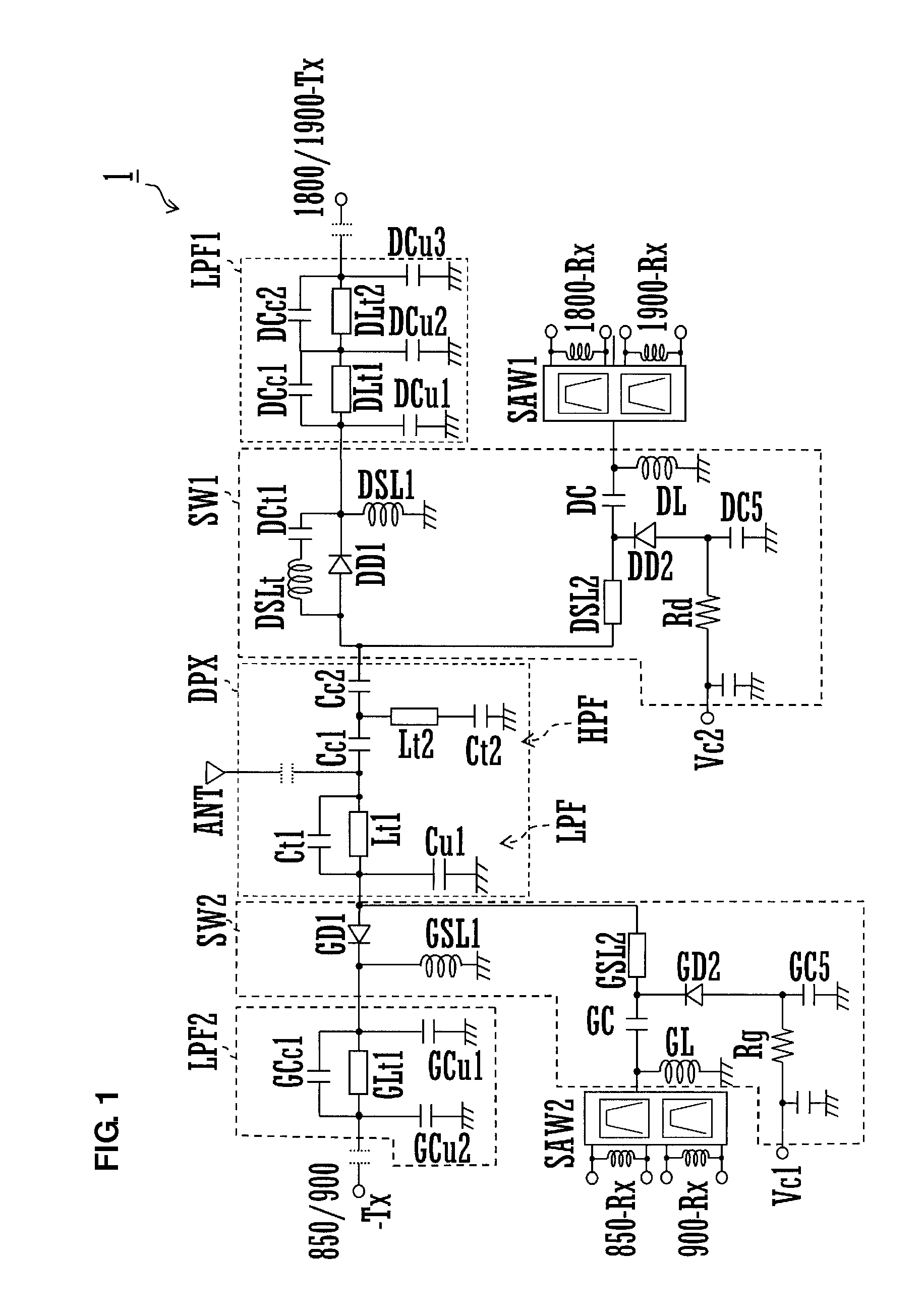

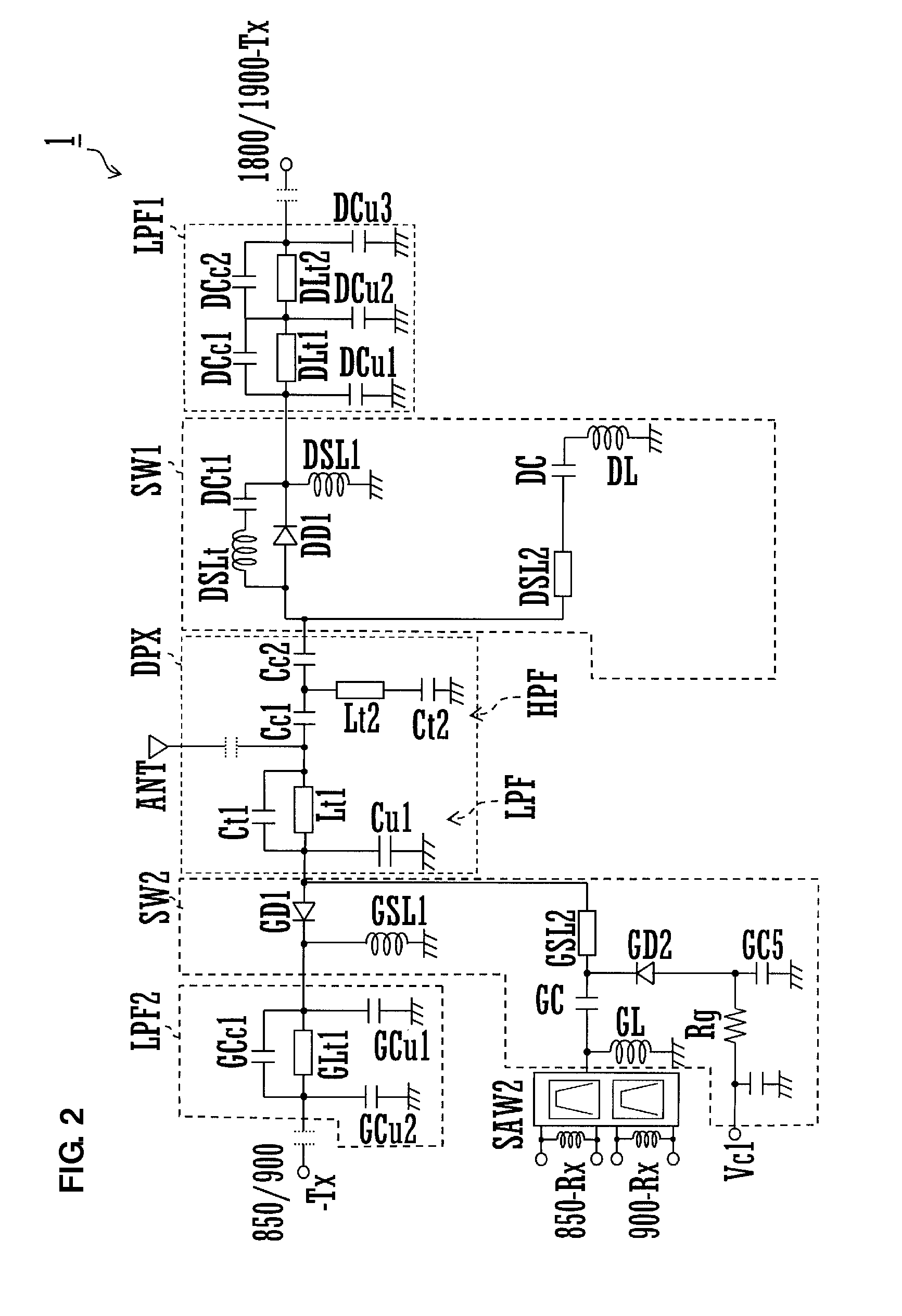

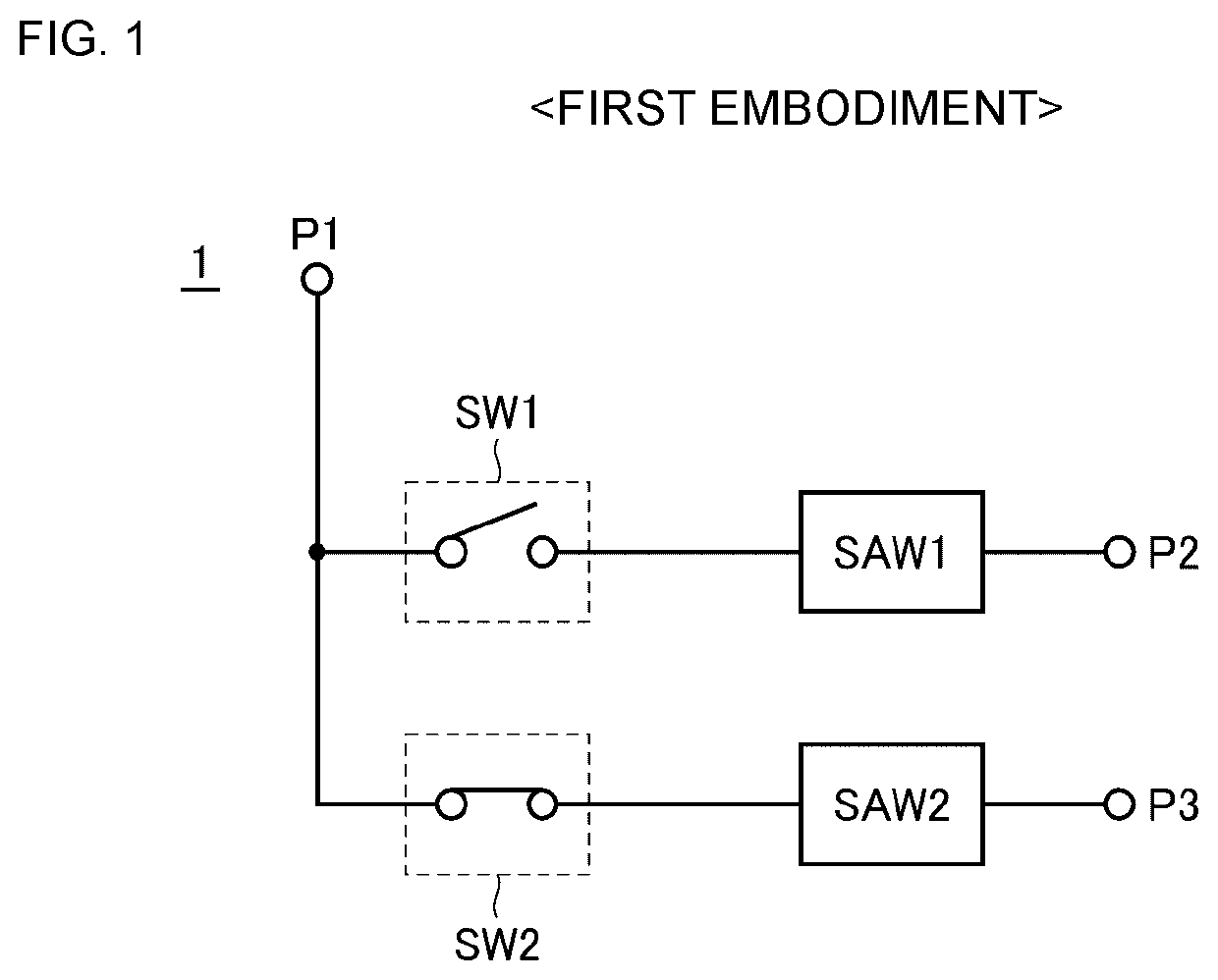

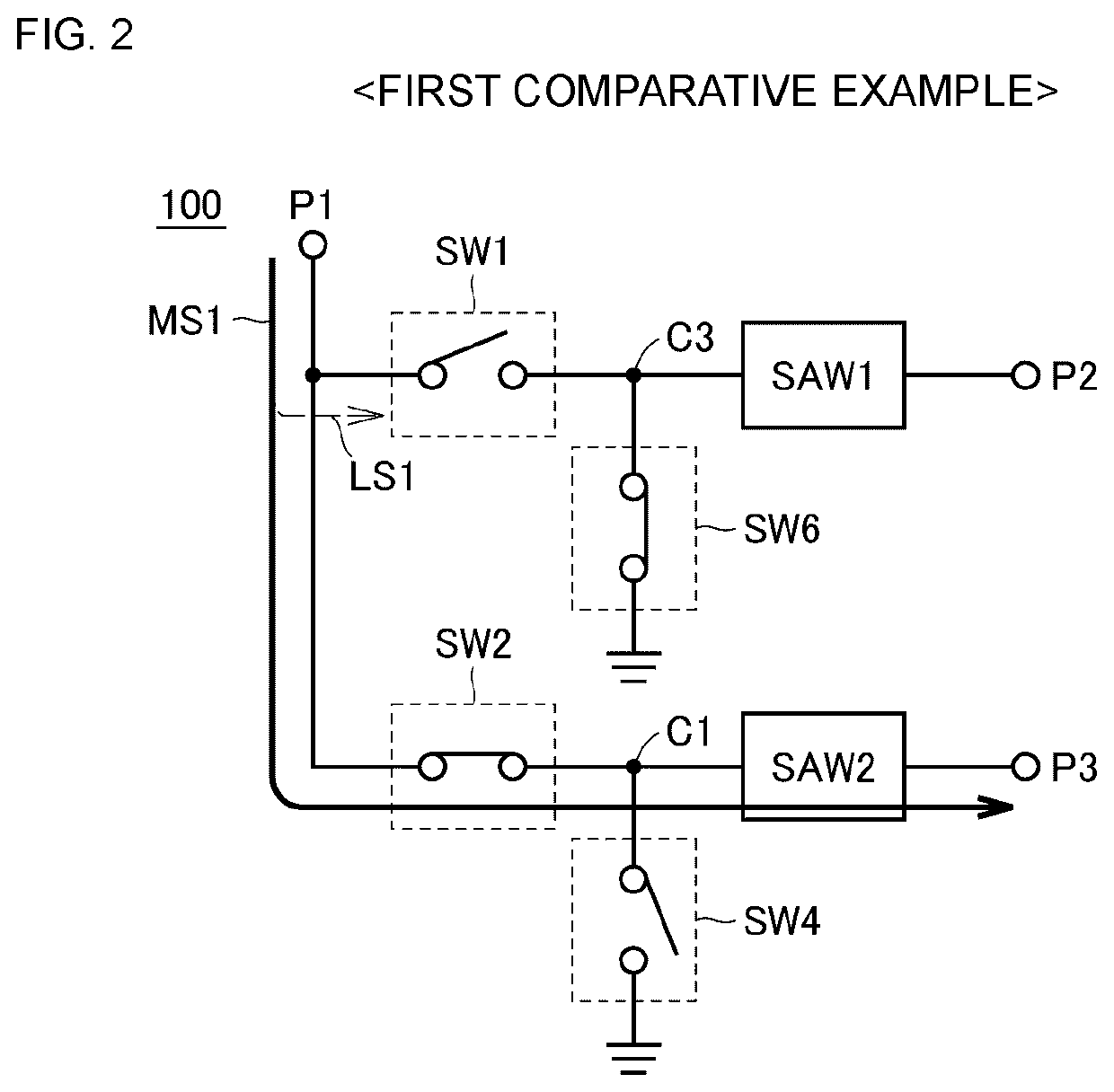

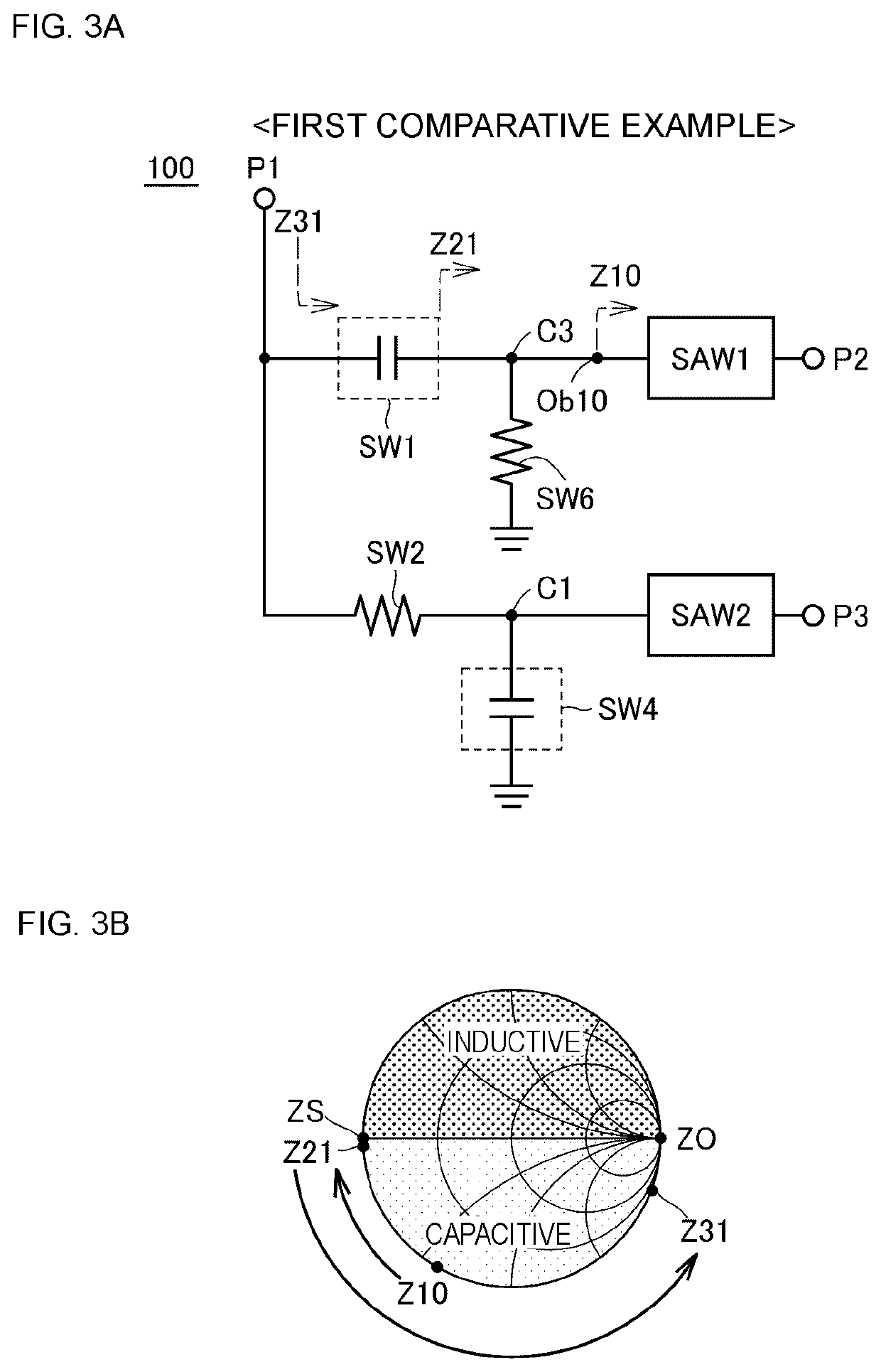

Switch module

ActiveUS20170331458A1Reduce insertion lossExclude influenceMultiple-port networksElectronic switchingElectrical impedanceShort circuit

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

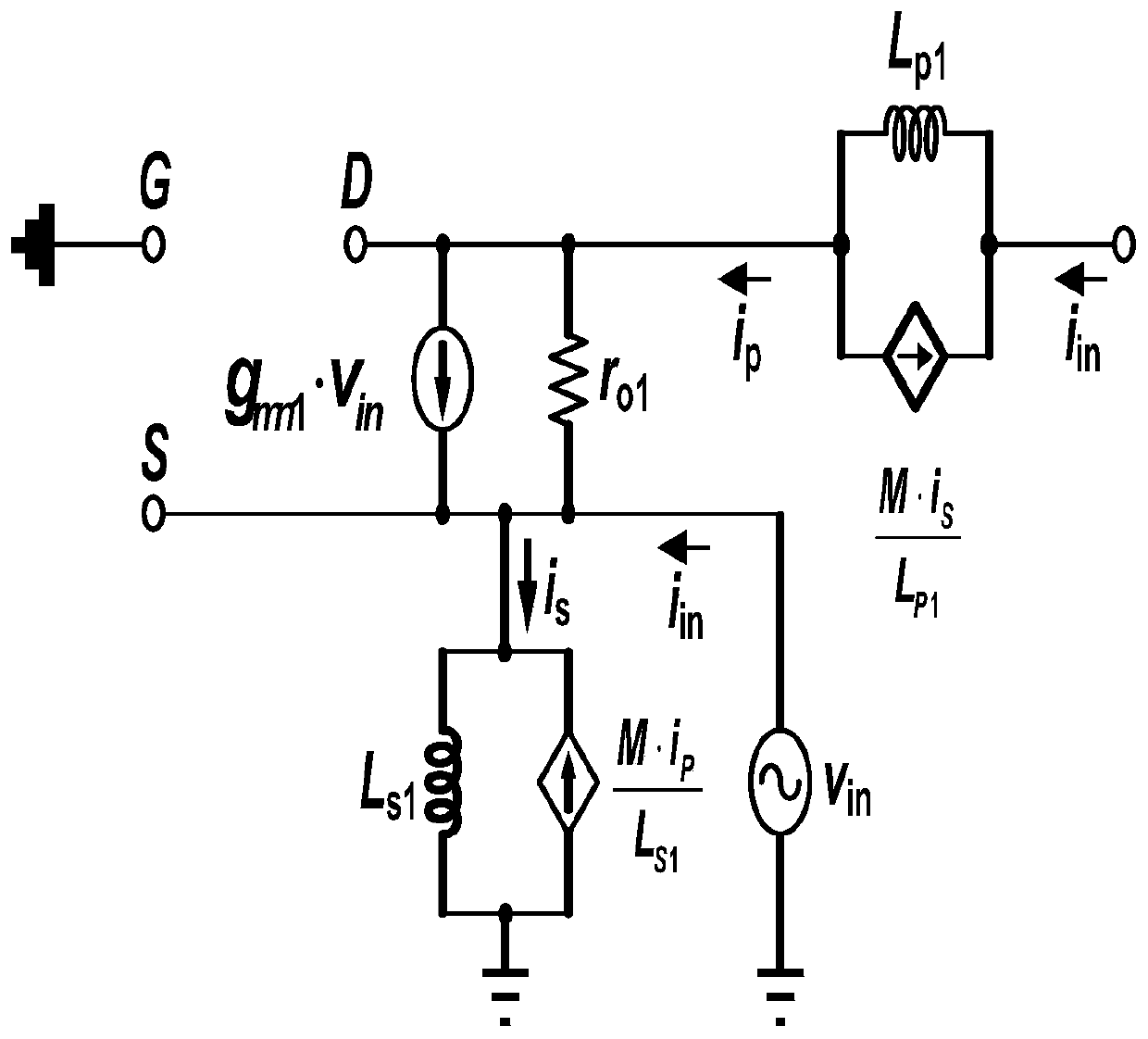

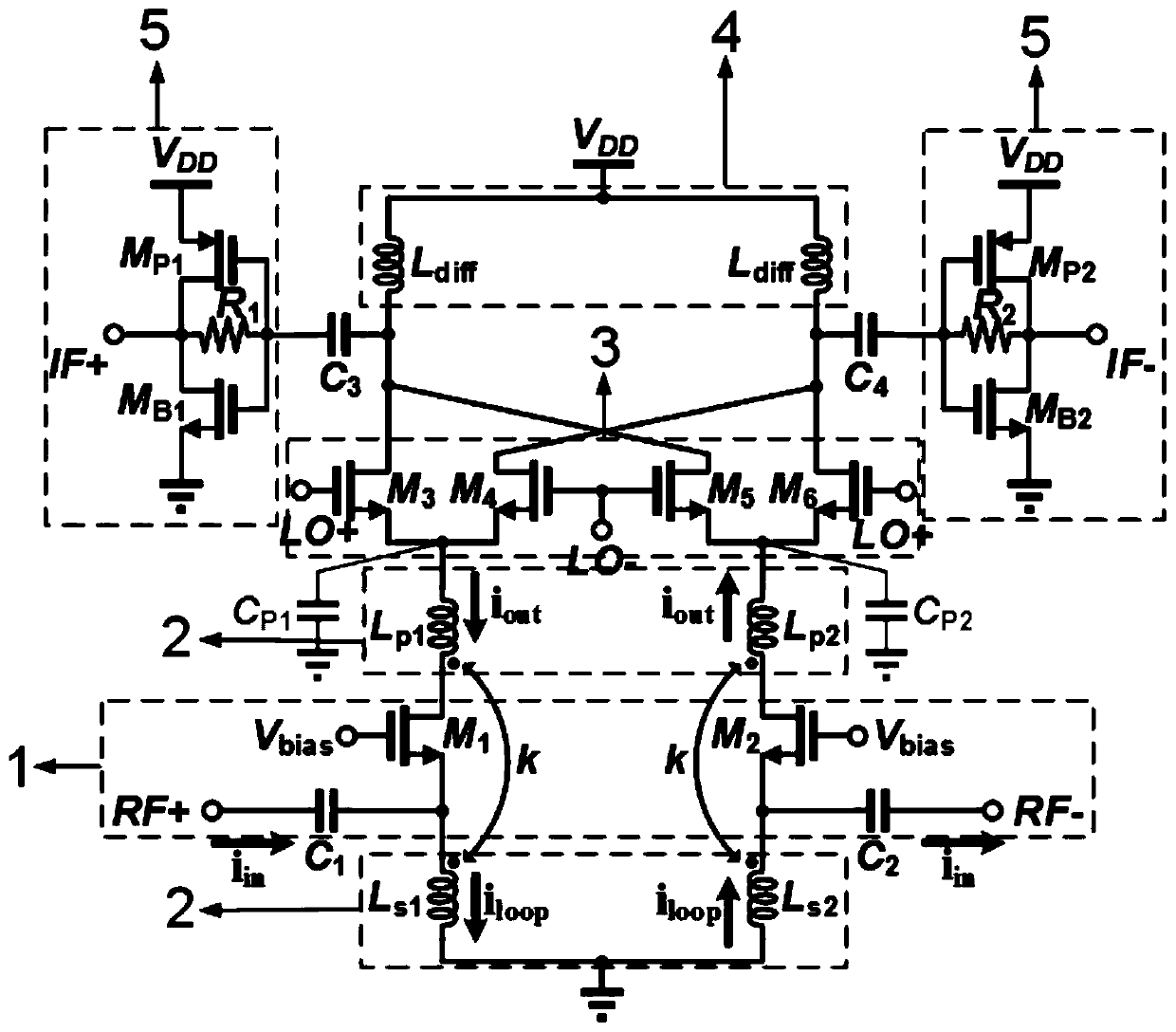

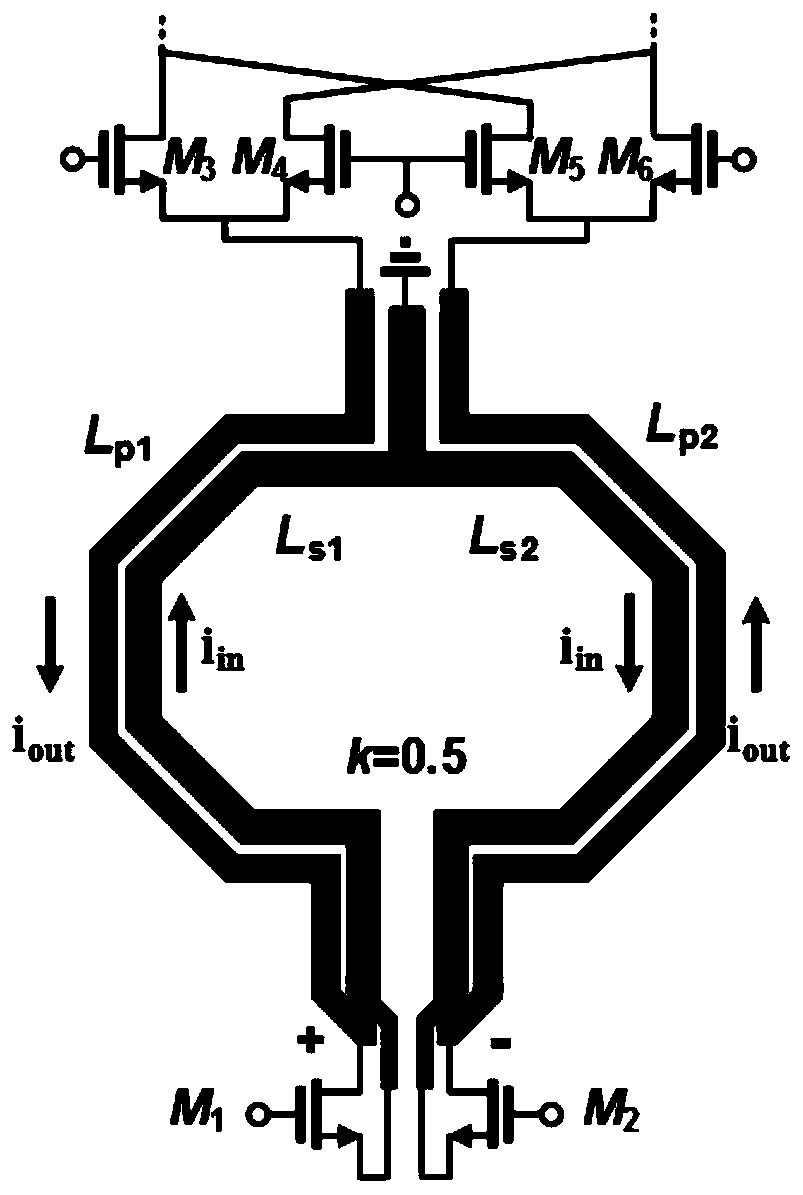

High-isolation broadband millimeter wave mixer applied to 5G communication

InactiveCN110535441APrevent leakageHigh Q valueMulti-frequency-changing modulation transferenceTransformerHigh isolation

The invention belongs to the technical field of wireless communication, and relates to a mixer, in particular to a high-isolation broadband millimeter wave mixer applied to 5G communication, which comprises a transconductance stage unit 1, an electromagnetic coupling unit 2, a switch stage unit 3, a load stage unit 4 and a buffer stage unit 5. According to the electromagnetic coupling type common-gate structure mixer based on the CMOS technology, the common-gate input transconductance stage is adopted, system-level design is facilitated, and broadband matching can be achieved without an extramatching network; the transformer network and the standard inductor LP introduced in the middle can counteract the interstage parasitic capacitance, so that the noise is reduced, the gain is improved,the differential inductor LS can be matched with and form feedback requirements, and the gain is further improved; and meanwhile, the circuit structure is symmetrical, so that the circuit structure can be well symmetrical when an actual layout is implemented, thereby being beneficial to the isolation of the mixer.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

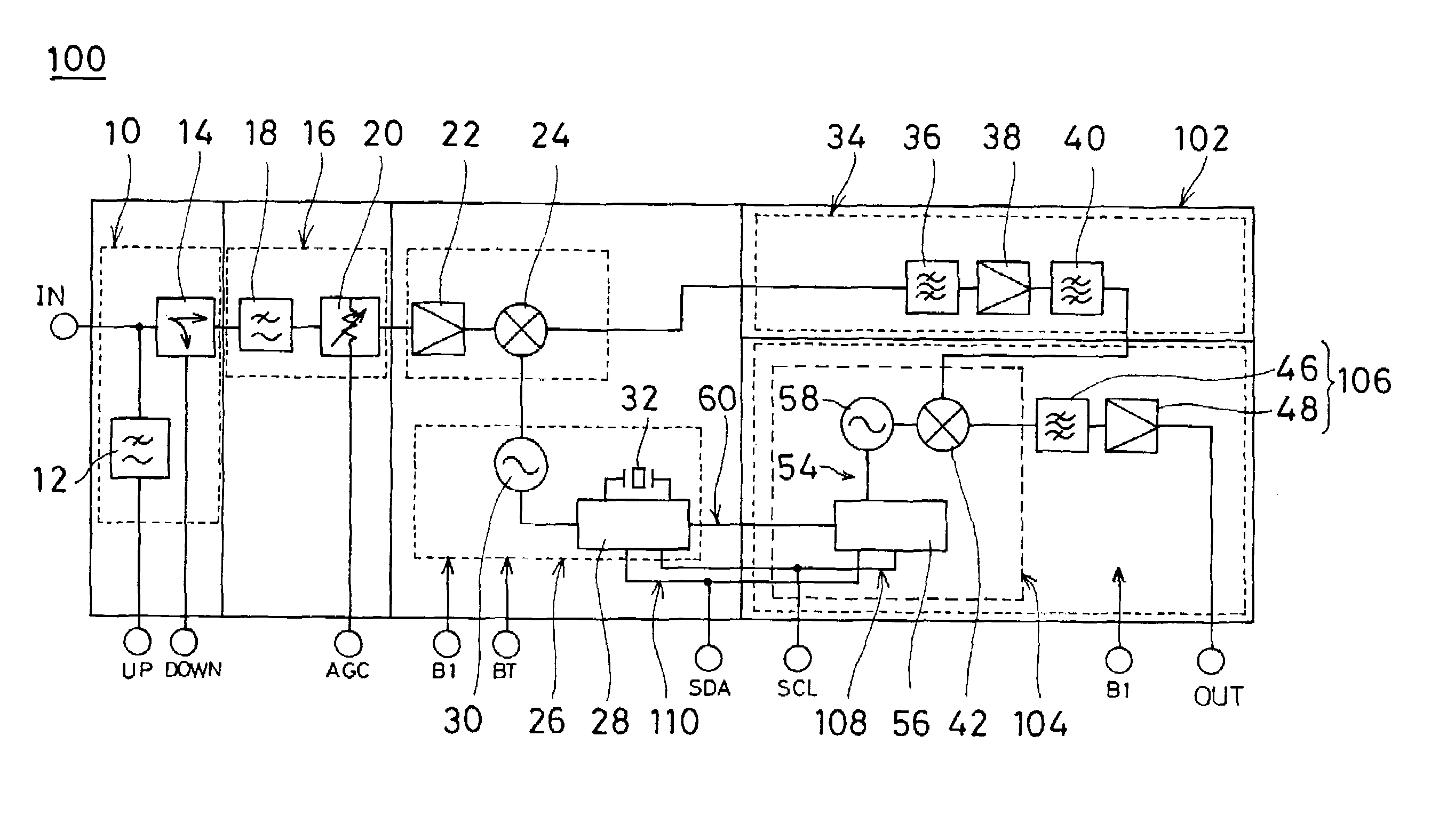

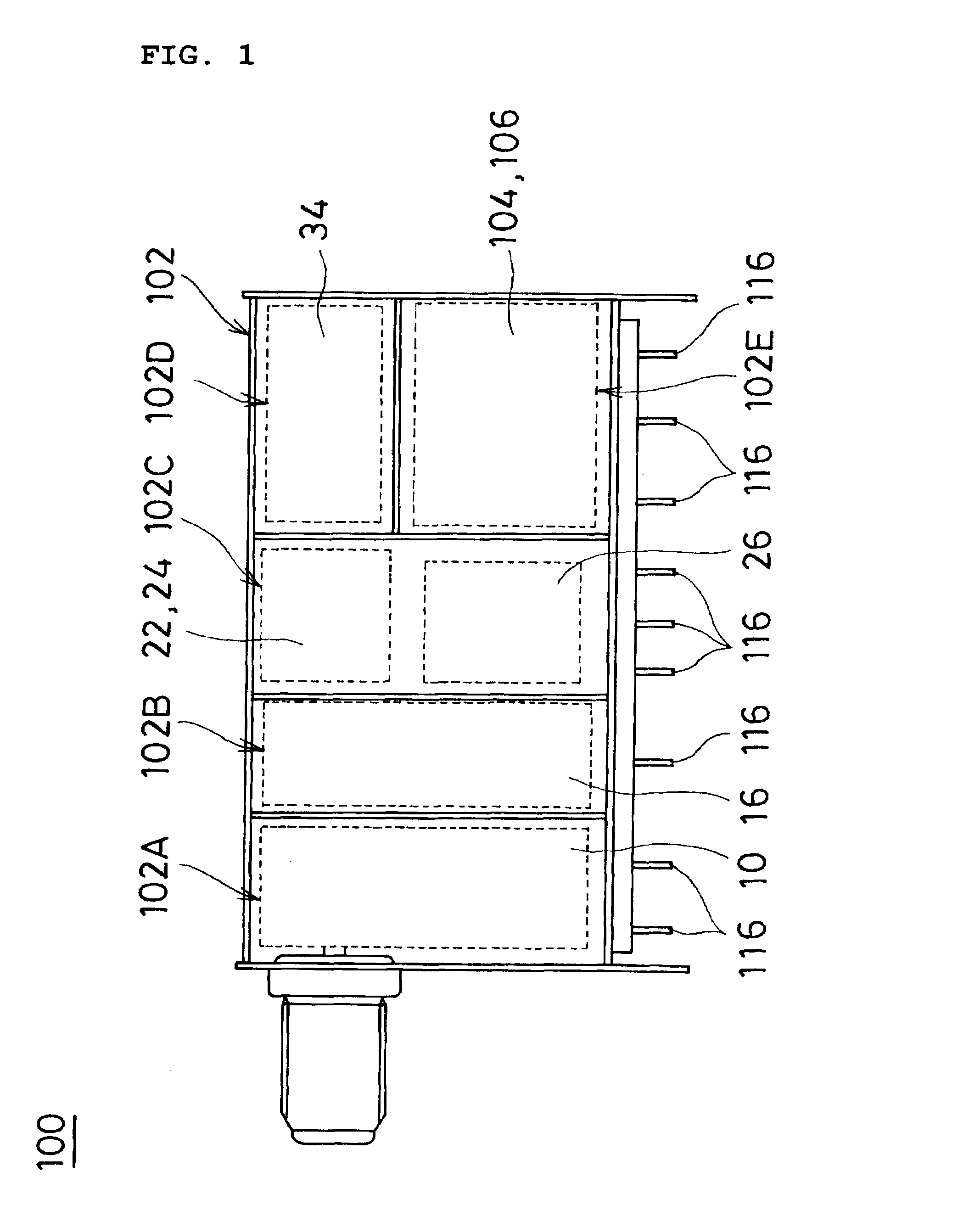

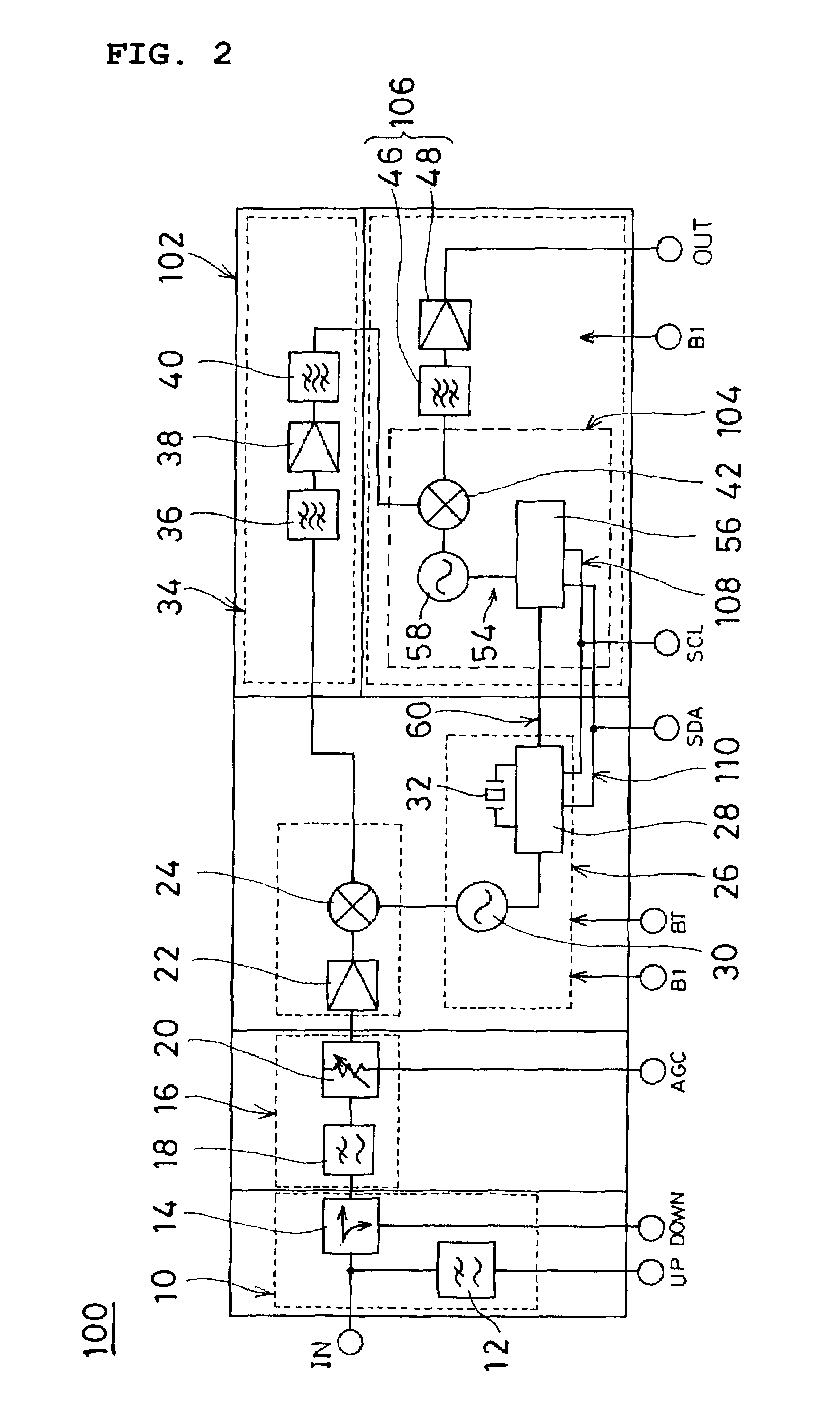

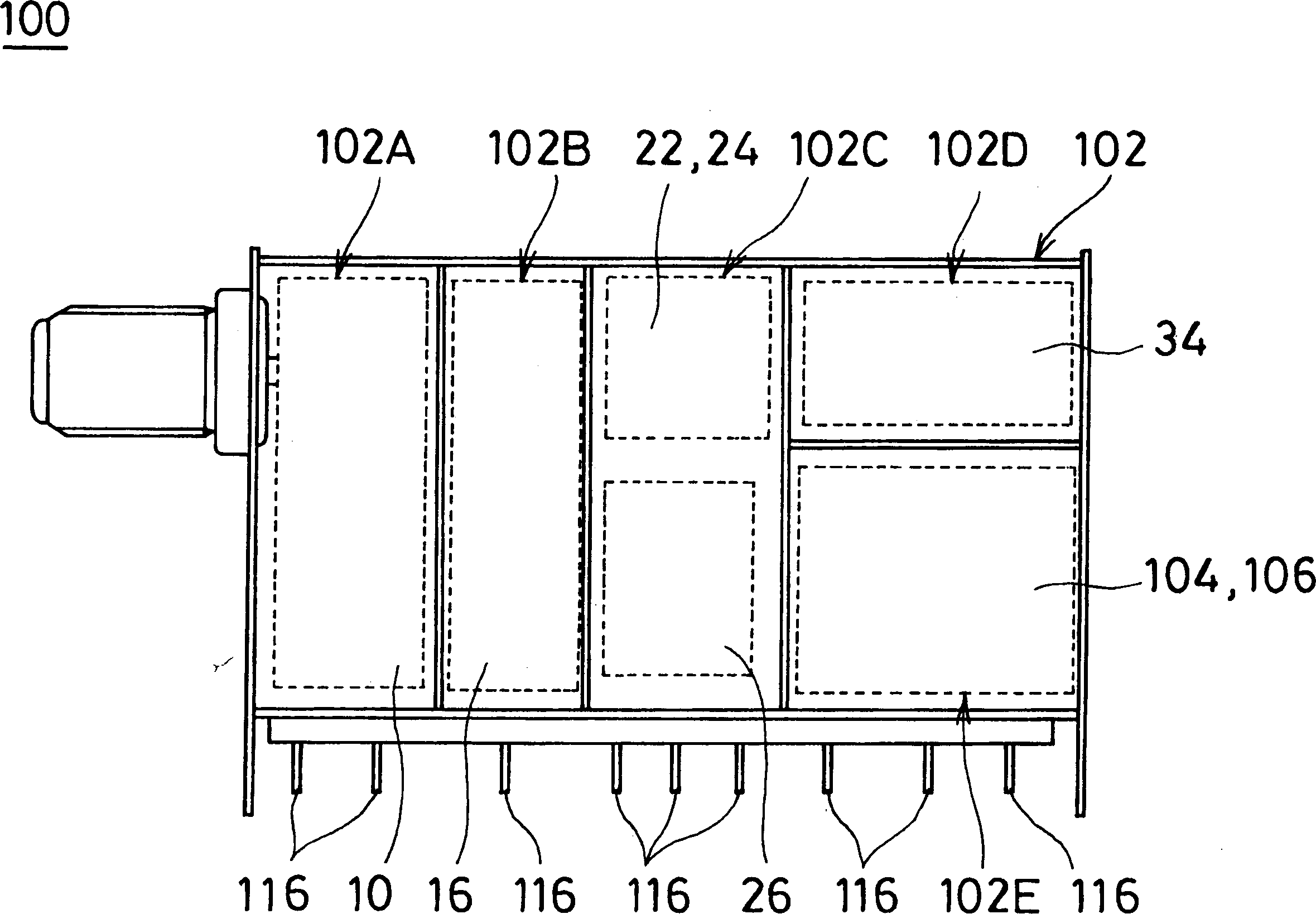

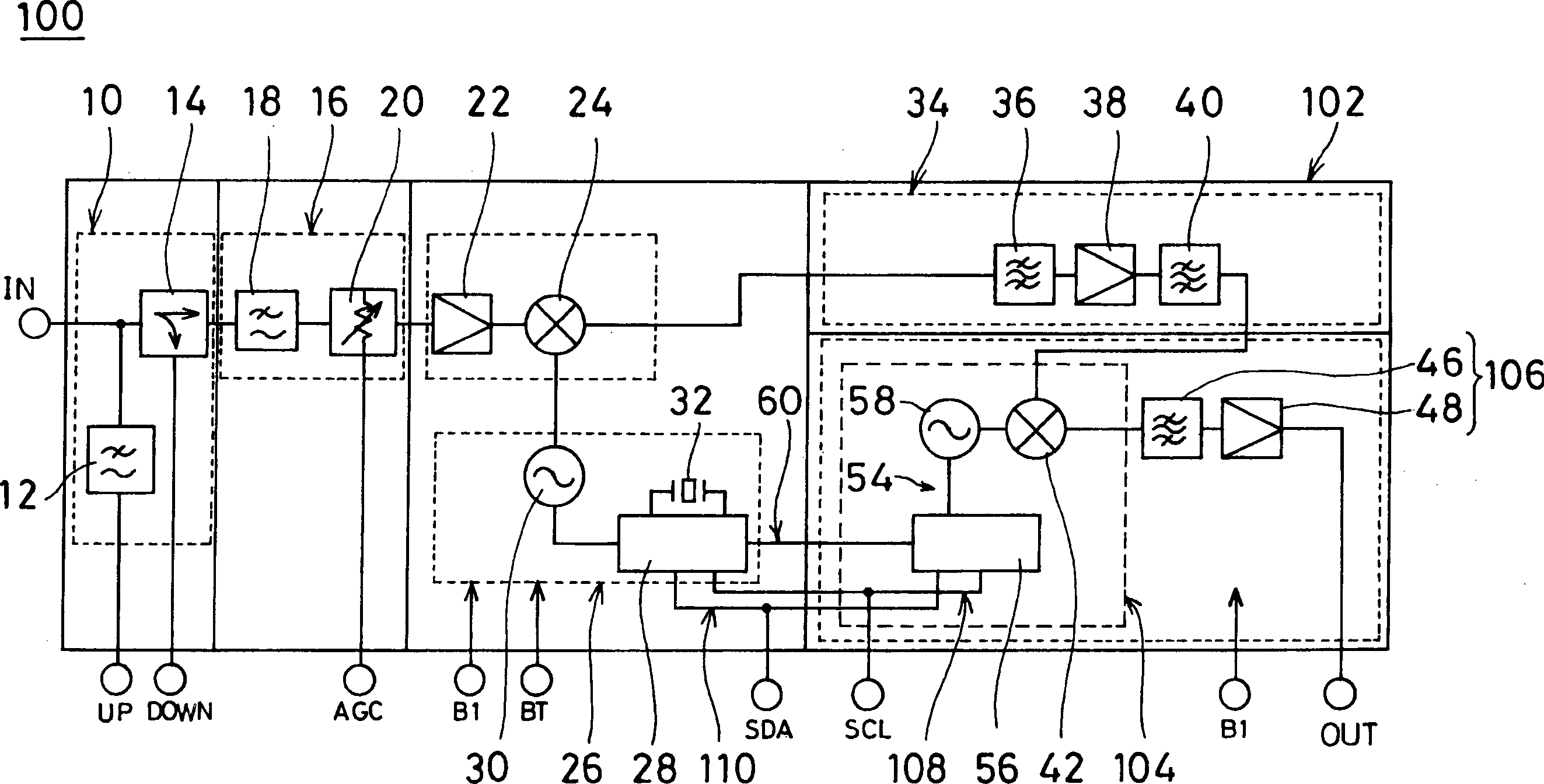

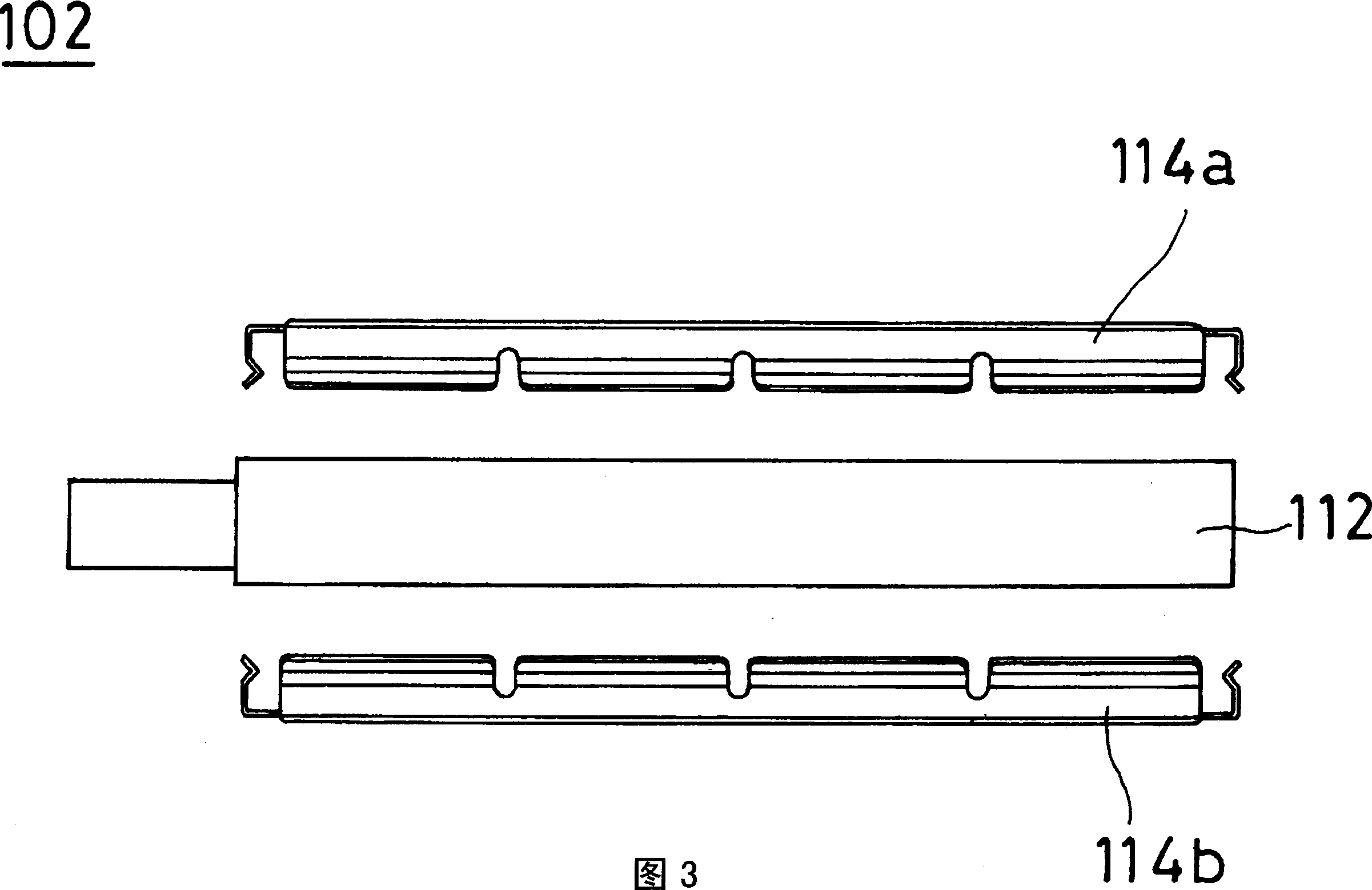

CATV tuner and one-chip IC used therein

InactiveUS7480495B2Prevent leakagePrevent signal leakageTelevision system detailsMagnetic/electric field screeningIntermediate frequencyEngineering

A CATV tuner includes a metallic housing having first through fourth partitioned chambers. In the first through fourth partitioned chambers, a data circuit, an input filter circuit, a first mixer circuit, a first local oscillation circuit, a first intermediate frequency circuit, and other elements are housed. In the fifth partitioned chamber, a second intermediate circuit and an IC including a second local oscillation circuit are housed. With this configuration, the CATV tuner defines an up / down tuner. The third partitioned chamber in which the first local oscillation circuit is housed and the fifth partitioned chamber in which the second local oscillation circuit is housed are located adjacent to each other. Lines and terminals are used both for a first PLL circuit and a second PLL circuit.

Owner:MURATA MFG CO LTD

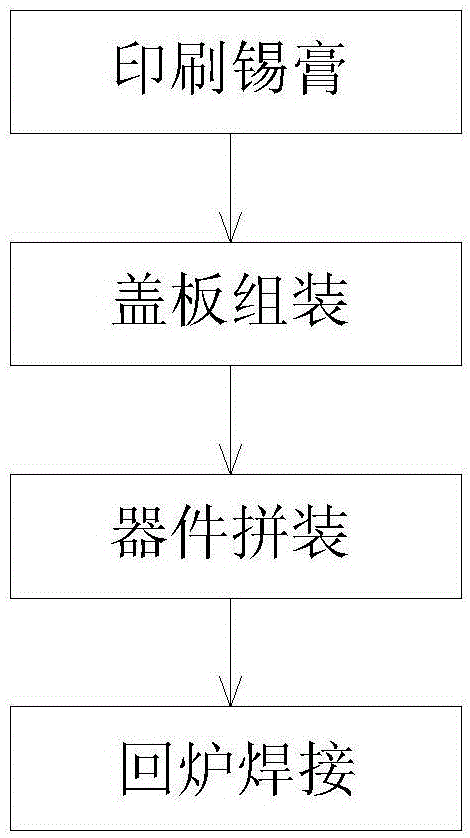

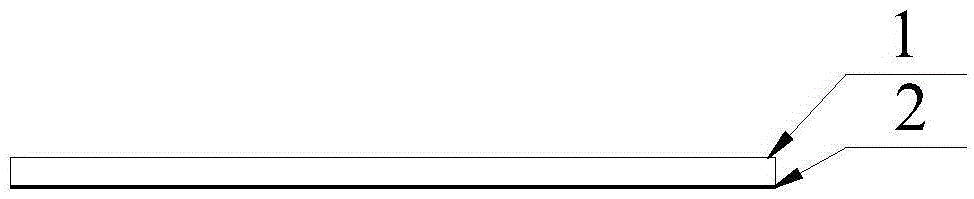

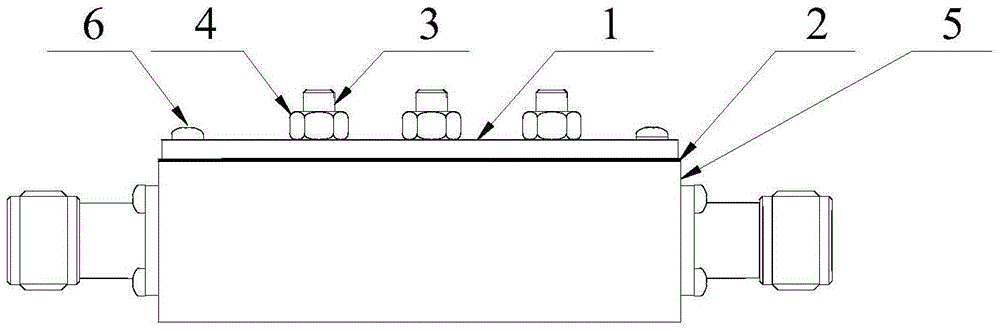

Assembling technology for metal cover board and cavity component of cavity filter

InactiveCN105489997AAssemble firmlyStability is not affectedWaveguide type devicesEngineeringSolder paste

The invention discloses an assembling technology for a metal cover board and a cavity component of a cavity filter. The assembling technology comprises the following steps: (1) printing of a solder paste, namely locating the metal cover board on a printing machine to print the solder paste; (2) assembling of the cover board, assembling tuning screws and tuning nuts into the metal cover bard according to the requirements; (3) assembling of devices, namely tightly assembling the metal cover board and the cavity component; and (4) melting and welding, feeding the clamped metal cover board and cavity component into a reflow oven for heating and welding, taking out the metal cover board and the cavity component for cooling, and disassembling the bolts or a compression tooling of fixing the metal board and the cavity component. An original bolt fastening method is replaced with a solder paste welding method, so that signal leakage is effectively avoided; the electrical properties and the stability of the devices are ensured; the processing time and the assembly work hours of the metal cover board and a cavity are shortened; the technology is simple; meanwhile, an original product ageing procedure can be simplified; the production efficiency is improved; the weight of the devices is reduced; and the market competitiveness of a product is improved.

Owner:WUHAN FINGU ELECTRONICS TECH

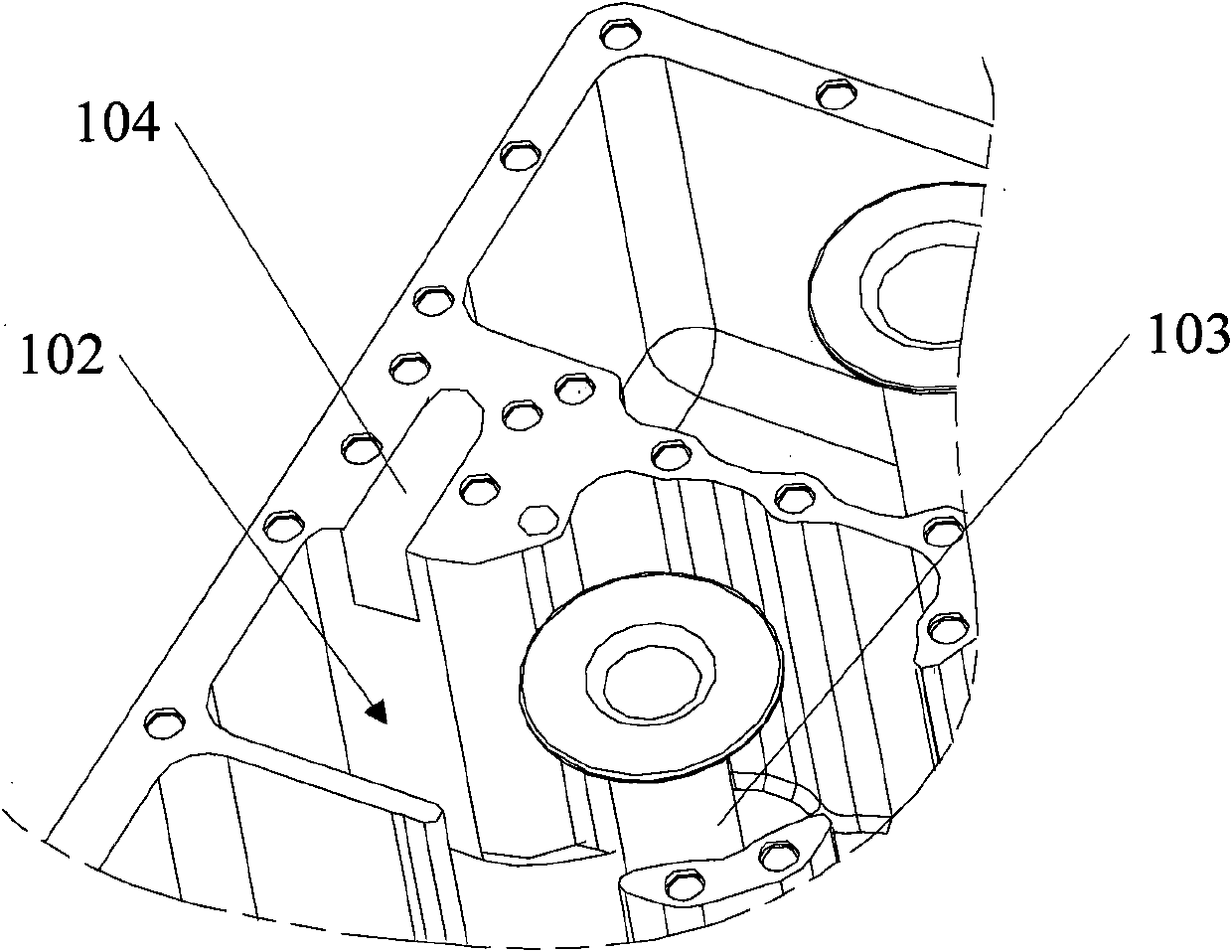

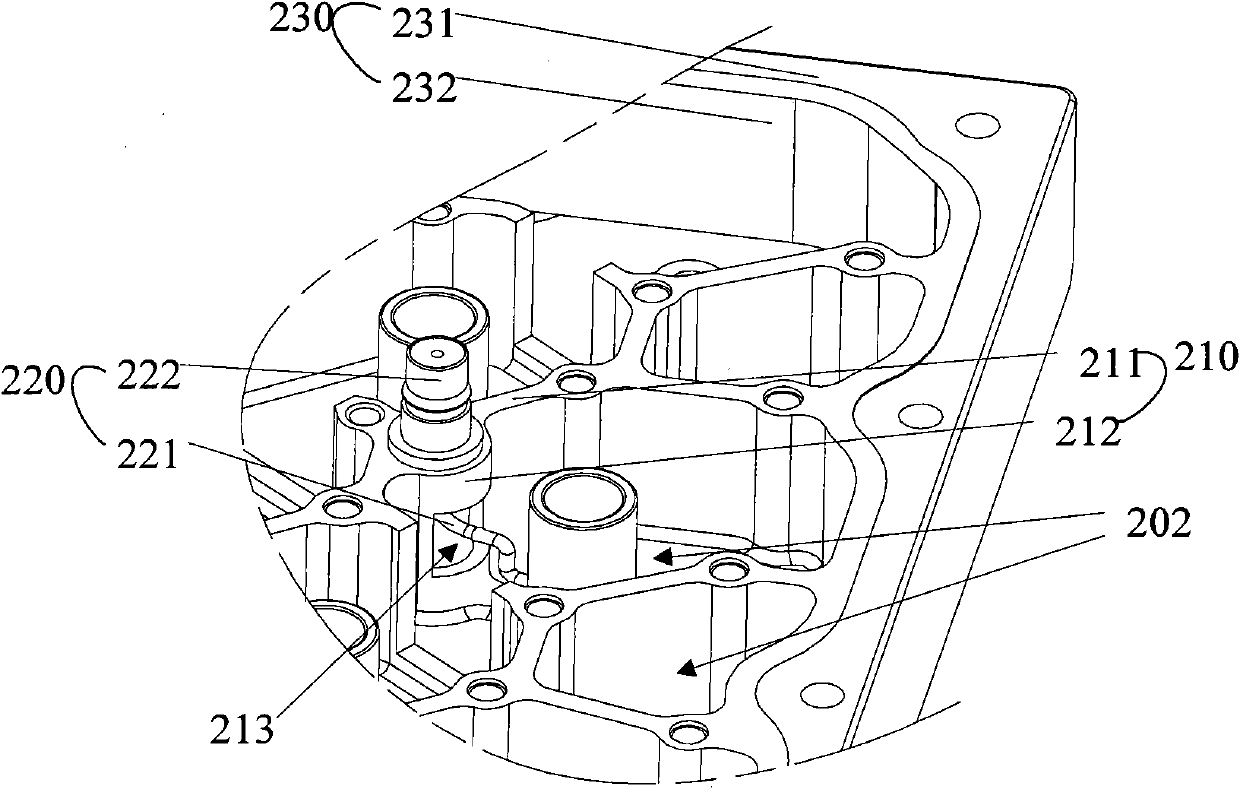

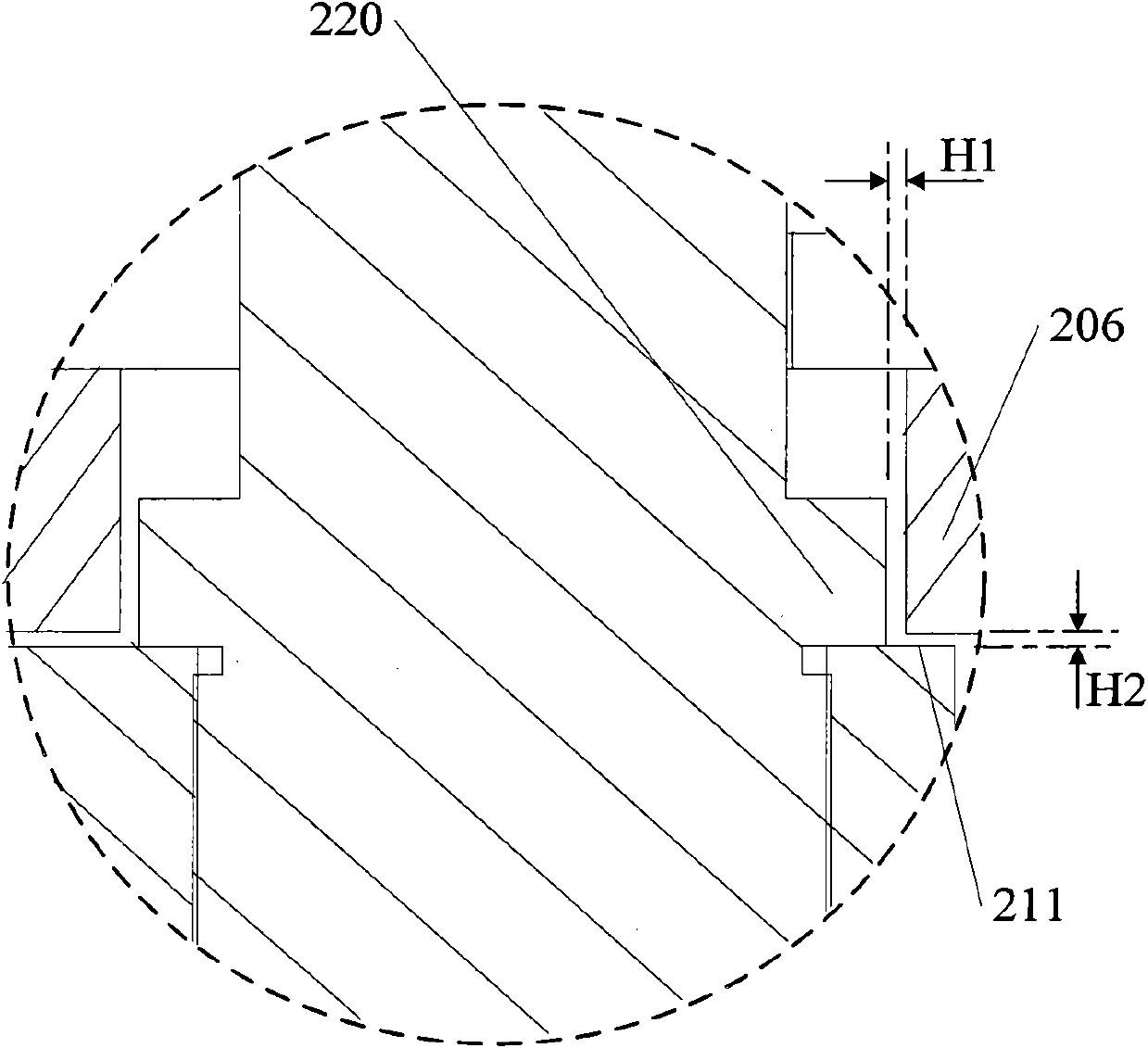

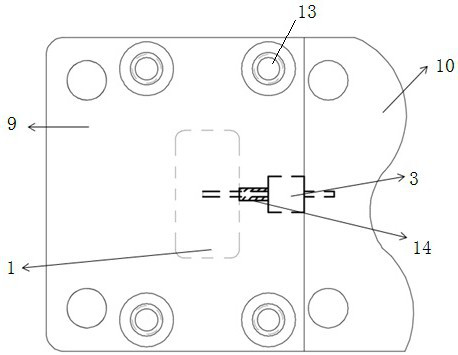

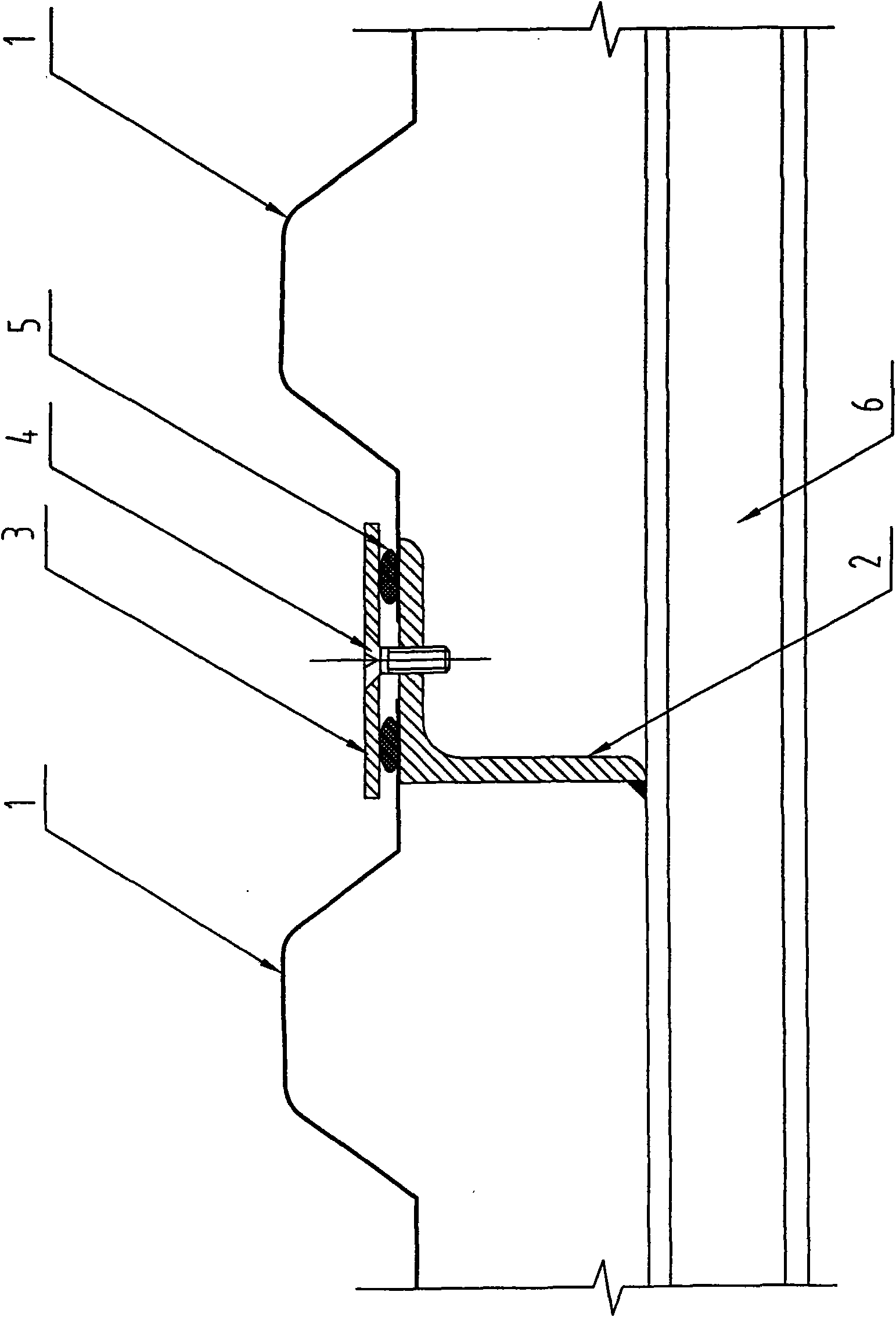

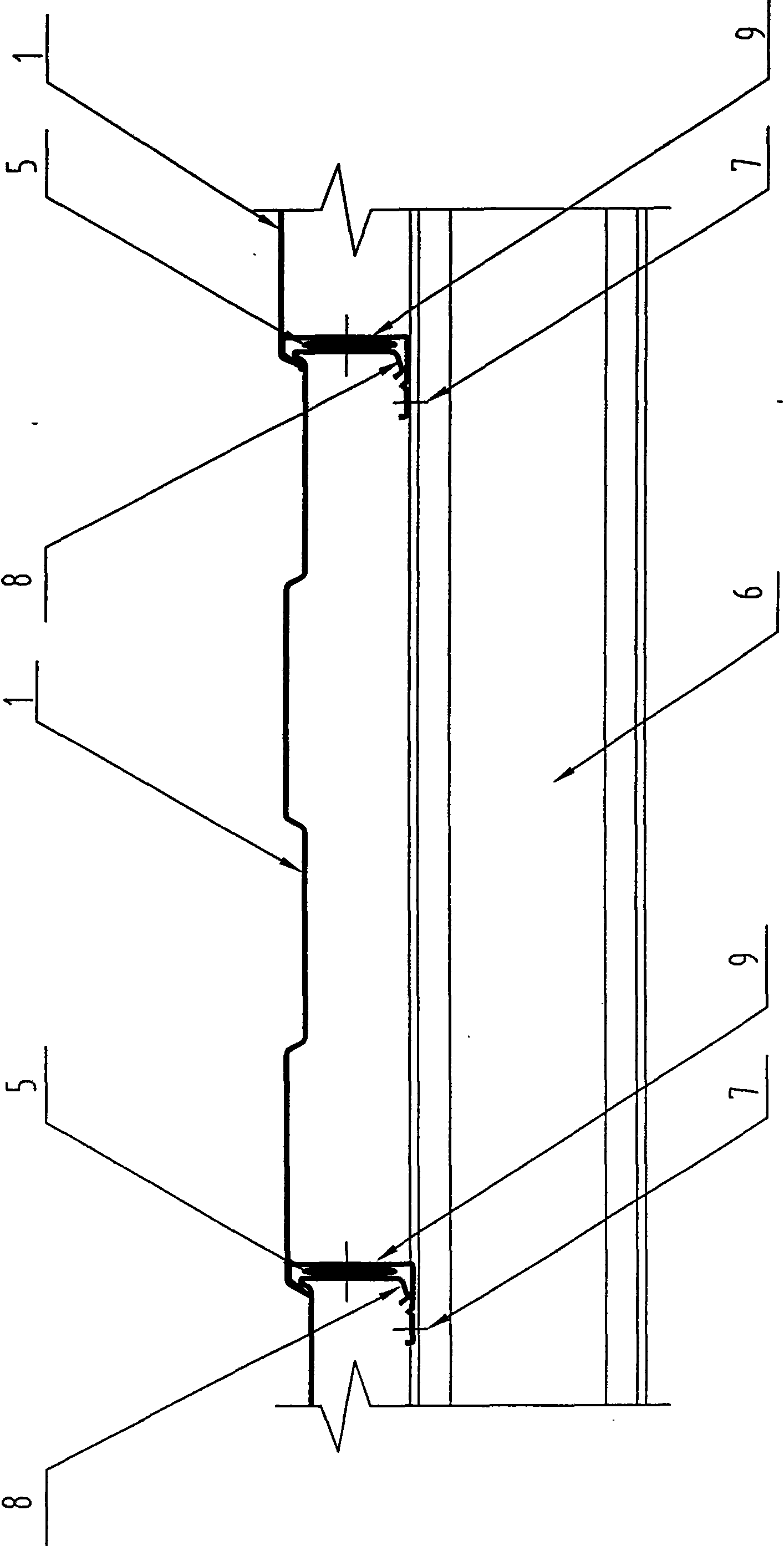

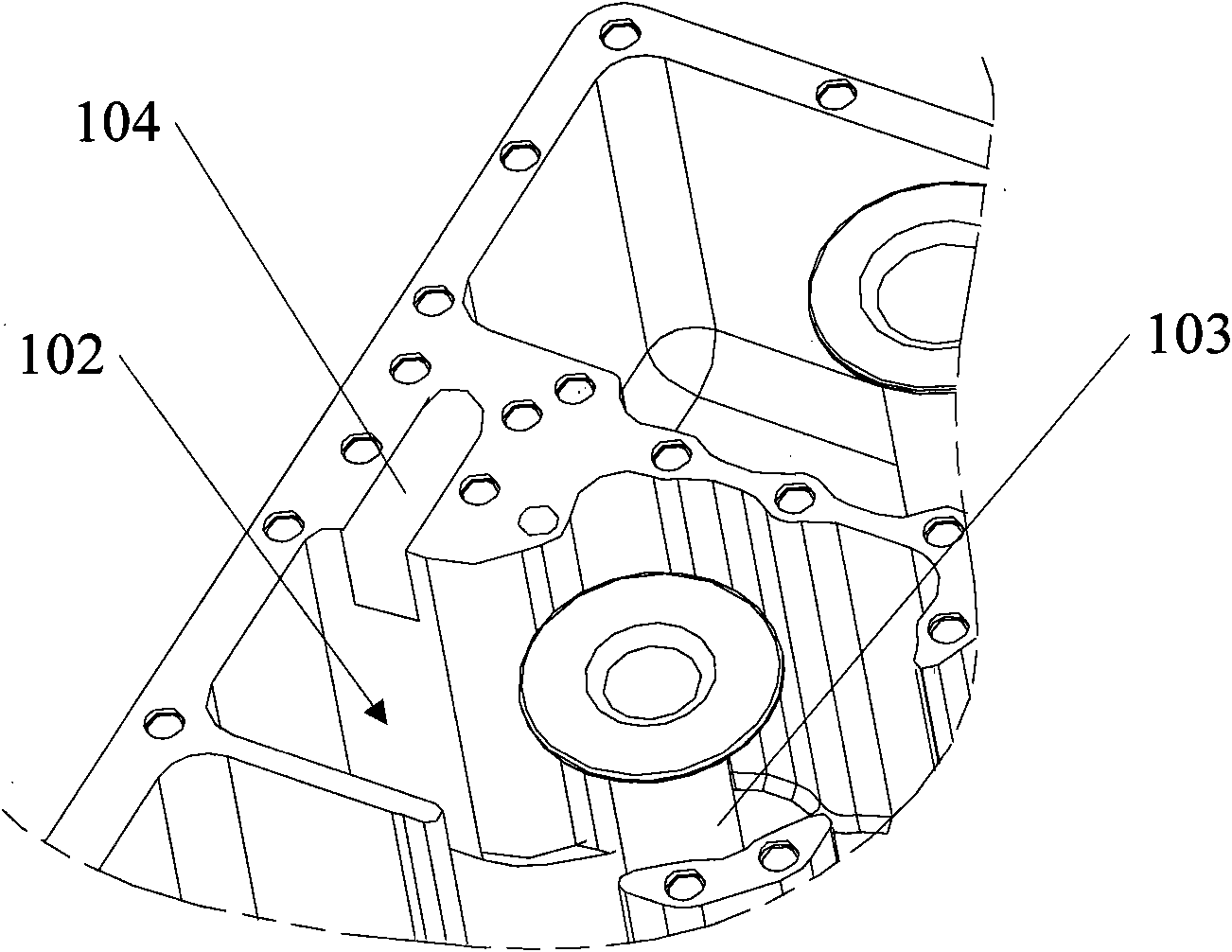

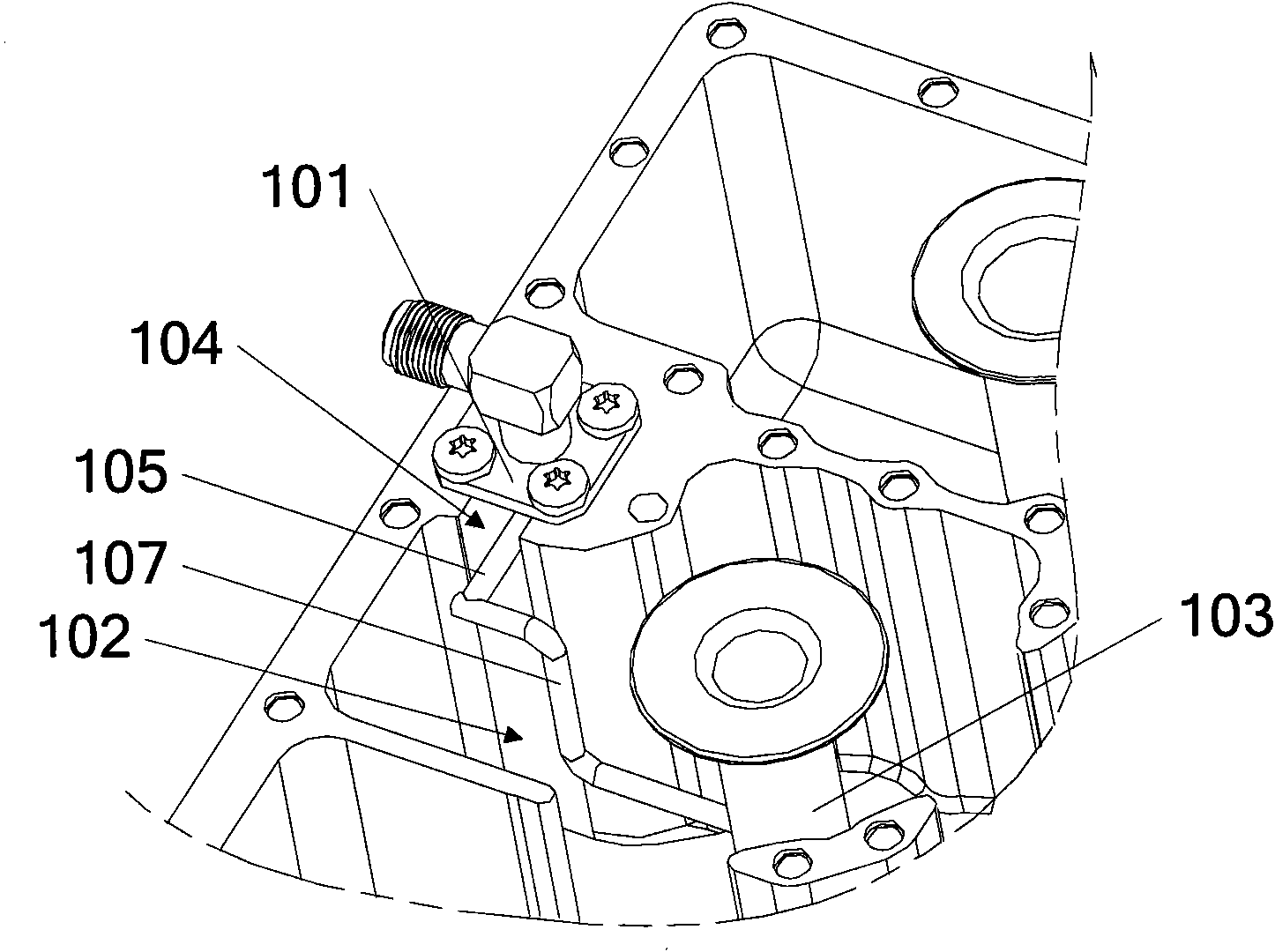

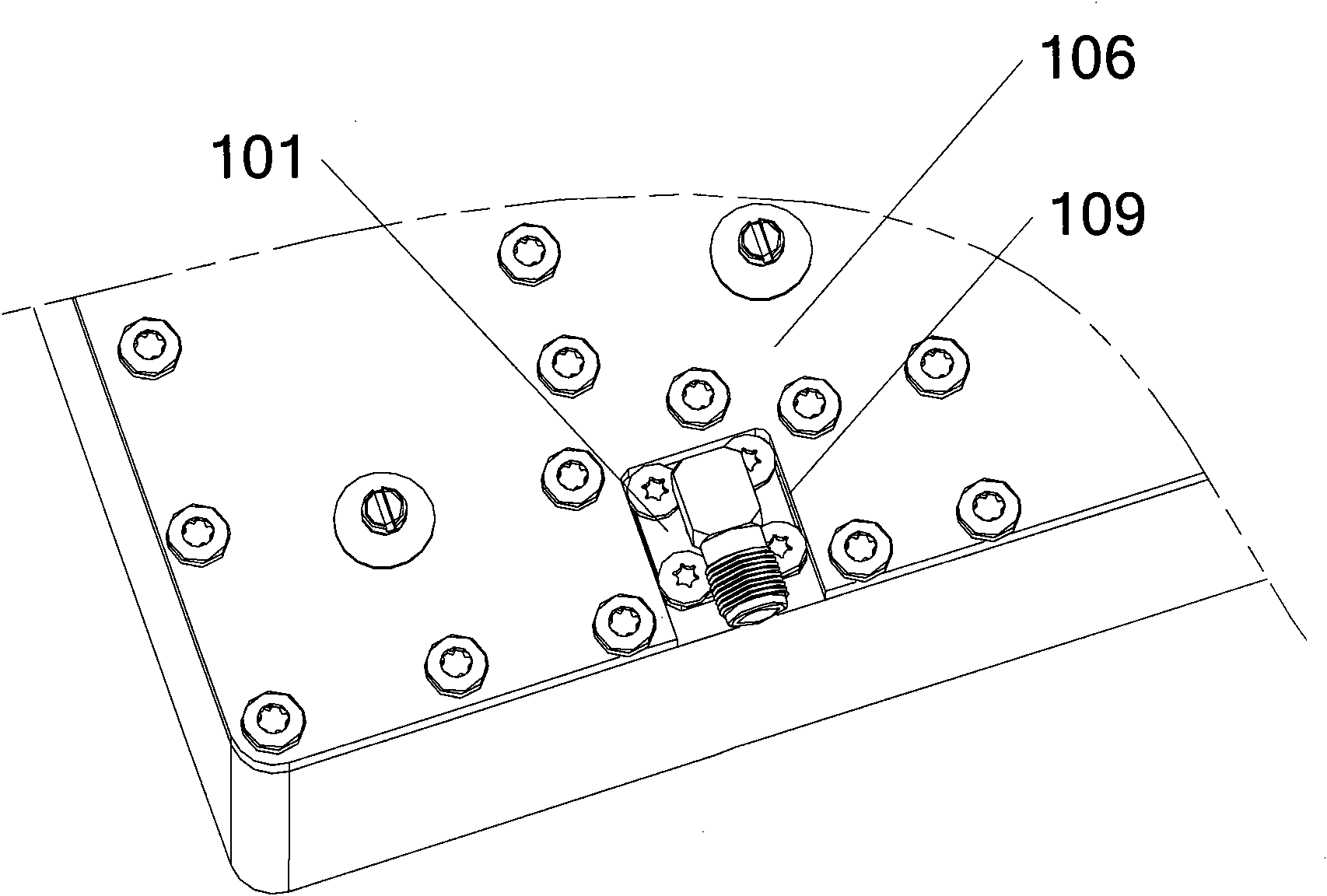

Cavity filter, filter cavity and installation method of connector

The invention discloses a cavity filter, a filter cavity and an installation method of a connector. In the embodiment of the invention, a connector installation hole is arranged on the top surface of an isolation rib or the side wall of the cavity and is communicated with a resonant cavity, and closed regions surround the connector installation hole. After the connector and a cover plate are installed, the resonant cavity and the outside can be reliably isolated, thus avoiding signal leakage and interference of signal leakage with other equipment in the system except the filter.

Owner:ANHUI TATFOOK TECH CO LTD

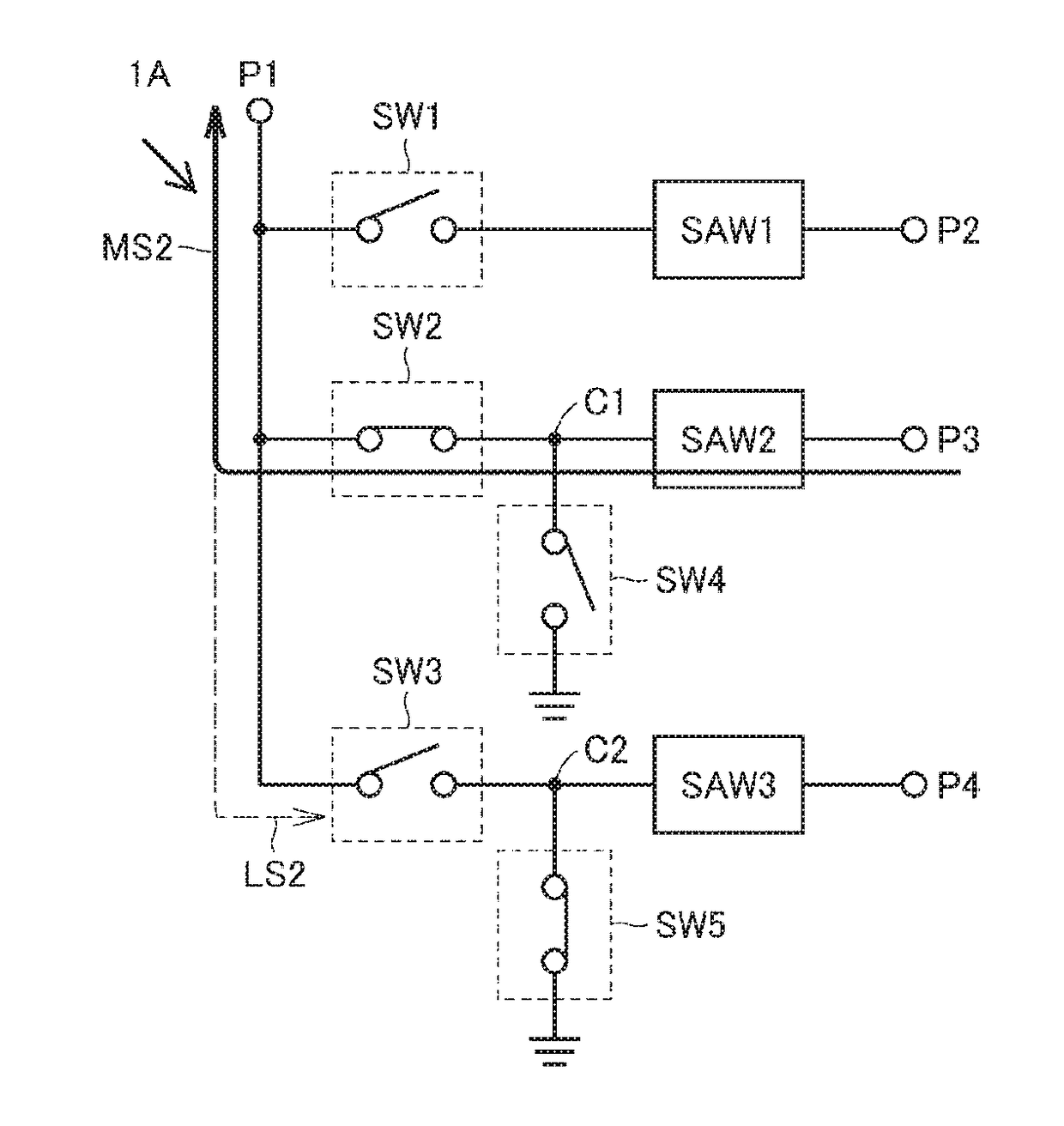

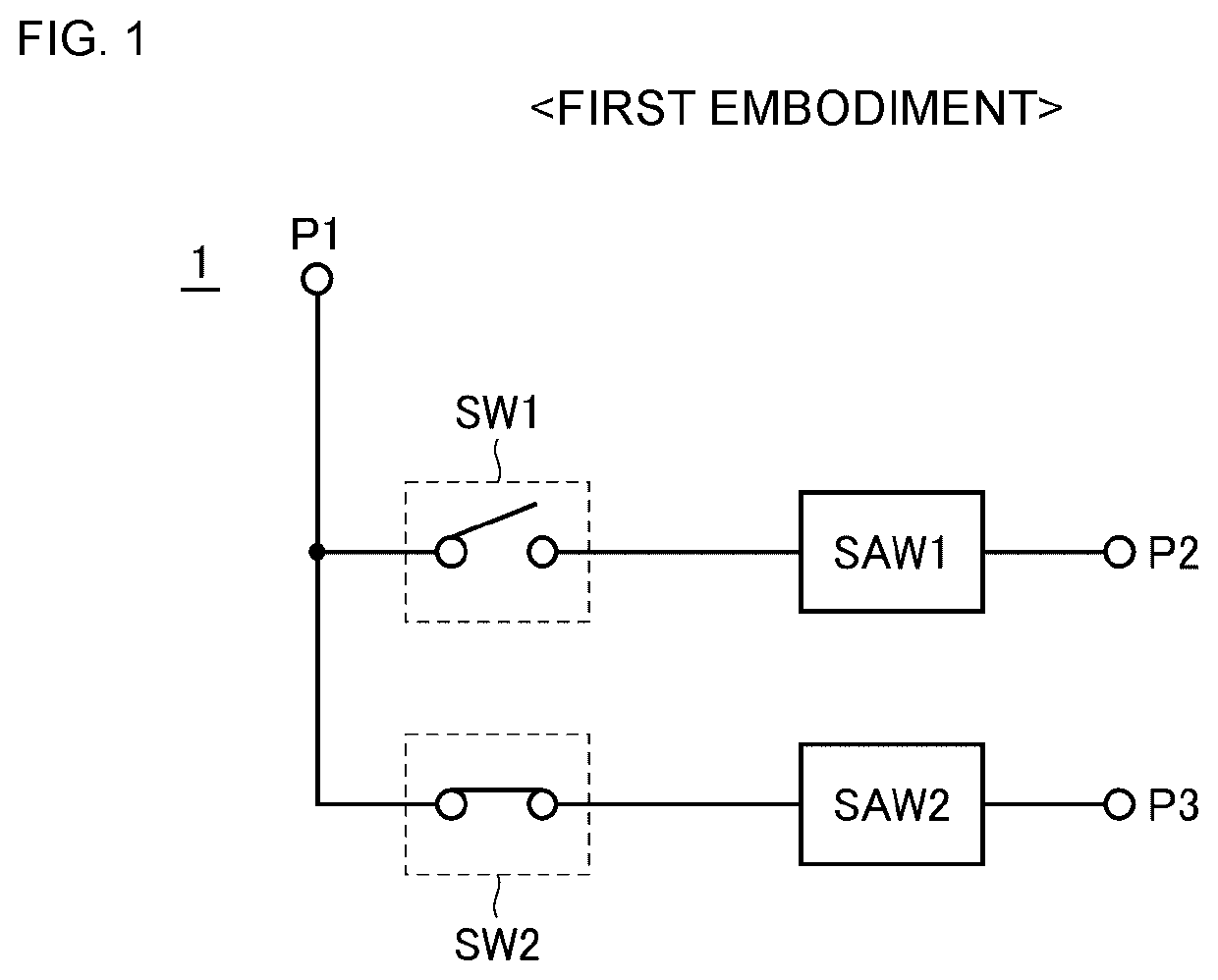

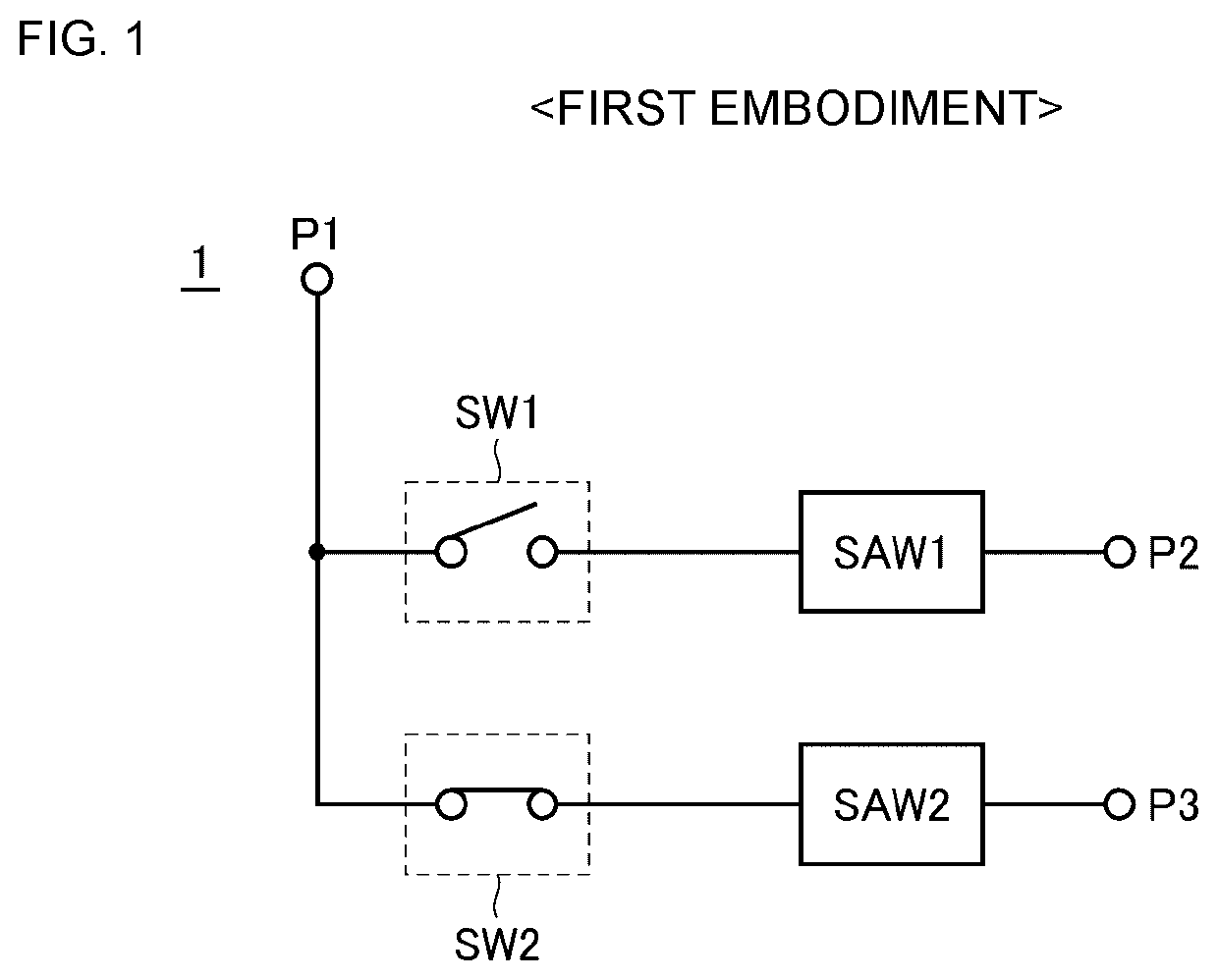

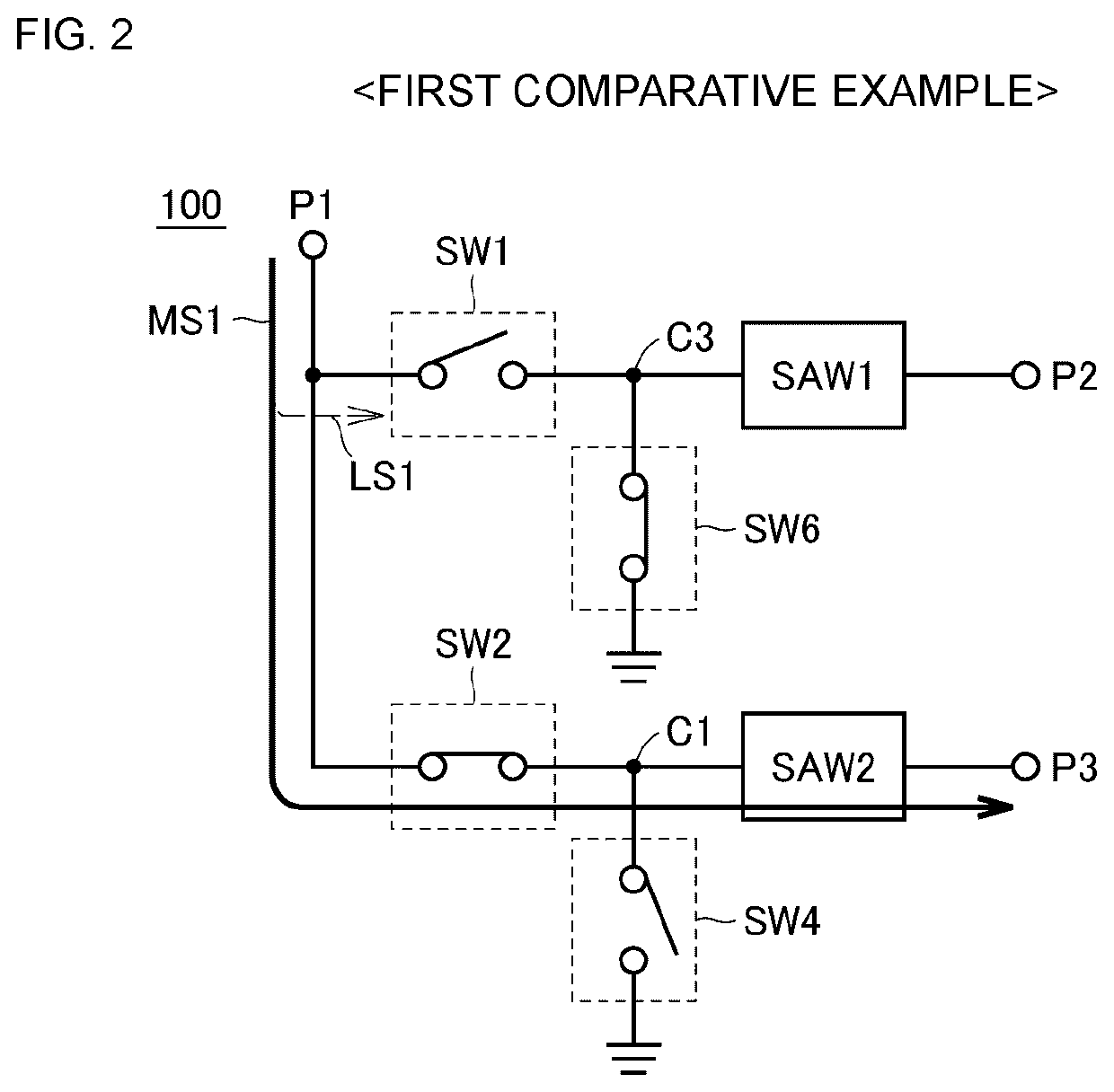

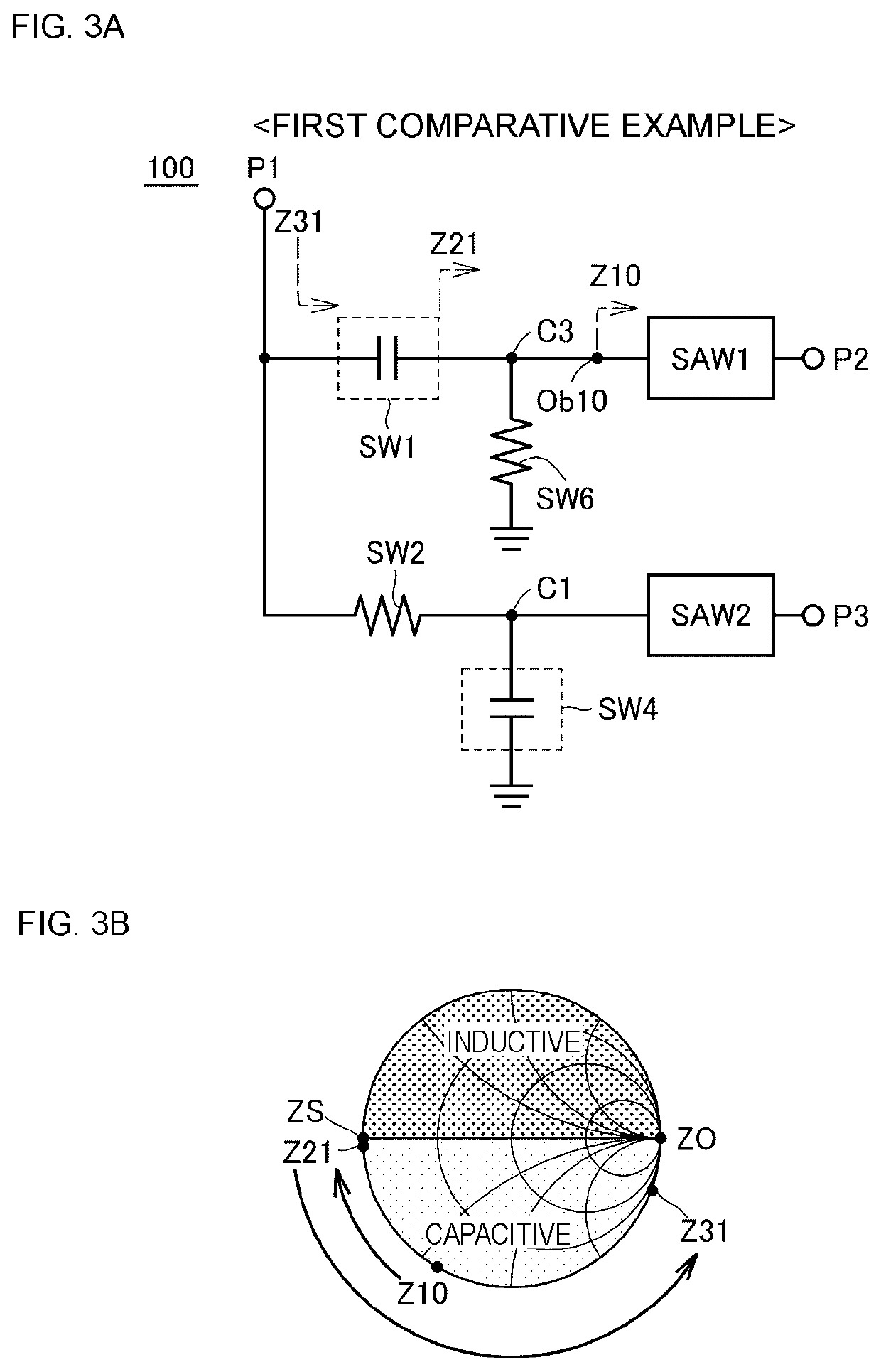

Switch module

ActiveUS10181839B2Exclude influencePrevent signal leakageMultiple-port networksElectronic switchingElectrical impedanceShort circuit

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

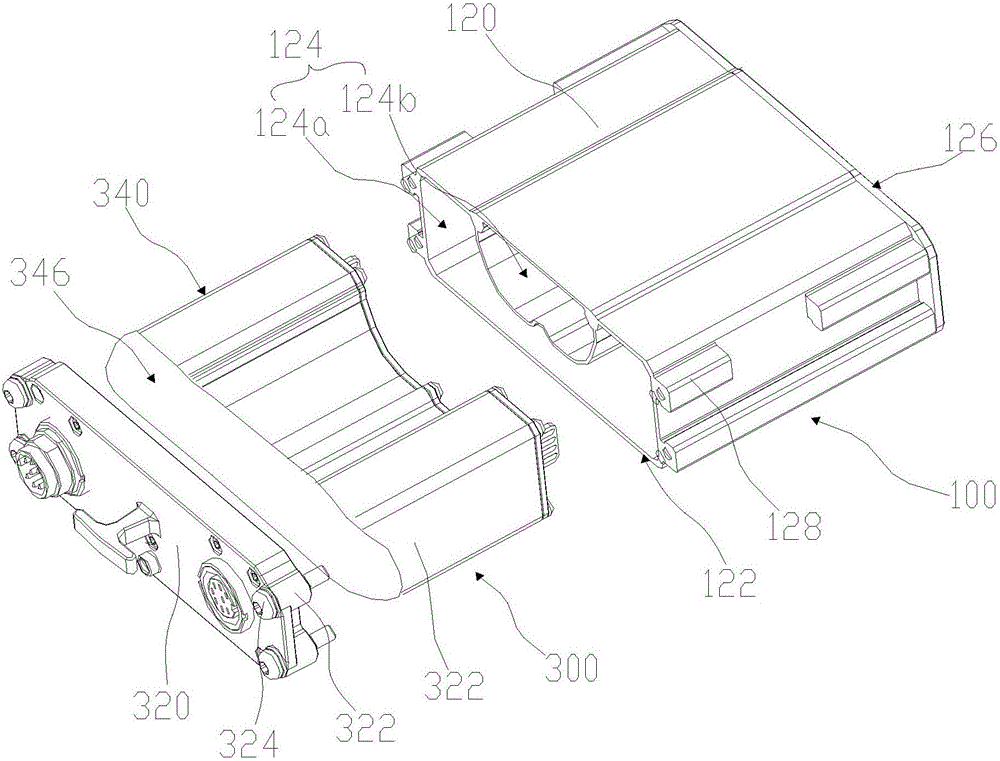

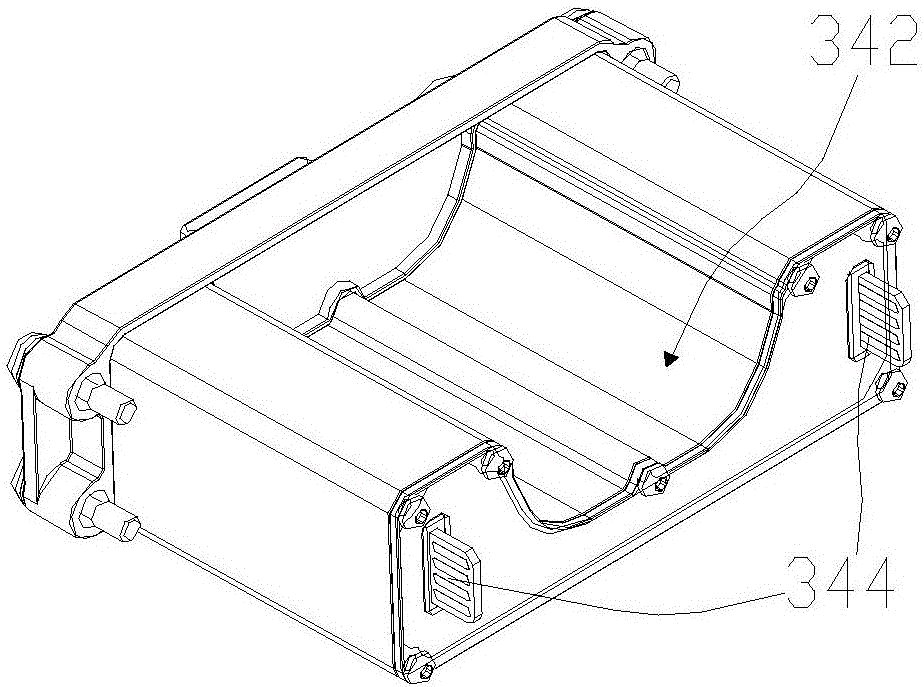

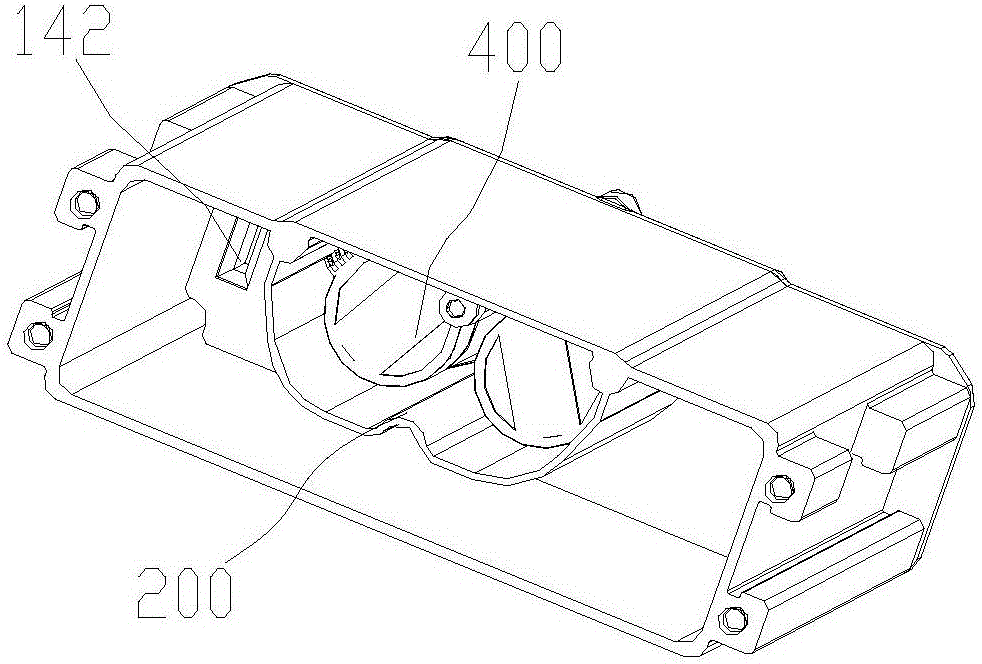

Electronic speed controller device with multilayer shielding structure

ActiveCN106785452AImprove intermodulation levelPrevent leakageScreening casingsAntennasControl signalMechanical engineering

The invention discloses an electronic speed controller device with a multilayer shielding structure. The electronic speed controller device comprises a drive module and a control module, wherein the drive module comprises a drive module shielding shell and a drive module end cover; the drive module shielding shell is provided with a first opening, an assembling vessel and a second opening which are mutually communicated; the drive module end cover is arranged at the second opening in a covering way; a drive part shielding shell is convexly arranged on the inner wall of the assembling vessel, and divides the assembling vessel into at least first shielding cavity; the control module comprises a control module end cover and a control module shielding shell which are mutually connected; the control module shielding shell is nested in the first shielding cavity; the control module end cover is arranged at the first opening in the covering way. The drive module shielding shell, the control module shielding shell and the drive part shielding shell form a three-layer shielding structure arranged in a laminating way inside and outside, and a control signal leaked during work can be completely shielded in the three-layer shielding structure, so that the influence on antenna intermodulation is reduced maximally, and thus the intermodulation level of an antenna product is improved.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

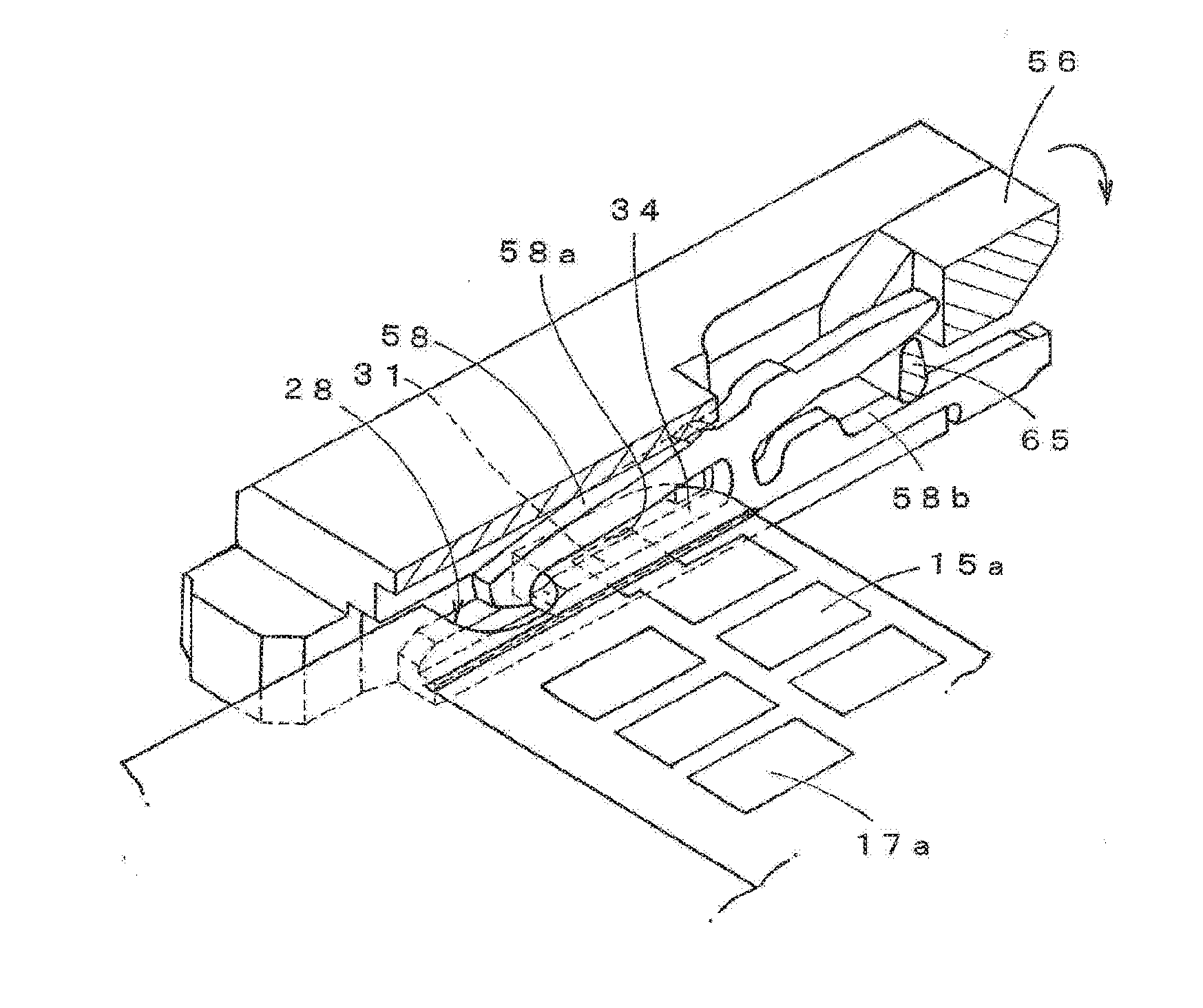

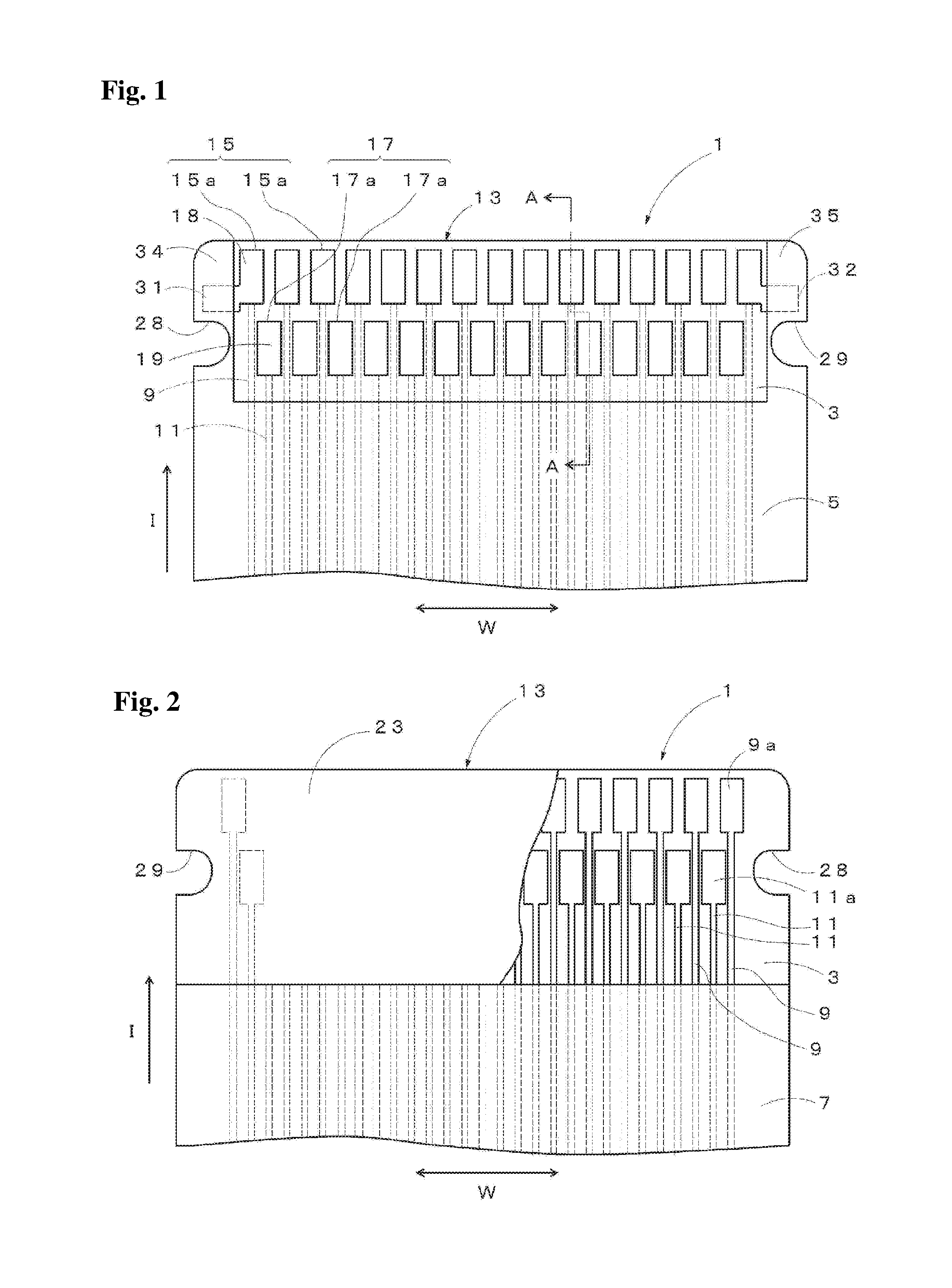

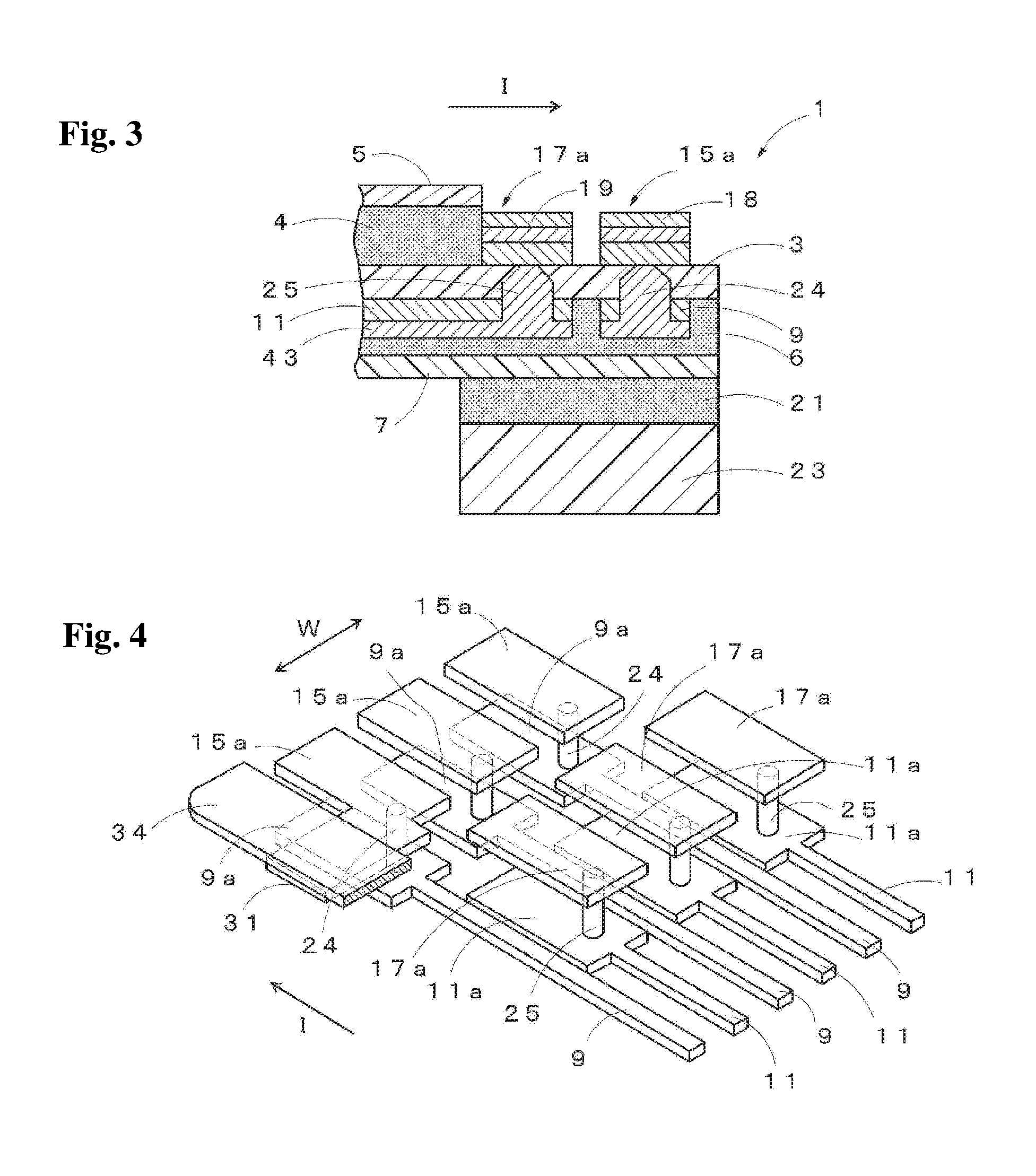

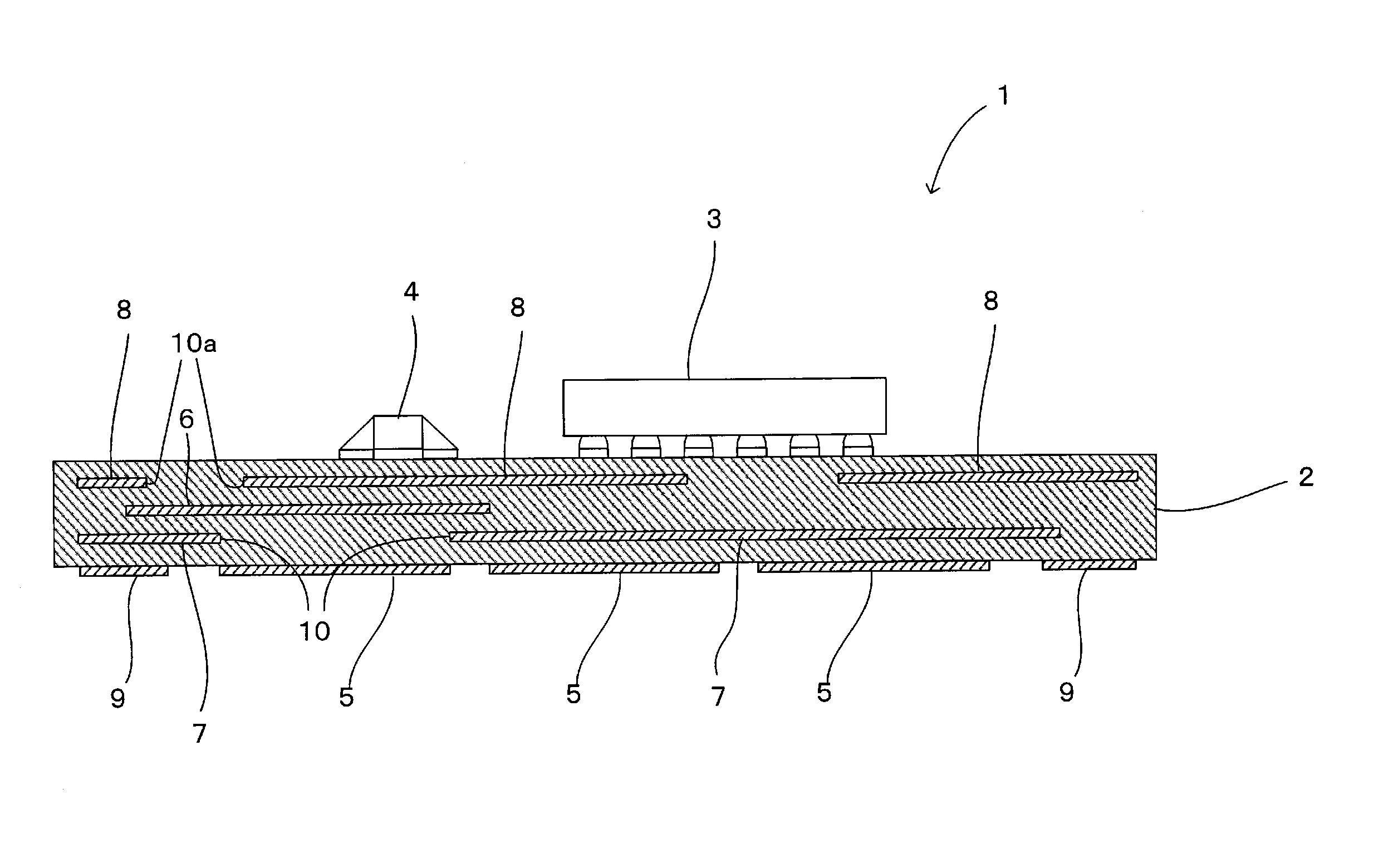

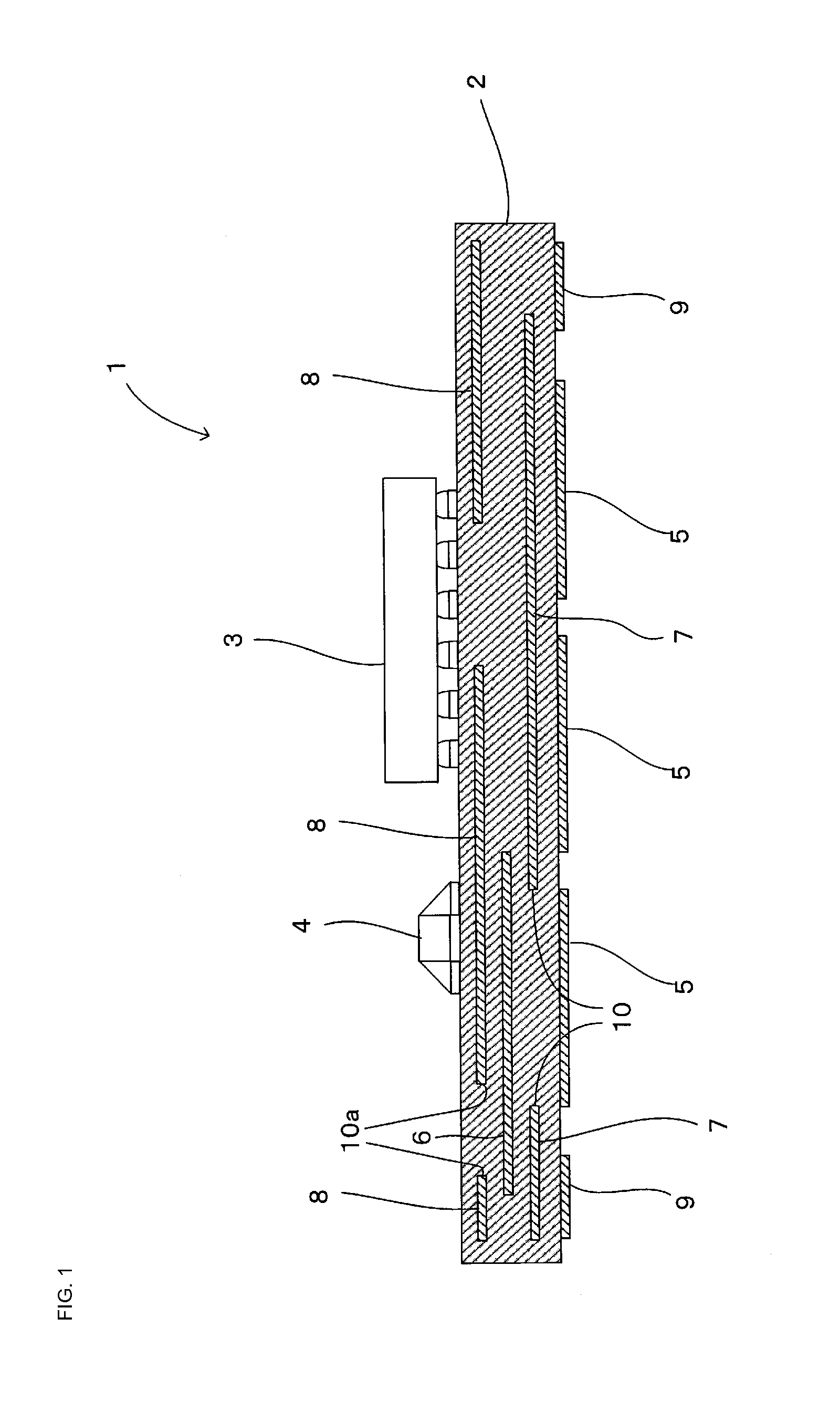

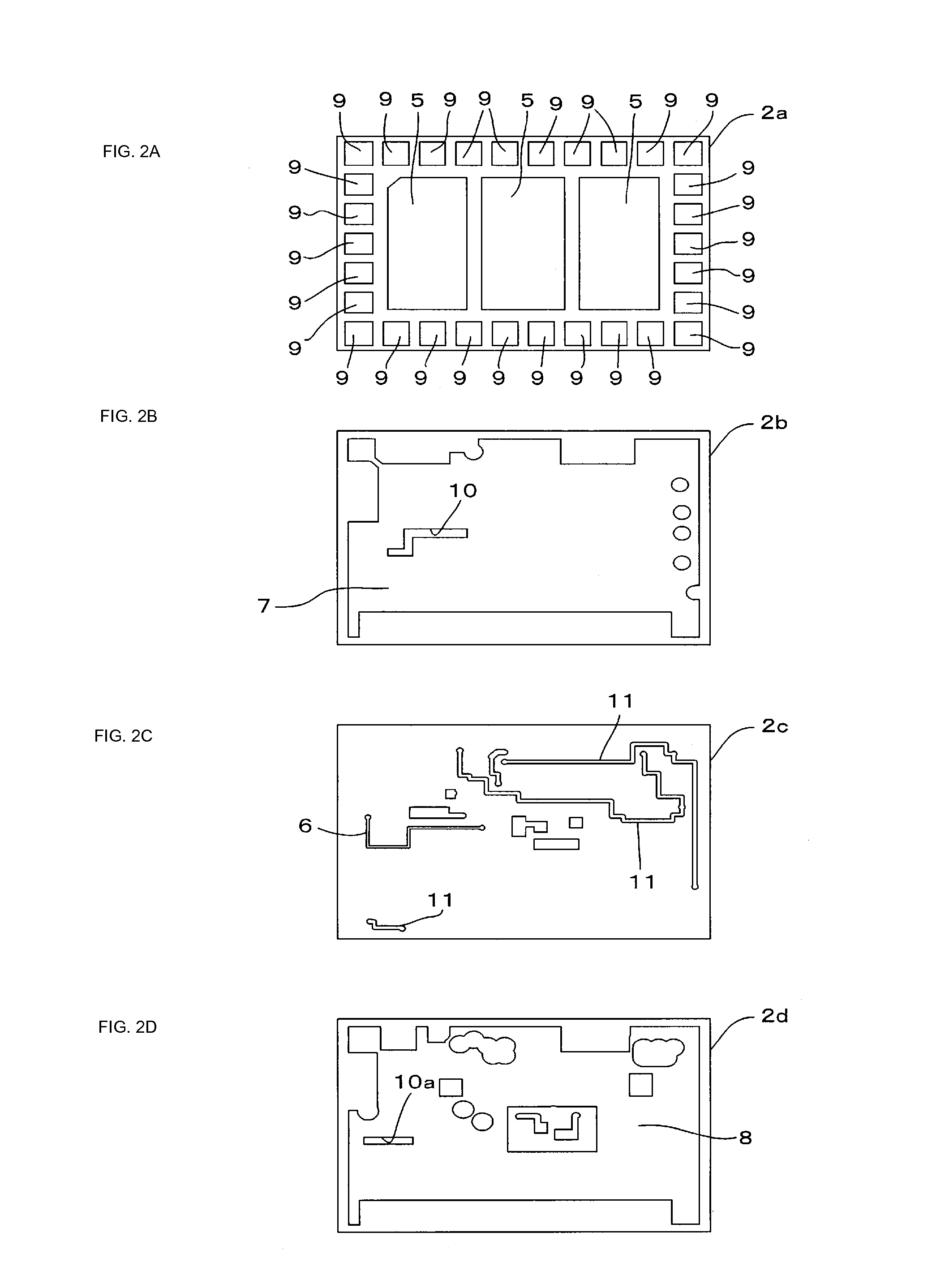

Printed wiring board and connector connecting the wiring board

ActiveUS20160204531A1High strengthDegree of freedom is loweredCoupling device connectionsPrinted circuit aspectsElectrical connectionEngineering

A printed wiring board (1) includes: a base substrate (3); a plurality of pads (15a, 17a) for electrical connection that are disposed at one surface side of the base substrate (3) and at a connection end portion (13) to be connected with another electronic component (50); wirings (9, 11) that are connected with the pads (15a, 17a); and engageable parts (28, 29) that are formed at side edge parts of the connection end portion (13) and are to be engaged with engagement parts (58) of the other electronic component (50) in the direction of disconnection. The flexible printed wiring board (1) further includes: reinforcement layers (31, 32) that are disposed at the one surface side of the base substrate (3) and at a frontward side with respect to the engageable parts (28, 29) when viewed in the direction of connection with the other electronic component and that are formed integrally with the pads (15a); and insulating layers (34, 35) that cover the reinforcement layers (31, 32).

Owner:THE FUJIKURA CABLE WORKS LTD +1

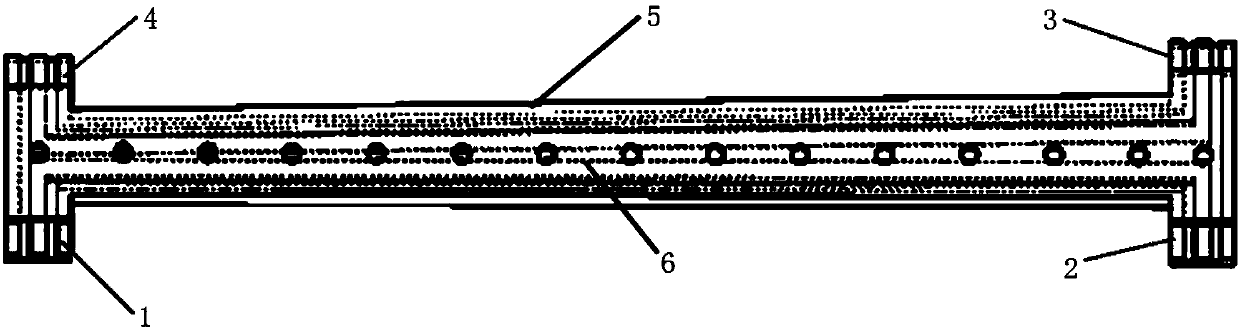

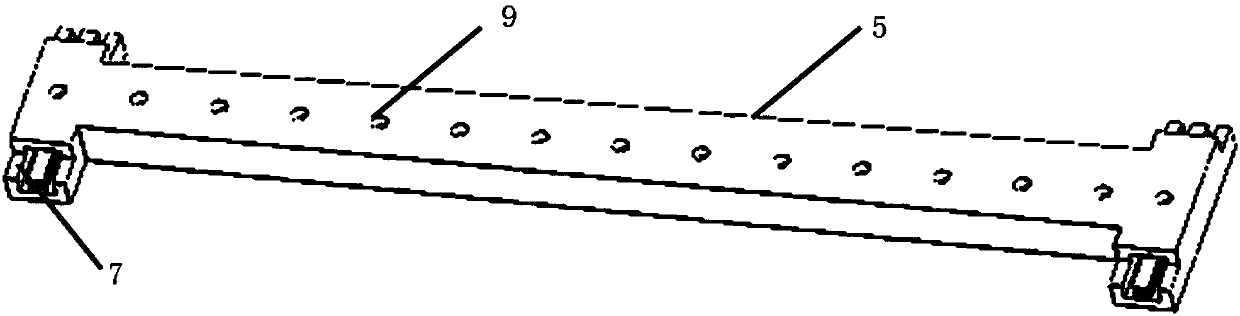

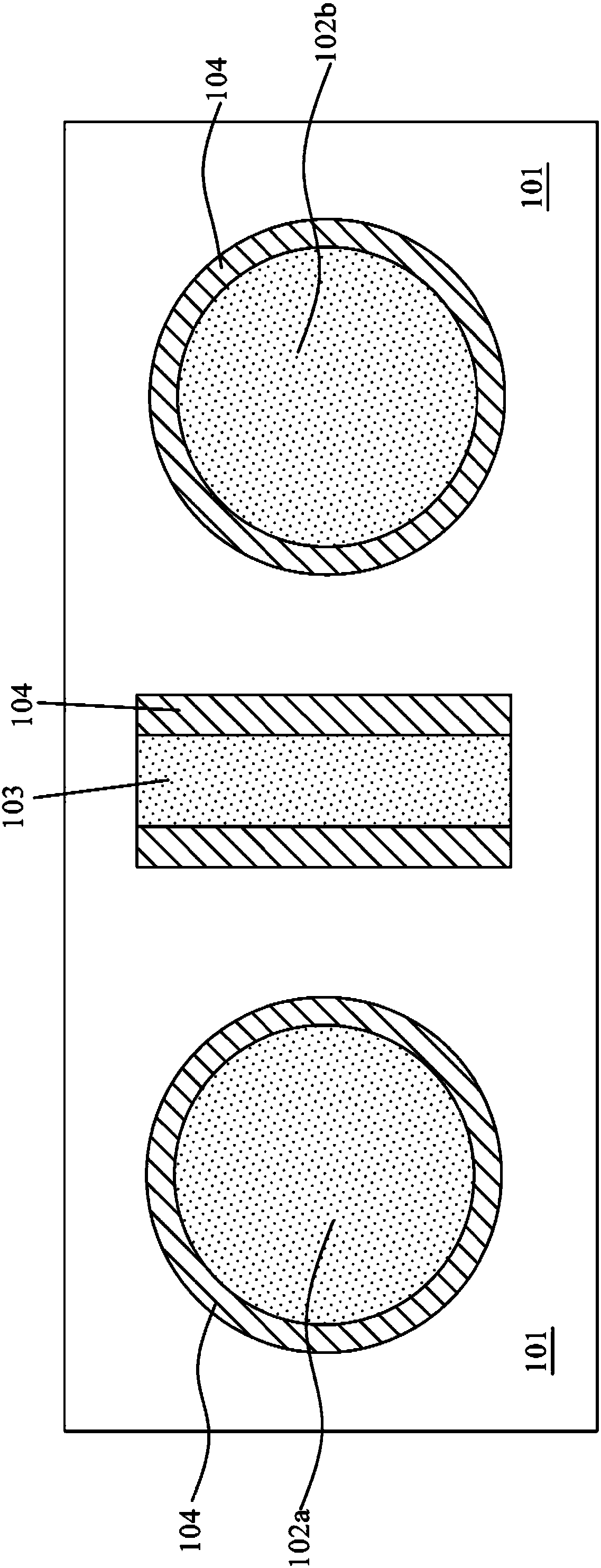

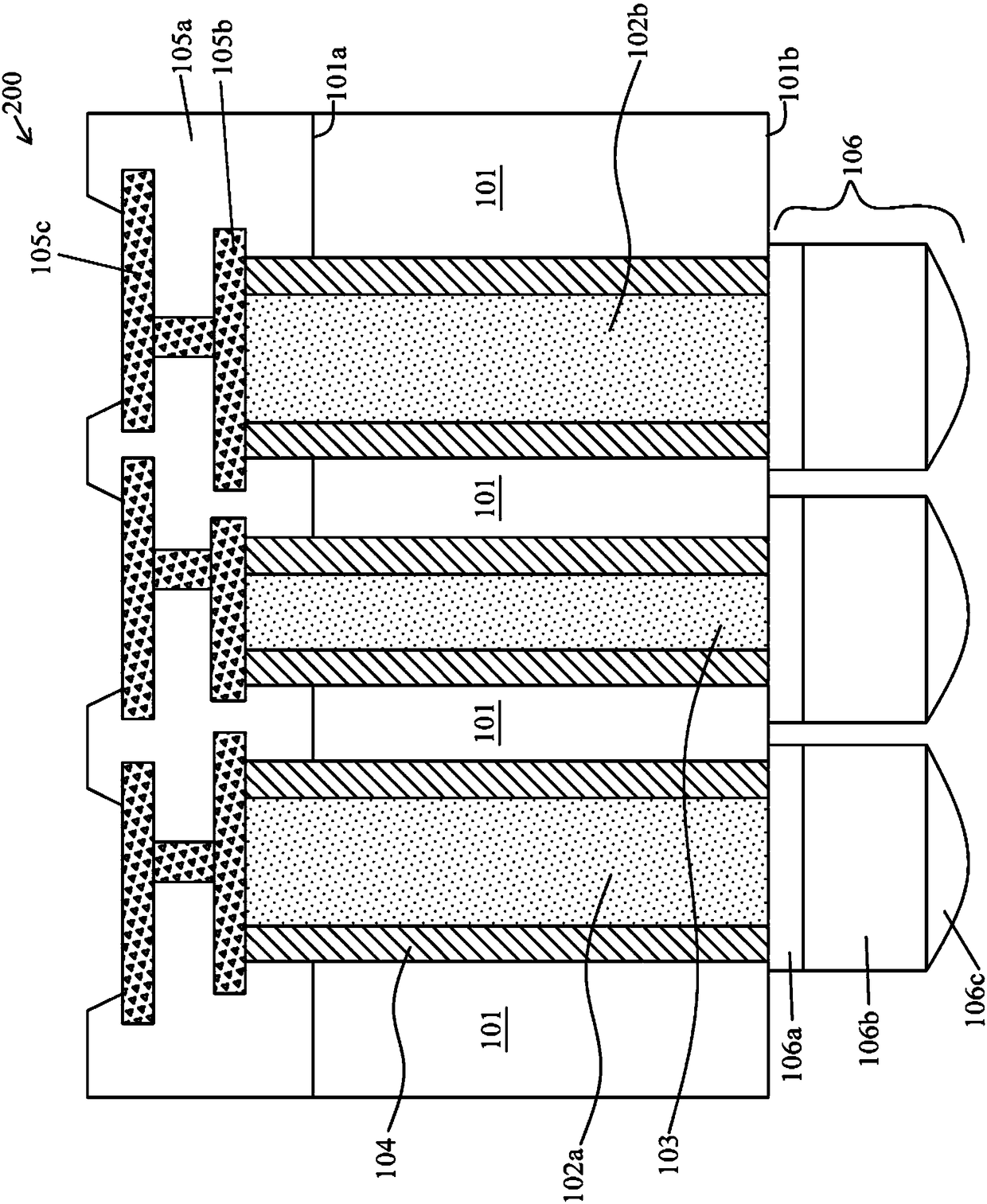

Composite module

ActiveUS20150080050A1Stray capacitance is preventedEfficient productionElectrically conductive connectionsSemiconductor/solid-state device detailsCapacitanceEngineering physics

A composite module includes outer ground electrodes on one main surface of a wiring substrate, a wiring electrode inside the wiring substrate, and a first ground electrode between the wiring electrode and the outer ground electrode. A cutout is provided in the first ground electrode at least at a portion of a region overlapping with the wiring electrode and the outer ground electrode when viewed from above, and the wiring electrode overlaps with at least one of the first ground electrode and the outer ground electrode when viewed from above to reduce stray capacitance produced on the wiring electrode and to adjust impedance of the wiring electrode while preventing signals leaked from the exterior from interfering with the wiring electrode.

Owner:MURATA MFG CO LTD

Microcoaxial ultrawide band coupling device

The invention discloses a microcoaxial ultrawide band coupling device, which comprises an outer conductor of an H-shaped metal cavity structure, an H-shaped inner conductor and a photoresist support body, wherein the inner conductor grows in the outer conductor; the photoresist support body is arranged between the bottom of the inner conductor and the bottom of the outer conductor; a first supportsection and a third support section are positioned on the same straight line; a second support section and a fourth support section are positioned on the same straight line; a gap with the graduallyincreased width is formed between the first conductor and the second conductor; the first conductor is in horizontal arrangement; the second conductor is in inclined arrangement along the first conductor; a plurality of through holes are formed in the upper surface of the outer conductor; the through holes are positioned in the gap of the first conductor and the second conductor. The invention provides a high-performance signal interconnection coupling structure with the advantages of smaller size, reliable performance and wider bandwidth. High integration degree and high performance of a microwave and millimeter wave system are realized; the microwave and millimeter wave coupling circuit with a plurality of octaves in the micro dimension structure is realized.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Implementing method for preventing signals of coaxial filter from leaking and signal processing device

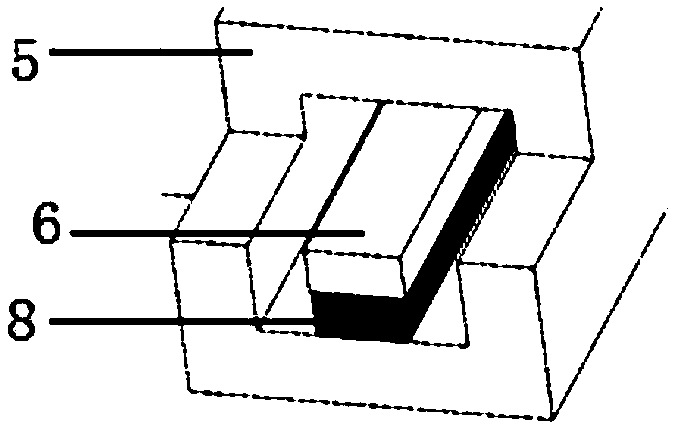

InactiveCN101728609AGood performancePrevent signal leakageWaveguide type devicesInternal cavityEngineering

The invention discloses an implementing method for preventing signals of coaxial filter from leaking. In the method, a device of box-shaped structure is arranged and comprises an external box-shaped structure, a cover board structure, a filter and a multi-section box-shaped structure; the filter is arranged in the internal cavity of the box-shaped structure and forms a signal channel with the box-shaped structure; a clapboard is arranged in the box-shaped structure to partition the internal cavity of the box-shaped structure into a plurality of blocking rooms; a concave groove is arranged on the contact face between the upper surface of the clapboard and the cover board; one end of the box-shaped structure is provided with a signal receiving port and the other end thereof is provided with at least two signal outputting ports, and the ports are in conducting connection with the box-shaped structure; an external transmission signal is transmitted into the box-shaped structure via the signal receiving port and transmitted to the signal outputting ports after the box-shaped structure and the filter induce with each other. And the invention also discloses a signal processing device for implementing the method.

Owner:东莞市苏普尔电子科技有限公司

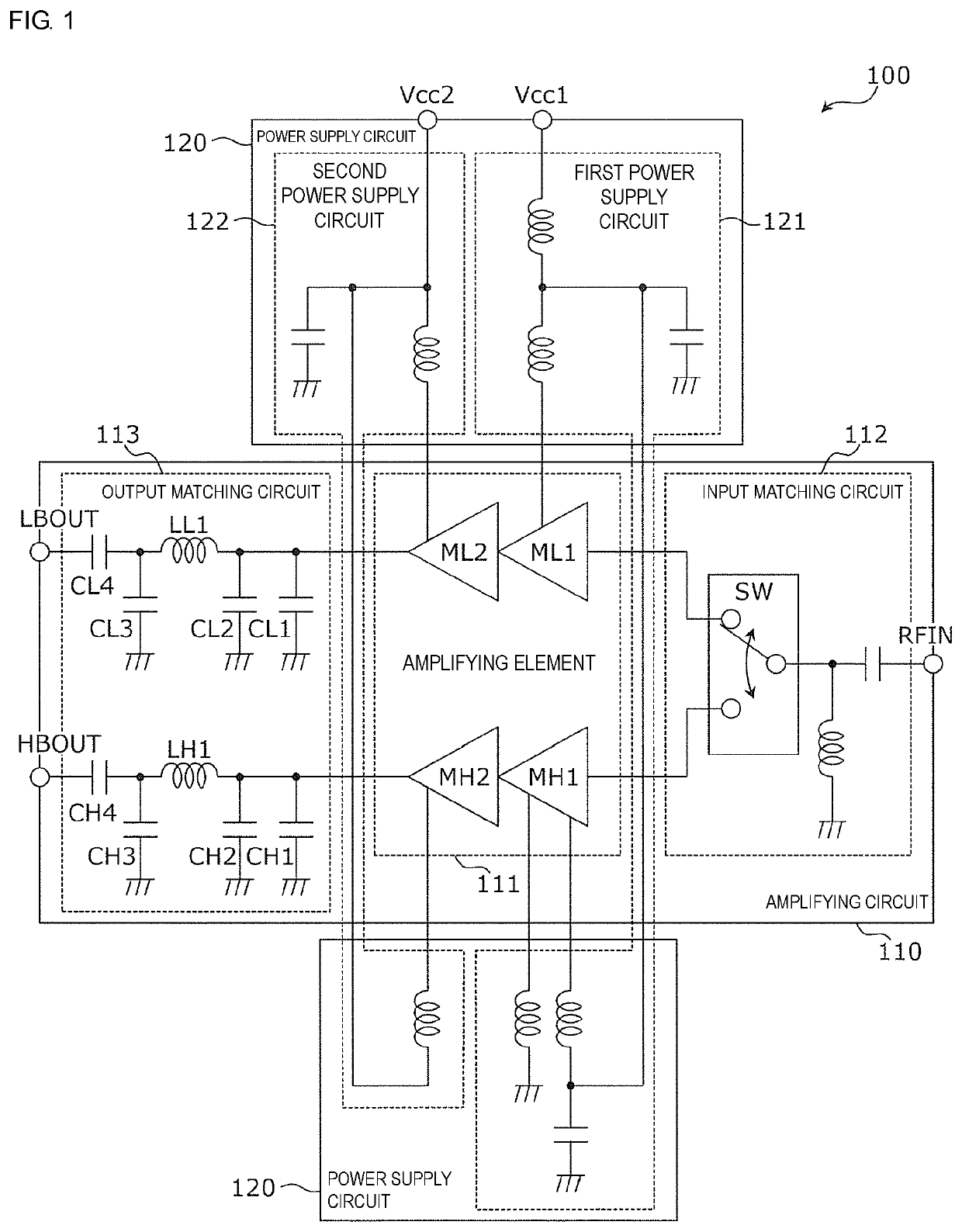

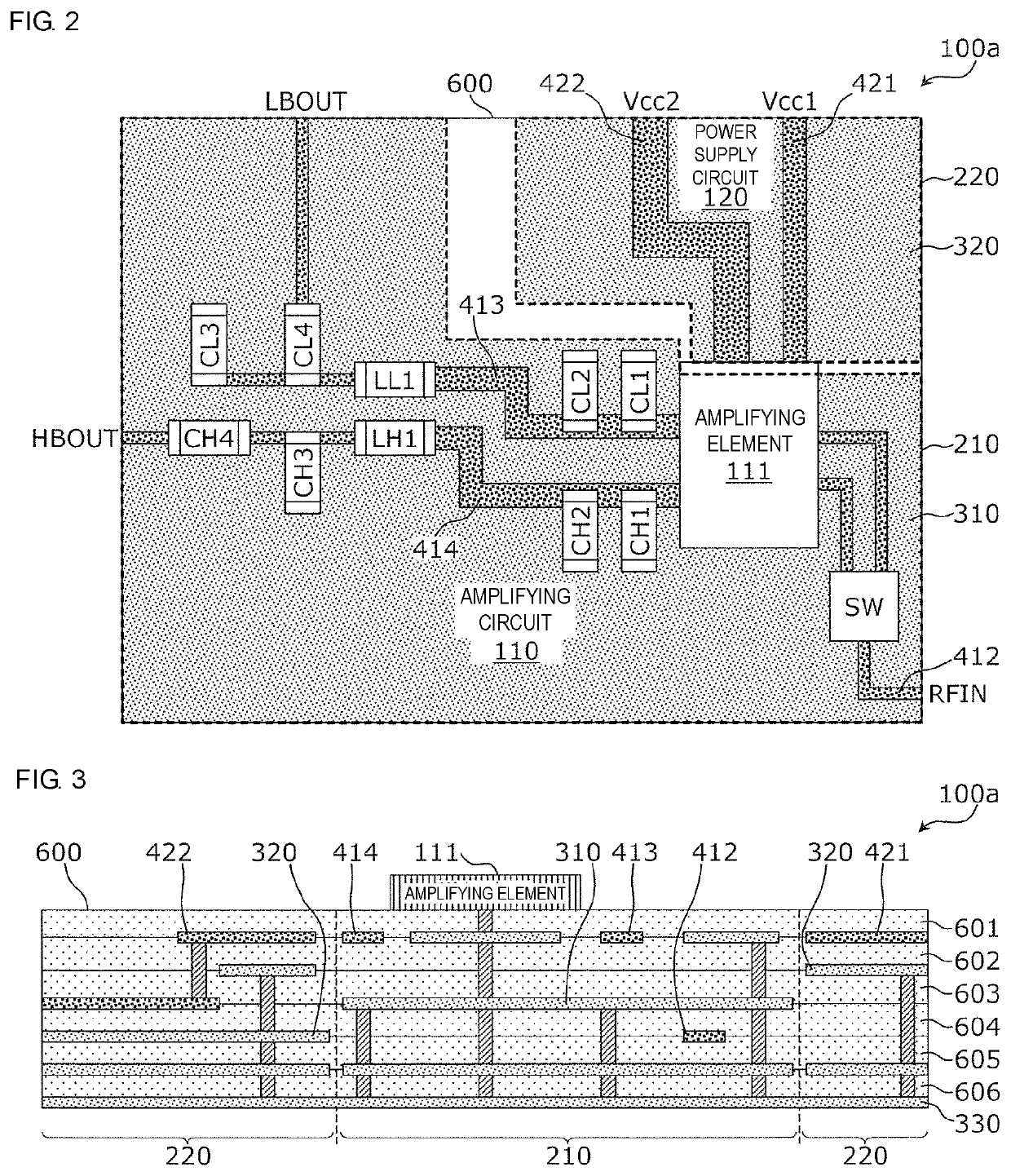

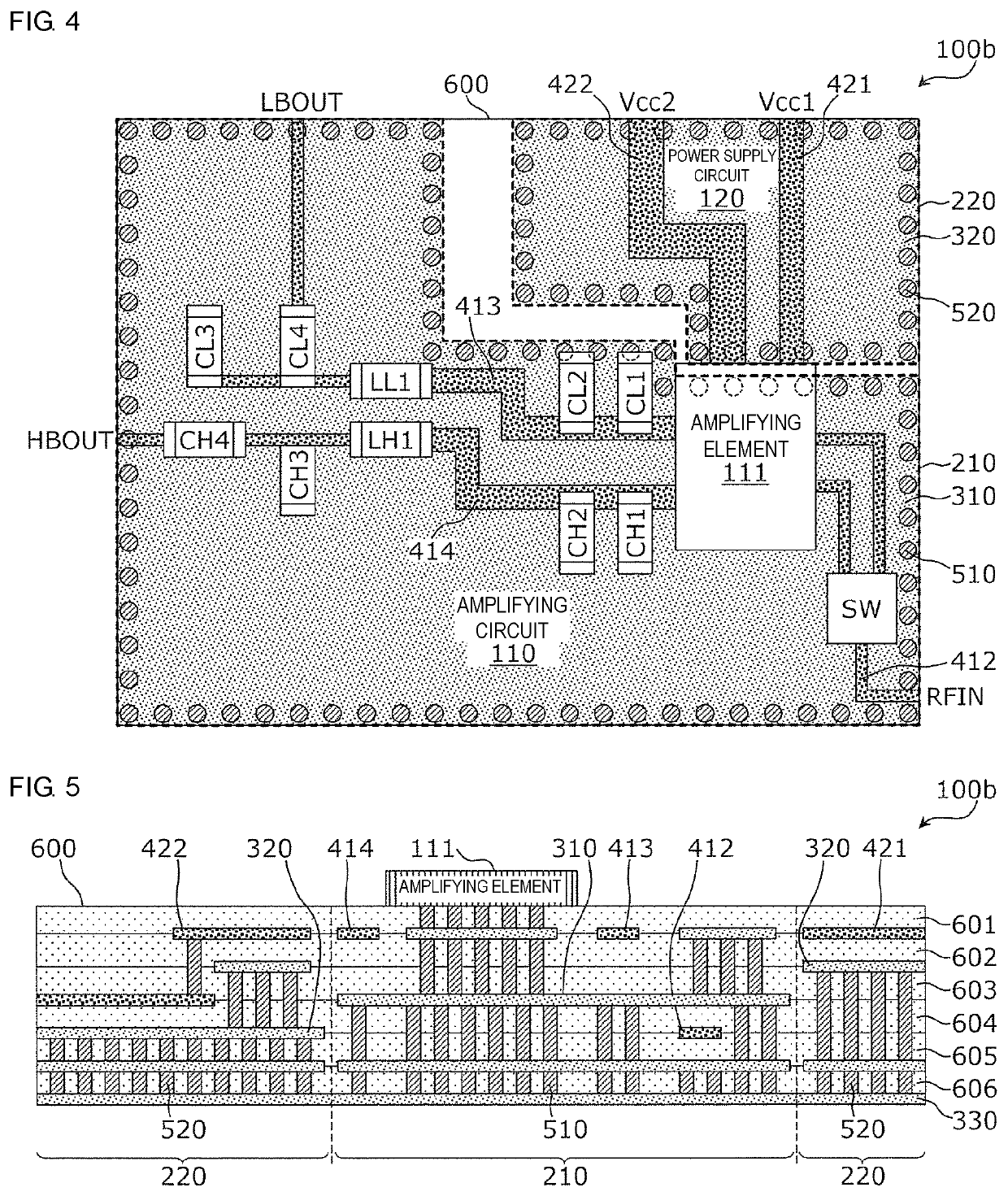

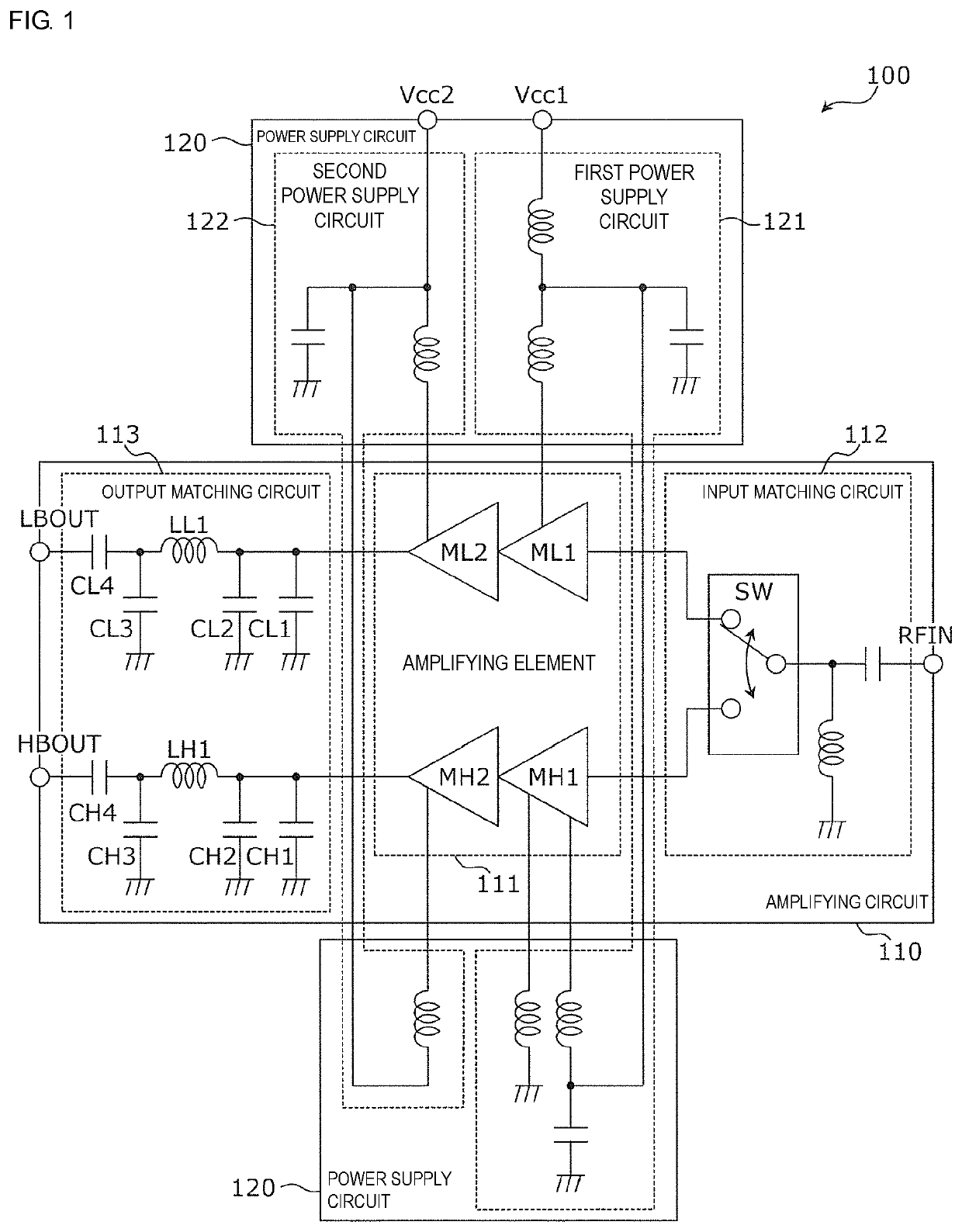

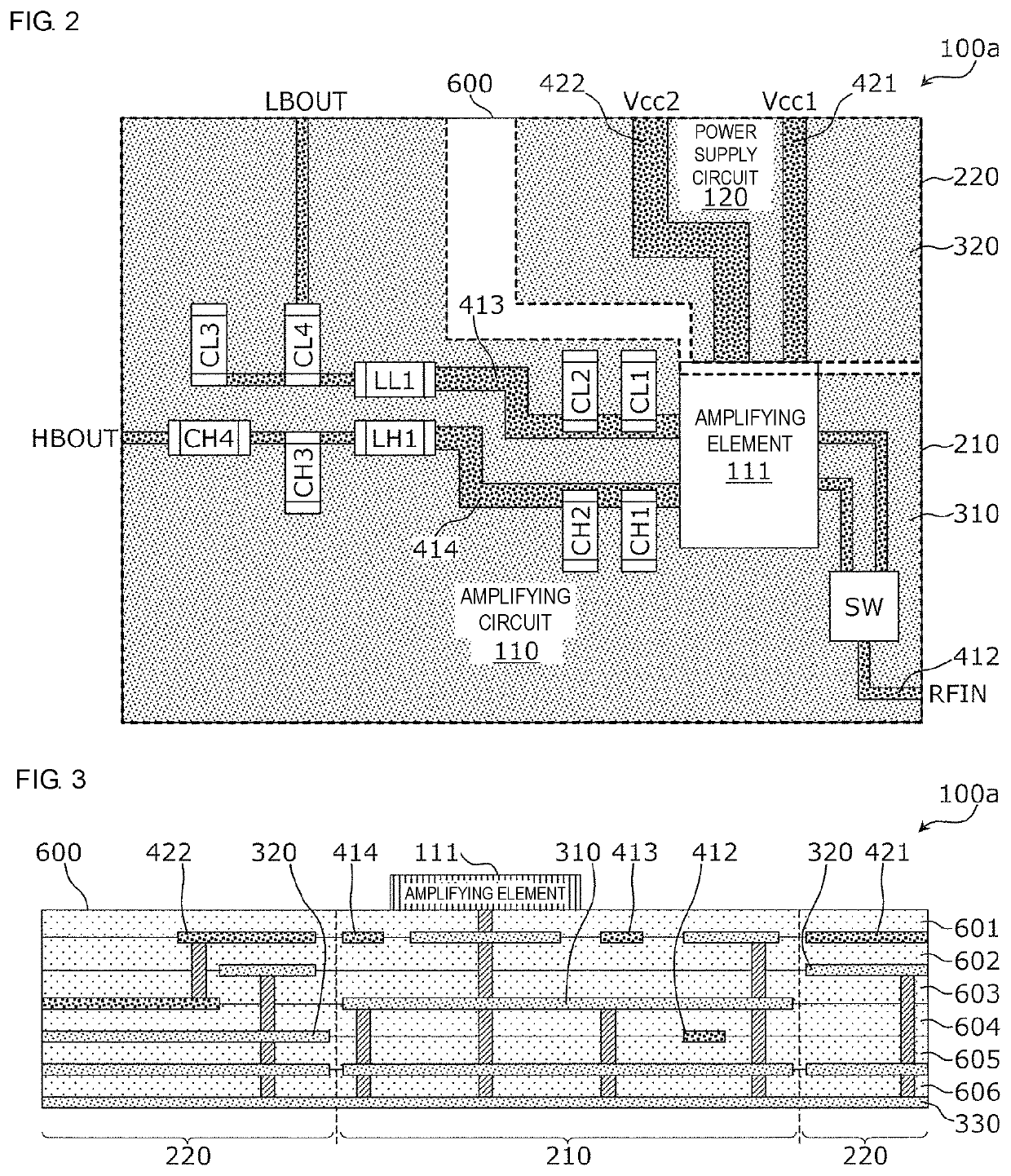

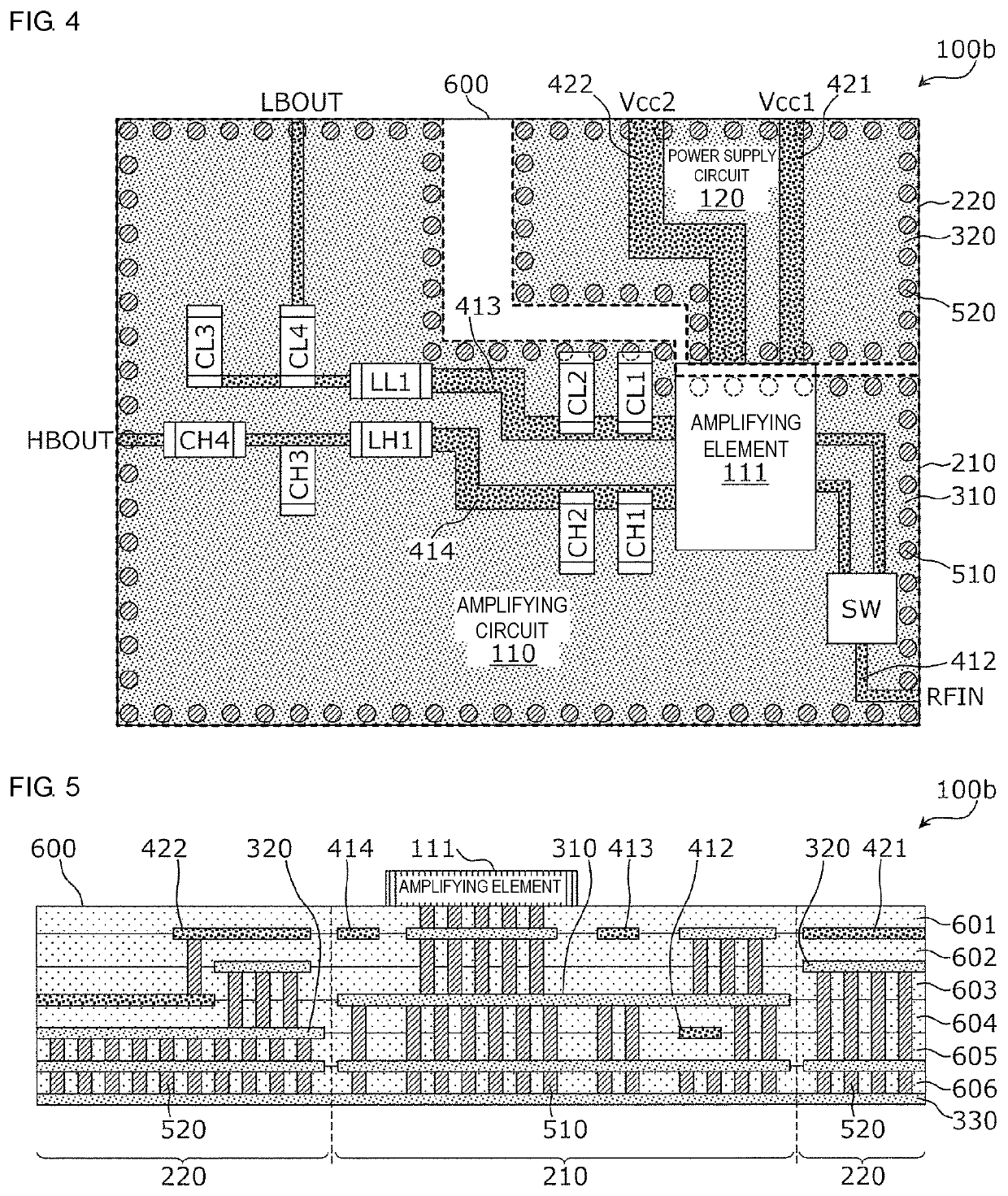

Radio frequency module and communication device

ActiveUS20200035592A1Improve certaintyPrevent leakageHigh frequency amplifiersSemiconductor/solid-state device detailsElectrical conductorRadio frequency signal

A radio frequency module includes: a multilayer substrate that includes a plurality of insulator layers; an amplifying circuit that is provided on the multilayer substrate and amplifies a radio frequency signal; a power supply circuit that is provided on the multilayer substrate and supplies power to the amplifying circuit; a ground conductor that is a first conductor pattern having a ground potential and used in the amplifying circuit; and a ground conductor that is a second conductor pattern having a ground potential and used in the power supply circuit. The ground conductors are physically separated from each other and provided in internal layers of the multilayer substrate.

Owner:MURATA MFG CO LTD

Switch module

ActiveUS20200244251A1Reduced insertion lossExclude influenceMultiple-port networksMulti-band filtersCapacitanceSoftware engineering

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

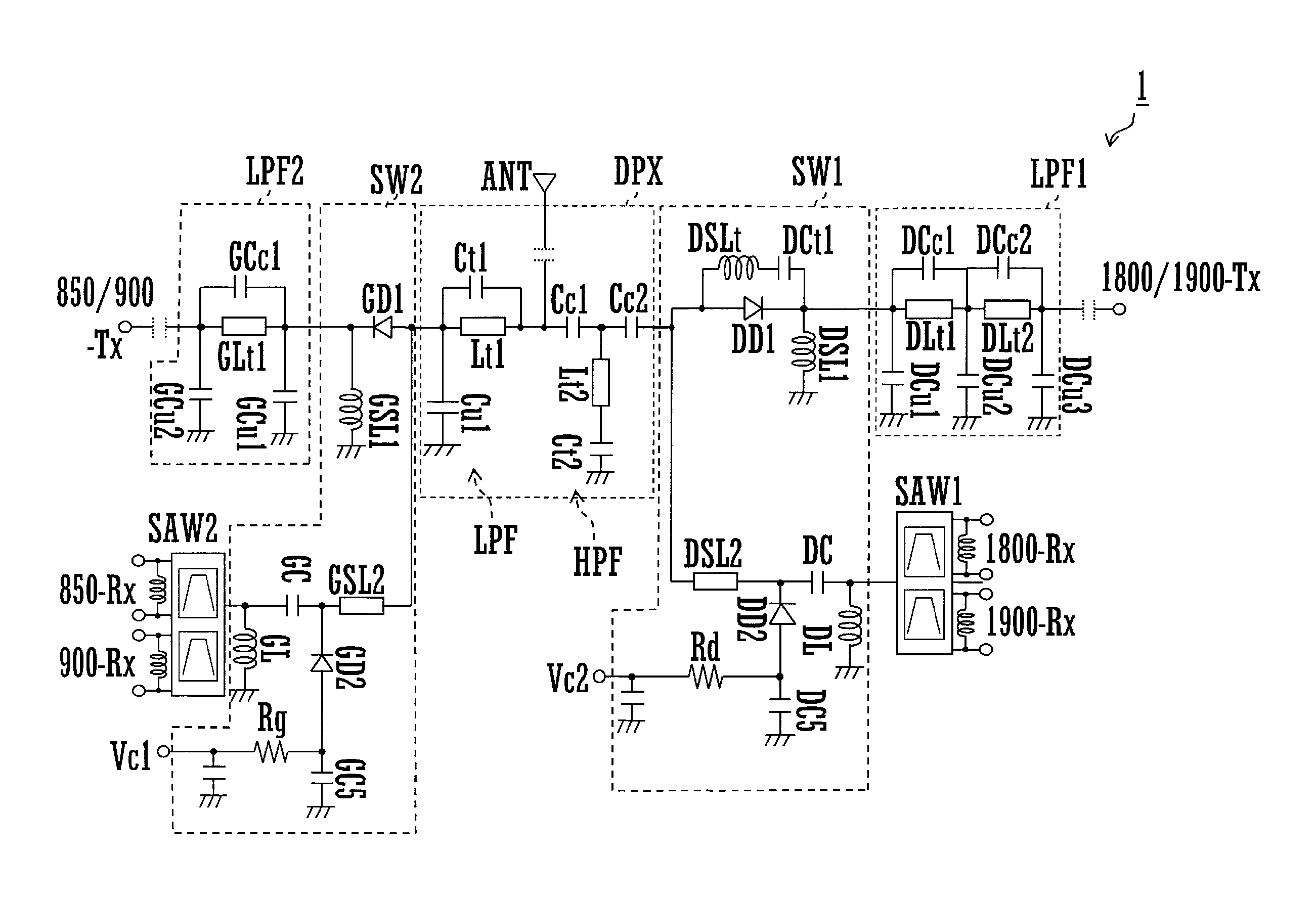

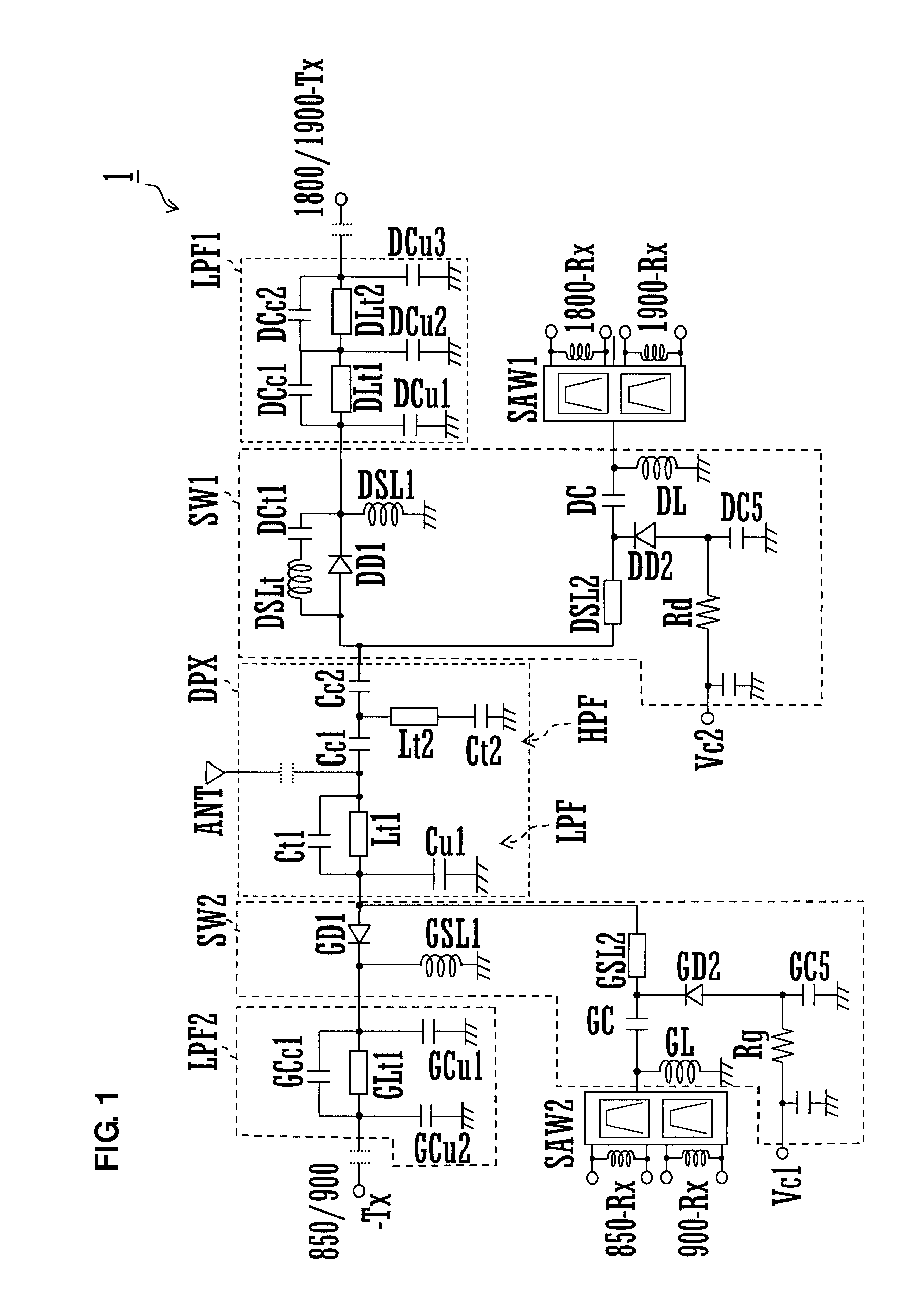

High-frequency module

ActiveUS20100301964A1Improve isolationInhibitionMultiple-port networksTransmissionTarget signalResonance

A high-frequency module includes at least first and second signal circuits that are each connected between a common antenna port and at least first and second signal ports. The first signal circuit includes a first inductor connected in series between the antenna port and the first signal port, a first capacitor connected in series between the first inductor and the first signal port, and a second inductor connected in shunt between the first capacitor and the first signal port. Series resonance is produced between the first inductor, the first capacitor, and the second inductor at a frequency within the frequency band of a target signal of the second signal circuit.

Owner:MURATA MFG CO LTD

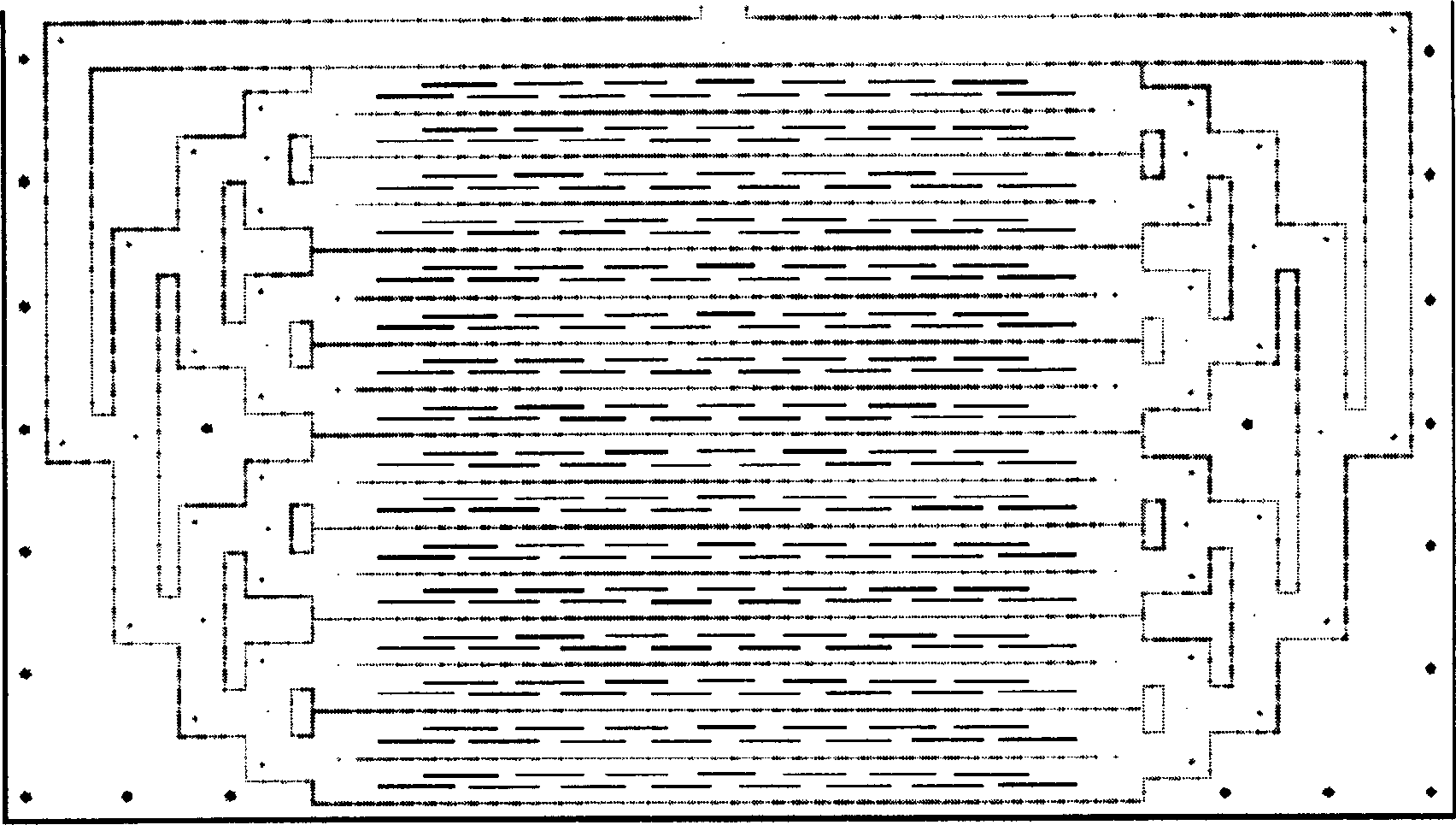

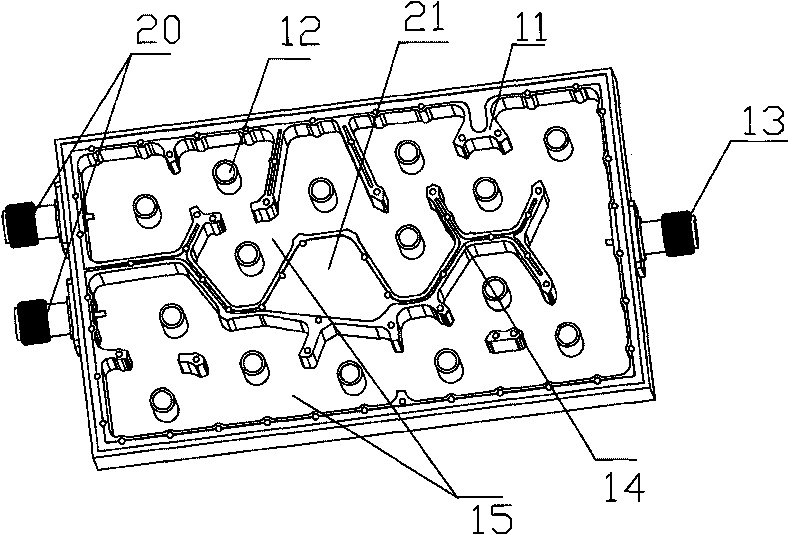

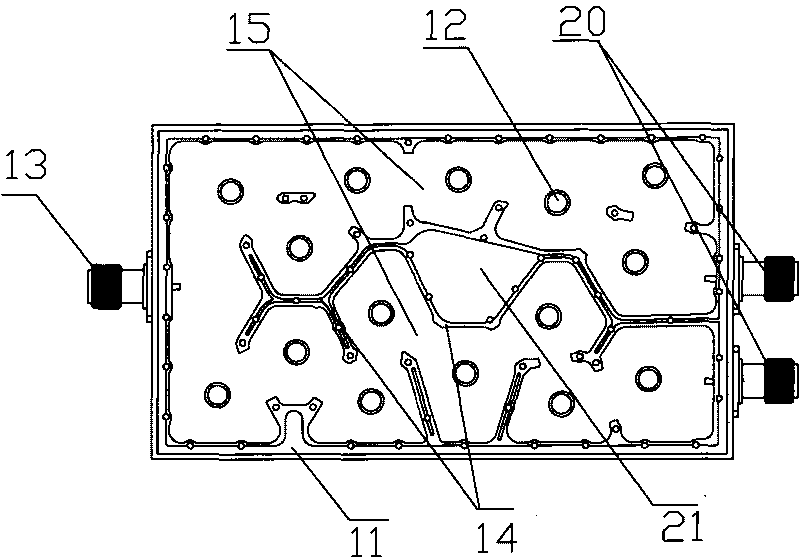

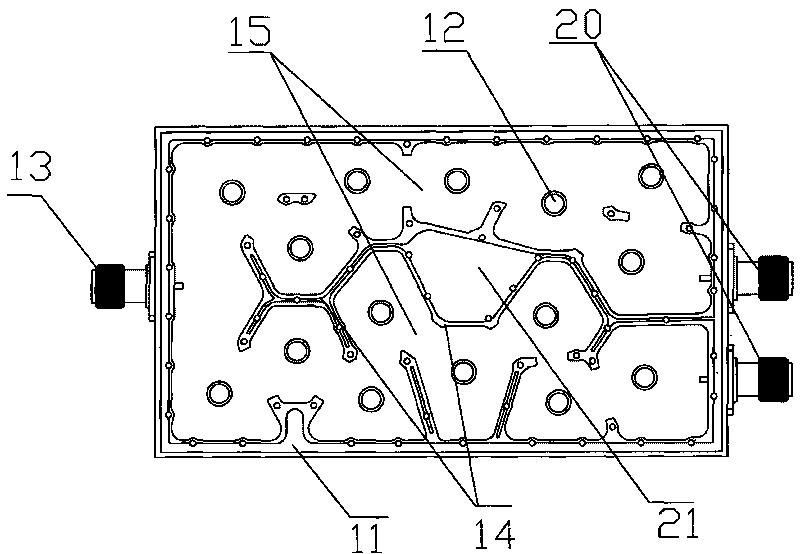

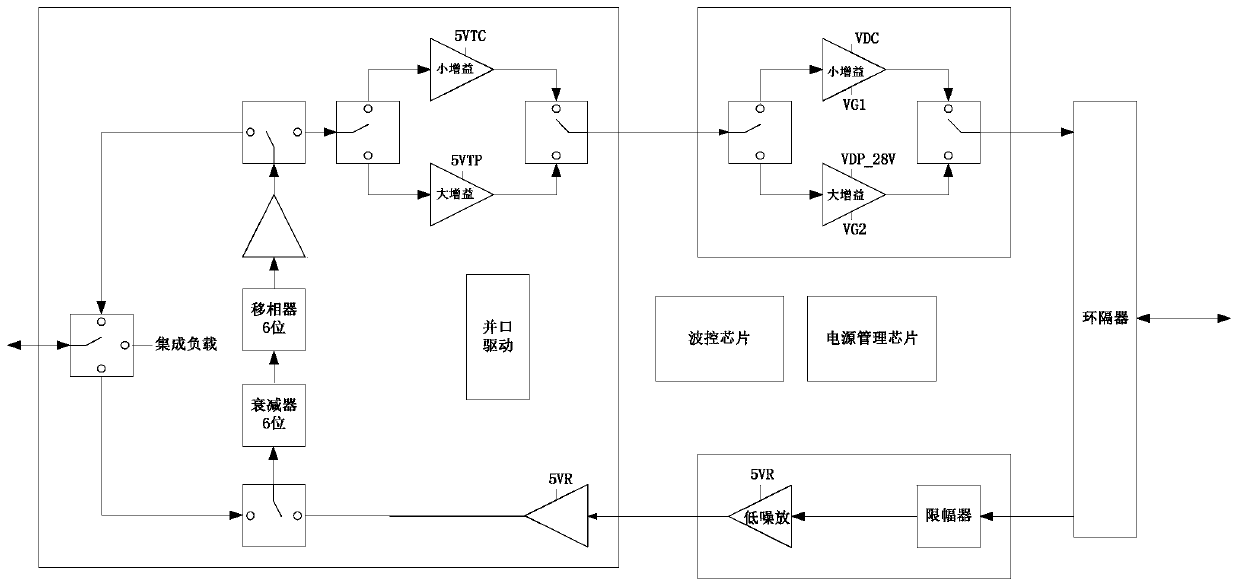

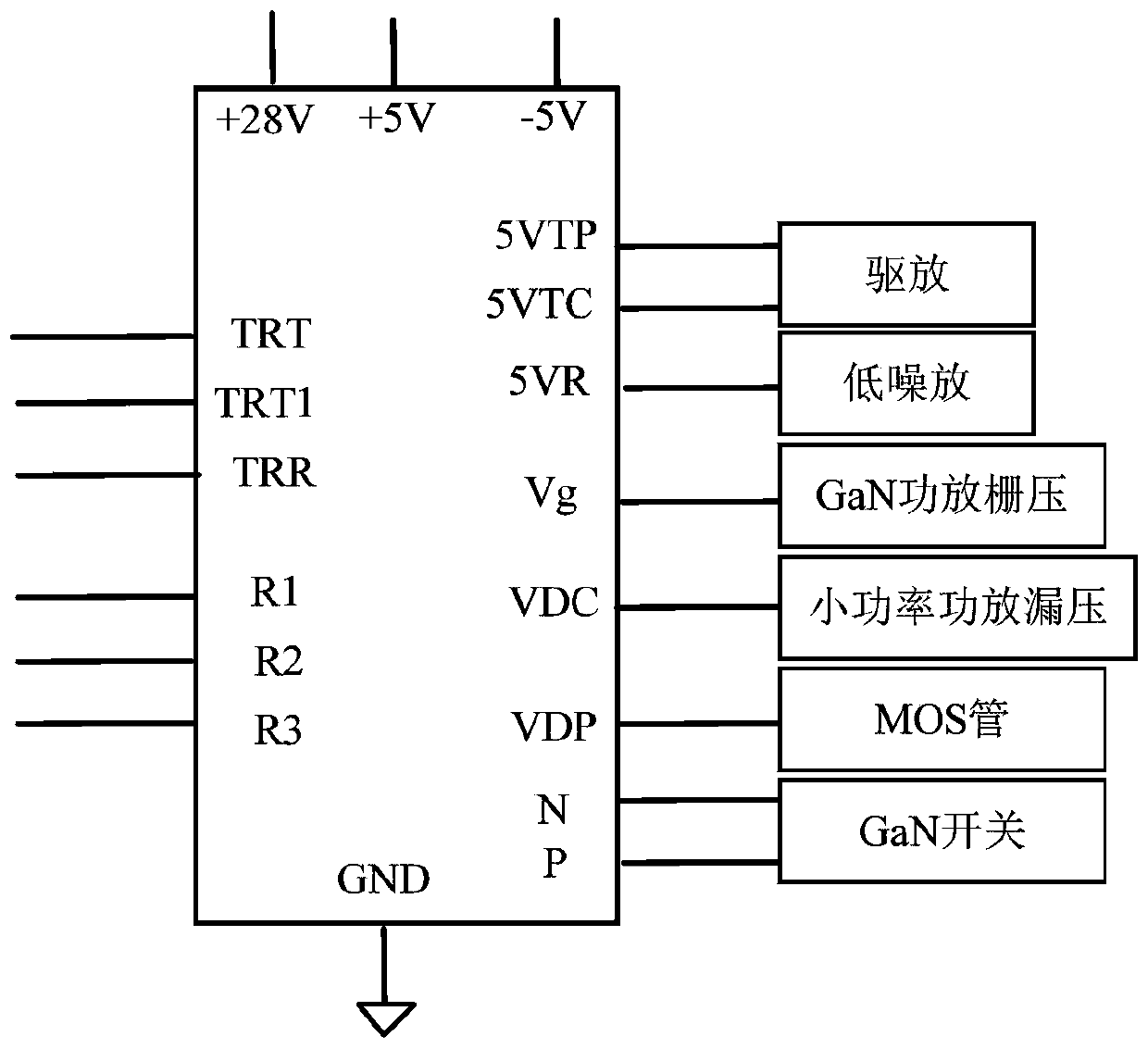

X wave band T/R assembly with switchable output power

ActiveCN110277970APrevent signal leakageLow reliabilityWave based measurement systemsGain controlPhase shiftedSignal leakage

According to an X wave band T / R assembly with switchable output power provided by the present invention, a receiving channel and a transmitting channel share a multifunctional chip, the six-phase shift and attenuation functions are achieved, and the amplification function of input signals is achieved; a transmitting channel can provide a large output power path and a small output power path, and the channel selection and switching is conducted through the control signals; a power amplifier is connected with a multifunctional chip and is used for amplifying the output power of the multifunctional chip so as to output an amplified signal with target power; the different amplification channels are selected by the control signal to perform the power amplification, and finally, the output signals with two different powers can be respectively generated; the amplitude-limiting low-noise amplifier chip is used for detecting and amplifying a signal outputted by the ring isolator in the receiving channel; a partition plate and a cover plate are arranged on a box body, and the partition plate is arranged between the driving amplifier and the power amplifier, so that the self-excitation caused by the mutual influence between the power amplifier devices is prevented, and the reliability of the T / R assembly is reduced. The cover plate is used for preventing the signal leakage and guaranteeing the stability of the microwave signals in a cavity.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

High-frequency module

ActiveUS8334731B2Improve isolationSuppress of degradationMultiple-port networksTransmissionResonanceTarget signal

A high-frequency module includes at least first and second signal circuits that are each connected between a common antenna port and at least first and second signal ports. The first signal circuit includes a first inductor connected in series between the antenna port and the first signal port, a first capacitor connected in series between the first inductor and the first signal port, and a second inductor connected in shunt between the first capacitor and the first signal port. Series resonance is produced between the first inductor, the first capacitor, and the second inductor at a frequency within the frequency band of a target signal of the second signal circuit.

Owner:MURATA MFG CO LTD

Switch module

ActiveUS20210159887A1Exclude influencePrevent signal leakageMultiple-port networksMulti-band filtersCapacitanceSoftware engineering

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

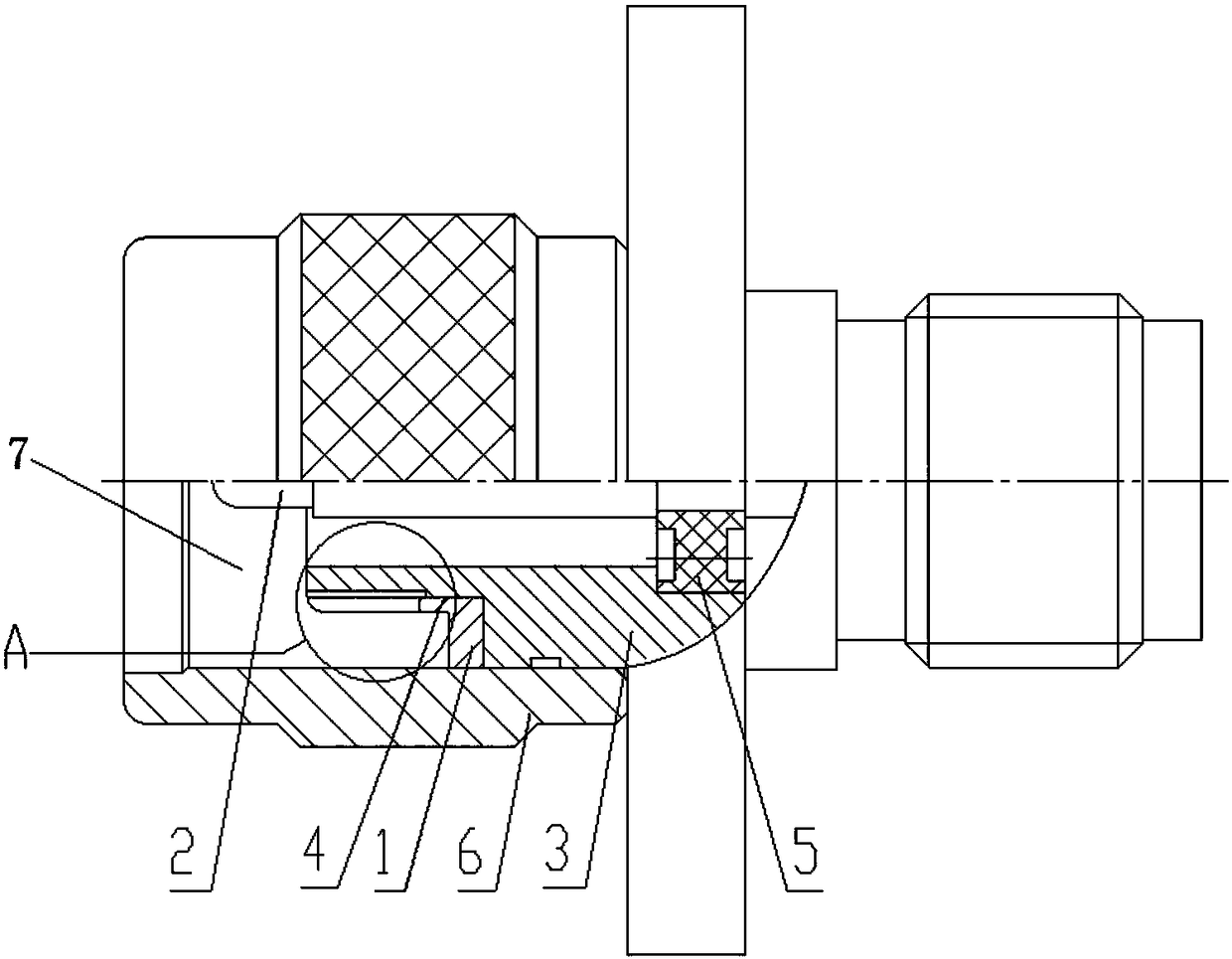

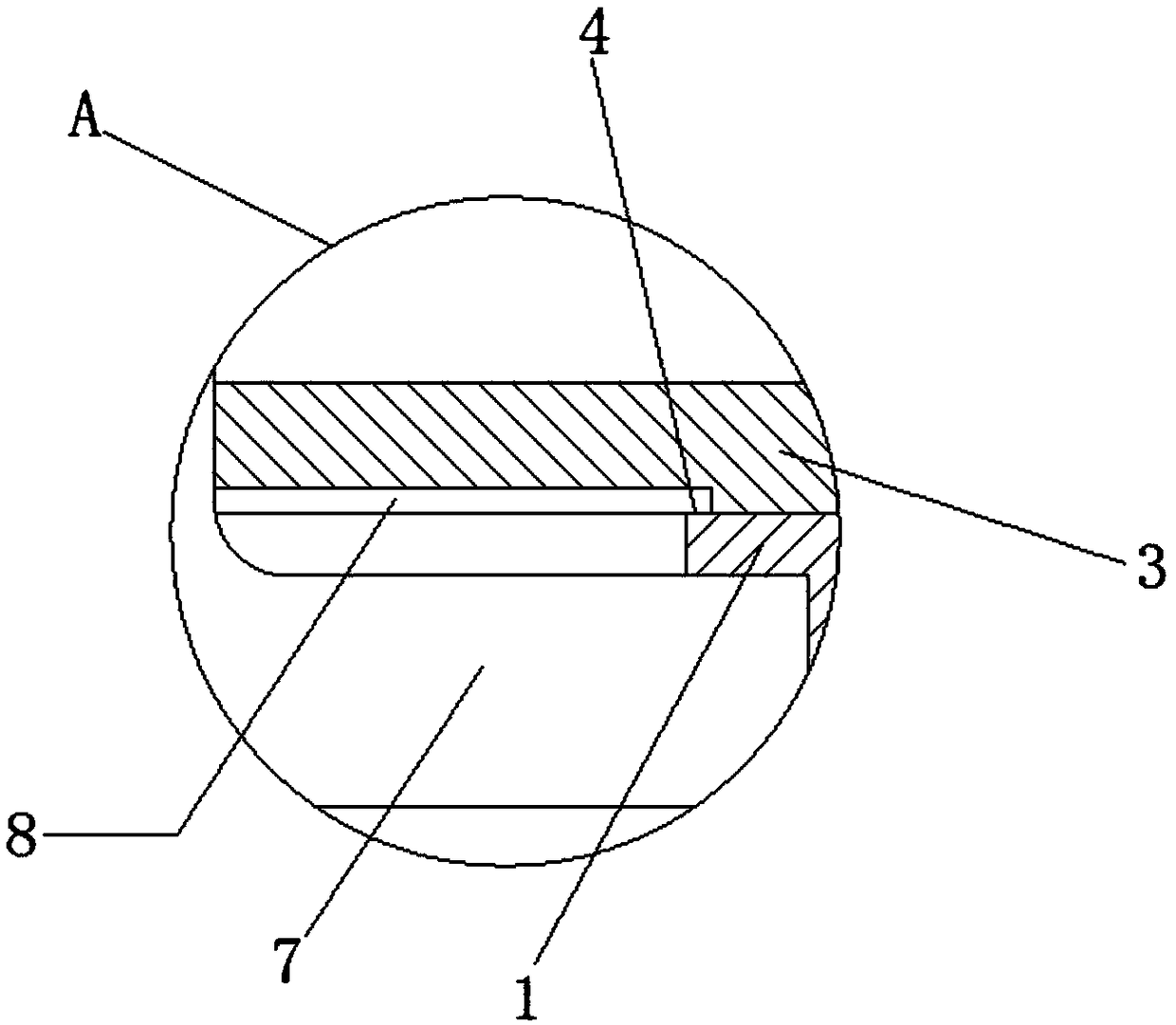

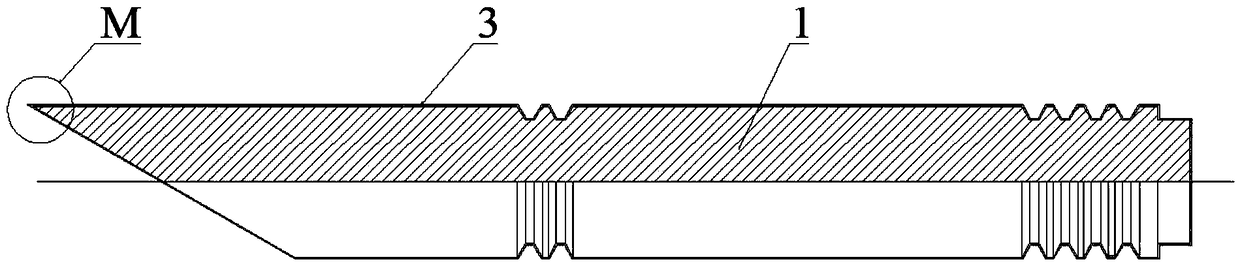

A quick plug-in test millimeter wave connector

ActiveCN106207616BPrevent leakageAchieve the purpose of insertingCoupling device detailsDielectricSignal leakage

The invention discloses a quick-inserting type millimeter wave connector for testing. The quick-inserting type millimeter wave connector comprises a connector main body, wherein a quick-inserting structure is arranged at one end of the connector main body; the quick-inserting structure comprises a first shell; a contact pin is arranged in the first shell; an insulating supporting dielectric is arranged on the periphery of the contact pin; the first shell is mounted in a second shell in a pressing manner; a contact head is arranged between the first shell and the first shell; a gap is formed between the contact head and the first shell; and a splitting groove is formed in the contact head. By setting the splitting groove in the contact head, the problem of signal leakage is avoided; and in addition, by adoption of the quick-inserting structure, the quick inserting of the connector is realized, thereby increasing the connecting speed.

Owner:XIAN ELITE ELECTRONICS IND

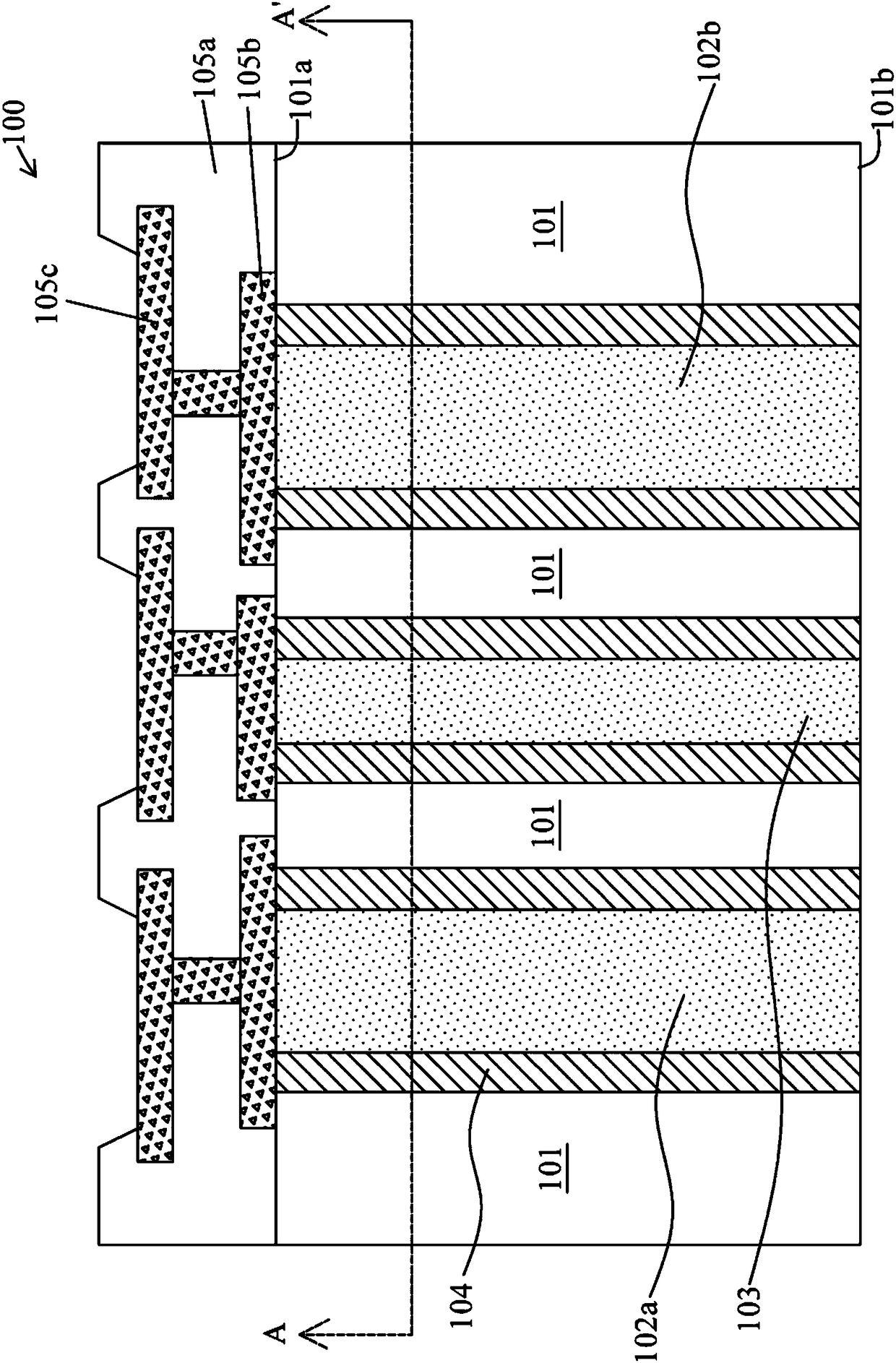

Semiconductor structure and manufacturing method thereof

InactiveCN108336066APrevent or minimize crosstalkIncrease transmission speedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

A semiconductor structure includes a substrate including a first side and a second side opposite to the first side; a first via extending through the substrate; a second via extending through the substrate; and a metallic structure disposed between the first via and the second via, wherein the first via is isolated from the second via by the metallic structure, the first via and the second via areconfigured to connect to a signal source or transmit a signal, and the metallic structure is configured to connect to a power or a ground.

Owner:NAN YA TECH

Switch module

ActiveUS10944382B2Exclude influencePrevent signal leakageMultiple-port networksMulti-band filtersCapacitanceSoftware engineering

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

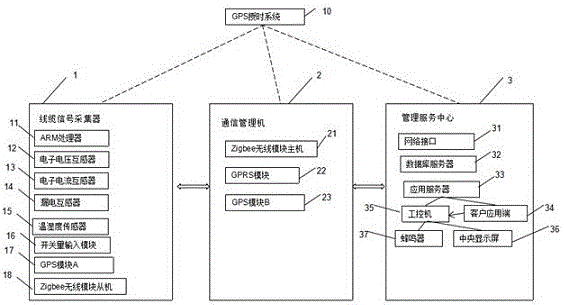

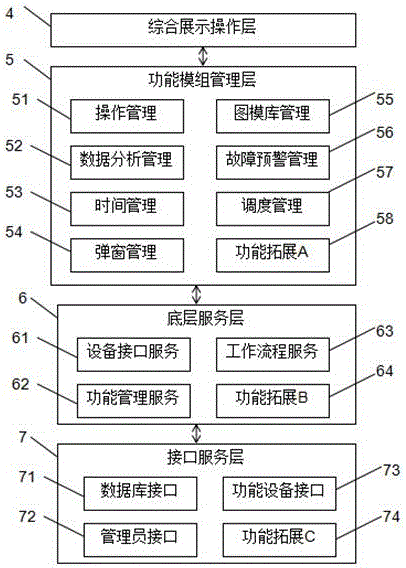

Precise analysis early warning system based on power grid fault information

InactiveCN106291196AReliable Advice for DecisionsImprove processing efficiencyElectrical testingEarly warning systemPower grid

The invention discloses a precise analysis early warning system based on power grid fault information. A cable signal acquirer communicates with a communication management machine in a wireless manner; the communication management machine communicates with a management service center; the cable signal acquirer is mounted on a working site to monitor the operation state of monitoring power equipment on site; the communication management machine can communicate with a plurality of distributed data monitoring devices and is used for summarizing data uploaded by each distributed data monitoring device; the cable signal acquirer, the communication management machine and the management service center are all subjected to unified timing through a GPS timing system. By adopting the precise analysis early warning system, promotion information can be analyzed and processed in a power grid deeply, and the processing efficiency of the power grid in emergent situations can be improved.

Owner:徐洪恩

Radio frequency module and communication device

ActiveUS11139231B2Improve certaintyPrevent leakageHigh frequency amplifiersSemiconductor/solid-state device detailsElectrical conductorRadio frequency signal

A radio frequency module includes: a multilayer substrate that includes a plurality of insulator layers; an amplifying circuit that is provided on the multilayer substrate and amplifies a radio frequency signal; a power supply circuit that is provided on the multilayer substrate and supplies power to the amplifying circuit; a ground conductor that is a first conductor pattern having a ground potential and used in the amplifying circuit; and a ground conductor that is a second conductor pattern having a ground potential and used in the power supply circuit. The ground conductors are physically separated from each other and provided in internal layers of the multilayer substrate.

Owner:MURATA MFG CO LTD

Precision molding method for low-temperature radiometer concealed cavity

InactiveCN108747213AGuaranteed dimensional accuracyGuaranteed shape and position accuracyRadiometerSurface roughness

The invention relates to a precision molding method for a low-temperature radiometer concealed cavity. The precision molding method for the low-temperature radiometer concealed cavity is characterizedby comprising the following steps that 1, precise machining of a core mold is carried out; 2, the surface of the core mold is coated; 3, part of the core mold is removed in a cutting mode; and 4, thecore mold is thoroughly removed in a chemical corrosion mode, so that precise molding of a cavity is completed, specifically, thermal treatment is conducted between the step 2 and the step 3 to remove stress of a coating. According to the new precision molding method for the low-temperature radiometer concealed cavity, the surface of the core mold is coated with a material, and then the core moldis removed, so that the problems that an existing method is low in bending precision, has welding defectives and welding deformation possibility and the like are solved. With adoption of the precision molding method for the low-temperature radiometer concealed cavity, size precision of the concealed cavity, form and position accuracy and inner surface roughness can be effectively ensured, the problems of signal leakage and the like are solved, and product consistency and yield are improved on the basis that the molding precision is improved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Cable TV. tuner and one-chip integrated circuit used by it

InactiveCN1445985APrevent signal leakageAvoid mixingTelevision system detailsMagnetic/electric field screeningIntermediate frequencyEngineering

A cable television tuner includes a metal cabinet having compartments isolated from first to fourth. In the first to fourth isolated cells, a data circuit, an input filter circuit, a first mixer circuit, a first local oscillator circuit, a first intermediate frequency circuit, and other components are accommodated. In the fifth isolated chamber, a second intermediate frequency circuit and an integrated circuit including a second local oscillator circuit are housed. According to such a structure, the present CATV tuner is defined as an up / down tuner. A third isolated cell containing the first local oscillator circuit and a fifth isolated cell containing the second local oscillator circuit are disposed adjacent to each other. Both the transmission line and the terminals are used by the first PLL circuit and the second PLL circuit.

Owner:MURATA MFG CO LTD

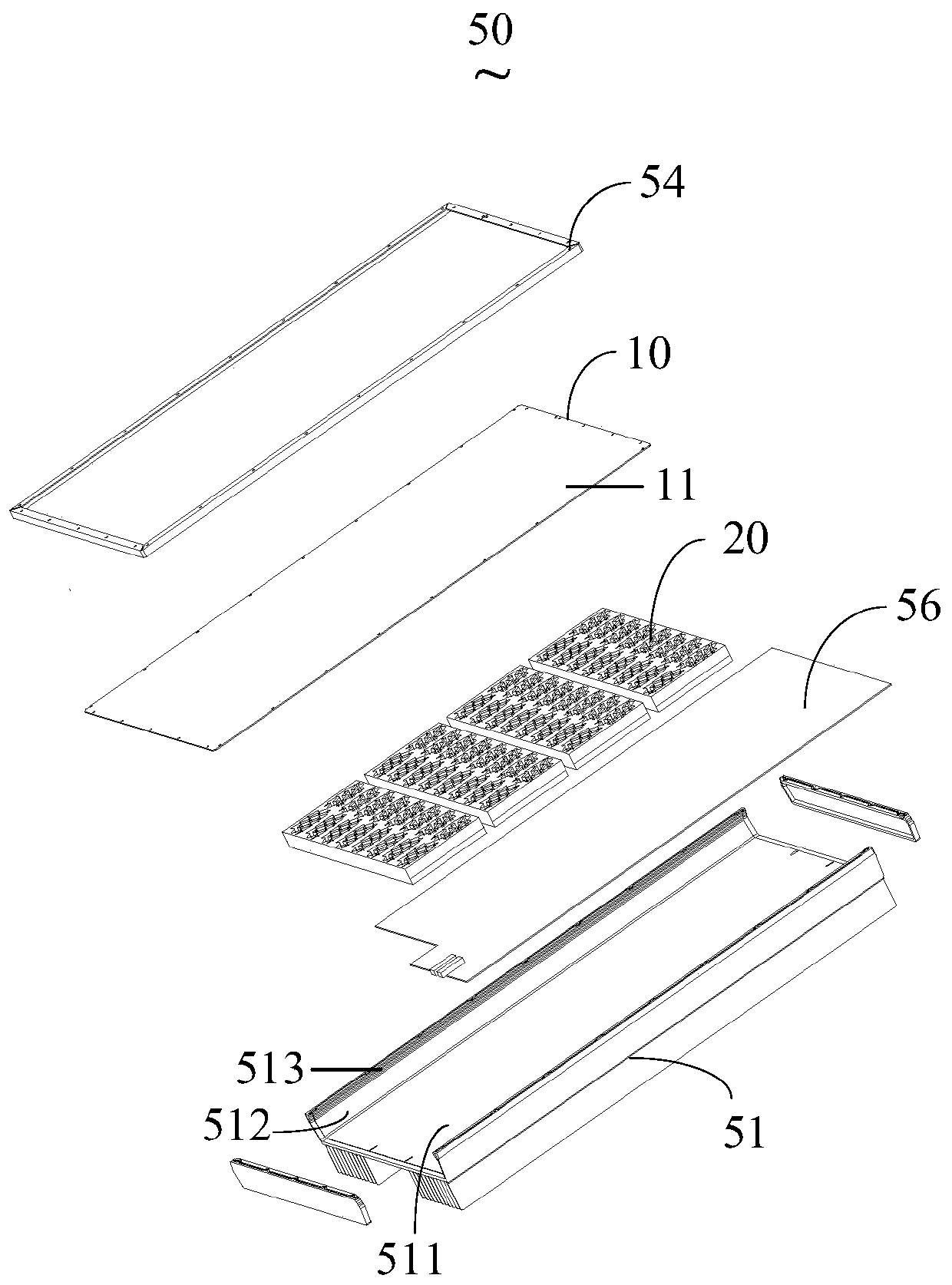

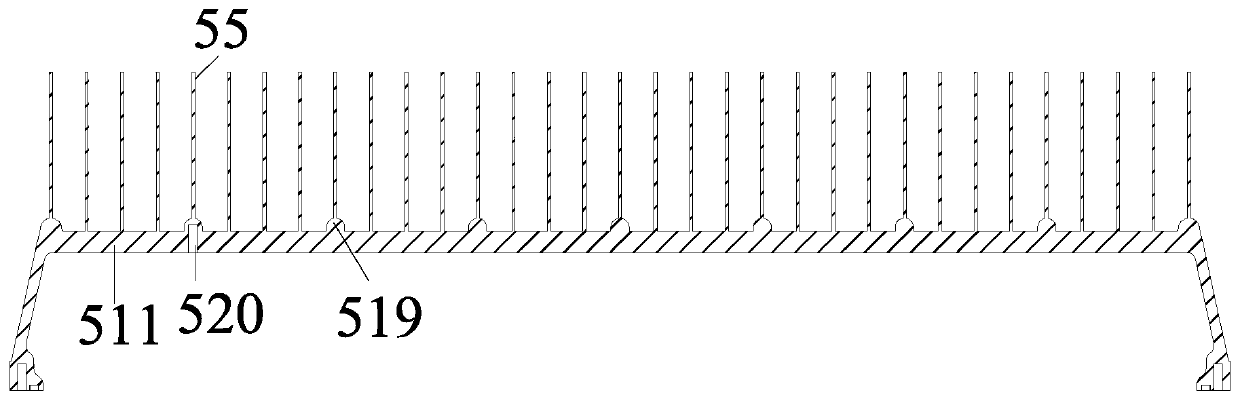

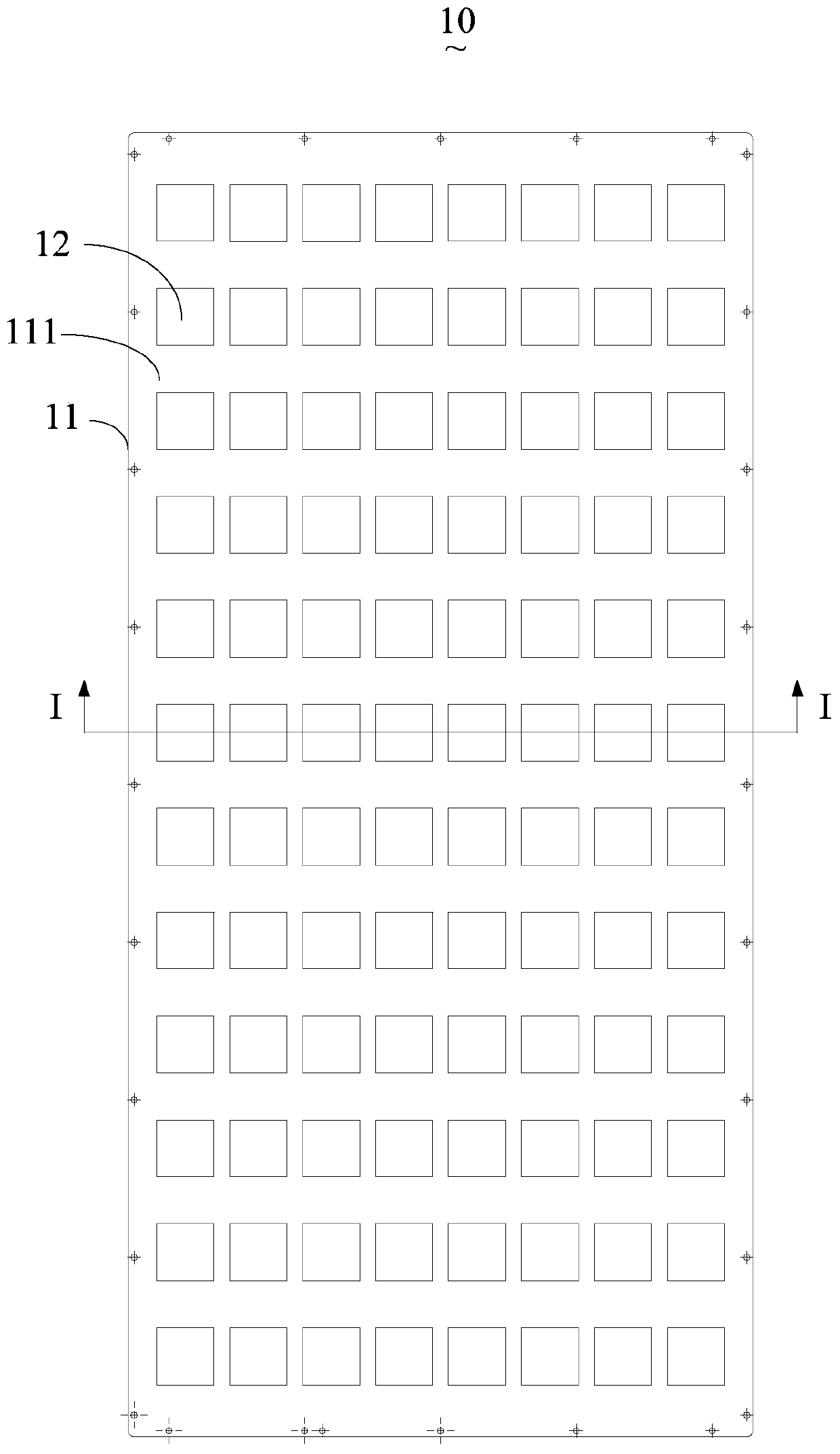

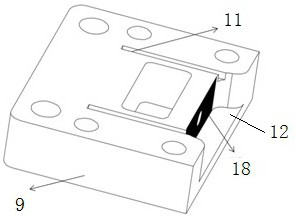

Active antenna unit and antenna unit for base stations

PendingCN110380191AGuaranteed tightnessPrevent signal leakageAntenna supports/mountingsRadiating elements structural formsMechanical engineeringActive antenna

The application discloses an active antenna unit and an antenna unit for base stations. The active antenna unit for base stations includes a shell. The shell includes a bottom wall and side walls connected with the bottom wall to define a cavity with an opening at one end. Convex ribs are integrally formed on one side, away from the cavity, of the bottom wall. The bottom wall is provided with assembly holes. The depth of the assembly holes is greater than the thickness of the bottom wall, and the assembly holes extend into the convex ribs. The assembly holes of the application do not need to run through the bottom wall, so that the tightness of the shell is ensured, and signal leakage and interference in the shell are avoided.

Owner:ANHUI TATFOOK TECH CO LTD

Airtight waveguide-microstrip transition structure

ActiveCN114069183AGuaranteed air tightnessEffective protectionCoupling devicesElectrical connectionHemt circuits

The invention discloses an airtight waveguide-microstrip transition structure. The transition structure comprises a waveguide cavity and an airtight cavity used for installing a microstrip circuit, wherein the waveguide cavity is electrically connected with the microstrip circuit through a glass bead. The transition structure is advantaged in that transition between the waveguide and the internal circuit is achieved through the glass beads, the glass beads are sintered into the waveguide cavity, air tightness from the waveguide cavity to the internal microwave circuit can be guaranteed, and therefore a bare chip in the microwave circuit is effectively protected.

Owner:航天科工微系统技术有限公司

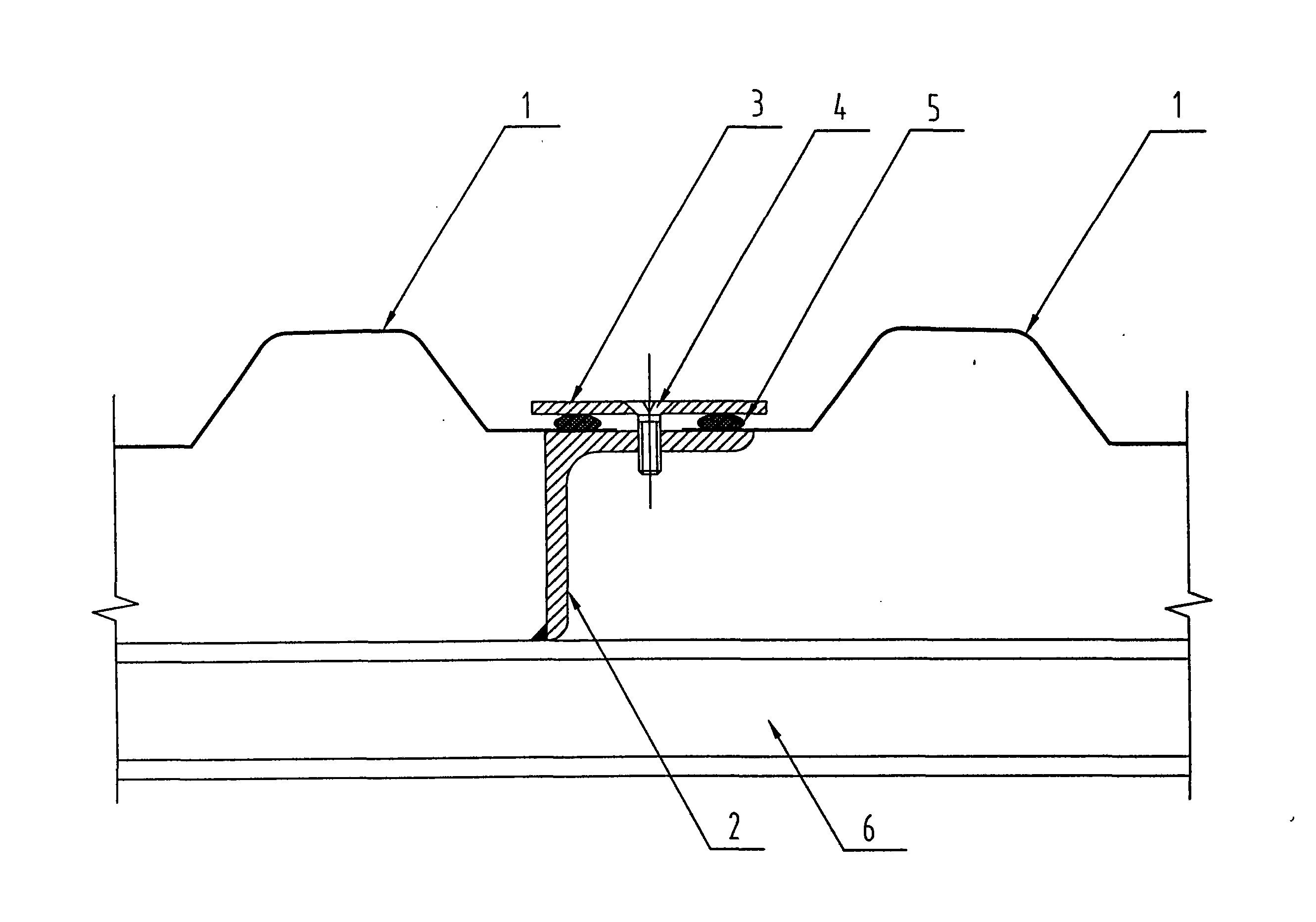

Corrugated plate for architectural shielding

ActiveCN101586386BReduce manufacturing costReduce installation costsCovering/liningsElectrical resistance and conductanceWave shape

A corrugated plate for architectural shielding and connection structure thereof, including waveshaped templates (1) shielding connected with each other, among the waveshaped templates (1) are connected by crimping structure or clamping structure, and the adjacent waveshaped templates (1) are electrically connected. In addition to conventional crimping, spiro union, riveting, welding and other programs, the invention provided seams shielding connection structure specifically utilizes resistance welding process, the seams are shielding connected by forcipated spot welding, the connection surfacehas small contact resistance, the surface has no damage and conquers defects of screw and riveting, both reducing shielding efficiency of seams caused by oxidation corrosion and conquering defects ofcontinuous welding, that are defects of large internal stress, surface irregularity and pollution in construction process. The process is provided with reliable connection, high efficiency, low costand good construction adaptability.

Owner:常州新区金利达电子有限公司

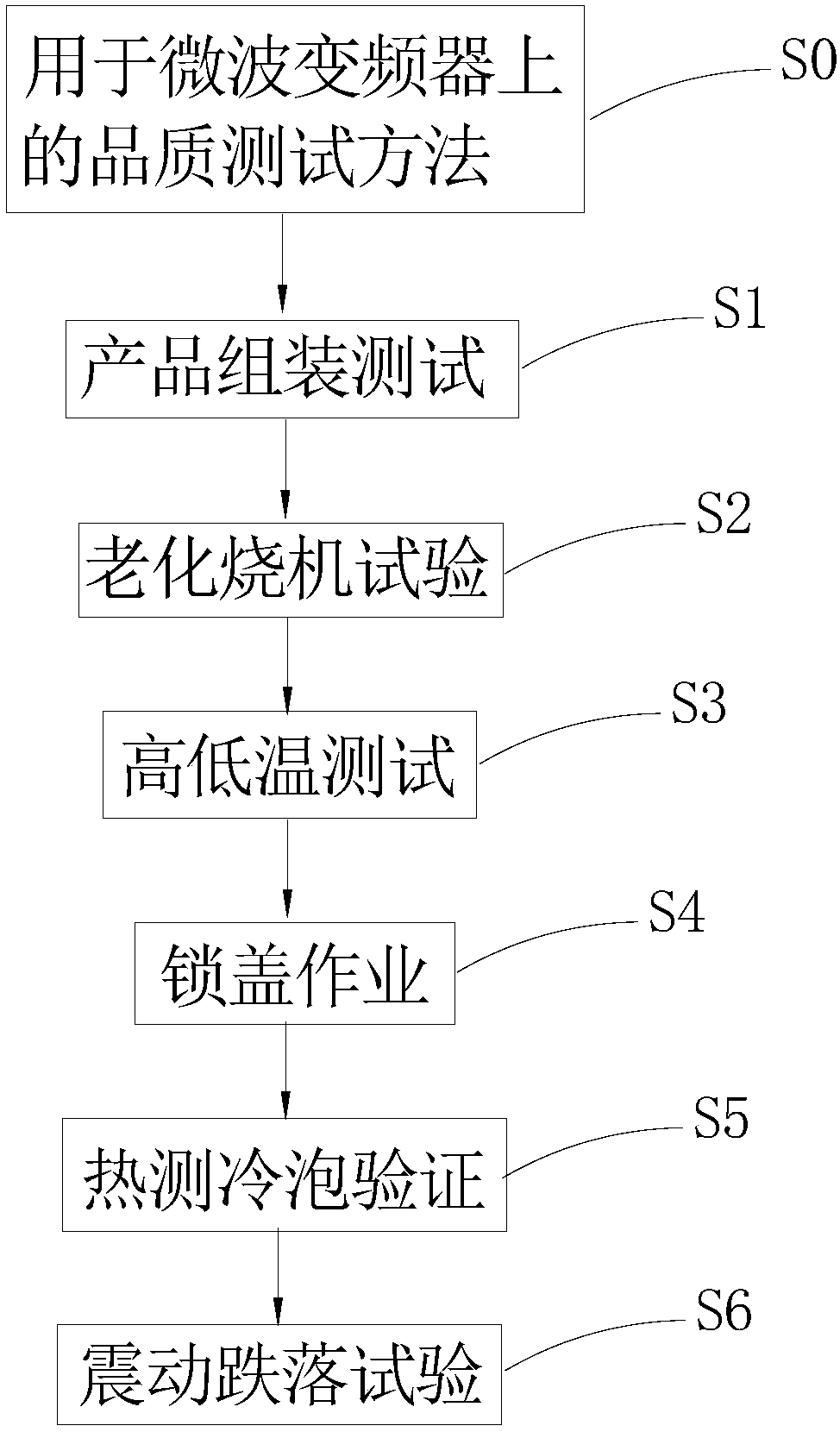

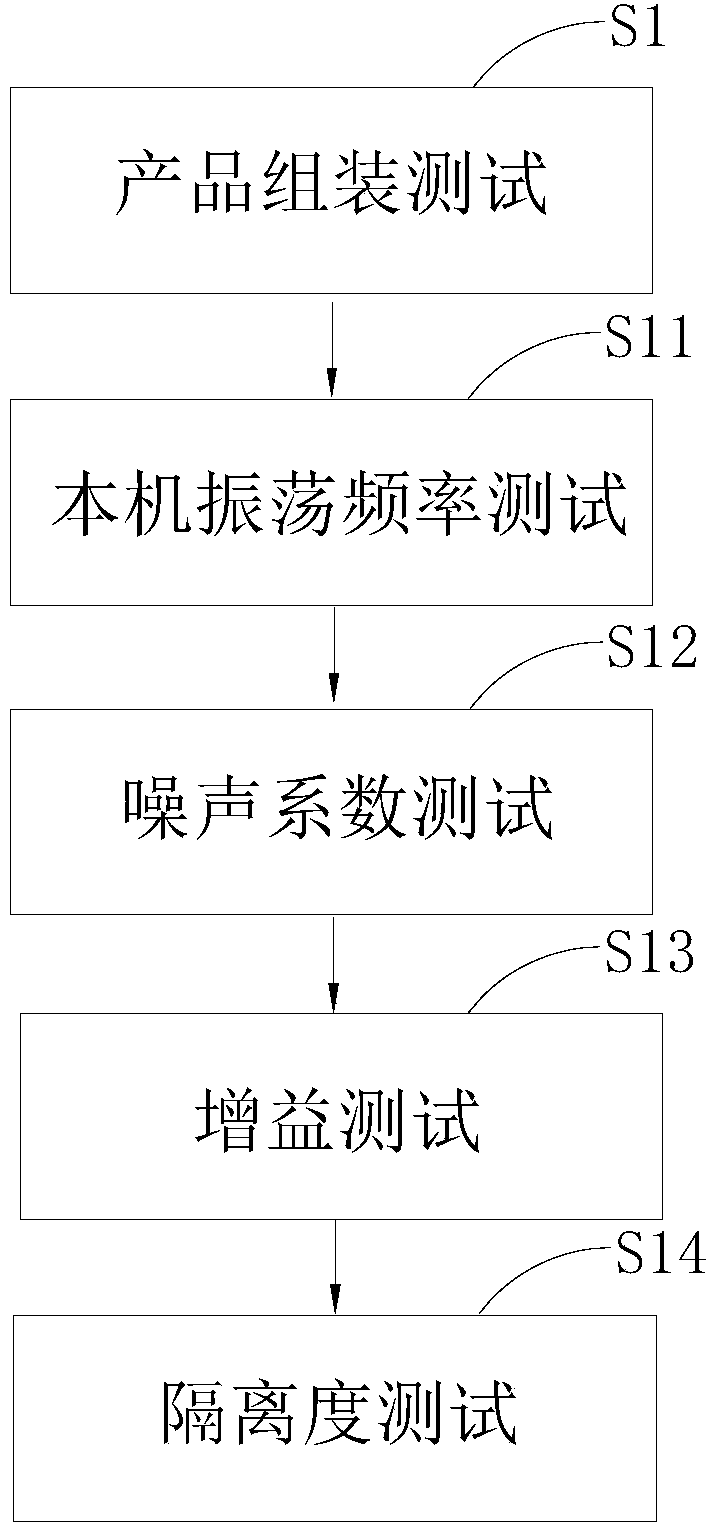

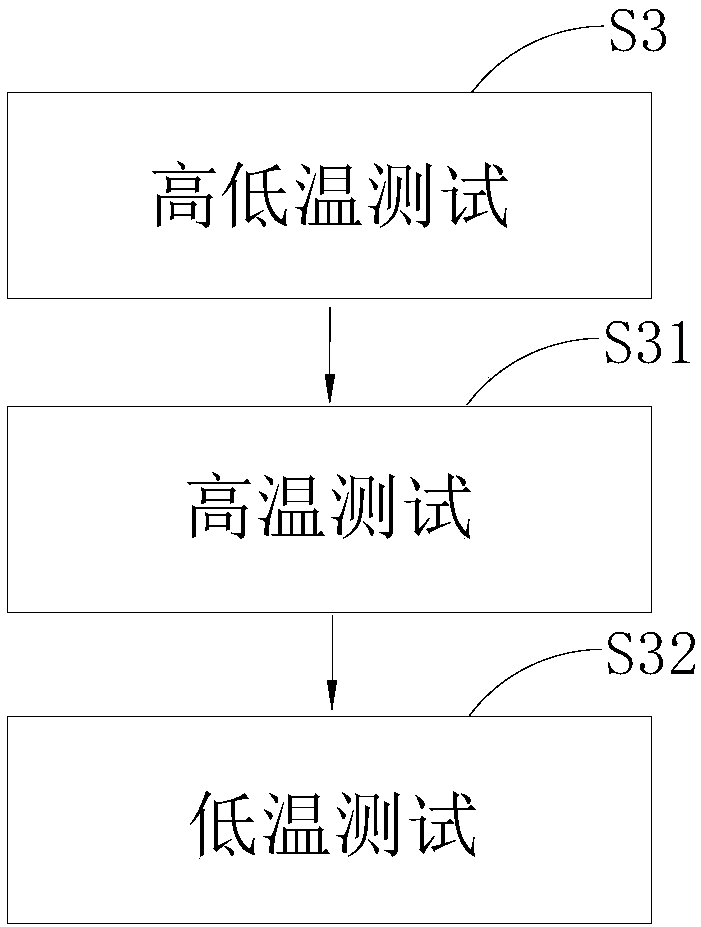

Quality Test Method Used in Microwave Frequency Converter

ActiveCN104865464BSolution to short lifeUse extremeElectrical testingVibration testingFrequency changerForeign matter

The invention relates to the technical field of quality testing for a frequency converter, and provides a quality testing method used on a microwave frequency converter. The quality testing method comprises the following steps: product assembling testing, burn-in testing, high-temperature and low-temperature testing, shielding cover locking operation, thermal-testing and cold-soaking verifying and vibration falling-off testing. Product assembling testing is used. A product use state is tested in a vibration environment, noise environment, gain environment or / and signal isolation environment. The product of the invention is suitable for various environments. Burn-in testing is used and longer service life of the product is realized. High-temperature and low-temperature testing is used, and the product can be used at an extreme temperature. Shielding cover locking operation is used for preventing signal leakage, realizing a waterproof and leakage-proof performance, and preventing entry of foreign matter into the product. Thermal-testing and cold-soaking verifying is used, and an excellent waterproof effect of the product is realized. Vibration falling-off testing is used, and high stability of a product package is obtained. In a word, the microwave frequency converter which is manufactured according to the quality testing method used on the microwave frequency converter has advantages of excellent waterproof effect, high in-use stability of the product and long service life. Furthermore the quality testing method satisfies a requirement for high-standard and high-quality products.

Owner:CCT SPACE INFO IND & TECH LTD

Cavity filter, filter cavity and installation method of connector

Owner:ANHUI TATFOOK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com