Patents

Literature

37results about How to "Reduce insertion loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

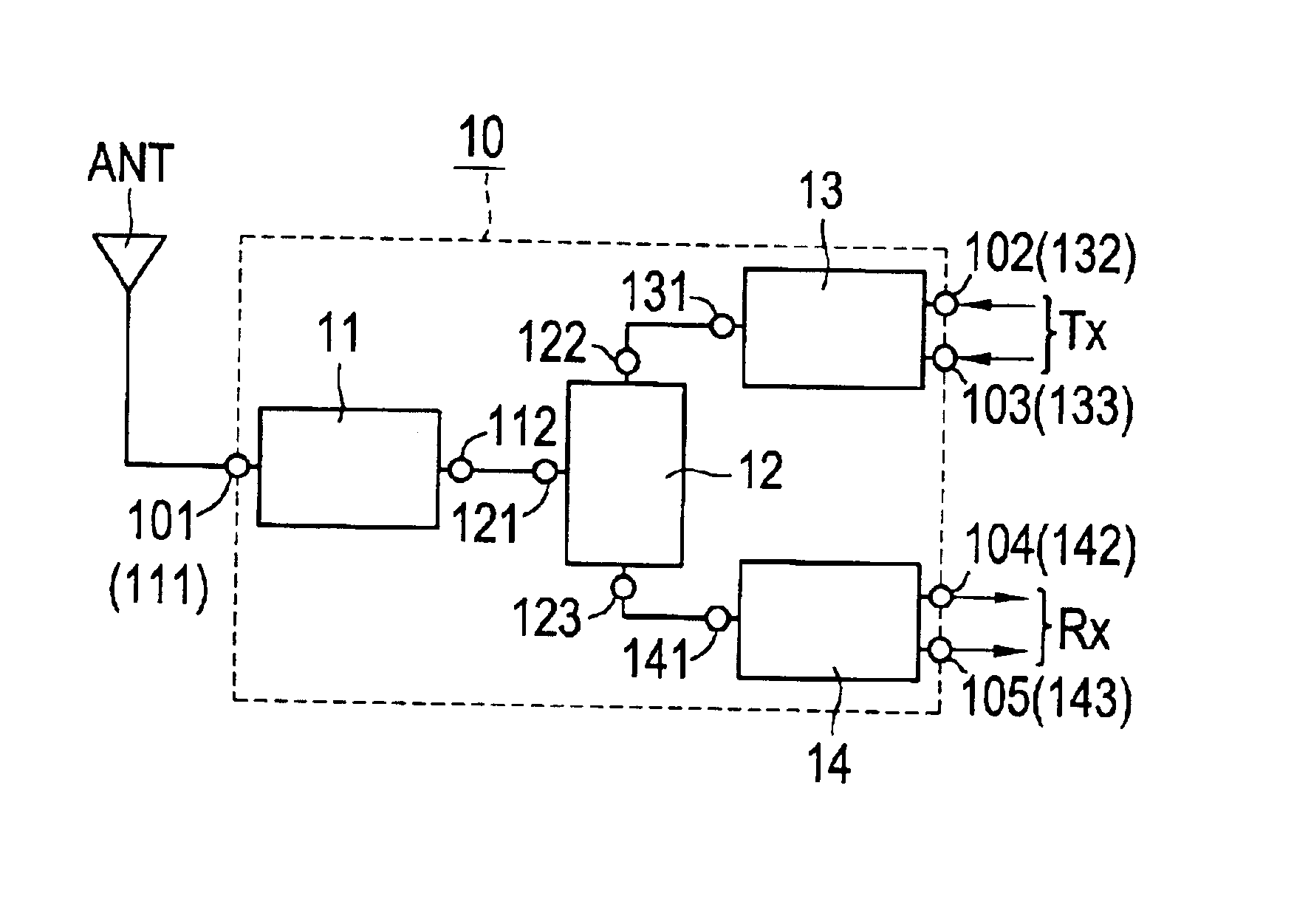

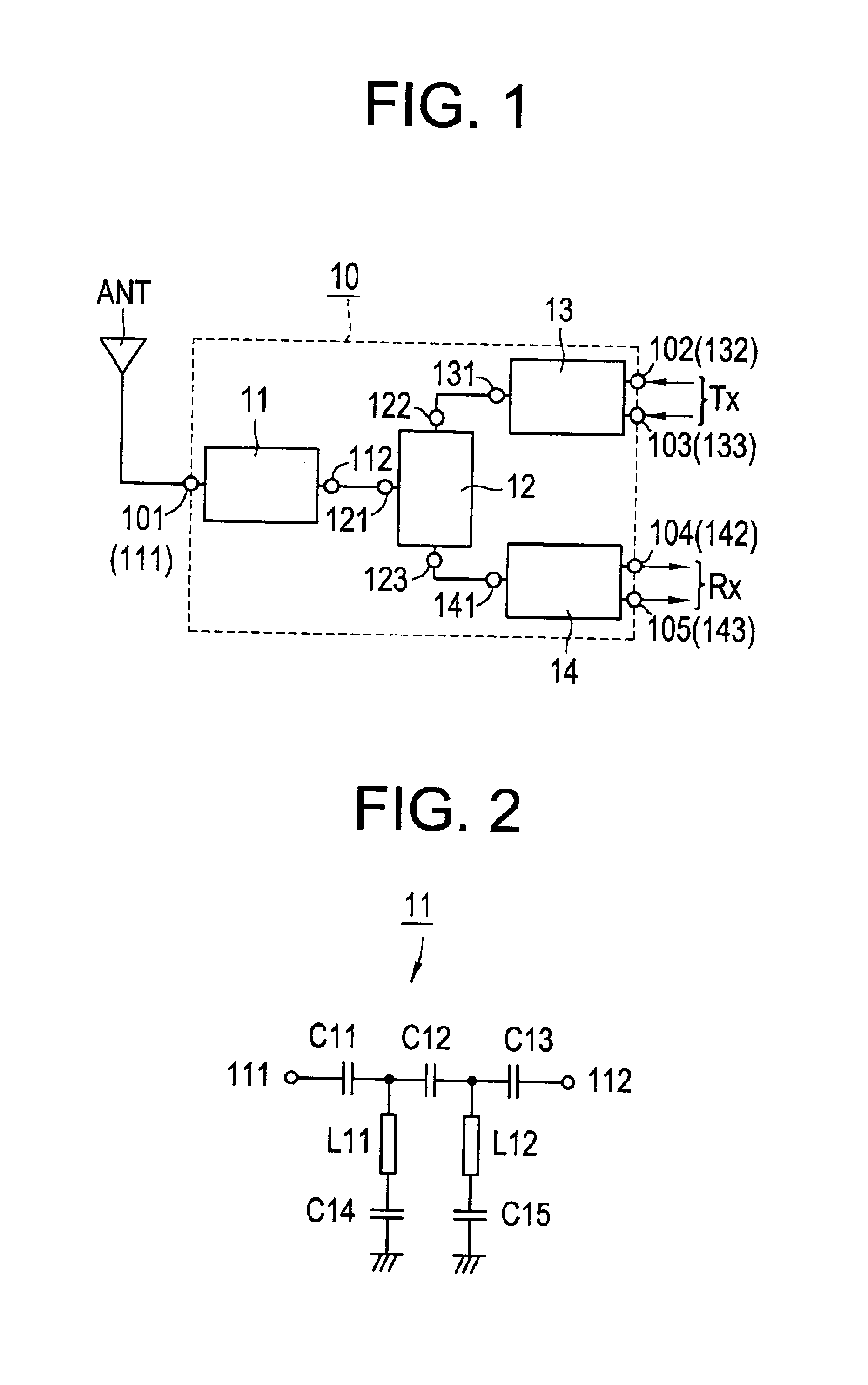

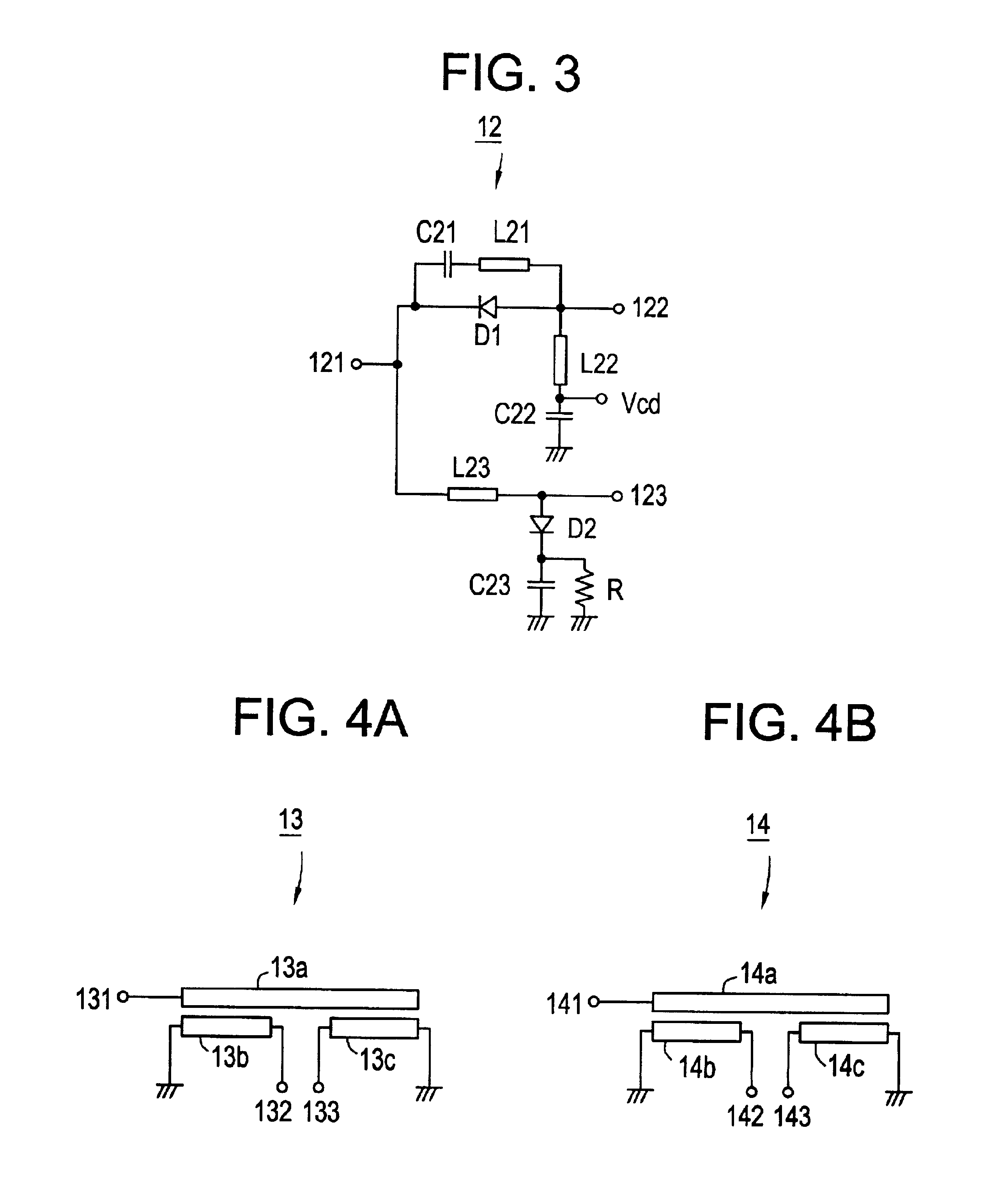

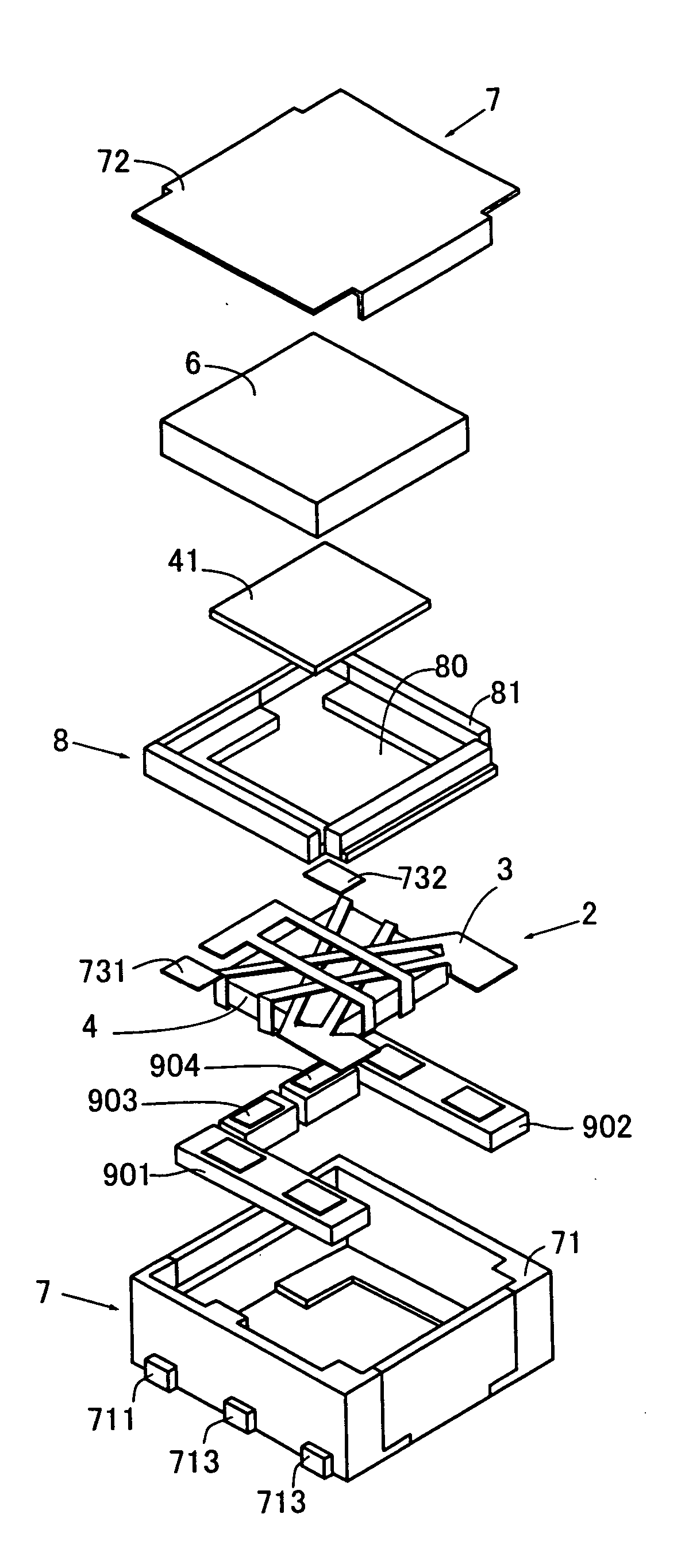

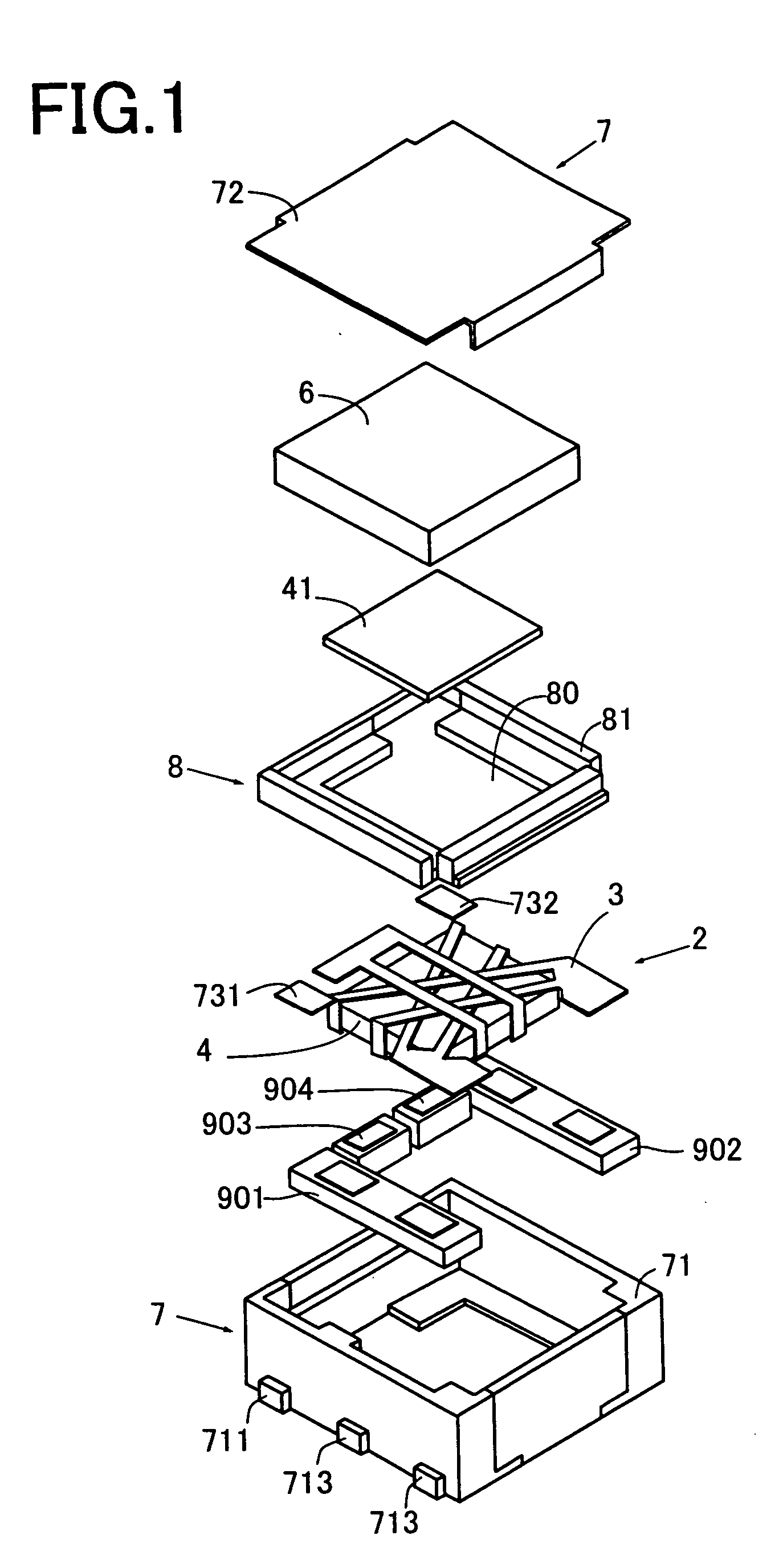

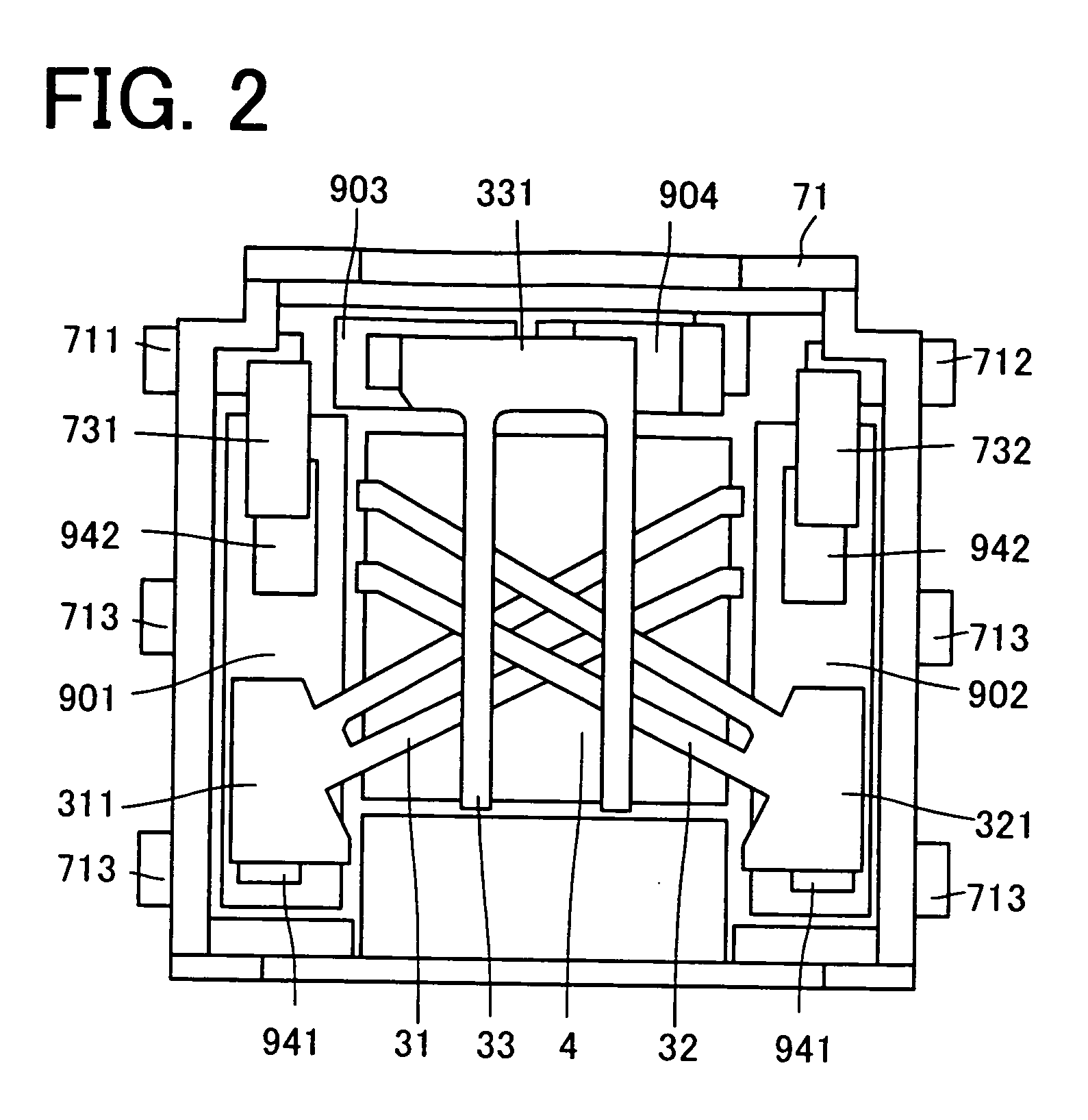

High-frequency module and radio device using the same

InactiveUS6937845B2Reduce insertion lossReduce insertionMultiple-port networksTransmissionHigh-pass filterEngineering

A high-frequency module includes first to fifth terminals, a high-pass filter, a high-frequency switch, a transmitter-side balun, and a receiver-side balun. The high-pass filter is connected to the high-frequency switch, and the high-frequency switch is also connected to the transmitter-side balun and to the receiver-side balun. The first terminal is connected to an antenna, the second and third terminals are connected to a transmitter circuit, and the fourth and fifth terminals are connected to a receiver circuit.

Owner:MURATA MFG CO LTD

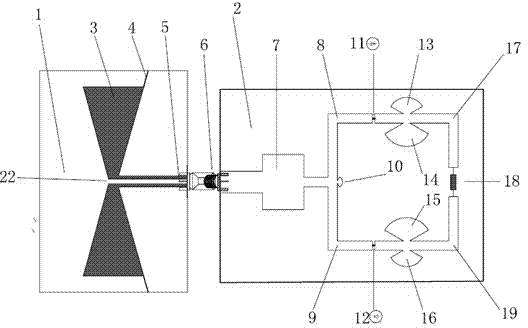

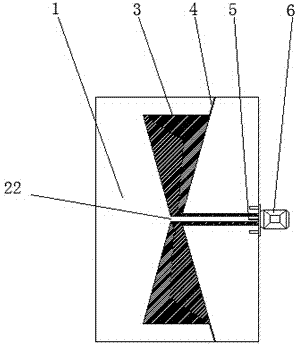

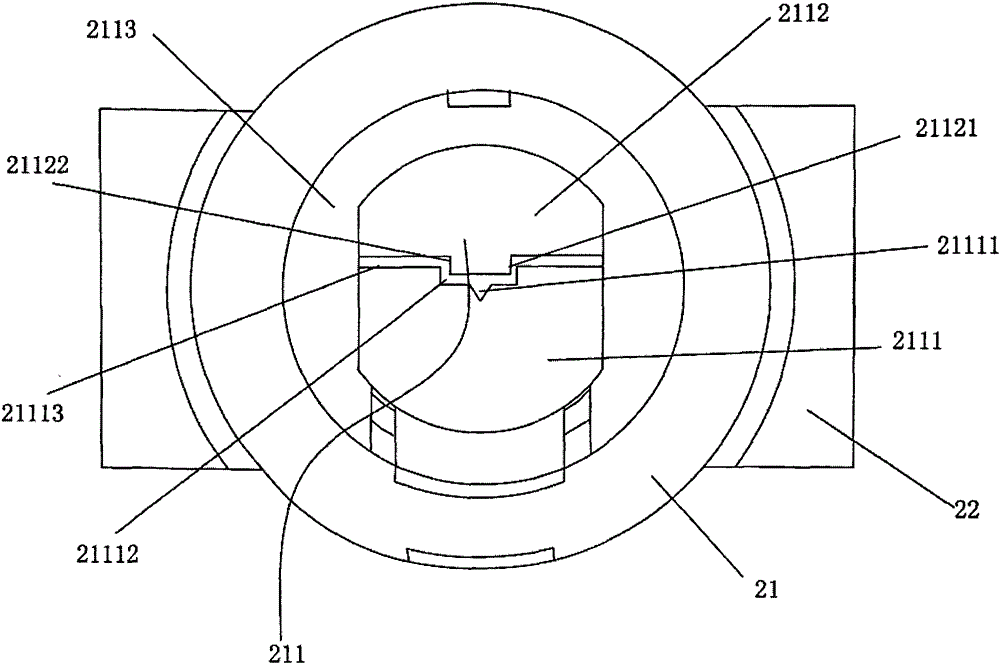

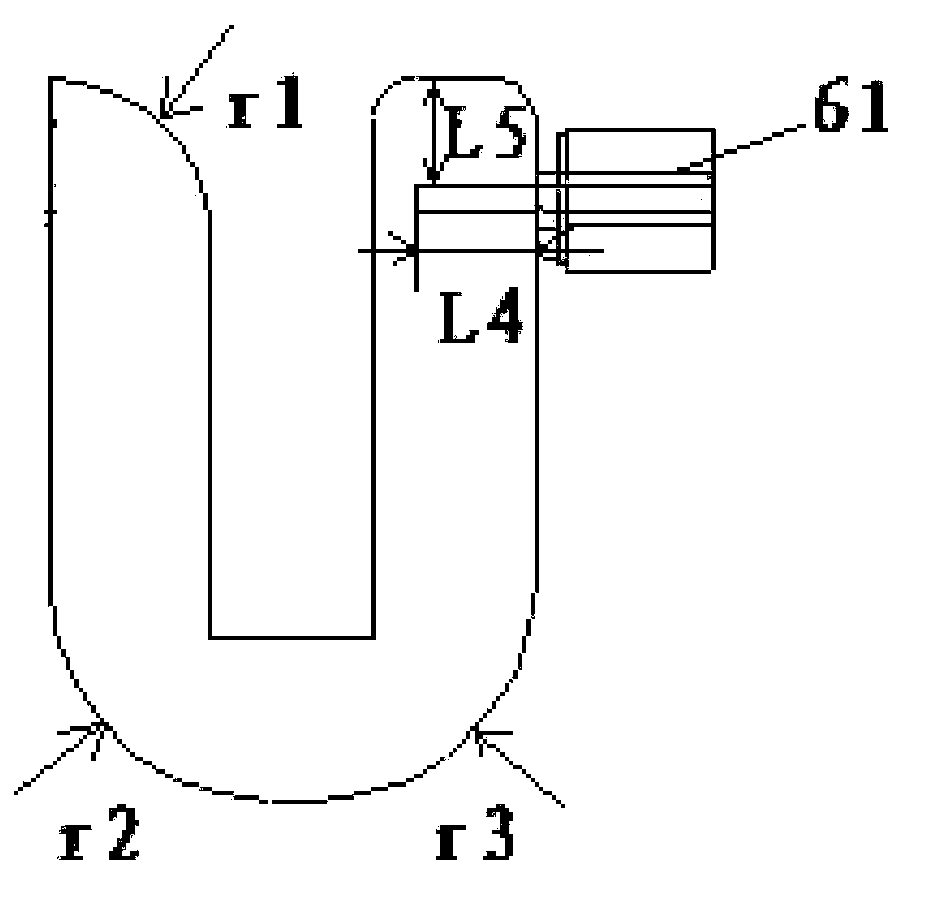

Micro-strip difference rectification antenna based on WIFI frequency band

InactiveCN104767027AReduce the amplitude of impedance changeReduce insertion lossRadiating elements structural formsSlot antennasPhysicsDielectric slab

The invention provides a high output voltage micro-strip difference rectification antenna based on a WIFI frequency band. The micro-strip difference rectification antenna based on the WIFI frequency band comprises a micro-strip receiving antenna and a micro-strip difference rectification circuit, wherein the micro-strip receiving antenna and the micro-strip difference rectification circuit are manufactured on a metal layer on the upper layer of a two-sided copper-coated dielectric substrate and connected through an SMA hermaphrodite connector. The micro-strip difference rectification antenna based on the WIFI frequency band adopts a disc-shaped slotting technology, so that the antenna has high direction gains, a wide work frequency band and low loss. A micro-strip line feed method is adopted, a multi-unit array can be formed easily, and the micro-strip difference rectification antenna based on the WIFI frequency band can be applied to large-power occasions. The positive and negative electrodes of a rectification diode are arranged on one side of a dielectric slab and are connected in the rectification circuit in series, and platemaking is easy; the rectification circuit is of a symmetrical structure, the size of the circuit is reduced, the complexity and machining difficulty of the system are reduced, and the integration degree is improved; the rectification circuit adopts a differential voltage output mode, the whole design is not provided with via holes, the parasitic parameter is small, the system performance is good, and output voltage is high.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

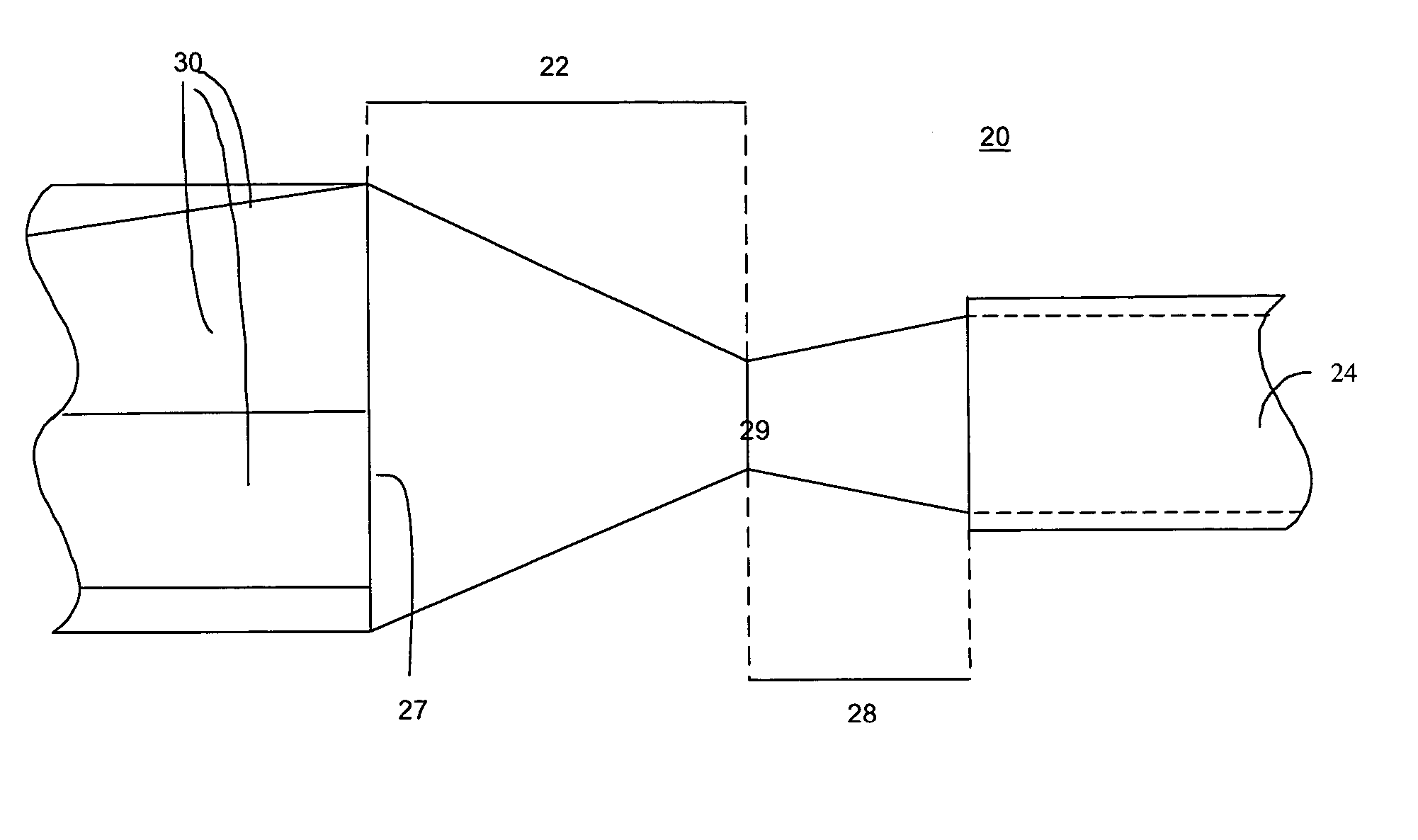

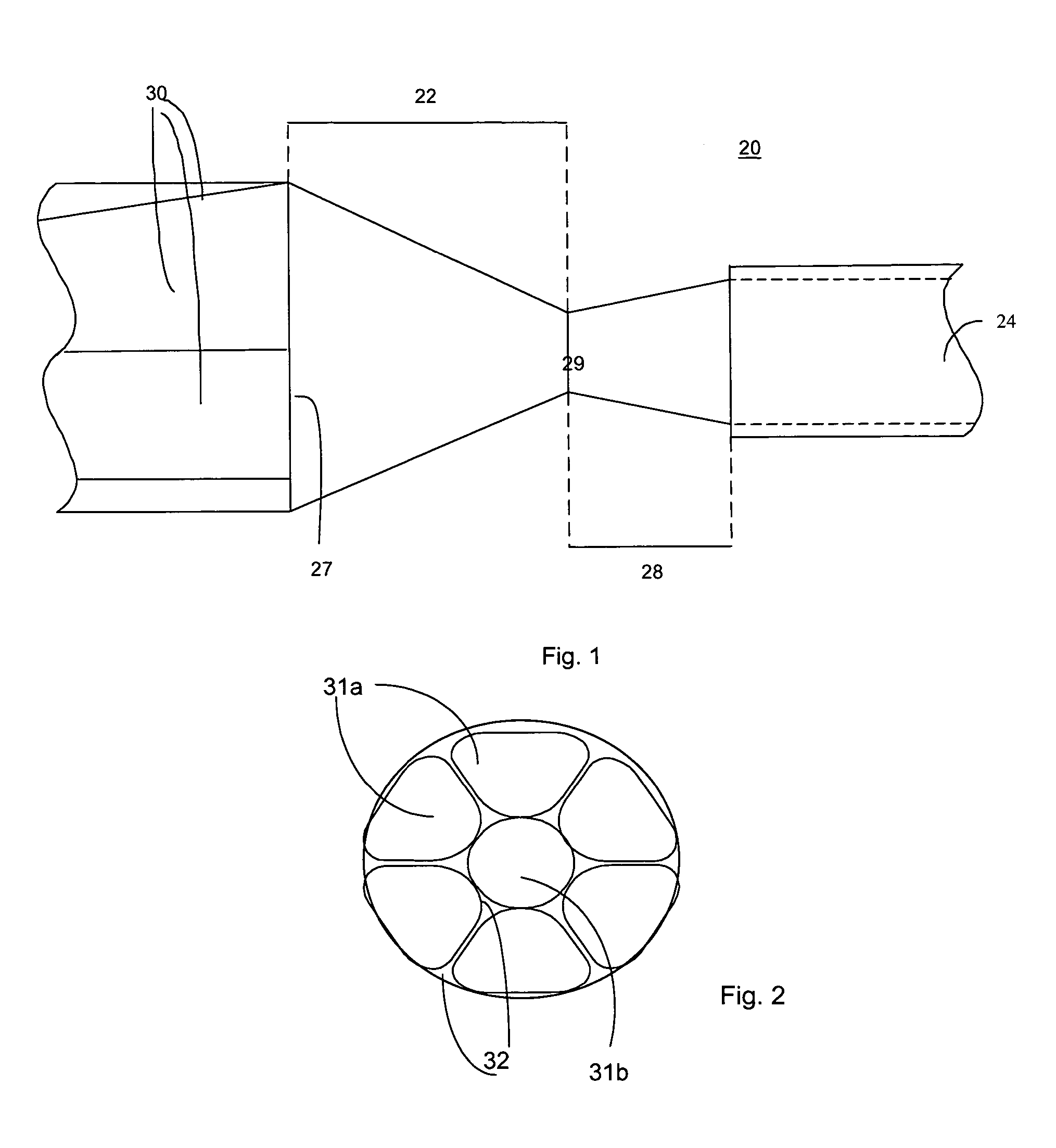

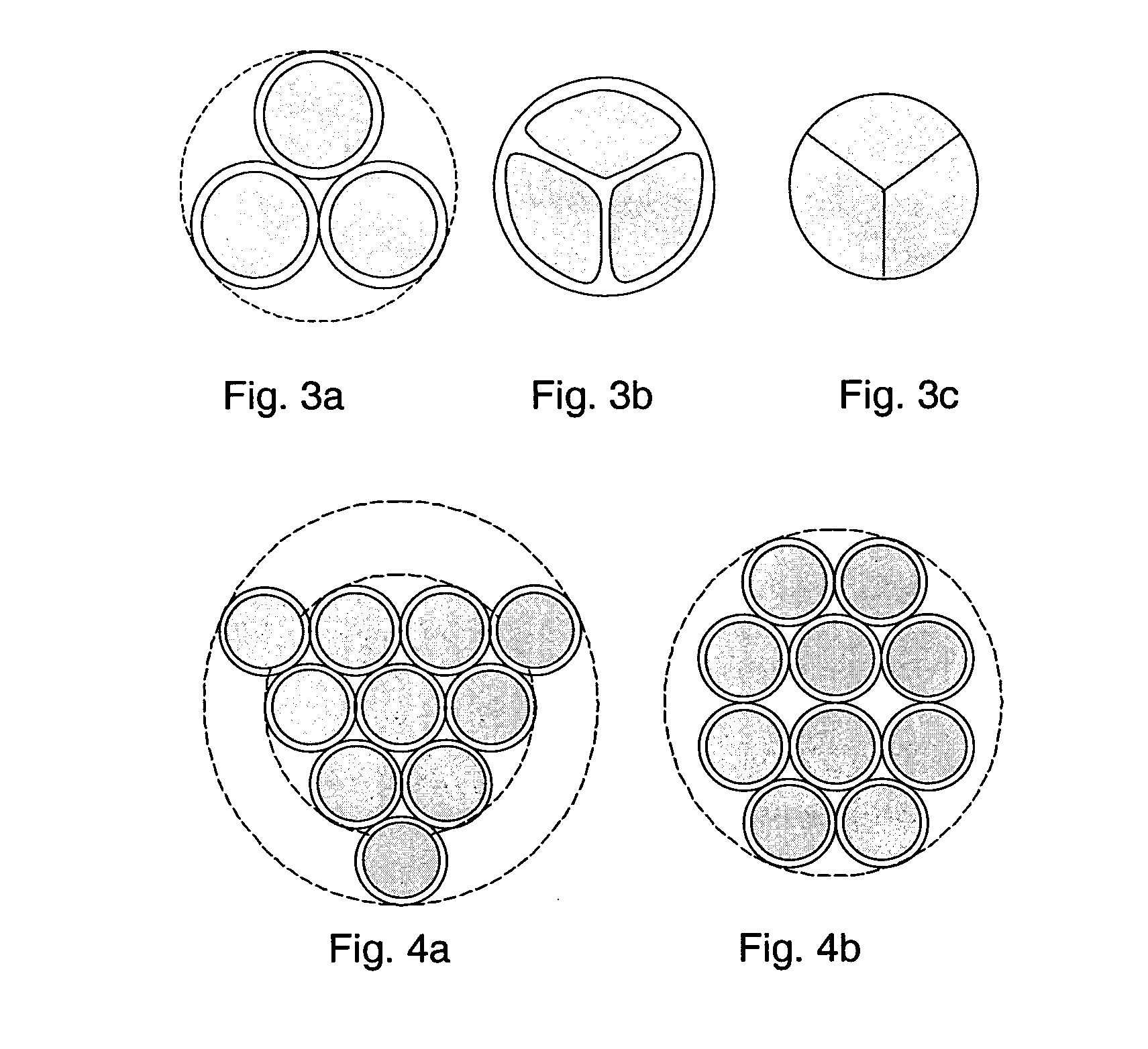

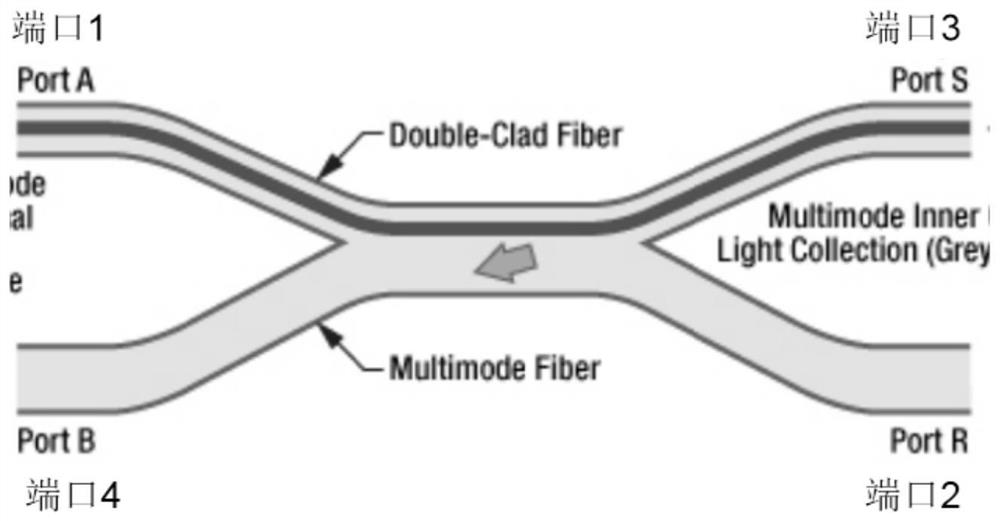

Mode multiplexing optical coupling device

InactiveUS20050031266A1Reduce insertion lossImprove couplingCoupling light guidesBundled fibre light guideOptical couplerMulti-mode optical fiber

An efficient tapered optical fiber bundle along with the method of manufacturing is presented. The tapered fiber bundle is fully fused to an induced shape with no interstitial space between fibers. To minimize fiber deformation and hence the tapered bundle's loss, the individual fibers are minimally deformed by positioning them in a fixture with predetermined geometry prior to fusion. The bundle could be optionally reshaped after fusion. The tapered bundle could then be used in its original form as a star coupler, or it could be cleaved and coupled to a multimode fiber, a multi-clad fiber, a cladding-pumped fiber, or an optical system to form an optical device. The resulting optical device has improved efficiency and lower loss compared with prior art devices.

Owner:COHERENT INC

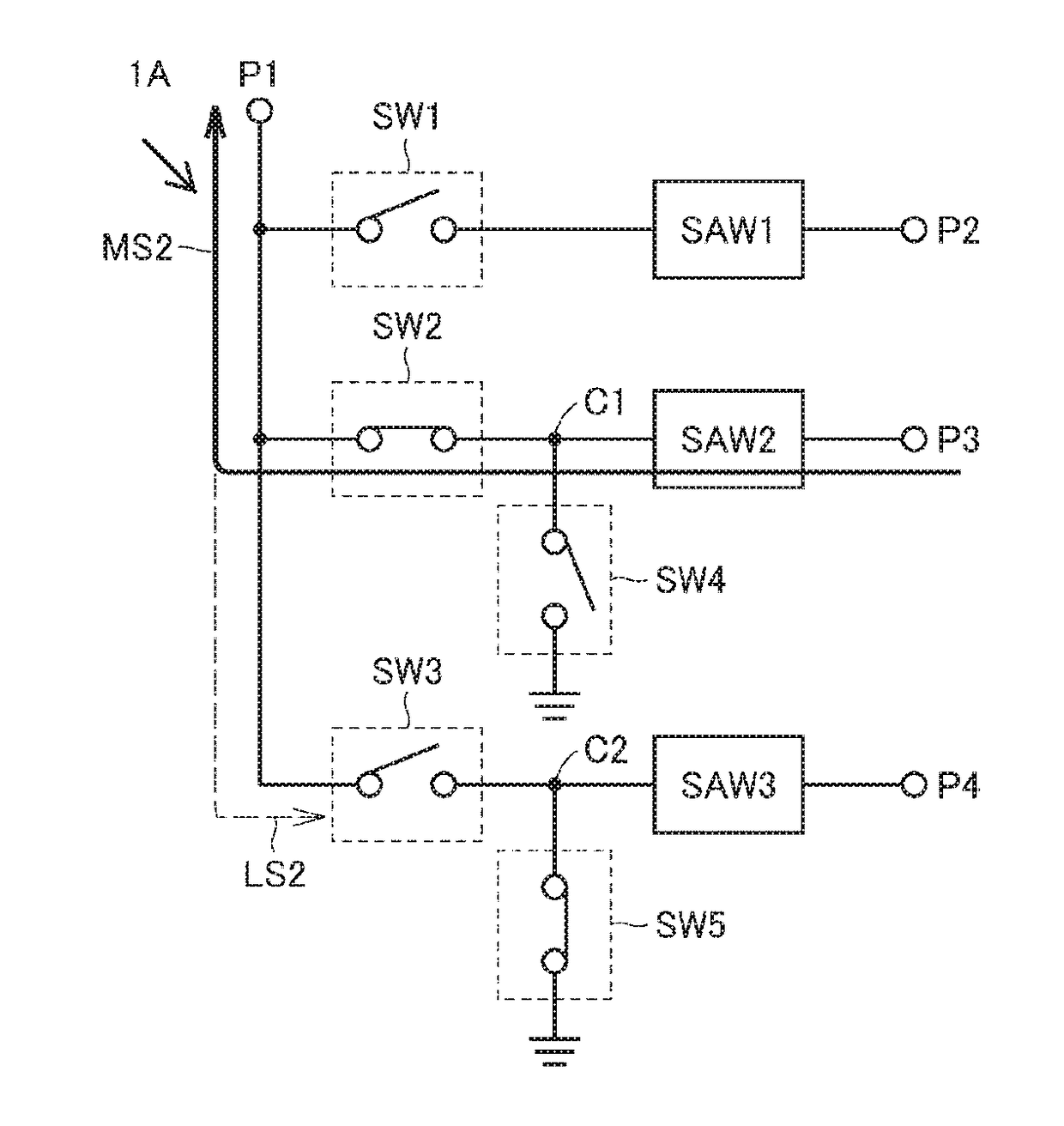

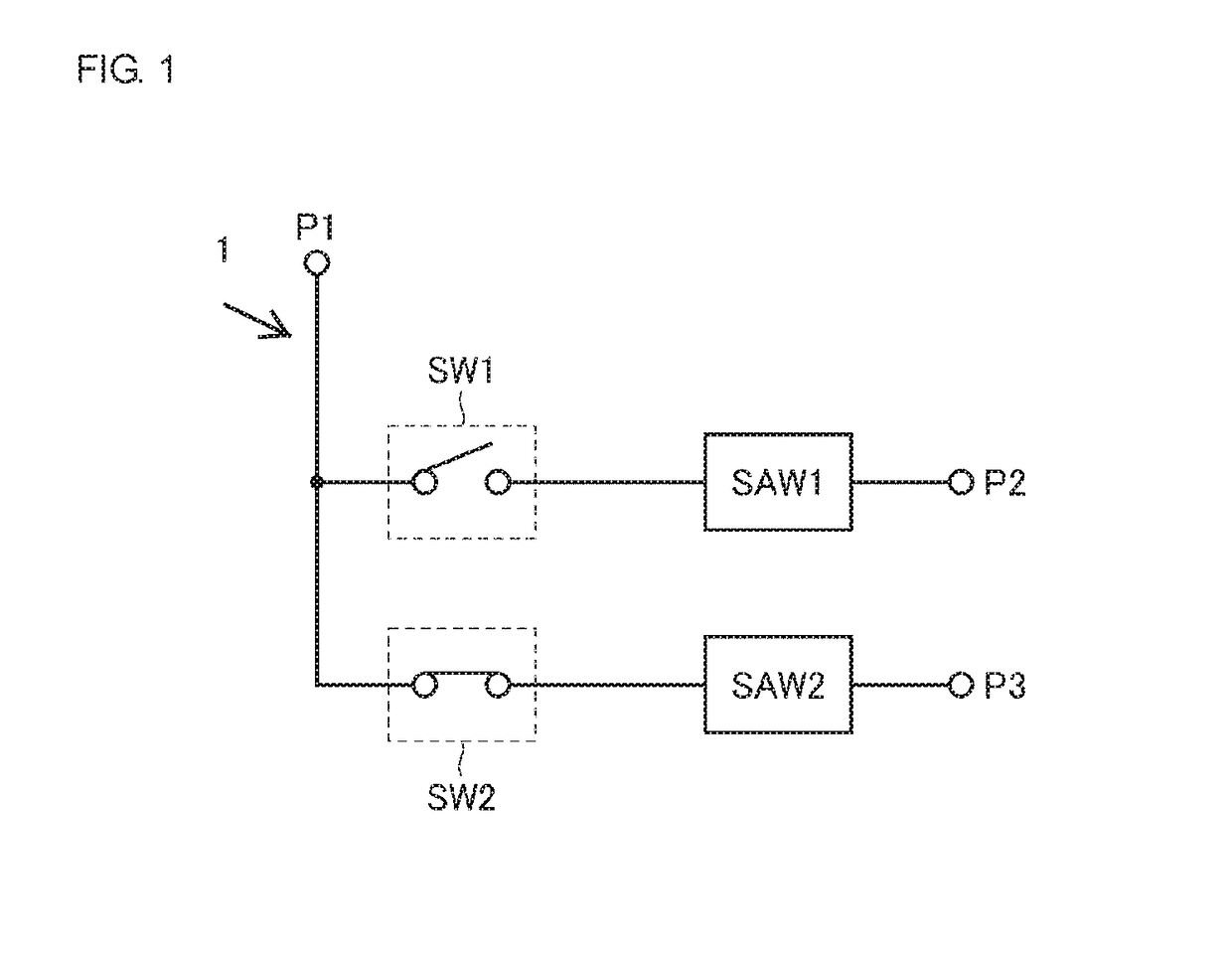

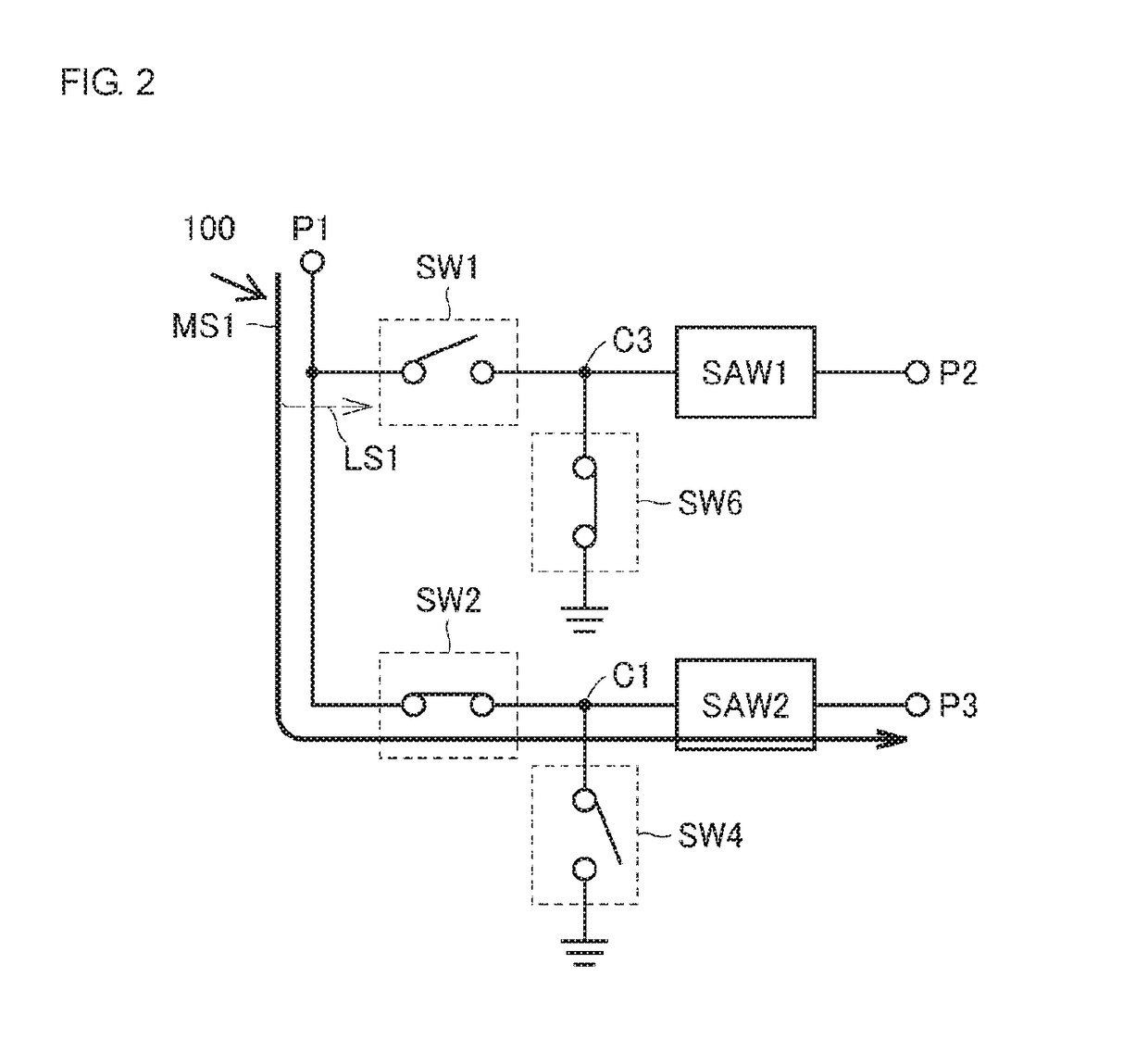

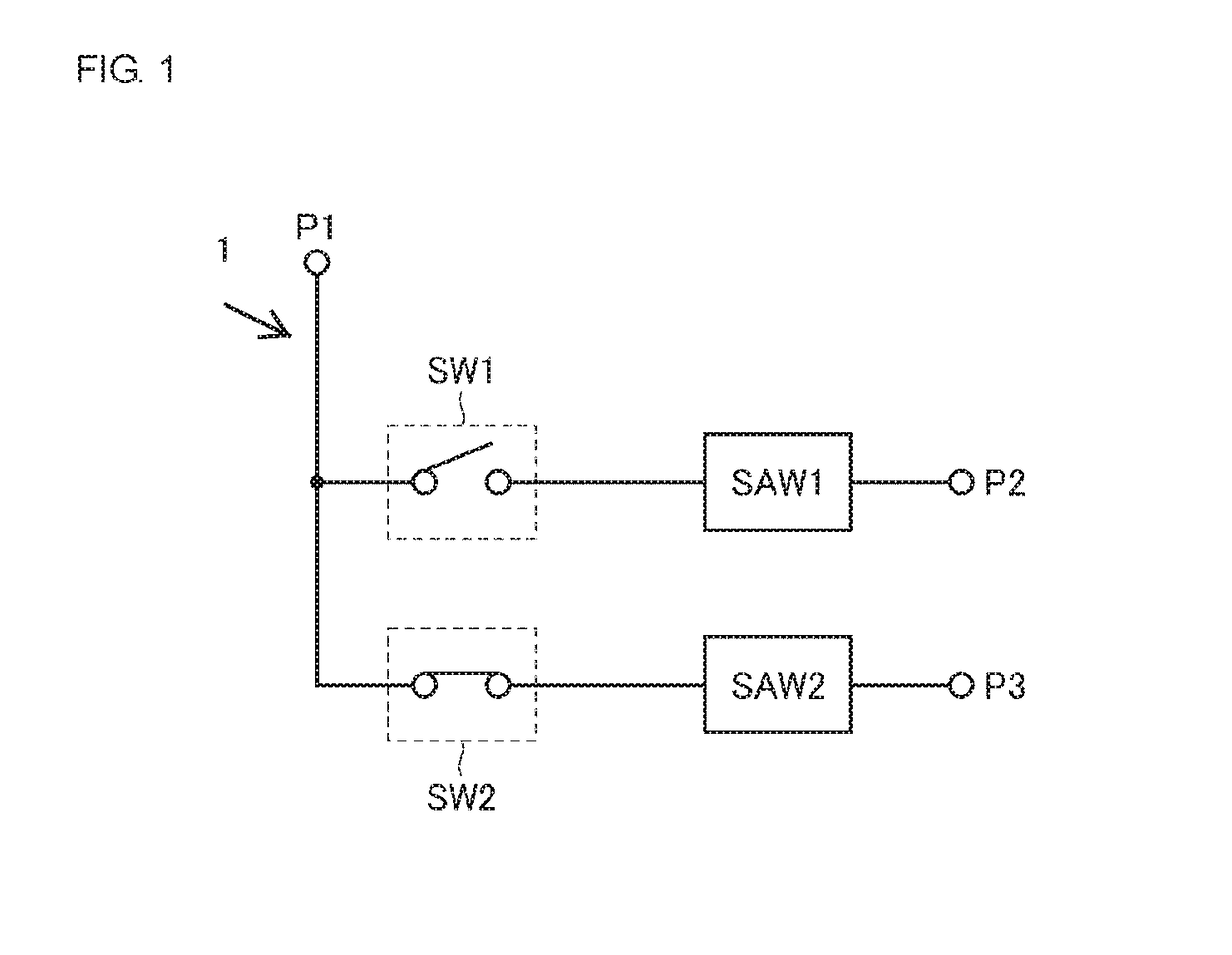

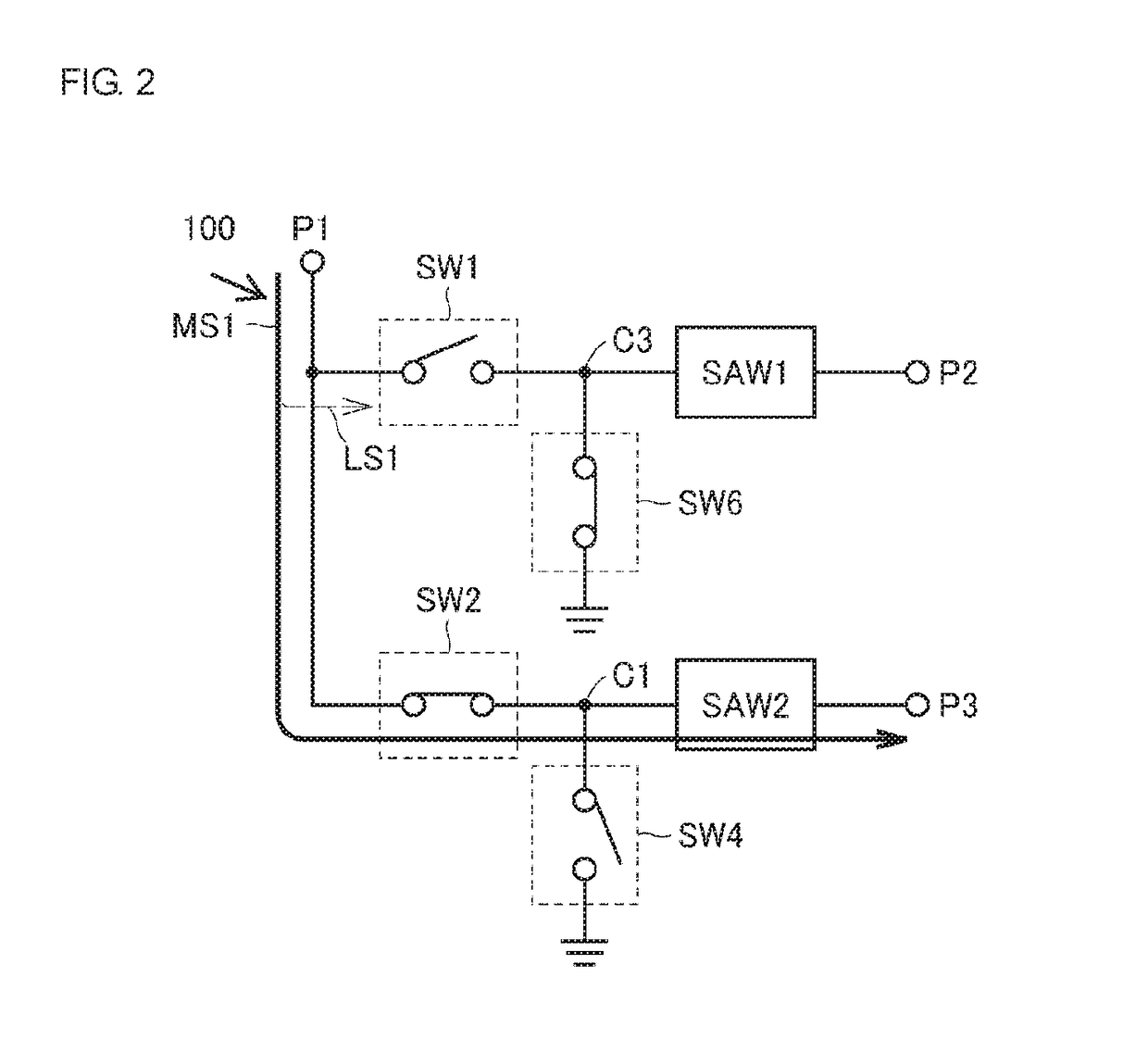

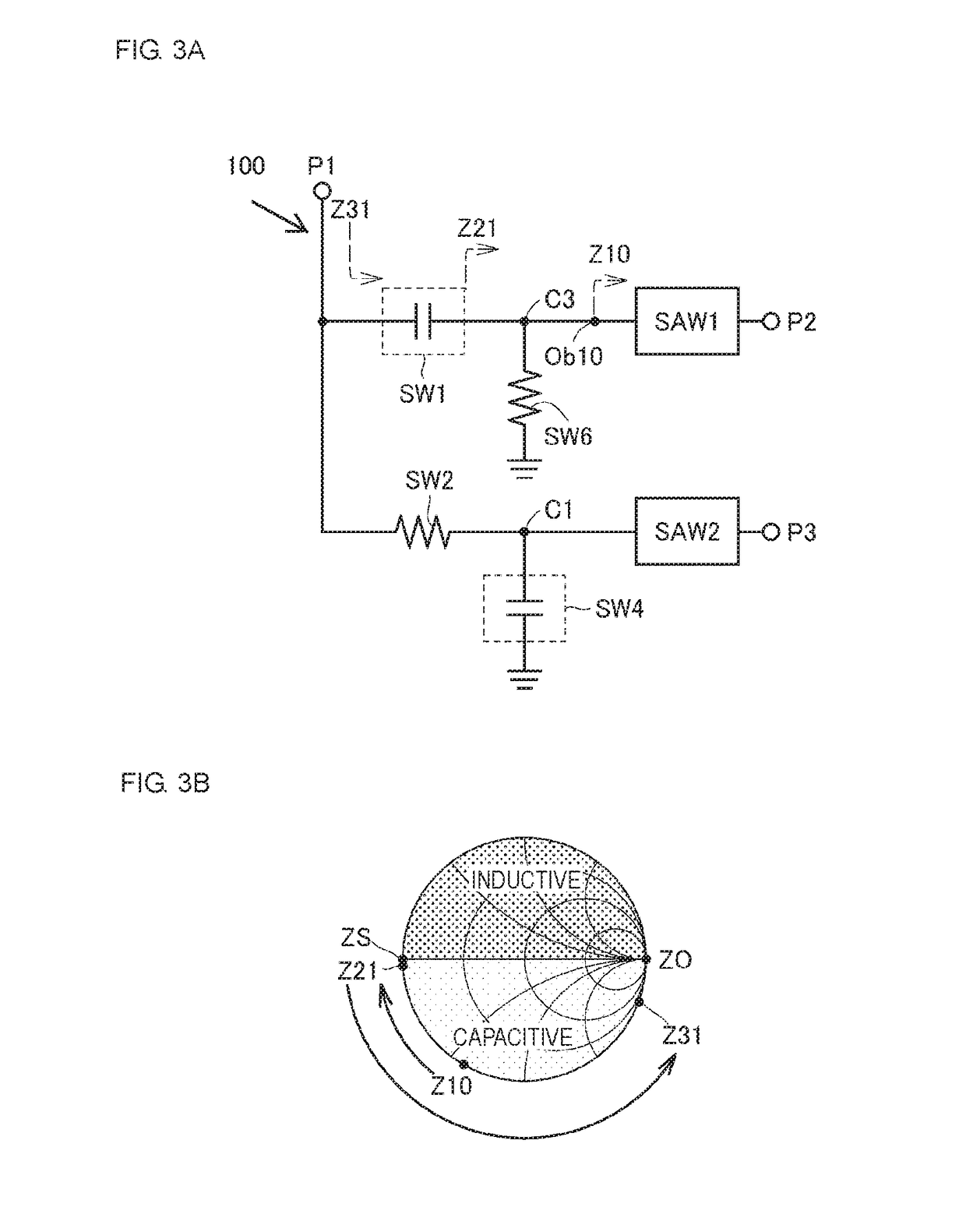

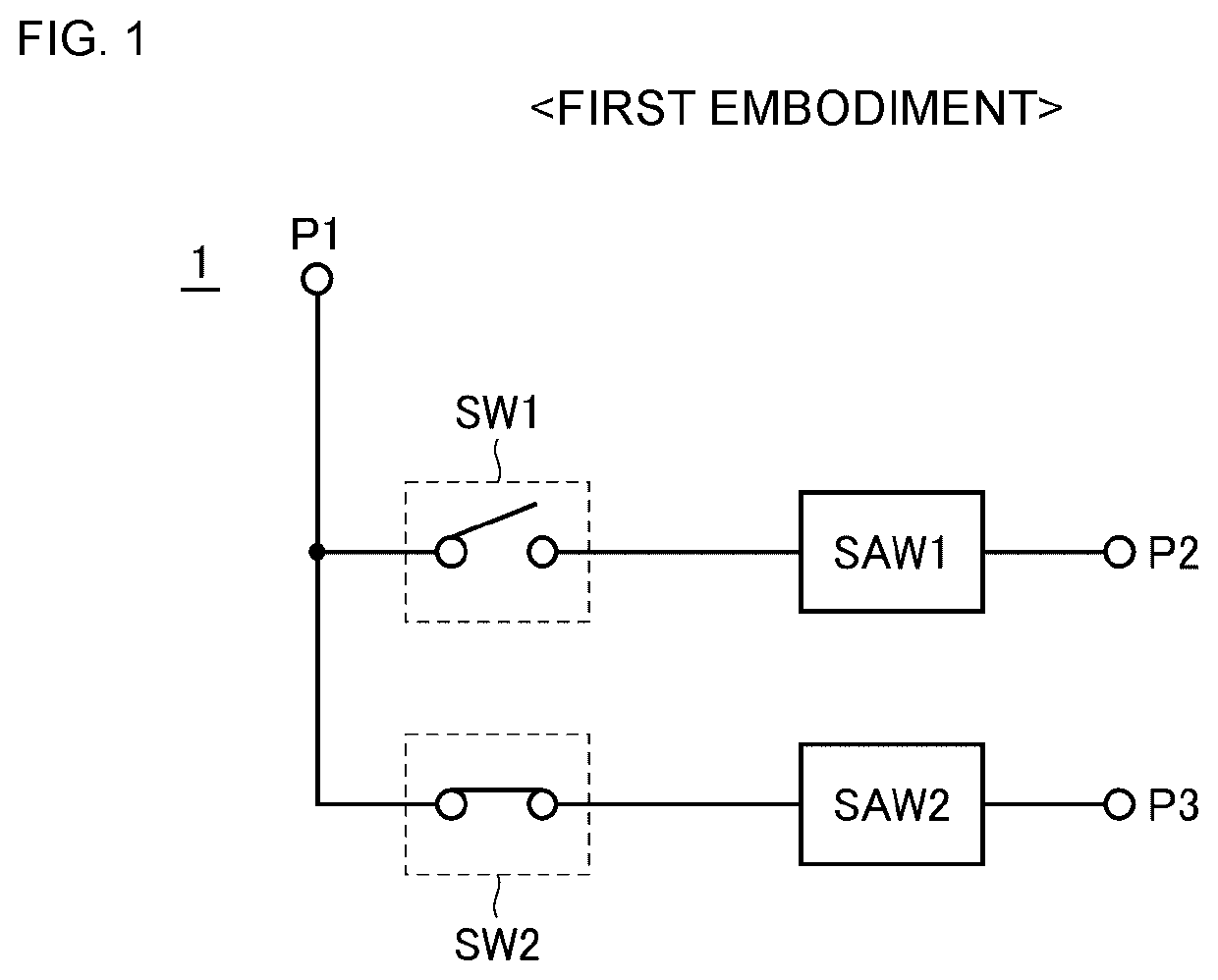

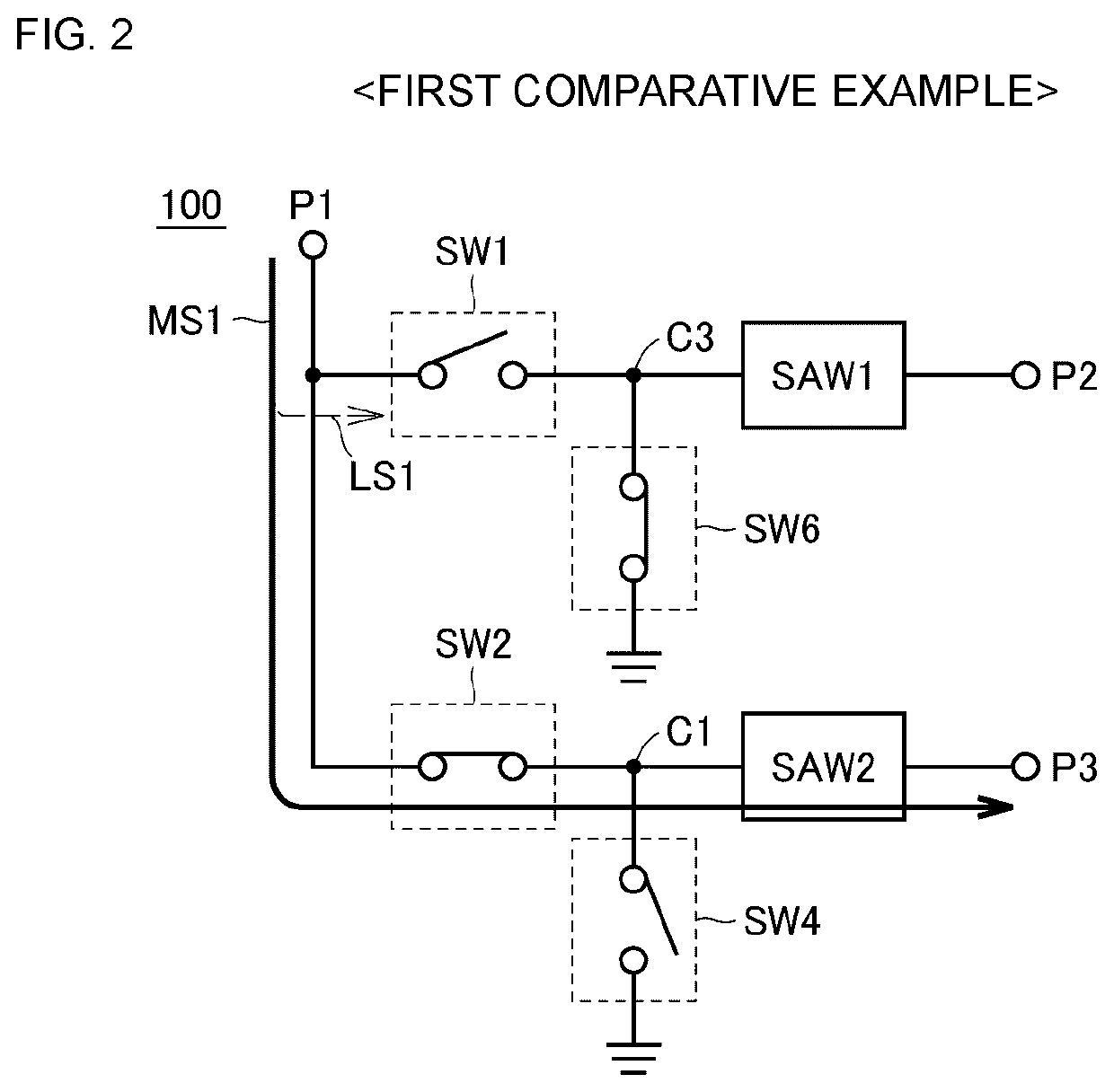

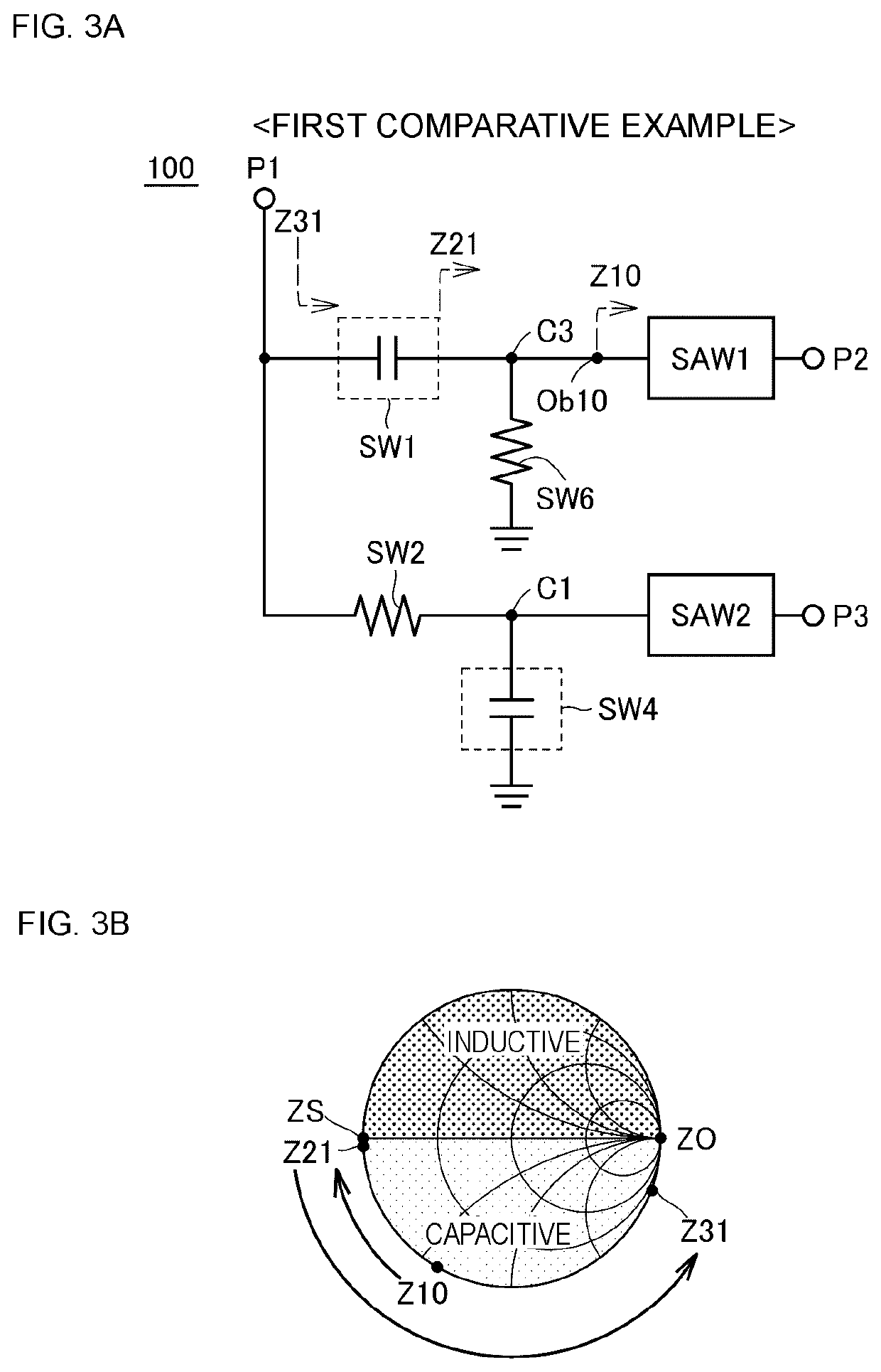

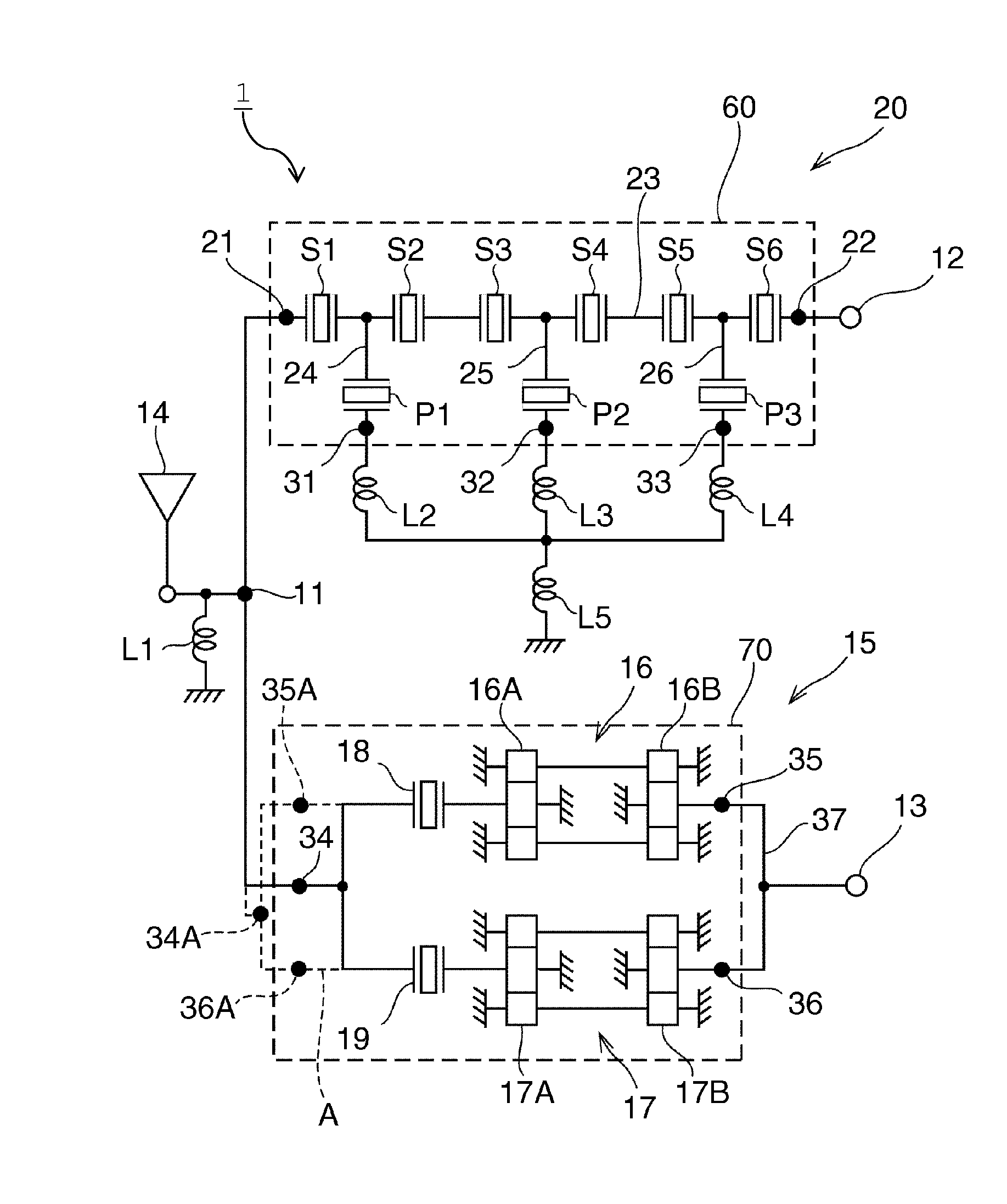

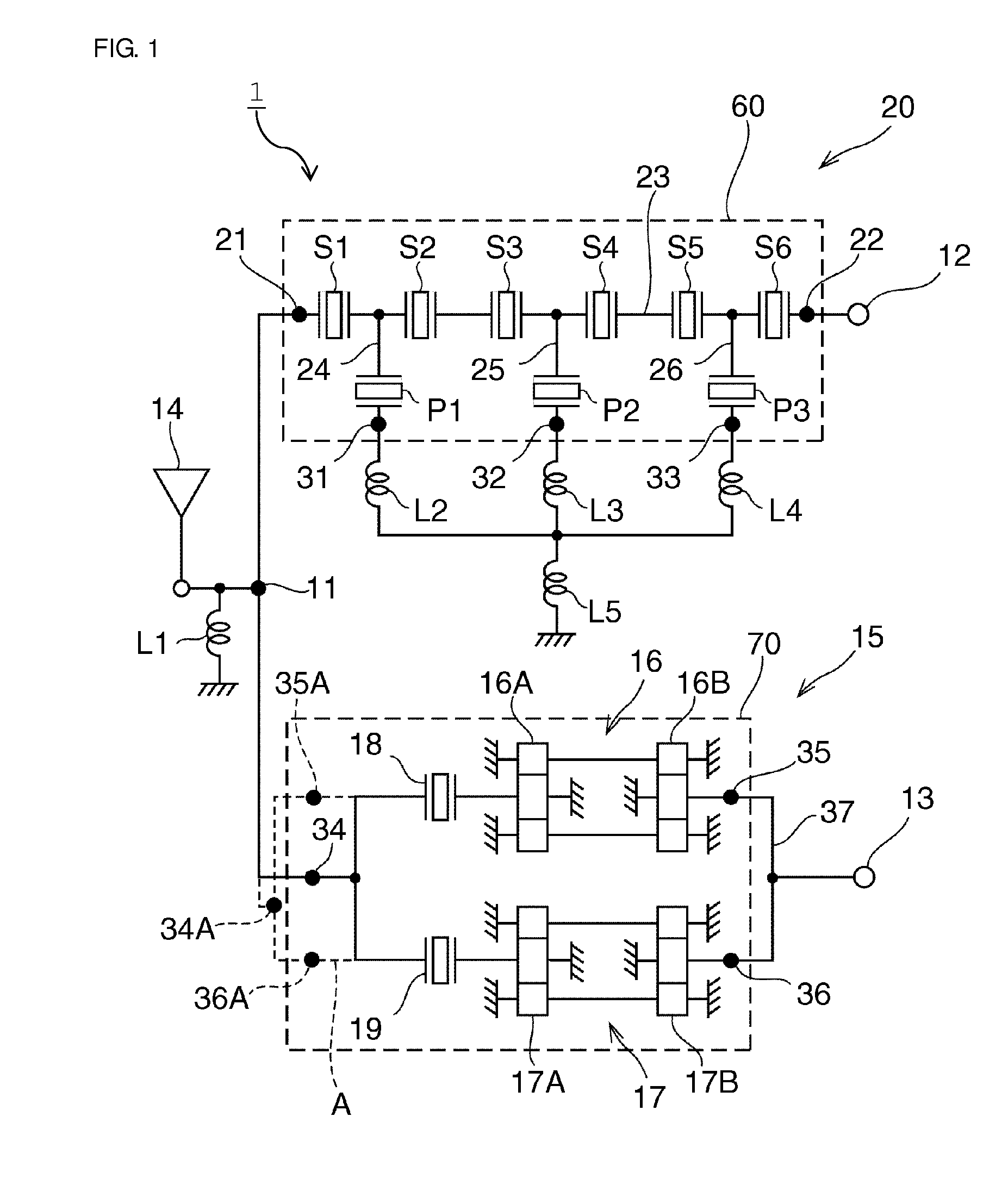

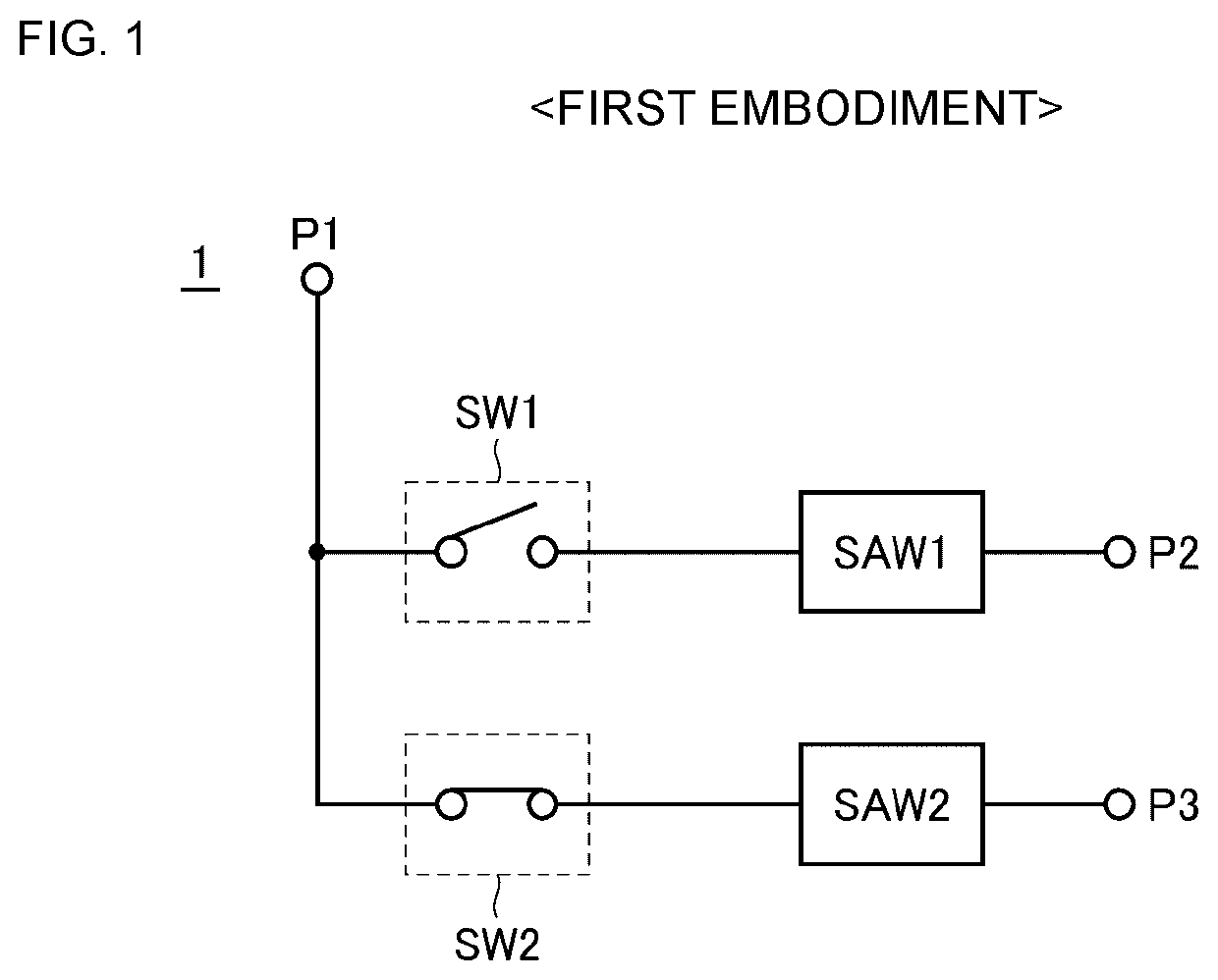

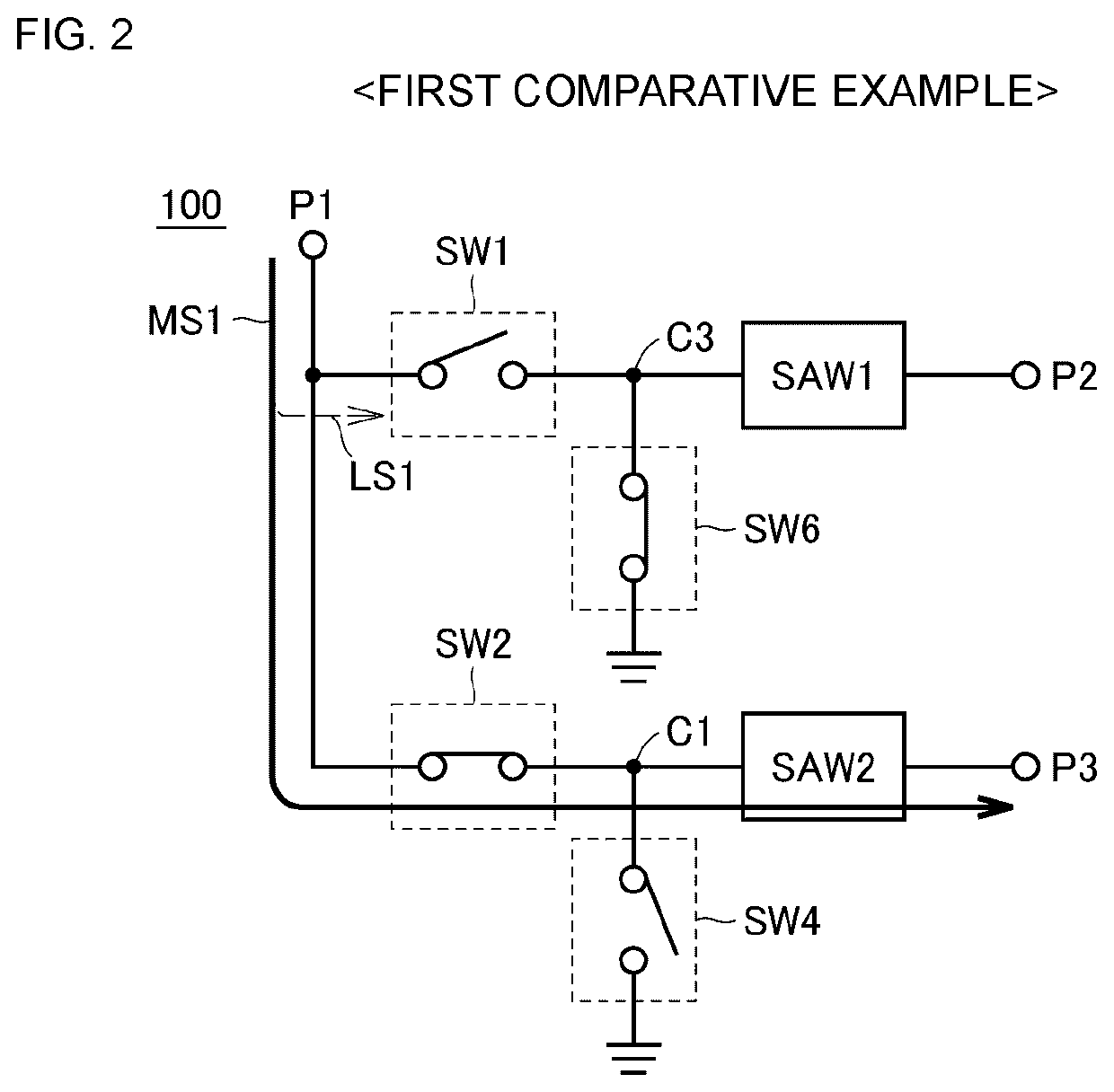

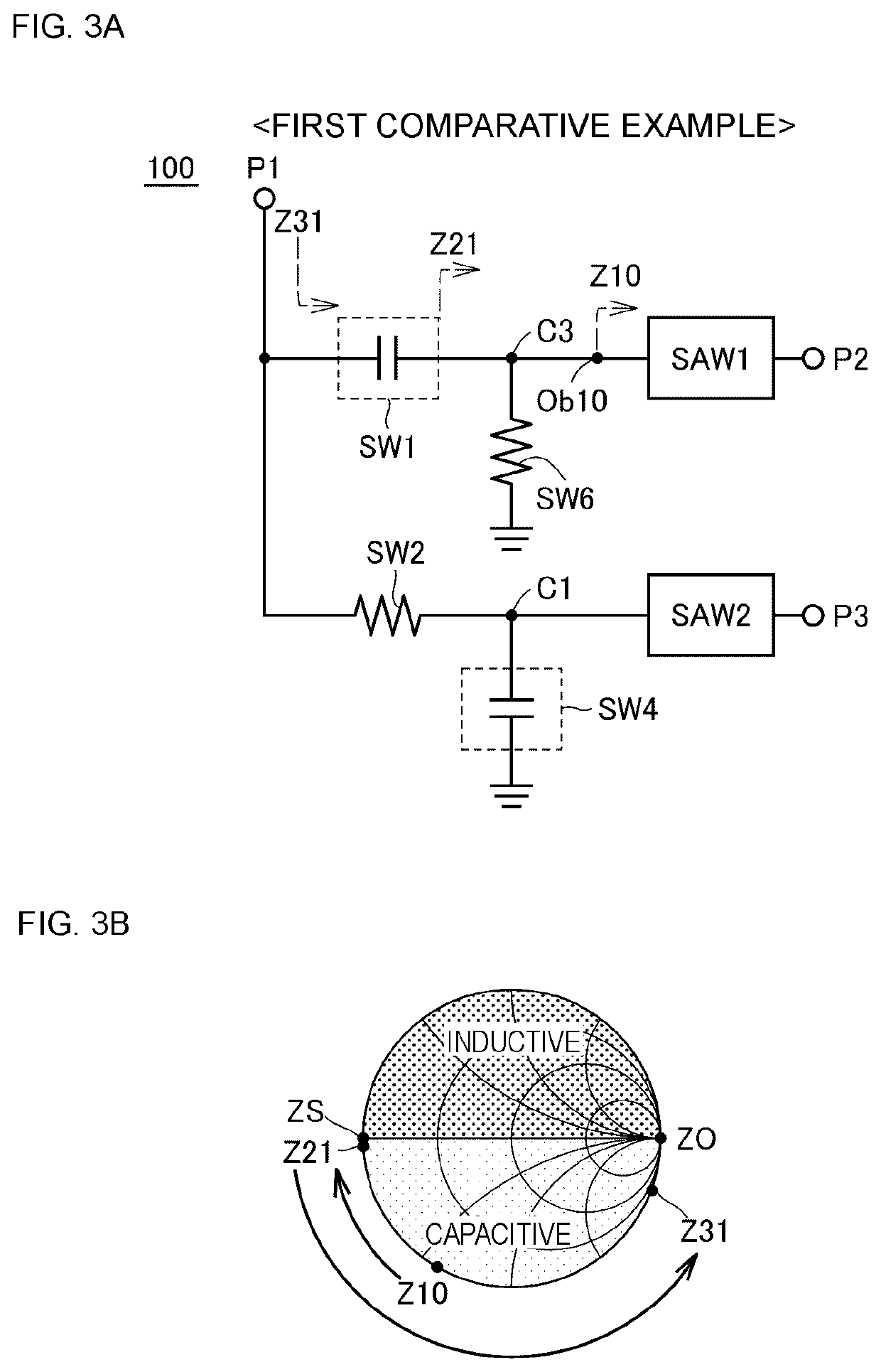

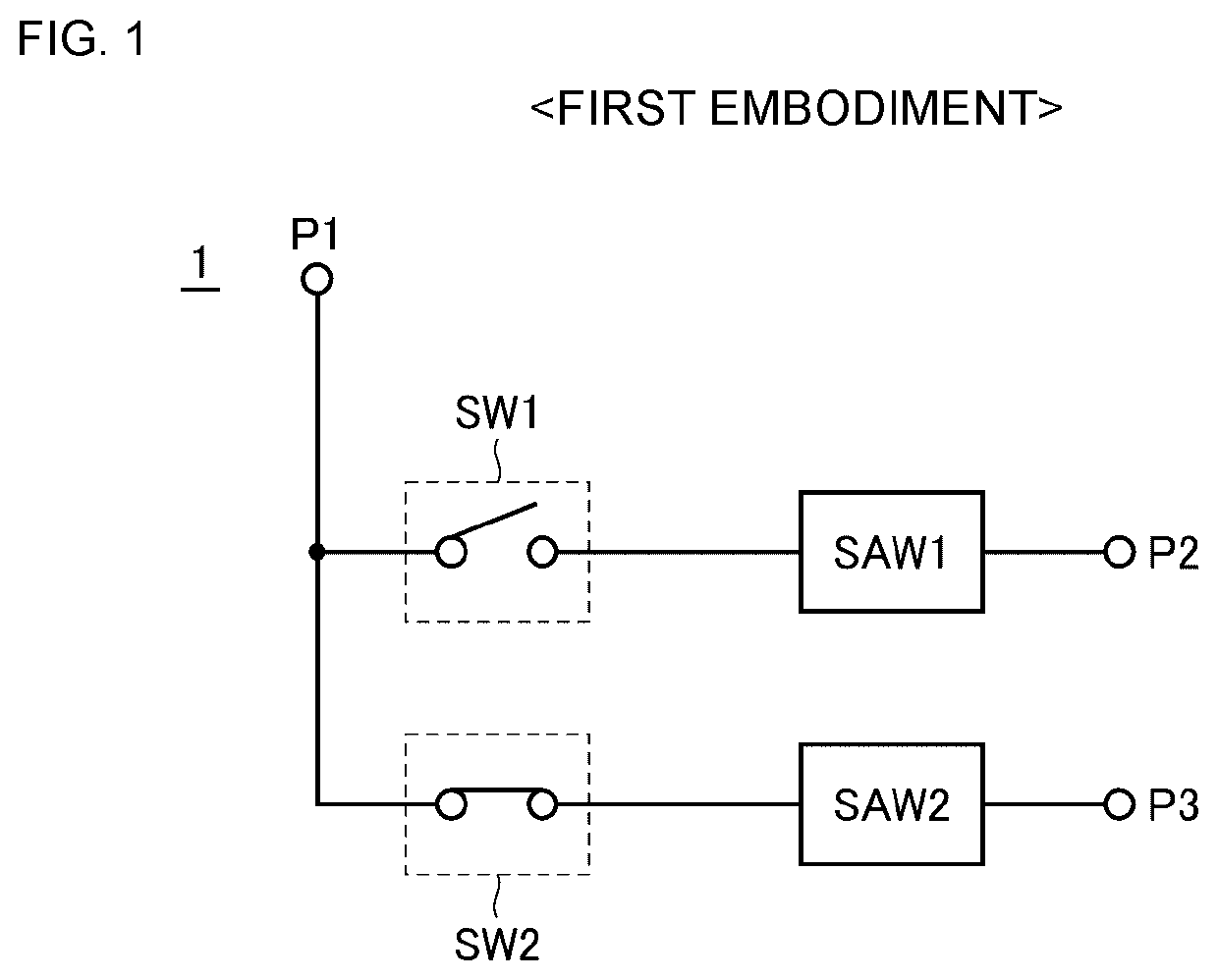

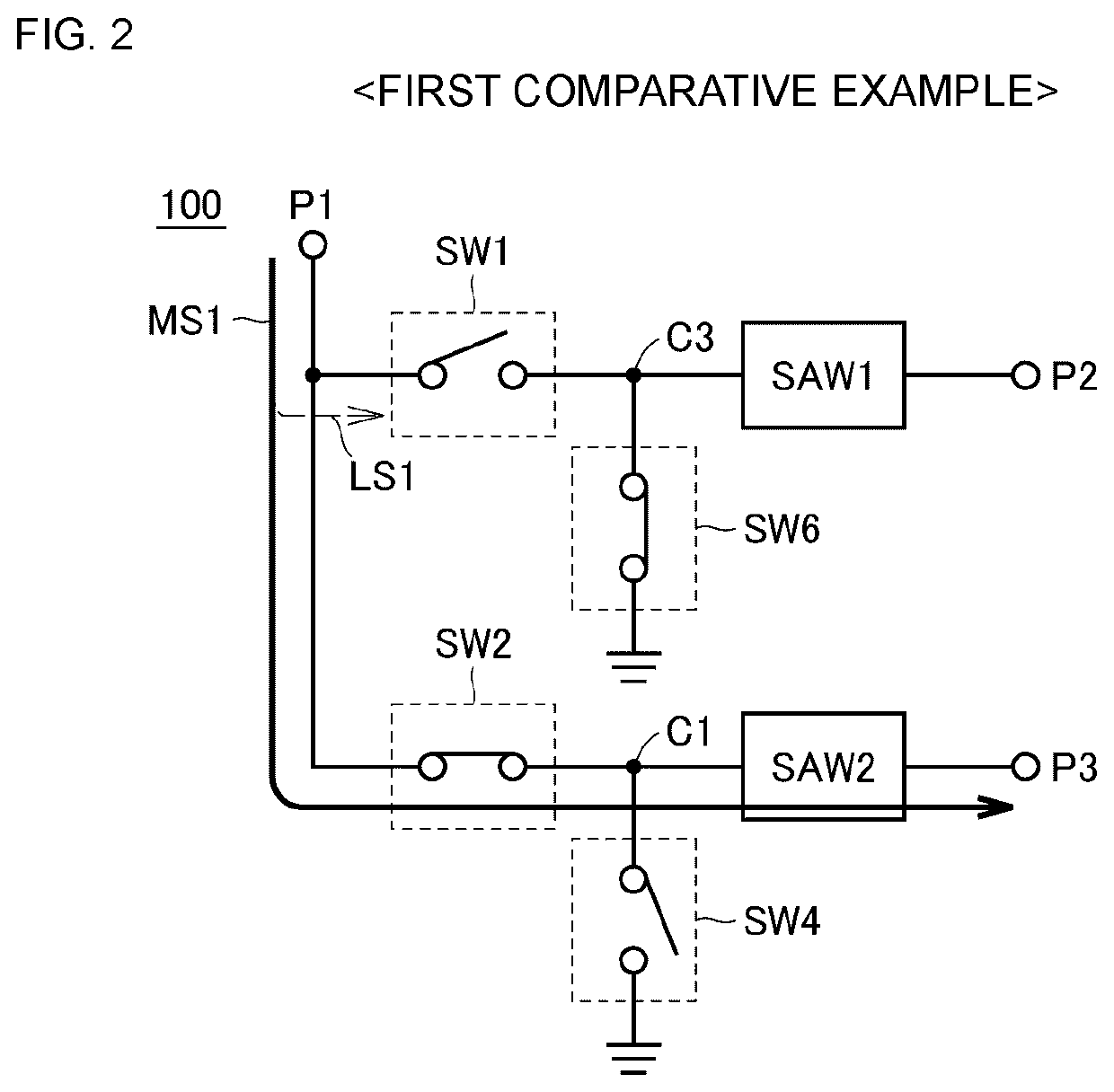

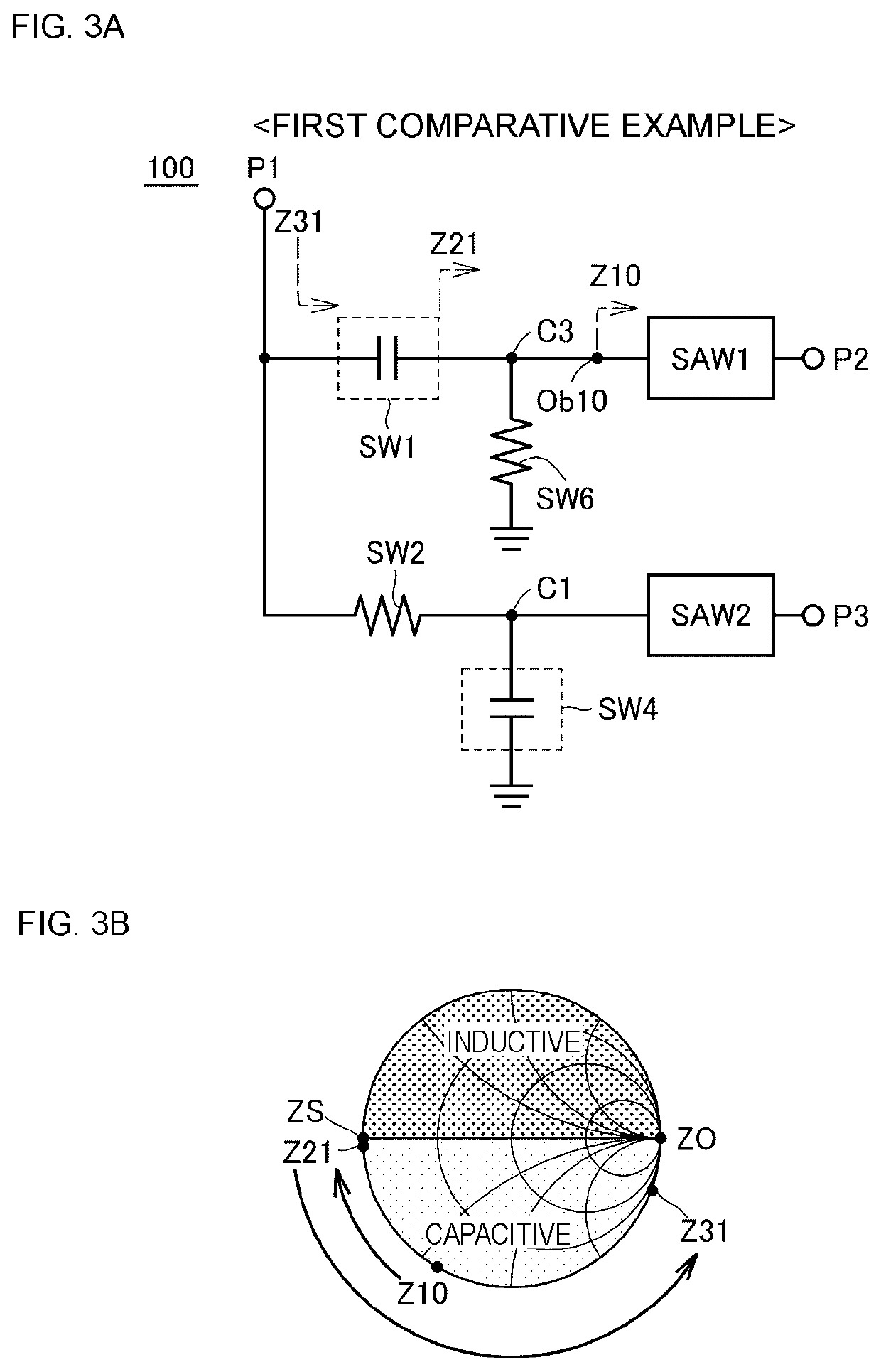

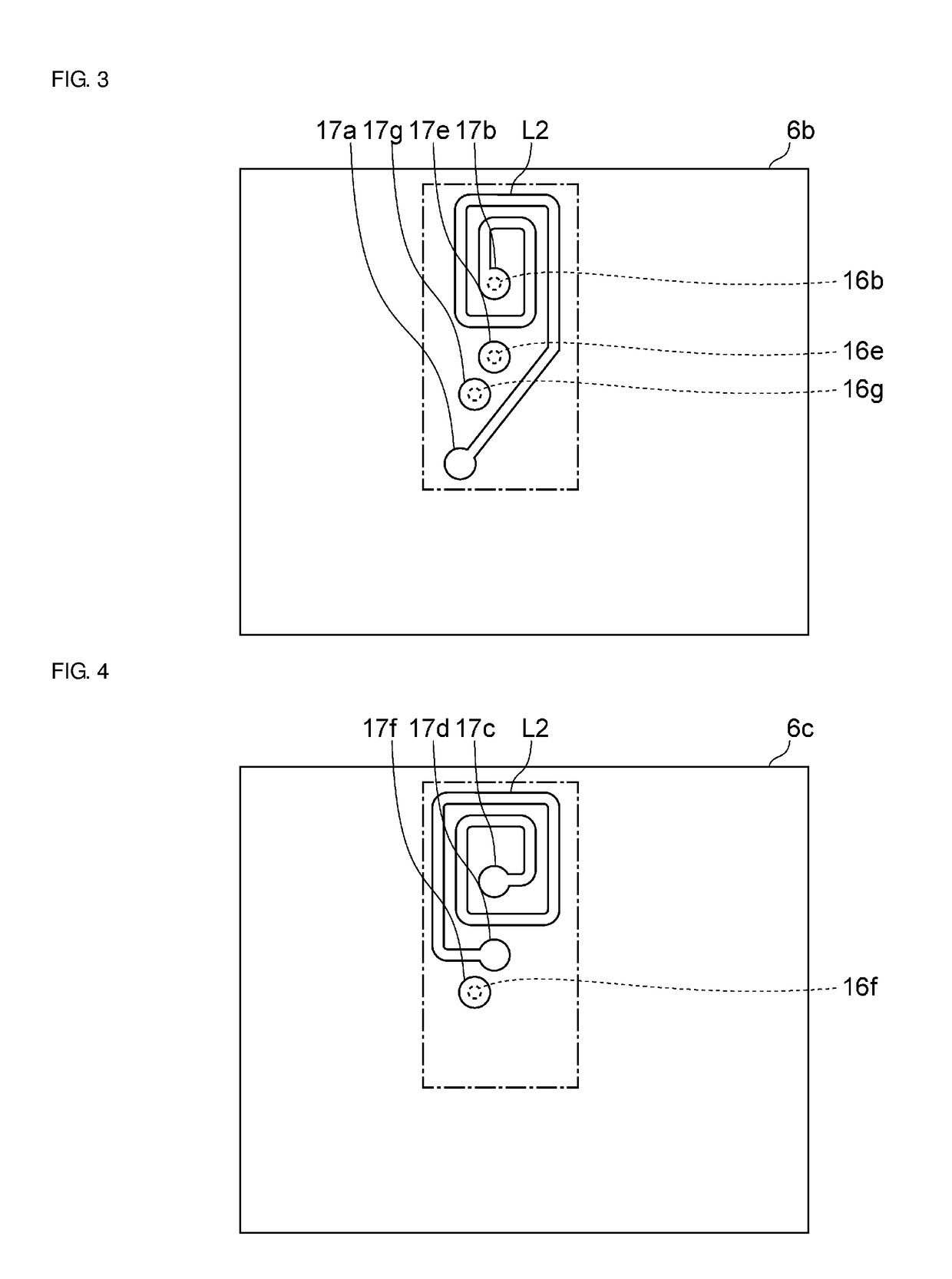

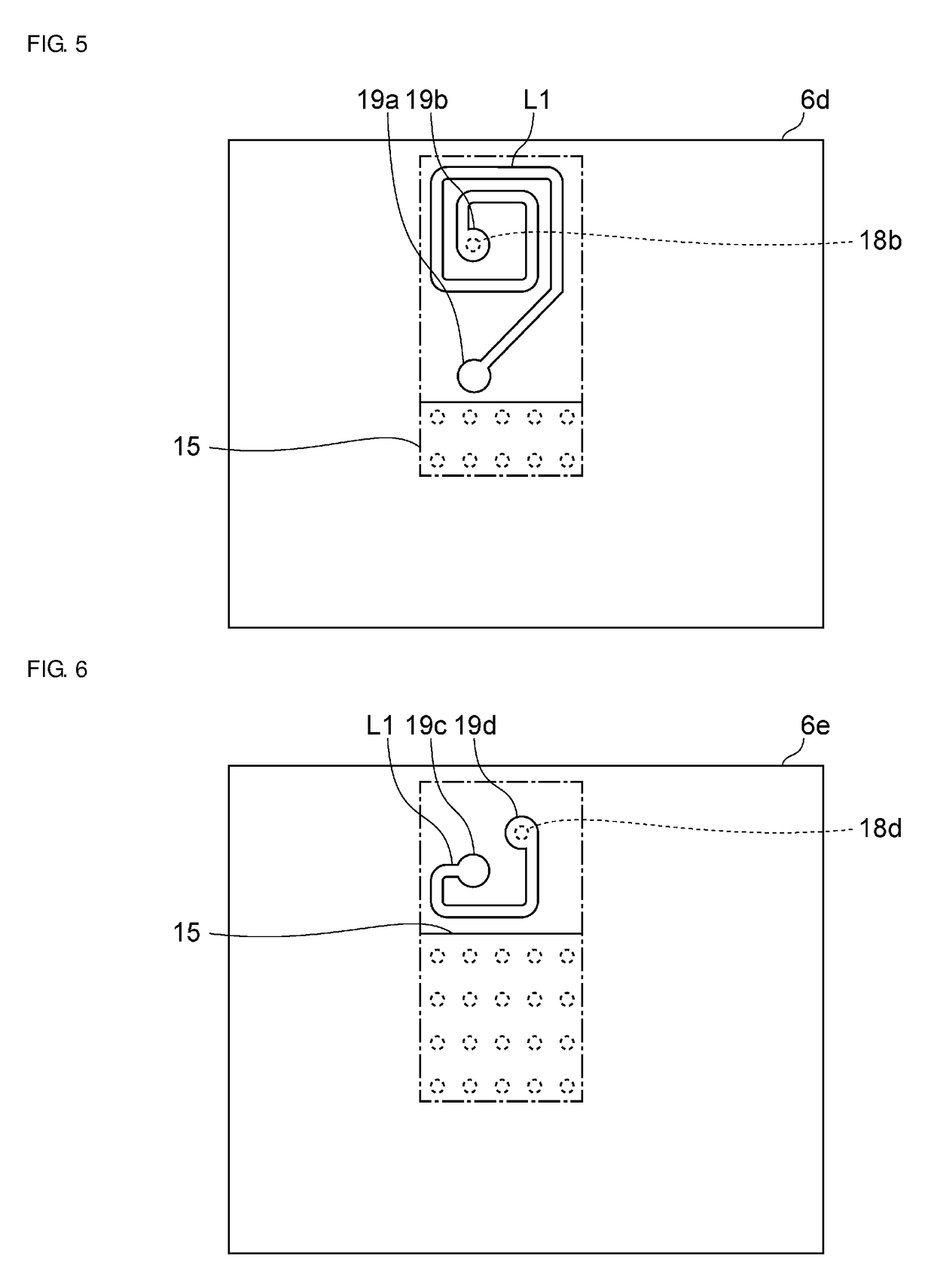

Switch module

ActiveUS20170331458A1Reduce insertion lossExclude influenceMultiple-port networksElectronic switchingElectrical impedanceShort circuit

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

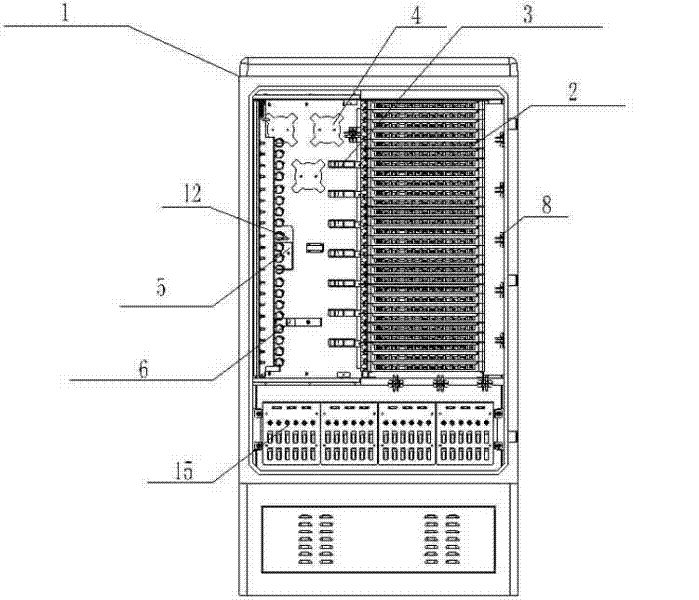

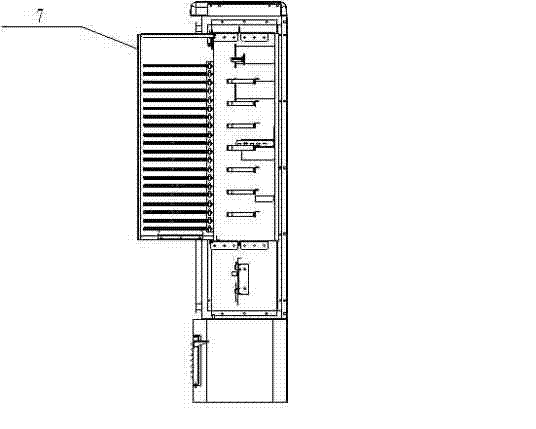

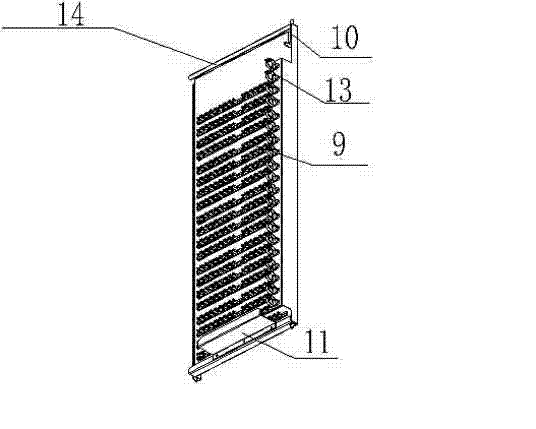

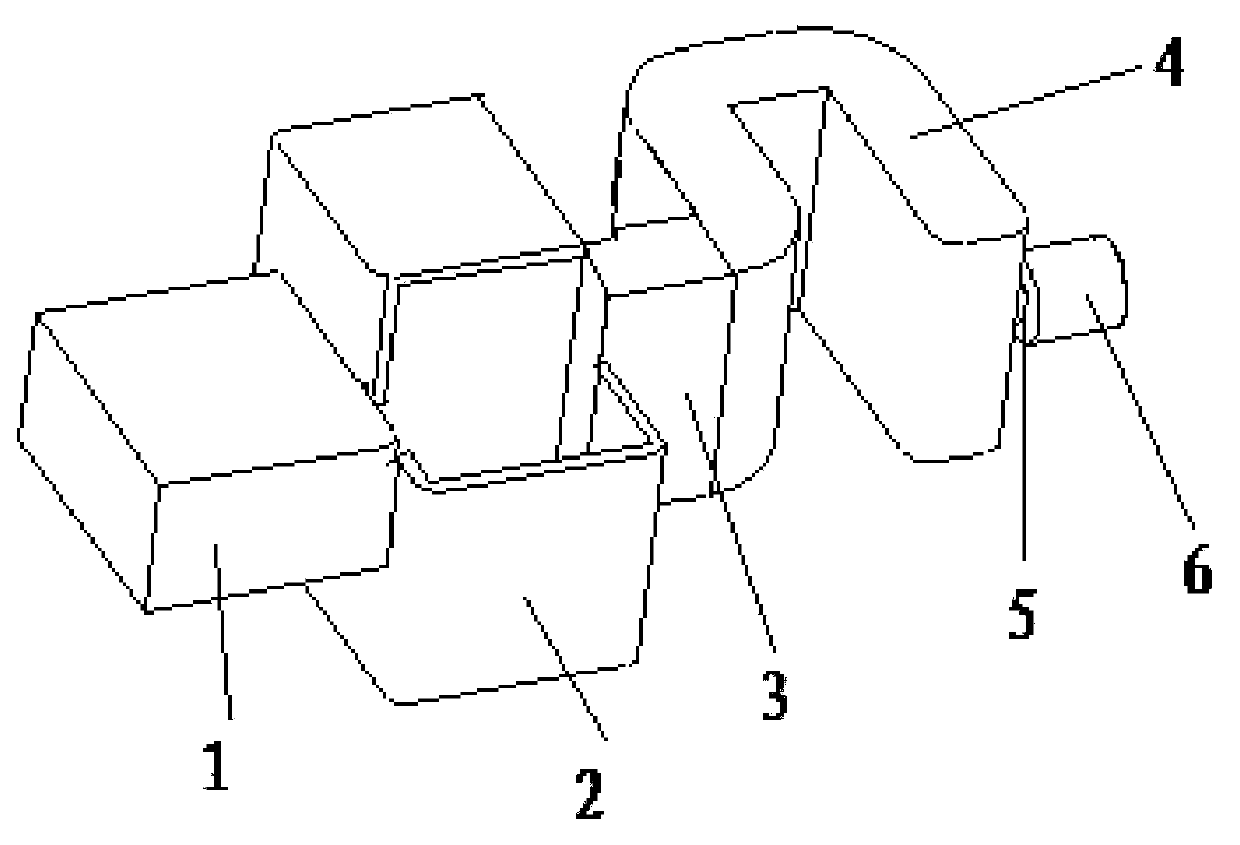

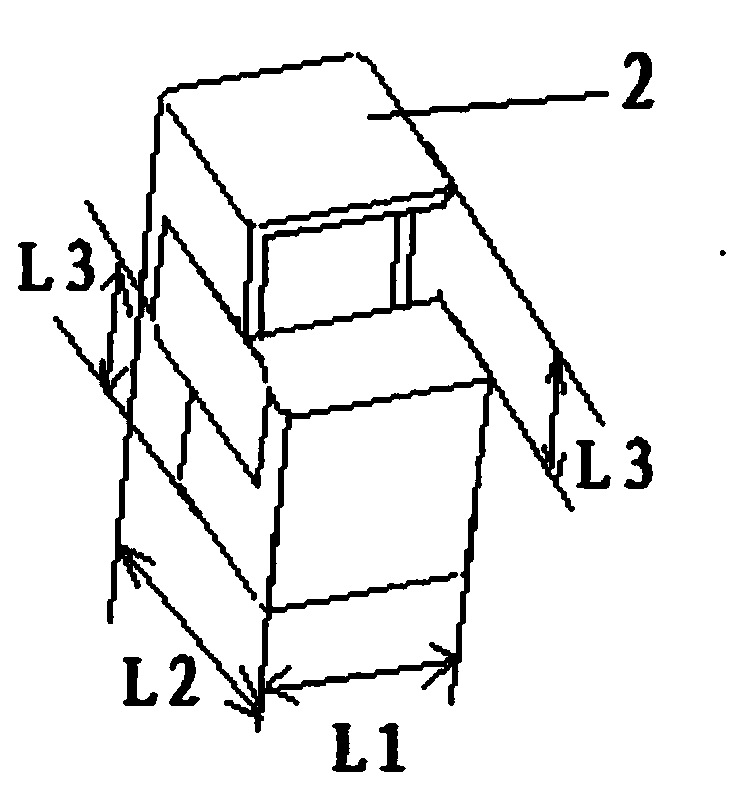

Non-jumper-connection optical cable cross connecting box

InactiveCN102419465AImprove securityReduce Communication Failure PointsFibre mechanical structuresFiberManagement unit

The invention relates to a non-jumper-connection optical cable cross connecting box. The non-jumper-connection optical cable cross connecting box is characterized by comprising a box body, wherein the right side of a rear wall in the box body is provided with a two-core fusion and distribution integrated tray, and the left side of the two-core fusion and distribution integrated tray is provided with a second jumper ring; the left side of the rear wall in the box body is provided with a fiber coiling barrel, the left side at the middle part of the rear wall in the box body is provided with a box type optical branching device mounting box, and a box type optical branching device is mounted in the box type optical branching device mounting box; a third jumper ring is arranged under the rear wall in the box body, and the left sidewall in the box body is provided with a rotationally connected optical branching device tail fiber plug management unit; a first jumper ring is arranged at the right sidewall in the box body, and an optical cable fixed stripping unit is arranged under the box body. The box type optical branching device meets the requirement of point-to-point and point-to-multipoint comprehensive development of the optical fiber, communication fault points and insertion loss are reduced, network security is improved, the defects of small wiring capacity and easily disordered layout are solved, and development of optical networks is promoted.

Owner:SUZHOU NEW SEA UNION TELECOM TECH CO LTD

Switch module

ActiveUS10181839B2Exclude influencePrevent signal leakageMultiple-port networksElectronic switchingElectrical impedanceShort circuit

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

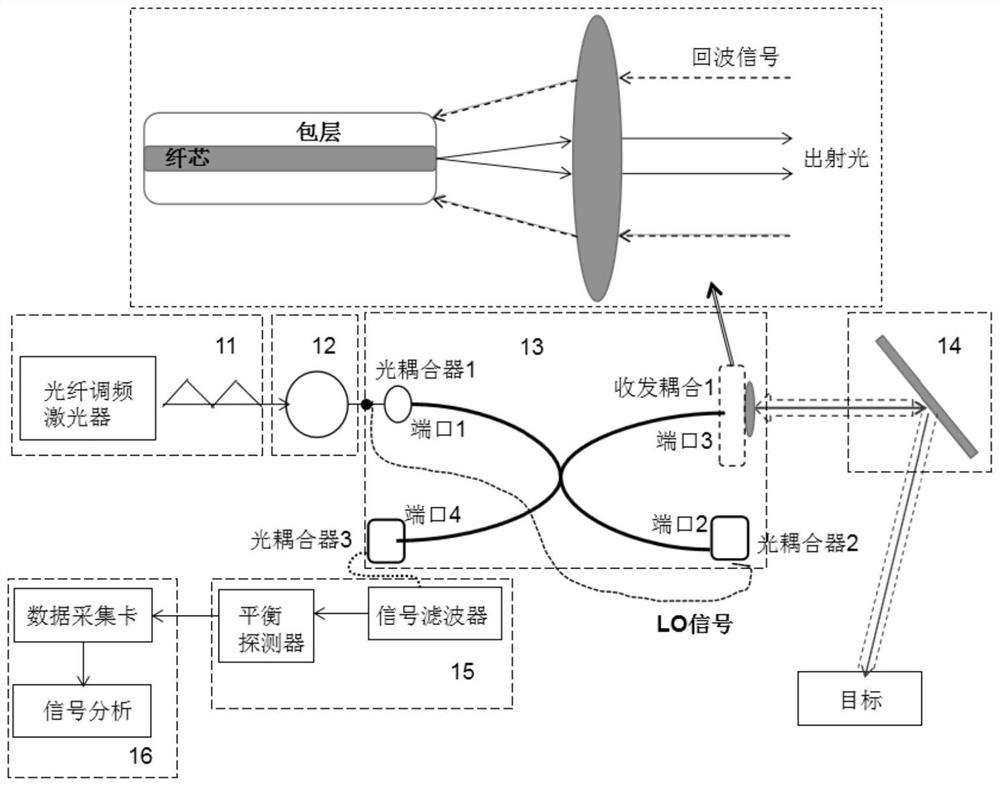

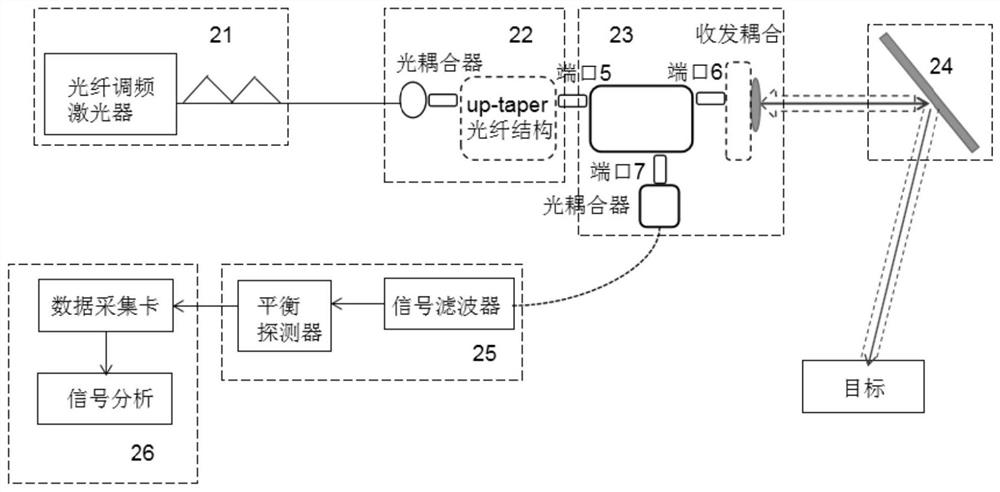

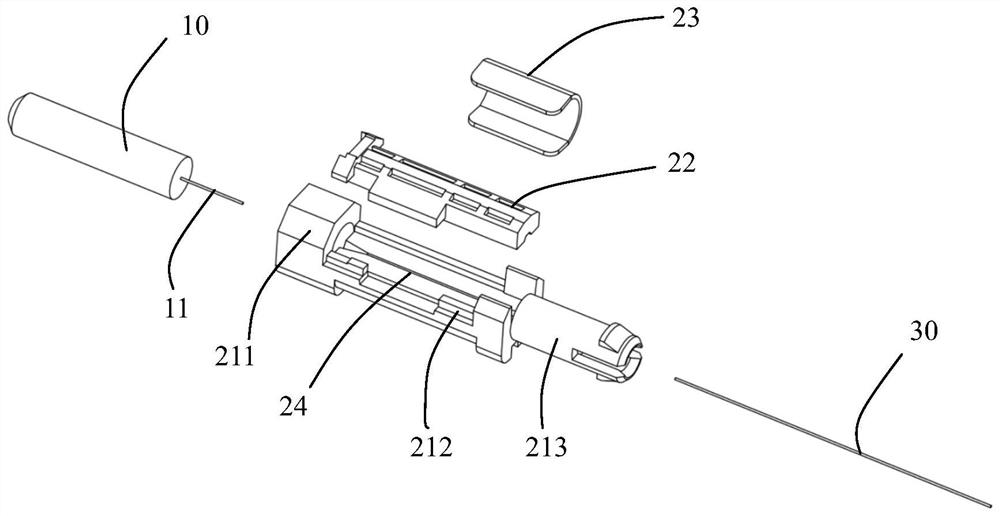

Fmcw lidar system

PendingCN113383246AOverall small sizeAccurate extractionElectromagnetic wave reradiationComputational physicsLidar

The embodiment of the invention discloses an FMCW LIDAR system. The system comprising an emission module, an optical fiber coupling module, a scanning module and a demodulation module. An output terminal of the emission module is connected to an input terminal of the optical fiber coupling module, a first output terminal of the optical fiber coupling module is connected to the scanning module, and a second output terminal of the optical fiber coupling module is connected to an input terminal of the demodulation module.

Owner:SUTENG INNOVATION TECH CO LTD

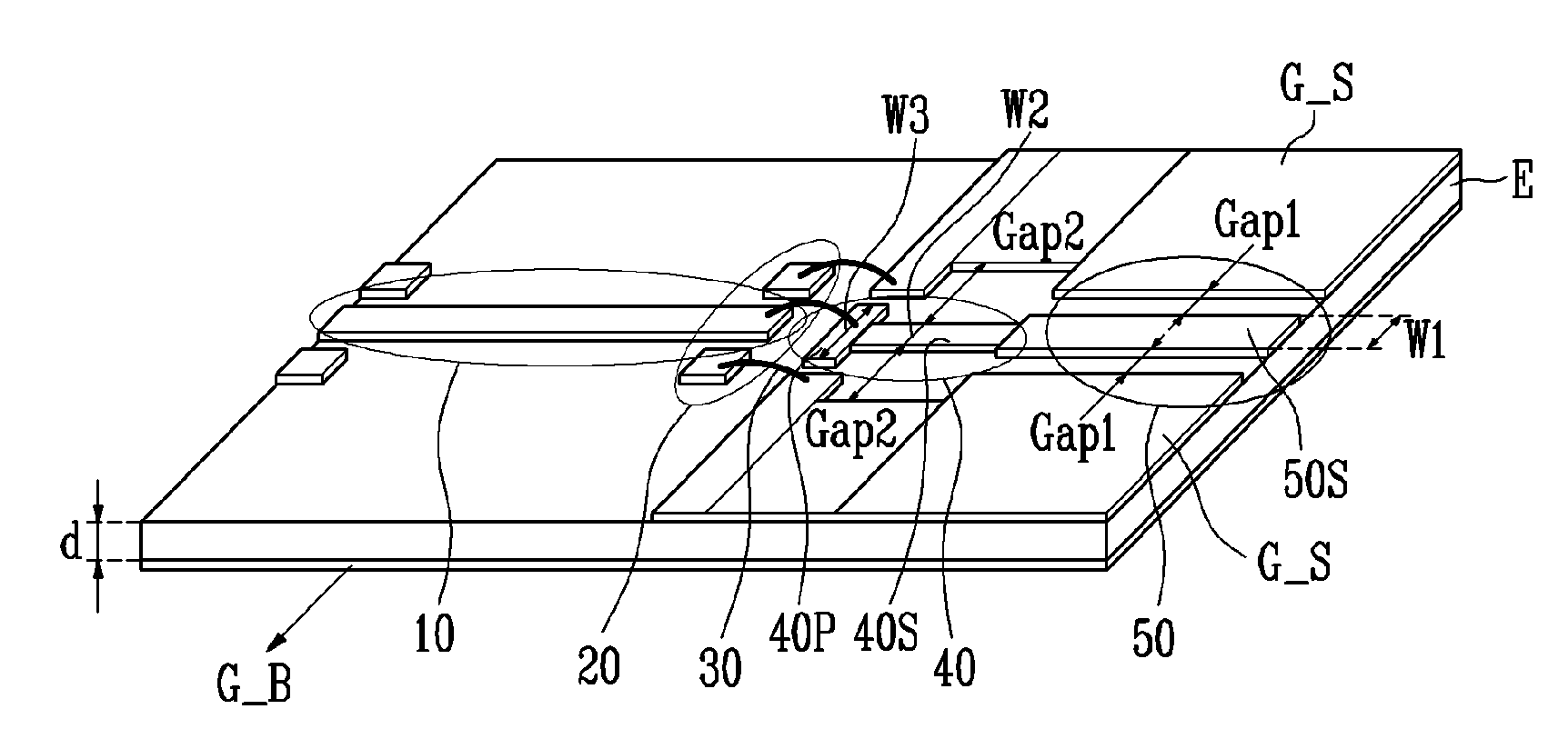

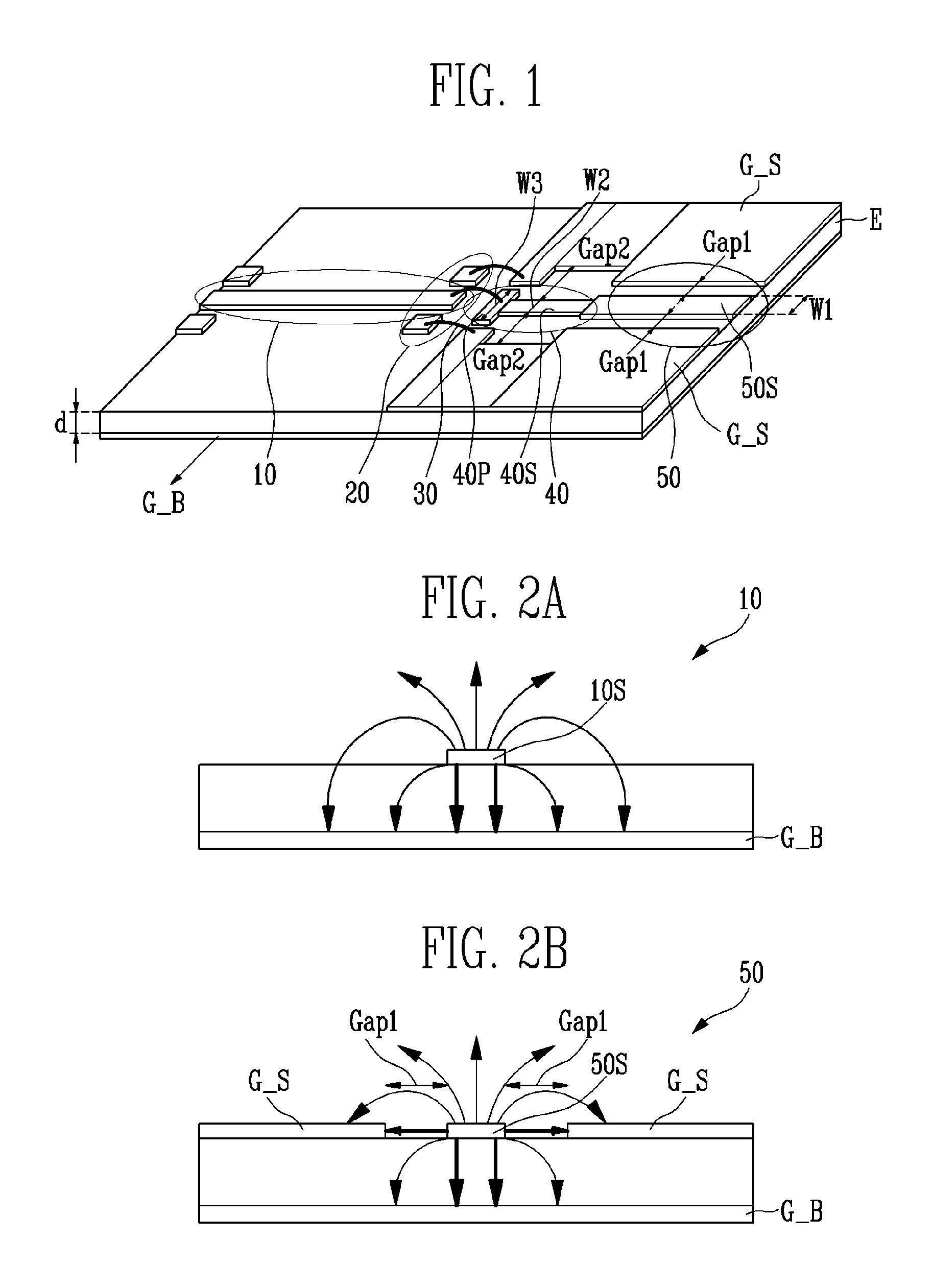

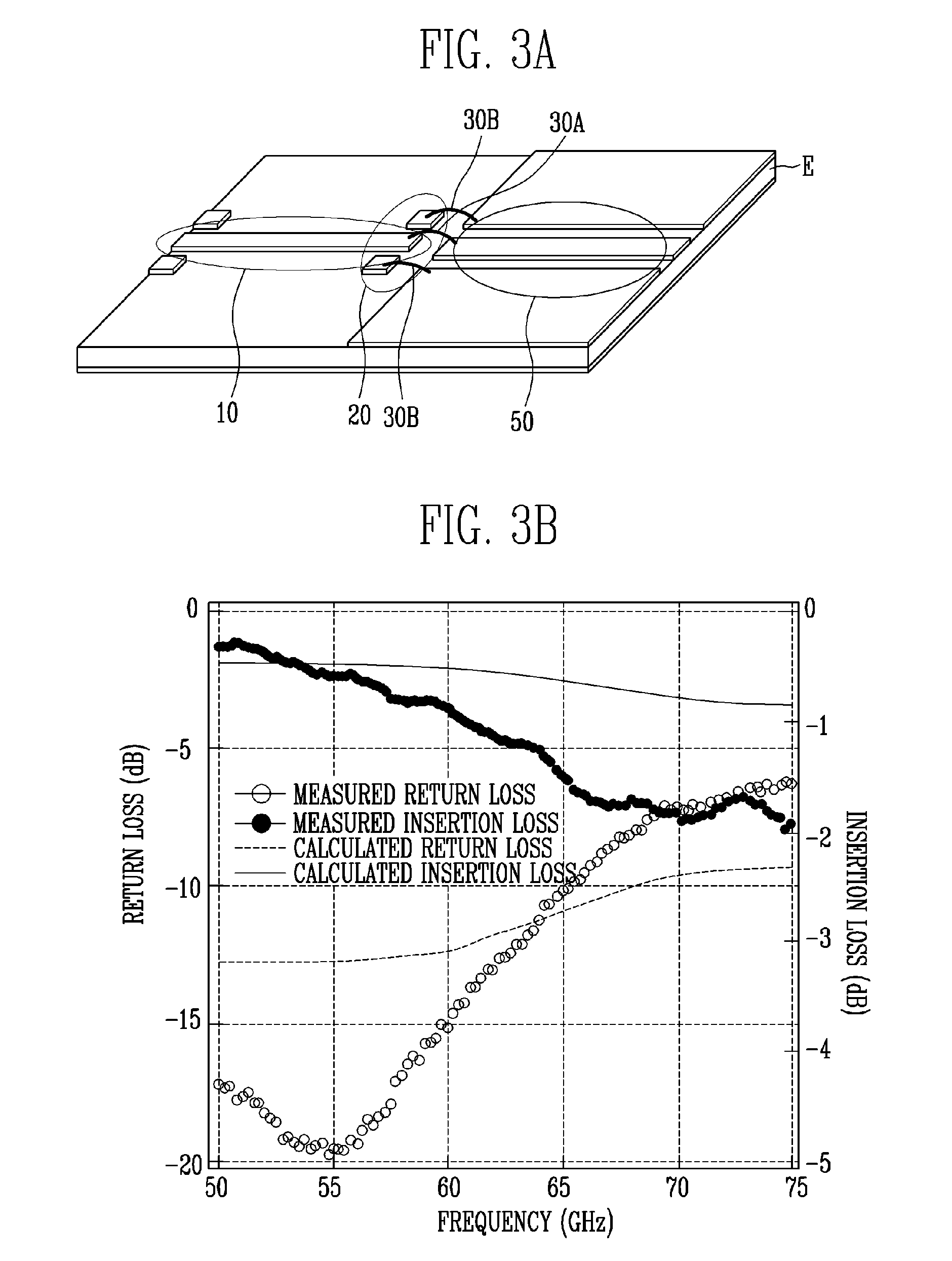

Microwave module having converter for improving transmission characteristics

InactiveUS20080136552A1Reduce insertion lossReduce change in impedanceMultiple-port networksSolid-state devicesTransmission propertiesWave band

Owner:ELECTRONICS & TELECOMM RES INST

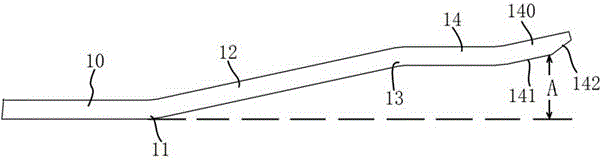

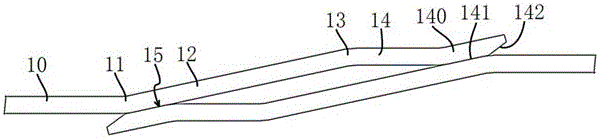

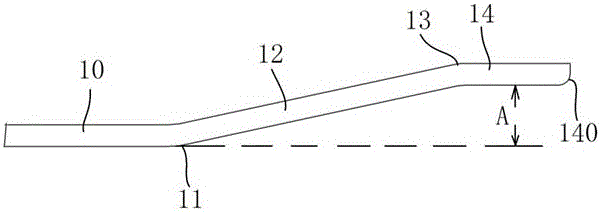

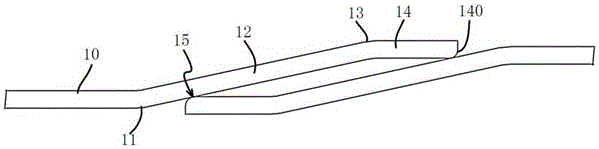

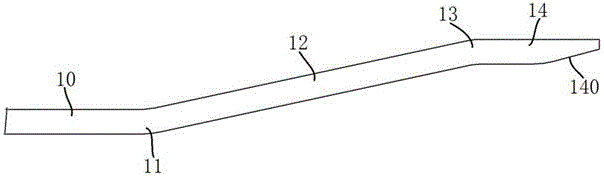

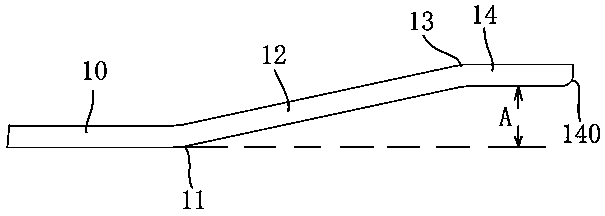

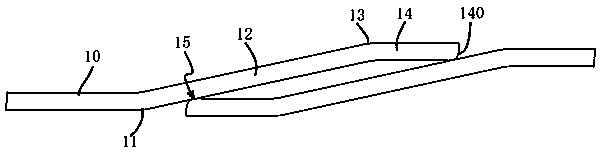

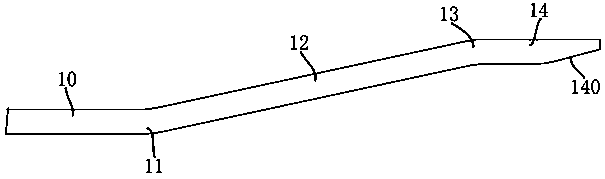

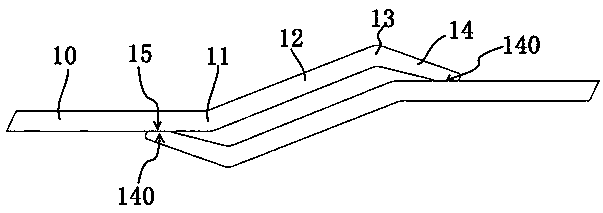

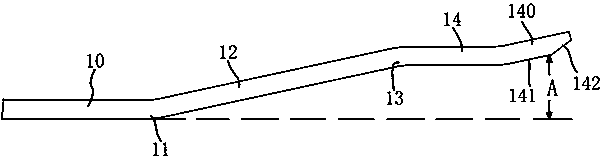

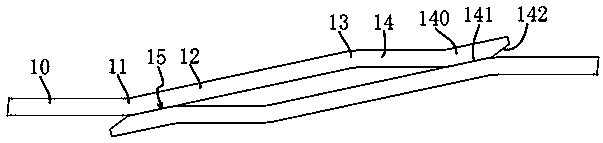

Conductive contact and electric connector

ActiveCN105958247AAvoid damageElimination of stub radiation effectCoupling contact membersEngineeringPoint contact

The invention provides a conductive contact and an electric connector, wherein the conductive contact comprises a base body, the front end of the base body is connected with an upward sloping first connecting section through a first bending section, the front end of the first connecting section is connected with a contact section through a second bending section, a front contact part is arranged on the contact section, a front contact point which is used for contacting with an adaptive conductive contact is arranged on the front contact part, the lower side of the first connecting section comprises a rear contact point which is used for contacting with the adaptive conductive contact, an insertion space which is used for being inserted by the adaptive conductive contact is arranged between the front contact point and the base body in up-down direction, and an insertion guide surface which avoids abutting between the conductive contact and the adaptive conductive contact in insertion is arranged on the front side of the front contact point on the front contact part. According to the invention, the structure of the conductive contact is improved, so that the overhang structure of the front side of the conductive contact point and the short pile irradiation effect are eliminated, the conductive connection is realized through two-point contact, and the insertion loss is low.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Electric conduction contact component and electric connector using same

ActiveCN105977678AAvoid stub radiation effectReduce insertion lossCoupling contact membersElectricityMechanical engineering

The present invention provides an electric conduction contact component and an electric connector using the same. The electric conduction contact component comprises a base body which extends flatly and straightly; the front end of the base body is connected with a first connecting section which is arranged in an upwards tilting manner through a first bent section; the front end of the first connecting section is connected with a contact section through a second bent section; the contact section is provided with a front contact portion which is in electric conduction contact with a matched electric conduction contact component; the lower side surface of the first connecting section is provided with a rear contact point which is in electric conduction contact with the front contact portion of the matched electric conduction contact component; and the front contact portion and space at the upper side and lower side of the base body form an insertion space into which the matched electric conduction contact component can be inserted. The electric conduction contact component provided by the invention is simple in structure. With the electric conduction contact component adopted, multi-point contact can be realized, the radiation effect of a short pile can be eliminated, and insertion loss can be decreased.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

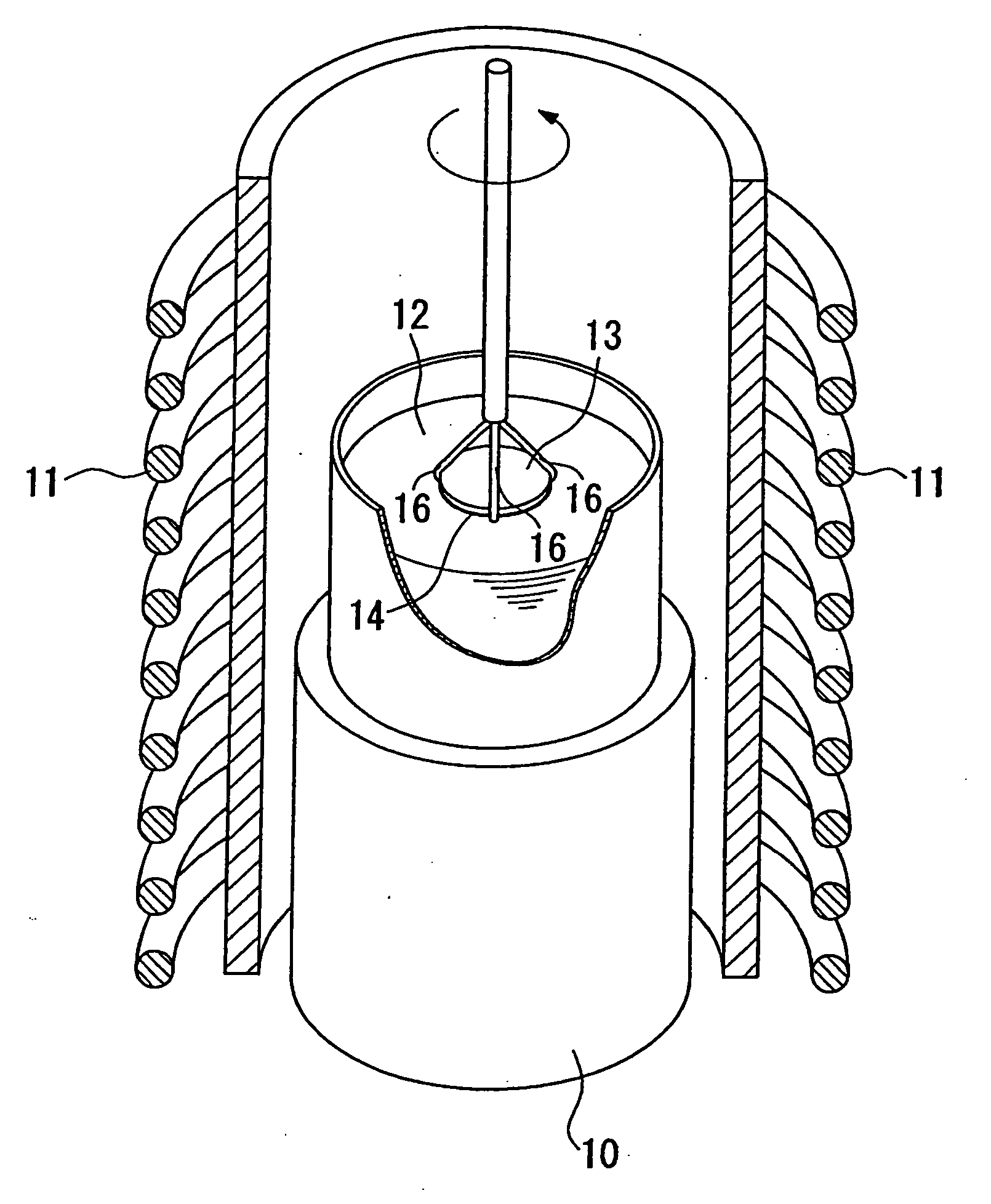

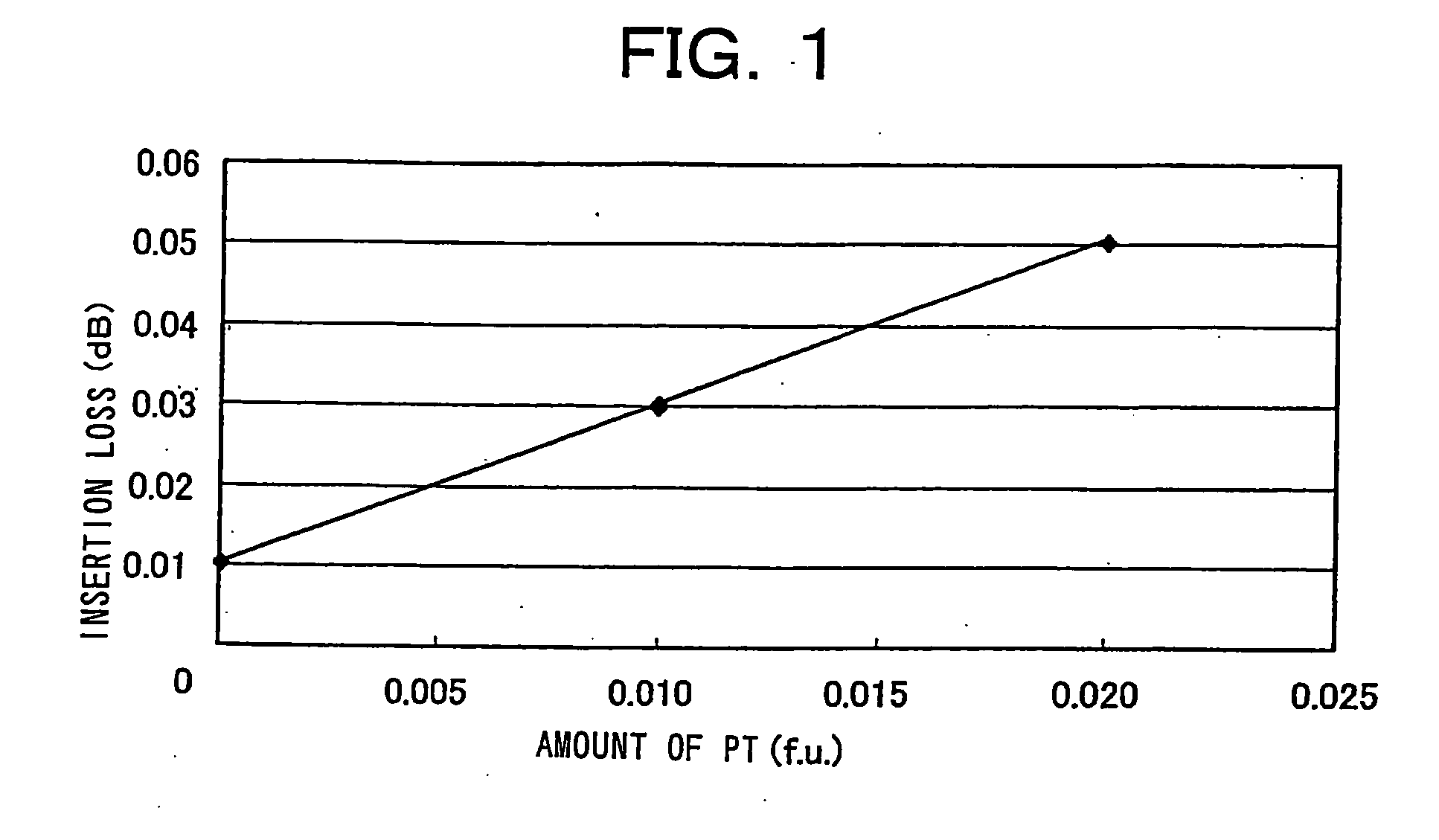

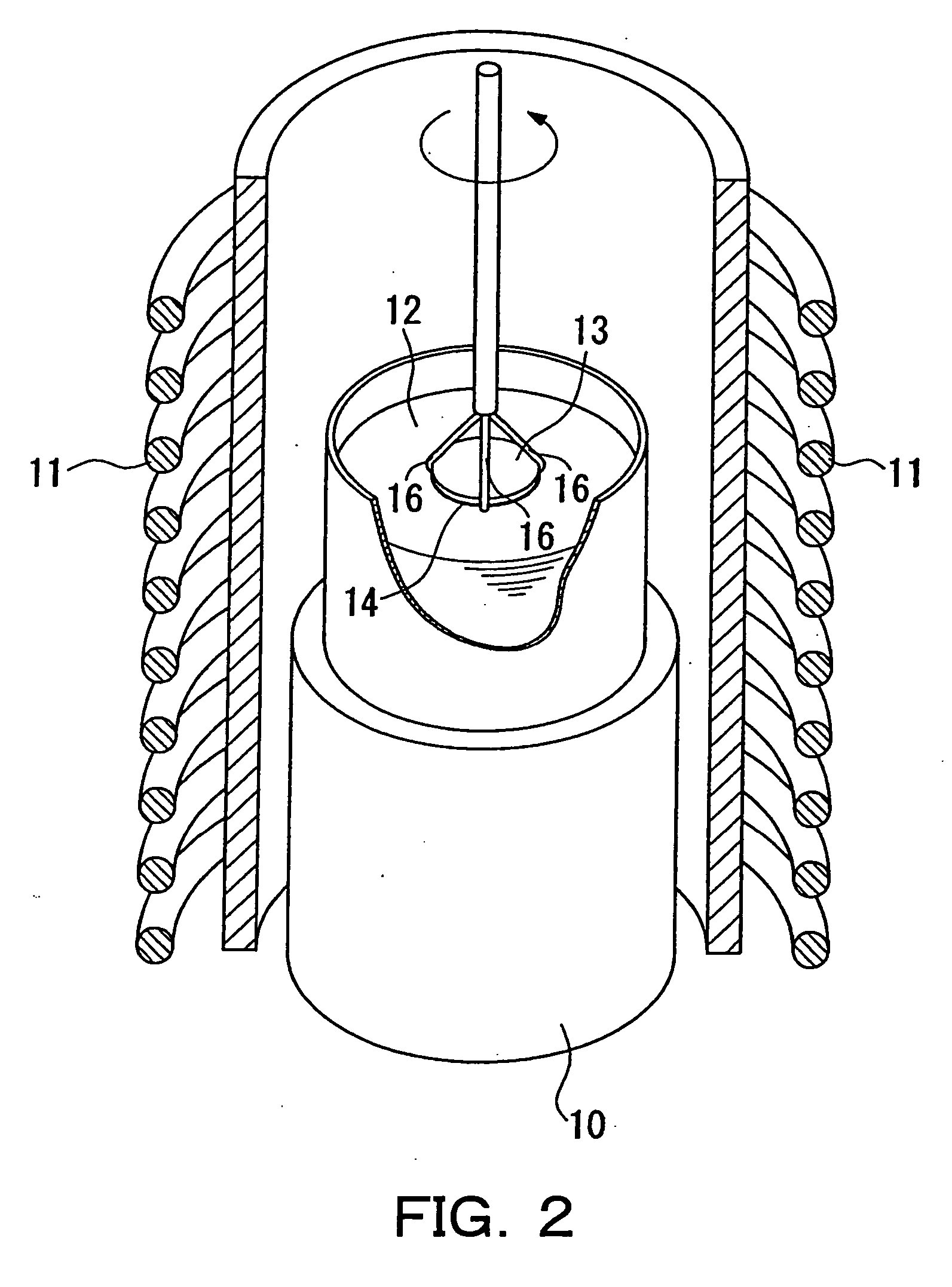

Magnetic garnet material, faraday rotator, optical device, bismuth-substituted rare earth-iron-garnet single-crystal film and method for producing the same and crucible for producing the same

InactiveUS20060187546A1Reduce insertion lossImprove magnetic characteristicPolycrystalline material growthLiquid-phase epitaxial-layer growthBismuth preparationInsertion loss

Proposed is a technique of producing a magnetic garnet material of which the light absorption characteristics worsen little even though it is produced through LPE. The crucible for LPE is formed of a material containing Au. The amount of Au to be taken in single crystal formed in an Au crucible is smaller than that of Pt to be taken therein formed in a Pt crucible. As compared with Pt, the influence of Au on magnetic garnet film that increases the insertion loss in the film is small.

Owner:TDK CORPARATION

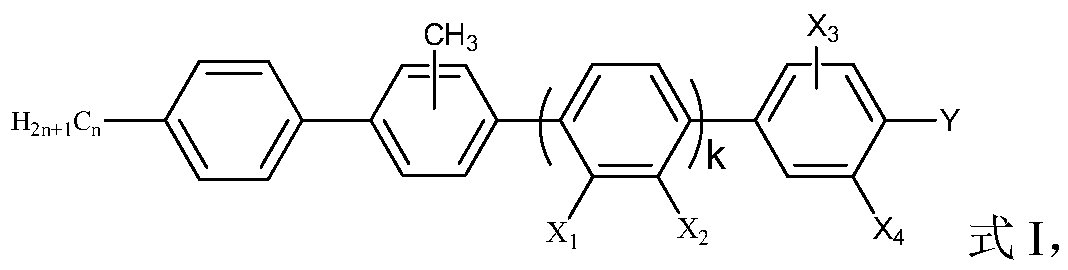

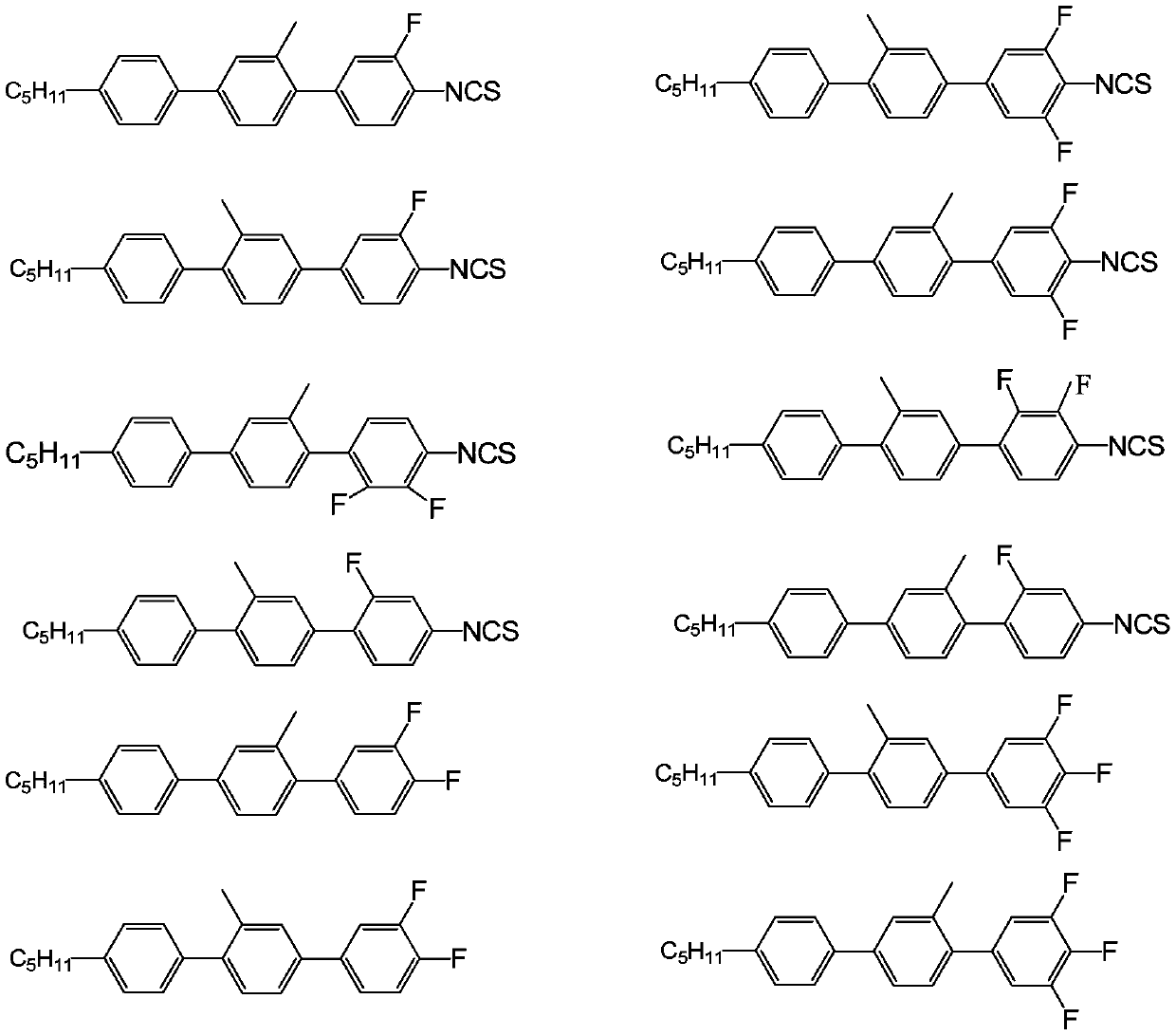

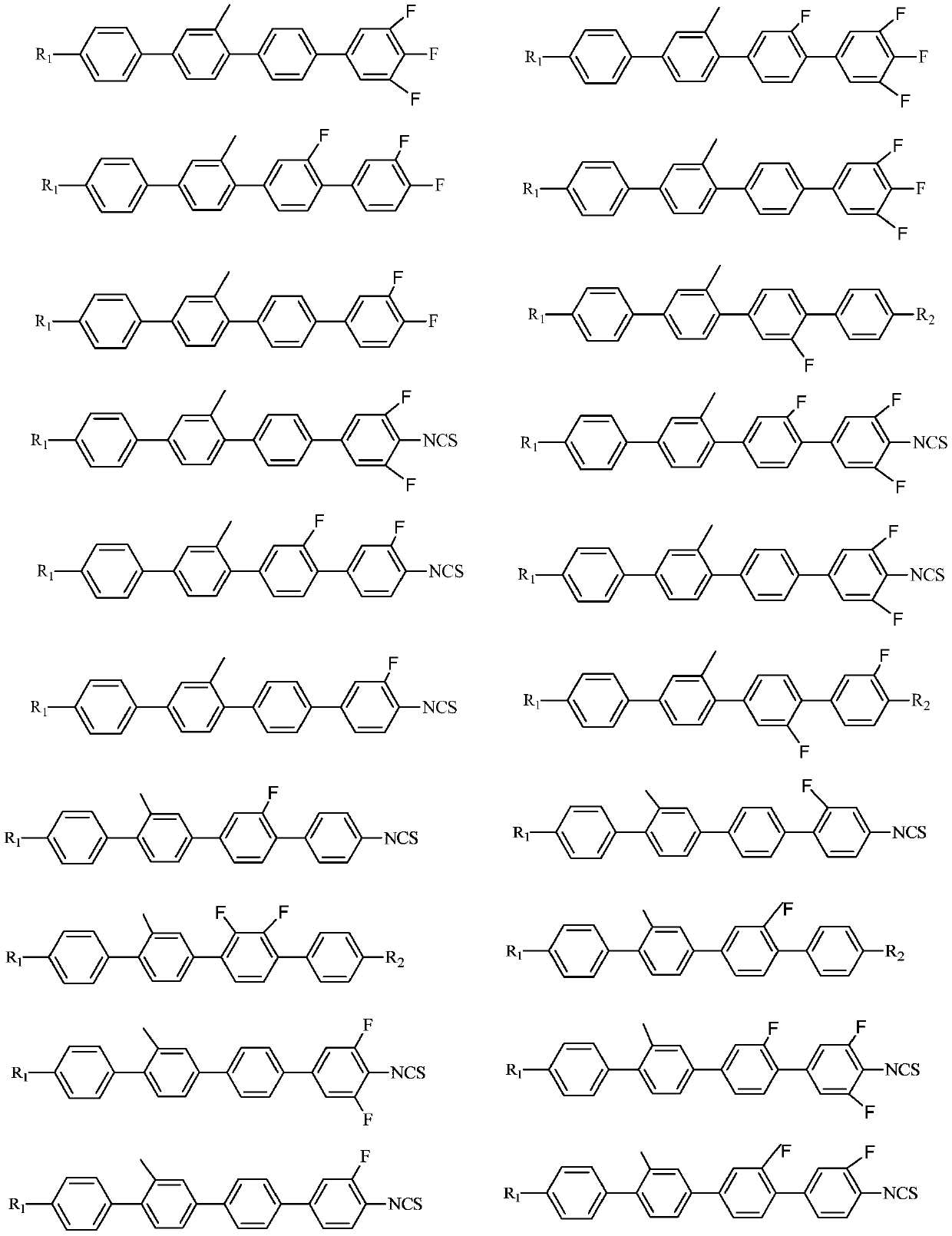

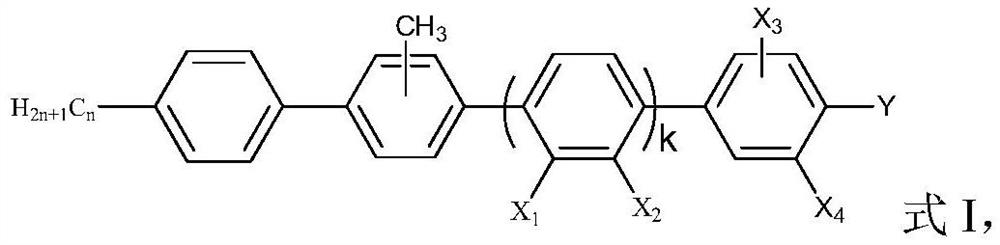

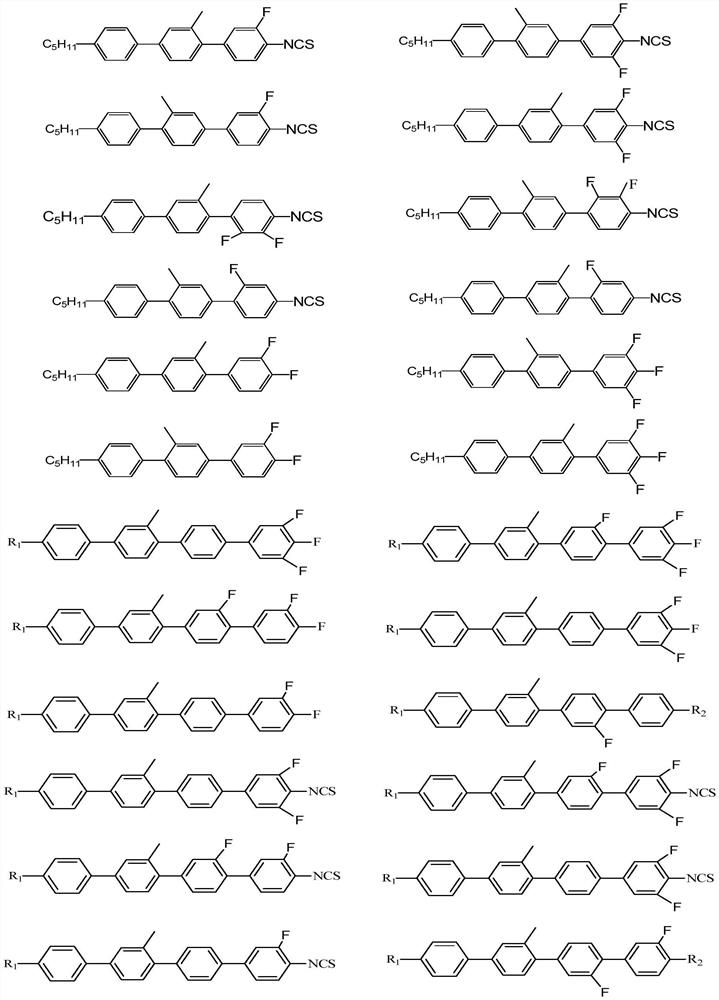

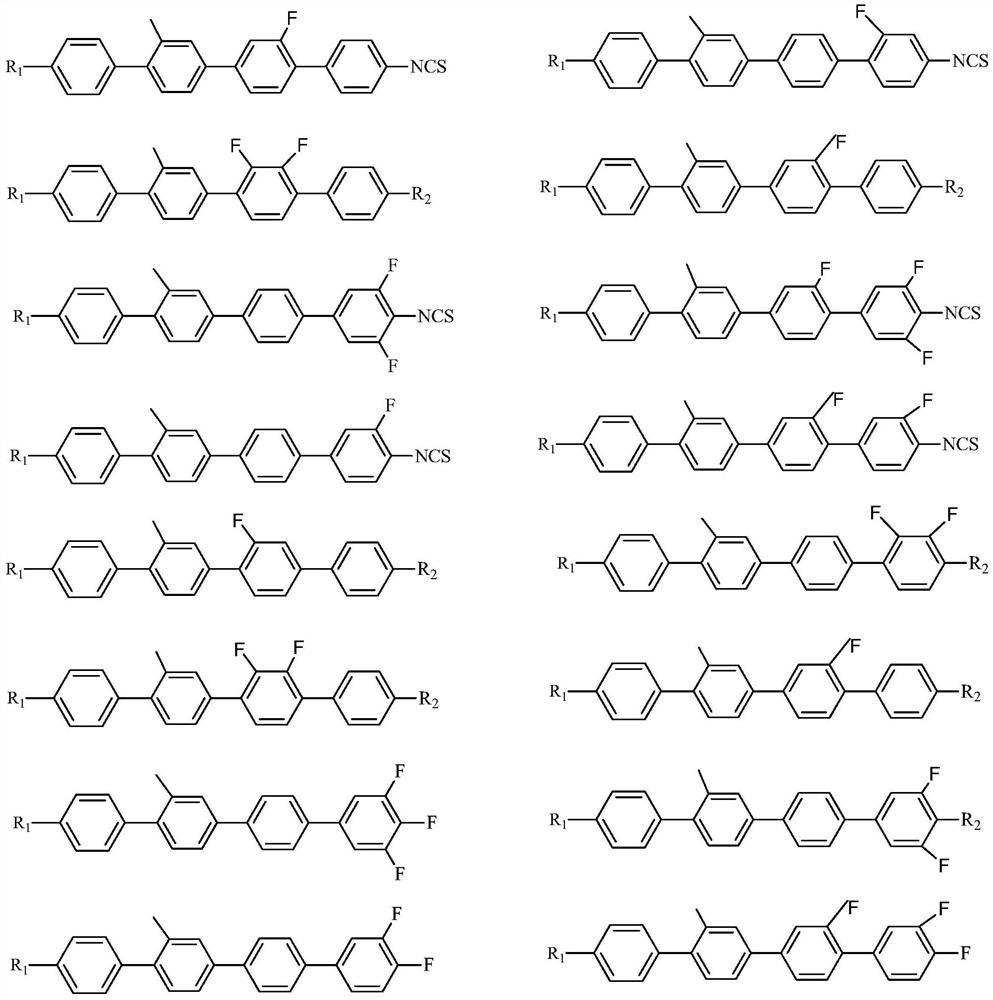

Side methyl polybiphenyl liquid crystal compound, liquid crystal composition and application of composition

ActiveCN110760311ALow melting pointLower eutectic pointLiquid crystal compositionsWaveguide type devicesCrystallographyPhysical chemistry

The invention discloses a side methyl polybiphenyl liquid crystal compound, a liquid crystal composition and an application of the composition. A structure of the liquid crystal compound is represented by a formula I shown in the specification, wherein n is an integer of 1 to 7; X1 to X4 are each independently selected from a H atom, a F atom or a Cl atom; k is 0 or 1; Y is NCS, a F atom or an R group; and R is one selected from the group consisting of a straight-chain alkyl group containing 1-6 carbon atoms, an alkenyl-contained straight-chain alkyl group containing 1-6 carbon atoms, and a straight-chain alkyl group containing 1-6 carbon atoms, wherein the a H atom on the alkyl chain of the straight-chain alkyl group is replaced by 1-2 fluorine atoms or one methyl. The compound provided by the invention and other materials are mixed to prepare the liquid crystal composition material with a <delta>n value of greater than 0.35, the microwave phase modulation amount is improved, and themicrowave wave frequency insertion loss amount is reduced.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Switch module

ActiveUS20200244251A1Reduced insertion lossExclude influenceMultiple-port networksMulti-band filtersCapacitanceSoftware engineering

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

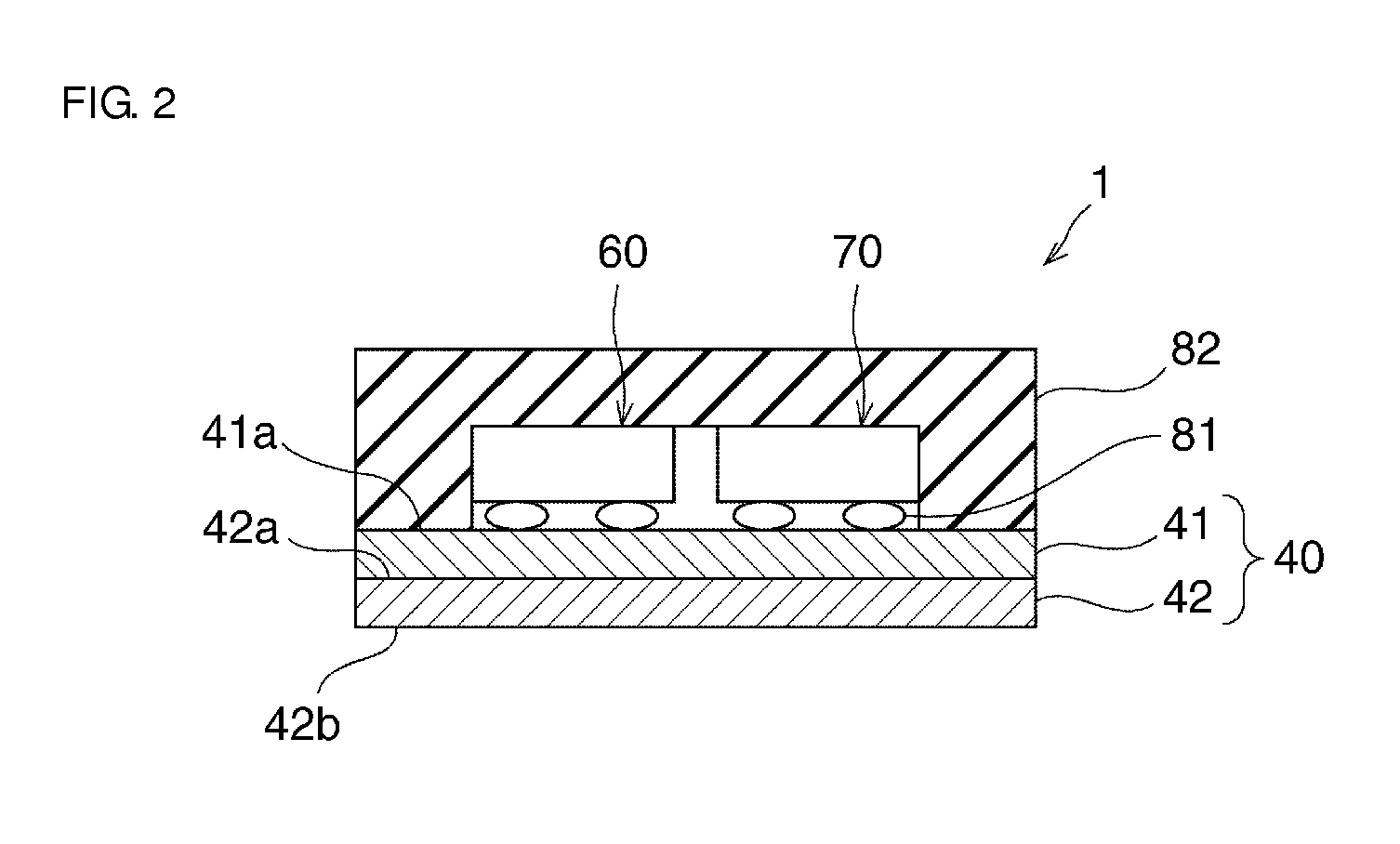

Elastic wave device

ActiveUS20140176258A1Reduce in sizeReduce insertion lossMultiple-port networksPiezoelectric/electrostrictive/magnetostrictive devicesReduced sizeVIT signals

An elastic wave device includes elastic wave filters connected in parallel between an input and an output, and has reduced size and insertion loss, and improved electric power handling capability. An elastic wave filter chip is mounted on a die-attach surface of a wiring board and includes an input signal terminal and output signal terminals. At least one of the input and output signal terminals includes a plurality of signal terminals. A common connection wiring line to commonly connect the plurality of signal terminals of the elastic wave filter chip is provided in the wiring board.

Owner:MURATA MFG CO LTD

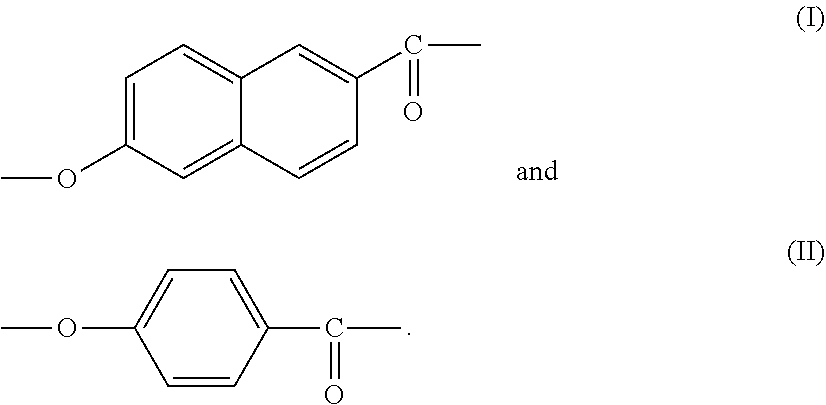

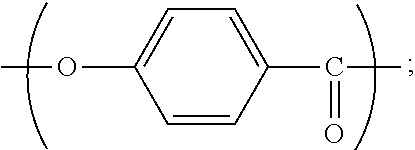

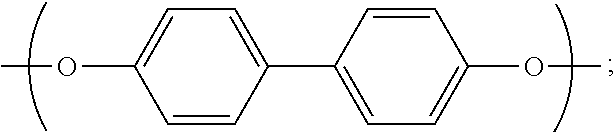

Liquid crystal polymer film and laminate comprising the same

PendingUS20210187884A1Enhance dielectric propertyReduce insertion lossLiquid crystal compositionsInsulating substrate metal adhesion improvementThin membraneStructural unit

Provided are an LCP film and a laminate comprising the same. The LCP film is made of an LCP resin comprising a structural unit represented by Formula (1): -L1-Ar-L2- (1), wherein -L1- and -L2- are respectively —O— or —CO—; —Ar— is an arylene group. Formula (1) comprises structural unitsBased on a total molar number of the structural unit represented by Formula (1), a molar number of the structural unit represented by Formula (I) is in the range from 15 mole % to 40 mole %, and a sum of molar numbers of the structural units represented by Formulae (I) and (II) is in the range from 80 mole % to 100 mole %. The LCP film has a thickness and a transmittance, wherein when values of the thickness (in μm) and the transmittance are put into Formula (III), the obtained value is from 0.055 to 0.090. Formula (III): Log(1 / TT %) / (Thickness)0.5.

Owner:CHANG CHUN PLASTICS

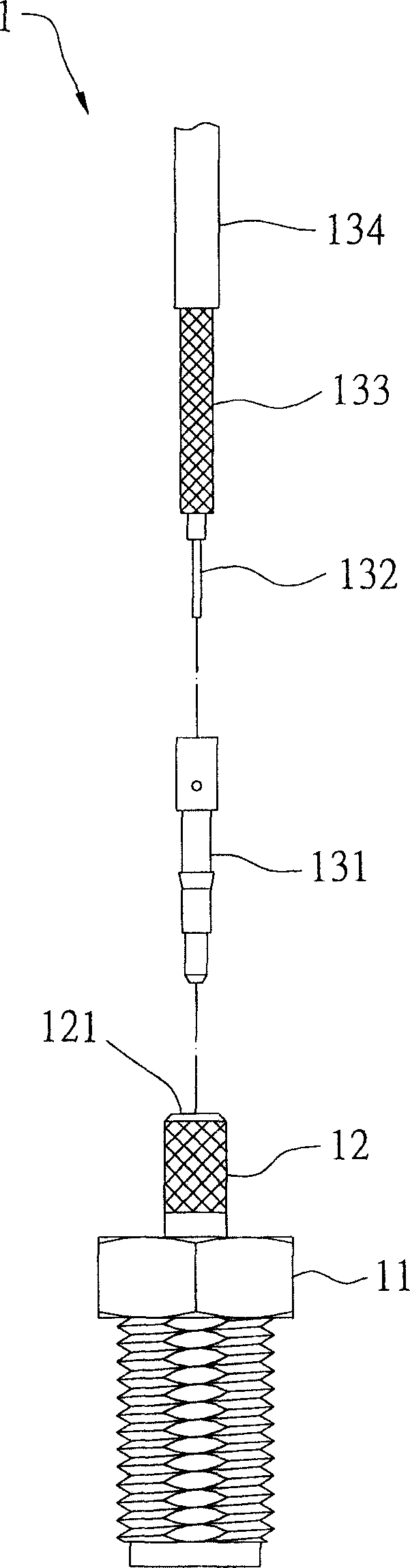

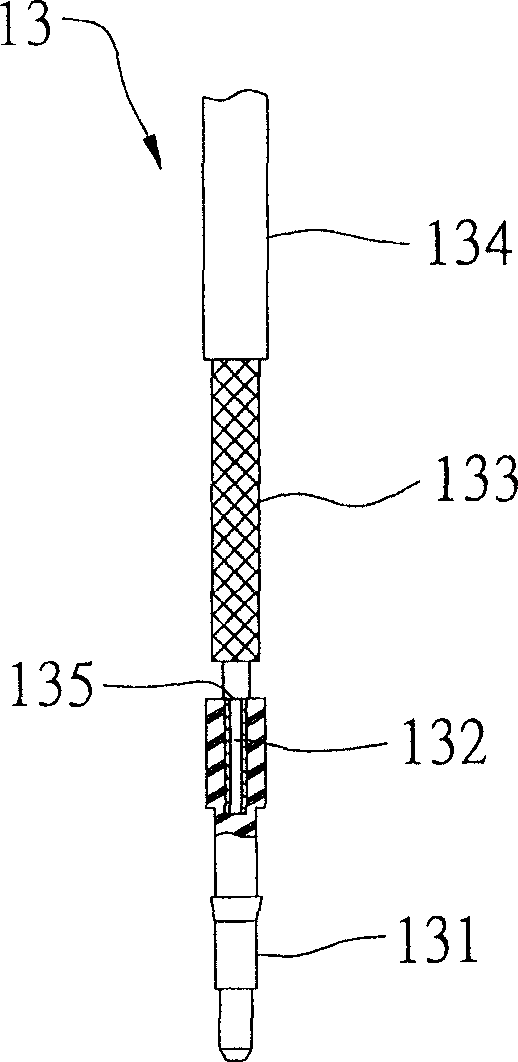

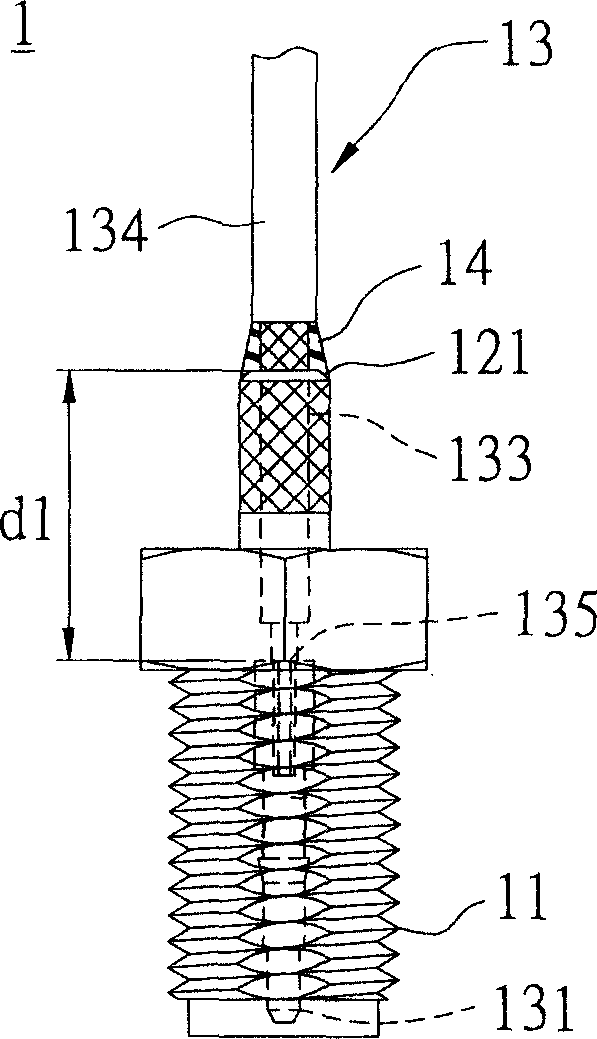

Antenna connector structure and its manufacturing process

InactiveCN1764025AExcellent electrical propertiesSave spaceContact member assembly/disassemblyTwo-part coupling devicesTin platingNetworking cables

The structure of an antenna adapter comprises: a main body with an embedded insulation material, a pin inserted in the insulation material, a cable with core wire welded with one pin end and screen wire both decorticating and tin plating, a shaft with base in top of main body, pole with said screen wire, and shaft hole crossed by said cable. The manufacture technique comprises: inserting the pin into insulation material, welding the shaft with cable, and assembling in main body end to compress the pole and screen wire together by clamp tool.

Owner:皓腾工业股份有限公司

A conductive contact piece and an electrical connector using the conductive contact piece

ActiveCN105977678BAvoid stub radiation effectReduce insertion lossCoupling contact membersElectricityElectrical connector

The present invention provides an electric conduction contact component and an electric connector using the same. The electric conduction contact component comprises a base body which extends flatly and straightly; the front end of the base body is connected with a first connecting section which is arranged in an upwards tilting manner through a first bent section; the front end of the first connecting section is connected with a contact section through a second bent section; the contact section is provided with a front contact portion which is in electric conduction contact with a matched electric conduction contact component; the lower side surface of the first connecting section is provided with a rear contact point which is in electric conduction contact with the front contact portion of the matched electric conduction contact component; and the front contact portion and space at the upper side and lower side of the base body form an insertion space into which the matched electric conduction contact component can be inserted. The electric conduction contact component provided by the invention is simple in structure. With the electric conduction contact component adopted, multi-point contact can be realized, the radiation effect of a short pile can be eliminated, and insertion loss can be decreased.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Switch module

ActiveUS20210159887A1Exclude influencePrevent signal leakageMultiple-port networksMulti-band filtersCapacitanceSoftware engineering

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

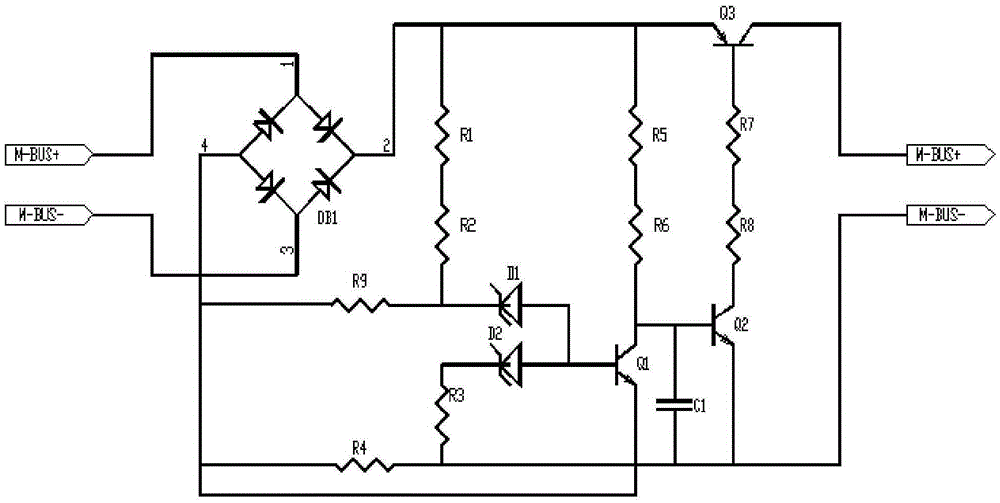

M-Bus protector with self-recovery function

InactiveCN105322500AReduce insertion lossDoes not affect loading capacityArrangements responsive to excess currentElectric digital data processingOvervoltageCurrent limiting

An M-Bus protector with a self-recovery function is disclosed. The M-Bus protector comprises a switch tube formed by a first switch triode, a second switch triode and a third switch triode that are cascaded in sequence, and a direct current power supply and an inversion bleeder circuit of the switch circuit; the base electrode of the first switch triode is connected with an overvoltage threshold valve generating circuit and an overcurrent threshold value generating circuit separately; the emitting electrode of the second switch triode is connected with a connection negative end of meters (such as an intelligent water meter, a gas meter or a calorimeter) and the other end of a delay capacitor; a current-limiting biasing resistor is connected between the collector electrode of the second switch triode and the base electrode of the third switch triode; the emitting electrode of the third switch triode is connected with the positive end of the direct current power supply, and is connected with a centralized meter reading device through the direct current power supply; and the collector electrode of the third switch triode is connected with the connection positive end of the meters. The M-Bus protector can automatically recover to work after faults are eliminated; the M-Bus protector is stable, reliable, and high in practicability; the overall circuit is extremely low in insertion loss and the load capacity of the bus is not affected; and the output voltage is always zero in overvoltage protection, overcurrent protection and short circuit protection, so that the dead zone voltage and the potential safety hazards of fire do not exist.

Owner:SHENZHEN JASON DIGITAL TECH CO LTD

Switch module

ActiveUS10944382B2Exclude influencePrevent signal leakageMultiple-port networksMulti-band filtersCapacitanceSoftware engineering

A switch module includes a first terminal, first and second filters, and first and second switches. Impedance of the first filter for a signal in a stop band is capacitive. When the first switch is turned OFF, impedance of the first switch is capacitive, and impedance of the first filter seen from an end portion of the first switch connected to the first filter is not in a short state and impedance of the first filter seen from the first terminal is in an open state.

Owner:MURATA MFG CO LTD

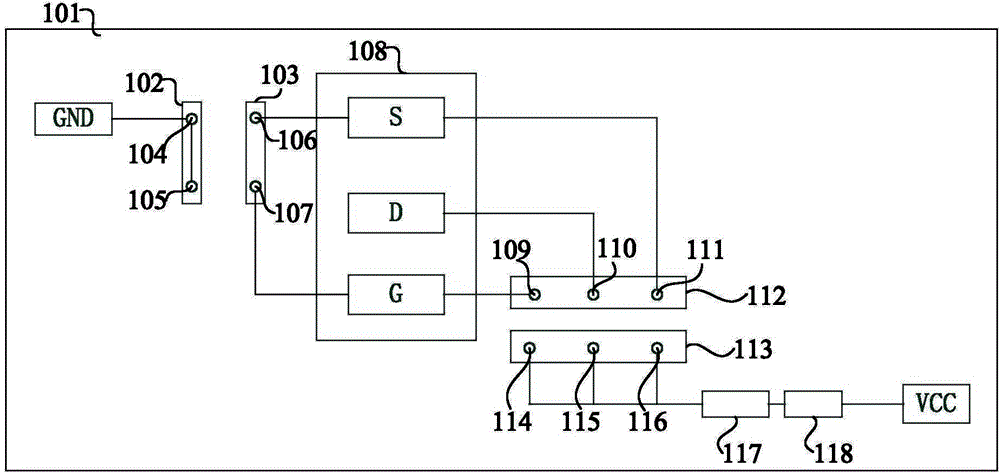

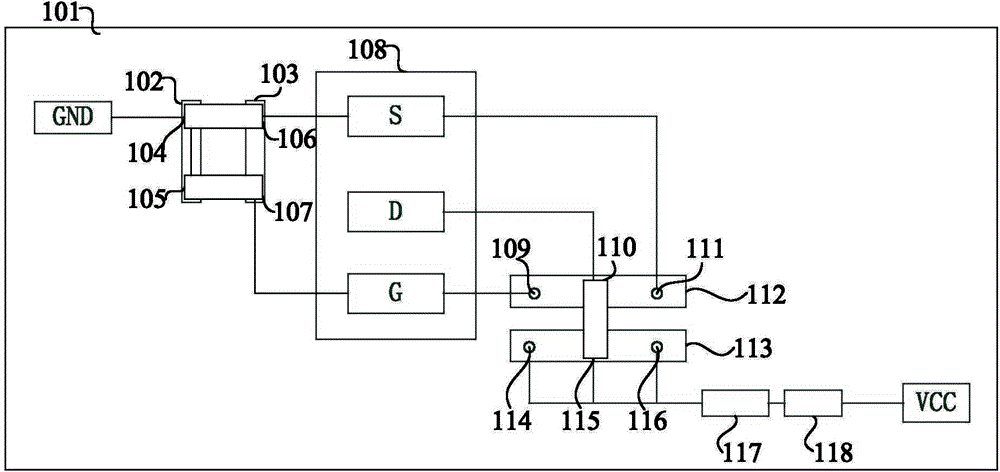

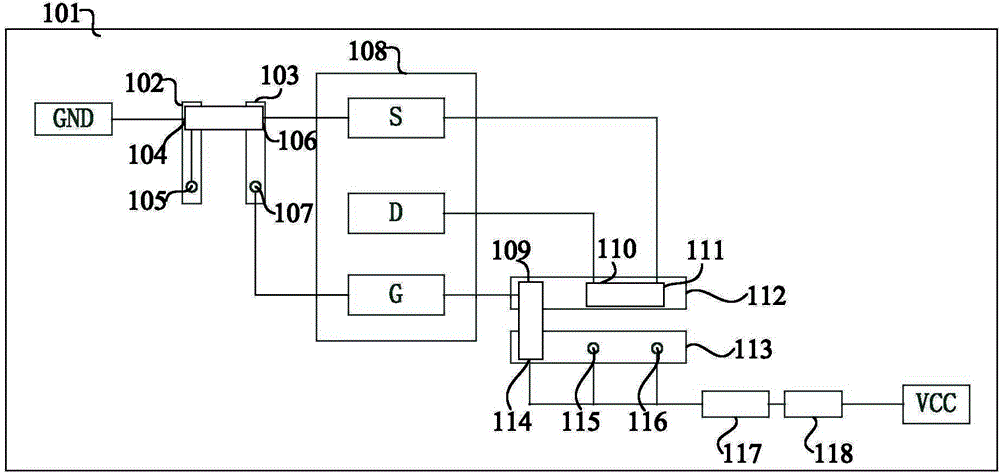

Burn-in board

ActiveCN105242077AImprove versatilityReduce insertion lossElectrical testingMeasurement instrument housingSemiconductor chipEngineering

The embodiment of the invention relates to the technical field of semiconductor chip quality reliability, and especially relates to a burn-in board which is simple to operate and highly universal. According to the embodiment of the invention, a first pin and a second pin on a first pin header are communicated, and the first pin or the second pin is grounded; a first pin on a second pin header is communicated with a port S, and a second pin is communicated with a port G; a first pin, a second pin and a third pin on a third pin header are respectively communicated with the port G, a port D and the port S; and a first pin, a second pin and a third pin on a fourth pin header are communicated with VCC. Any of the port S, the port D and the port G can be grounded or connected to a power source by plugging a short-circuit cap onto the pin headers, so that a variety of experiments can be conducted by changing the plugging of the short-circuit cap, and the universality of the burn-in board is further improved.

Owner:FOUNDER MICROELECTRONICS INT

Conductive contact and electrical connector using the same

ActiveCN106654751BAvoid stub radiation effectReduce insertion lossSecuring/insulating coupling contact membersCoupling contact membersElectrical connectorRadiation effect

The present invention provides a conductive contact component and an electrical connector using the same. The conductive contact component comprises a base body; the front end of the base body is connected with a first connection segment disposed obliquely and upwardly through a first bent segment; the front end of the first connection segment is connected with a contact segment through a second bent segment; the contact segment is provided with a front contact portion which conductively contacts with a matching conductive contact; the lower side surface of the base body is provided with a rear contact portion which conductively contacts with the front contact portion of the matching conductive contact; and the front contact portion and the rear contact portion form a plugging space in a vertical direction, and the matching conductive contact can be plugged into the plugging space. The plugging space is provided for the matching conductive contact in a manner as the above mentioned, so that a guiding structure which is used for avoiding abutting against the end portion of the conductive contact component is not required, thus, a short-pile radiation effect is avoided, and insertion loss is reduced.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

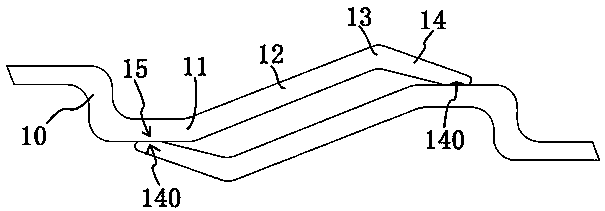

Elastic wave apparatus

An elastic wave apparatus includes a multilayer substrate, first through fourth band pass filters, an antenna terminal, and first and second inductors. The multilayer substrate includes first through sixth wiring layers. The first through fourth band pass filters are disposed on the multilayer substrate and are connected to a common node. The antenna terminal is connected to an antenna and also to the common node. The first inductor is connected to the antenna terminal. The second inductor is connected between the first band pass filter and the common node. The first inductor is disposed on the fourth and fifth wiring layers. The second inductor is disposed on the second and third wiring layers which are different from the fourth and fifth wiring layers. The first and second inductors overlap each other at least partially as viewed from above.

Owner:MURATA MFG CO LTD

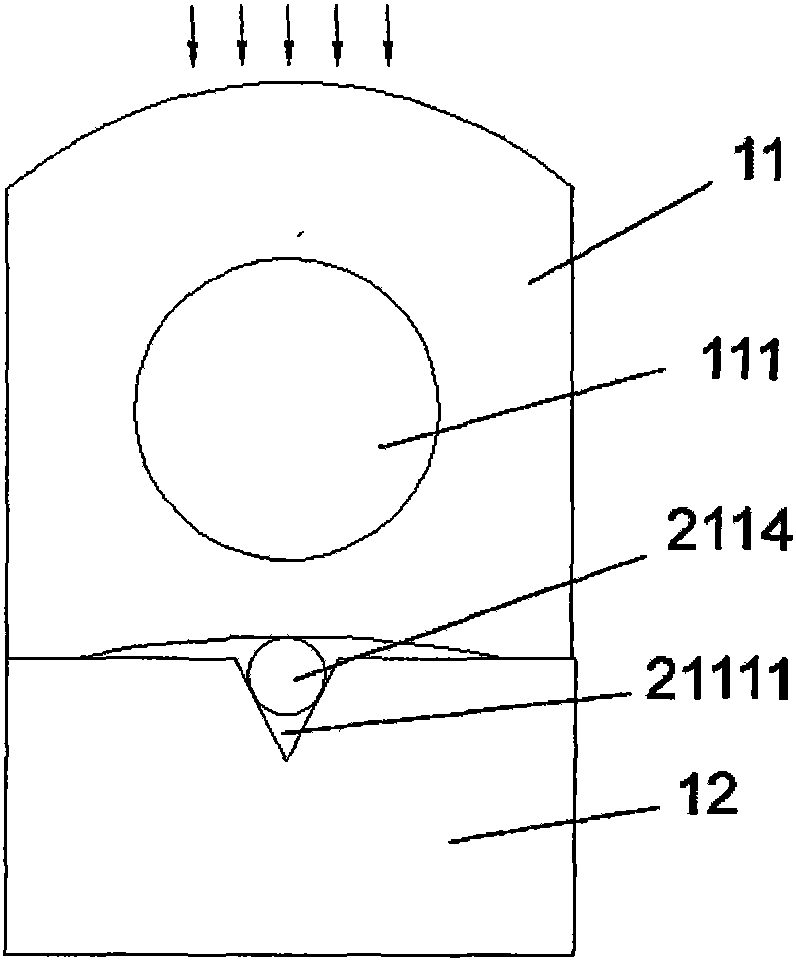

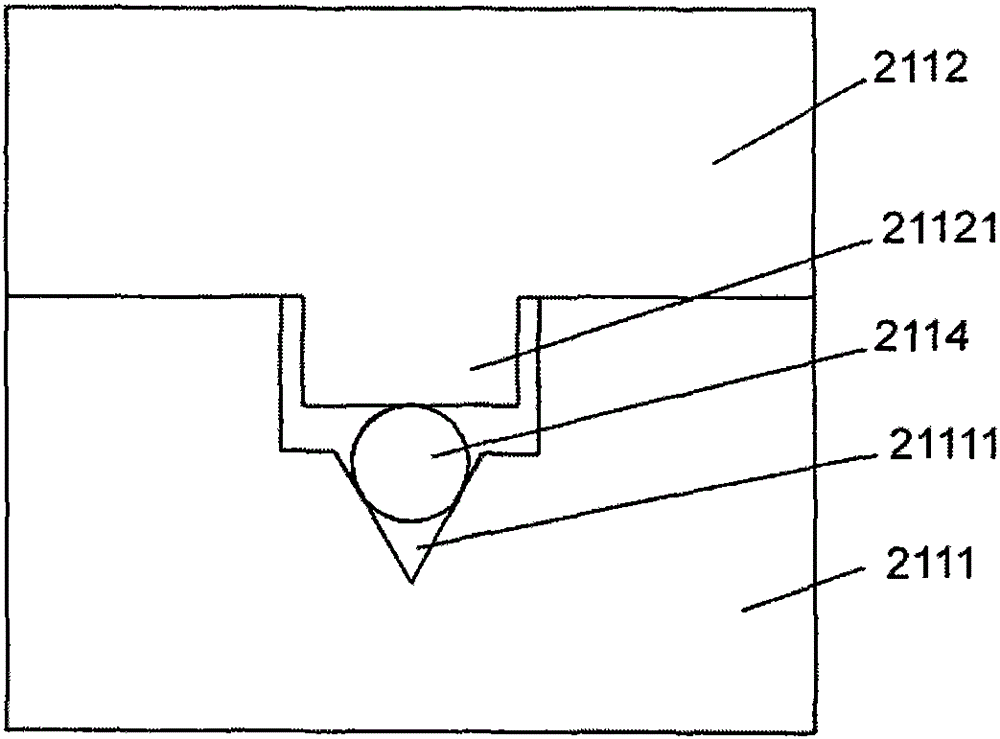

A kind of mechanical compression device and optical fiber connector

ActiveCN103676013BPrevent overpressureHigh dimensional accuracyCoupling light guidesFiberOptical fiber connector

The invention discloses a mechanical pressing device of an optical-fiber connector and an optical-fiber connector which is provided with the mechanical pressing device. The mechanical pressing device of the optical-fiber connector includes a V-groove substrate. The V-groove substrate is provided with a V-shaped groove used for burying an optical-fiber insert core, a V-groove press block, a fixed sleeve and a sliding pressing sleeve. The V-groove substrate and the V-groove press block are arranged in a cavity of the fixed sleeve. The sliding pressing sleeve is sleeved outside the fixed sleeve. The mechanical pressing device is characterized in that the V-groove substrate cooperates with the V-groove press block through a groove; a boss is in cooperation with the groove; the V-shaped groove is arranged on the boss or in the groove; and when the V-groove substrate and the V-groove press block contact, the boss or the groove contacts the optical-fiber insert core. Even if the V-groove substrate and the V-groove press block are subjected to extrusion, faces which bear the force first are step faces of the V-groove substrate and the V-groove press block so that a problem that the optical-fiber insert core in the V-shaped groove is overly pressed is prevented.

Owner:SHENZHEN ZHAOWEI MACHINERY&ELECTRONICS CO LTD

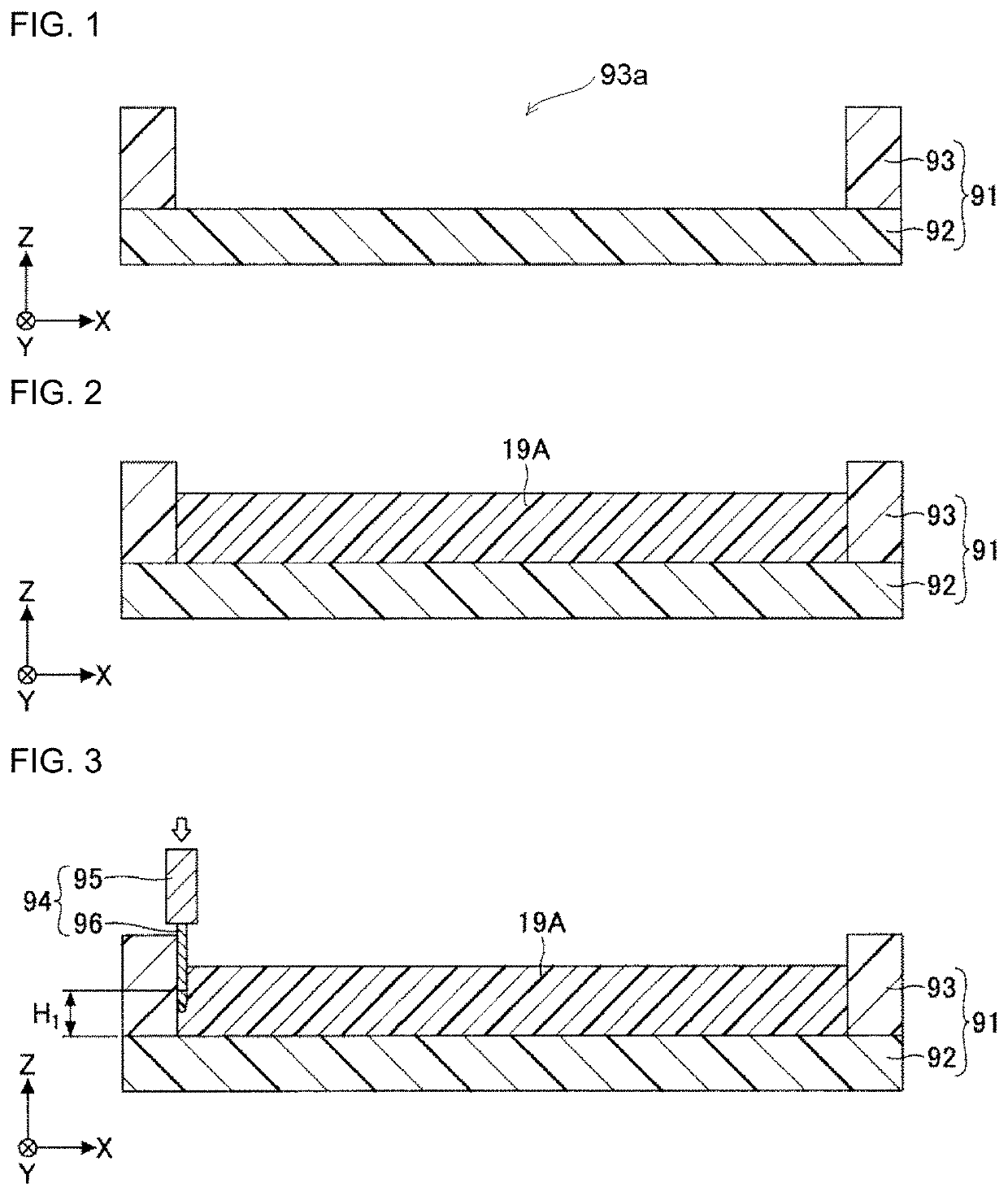

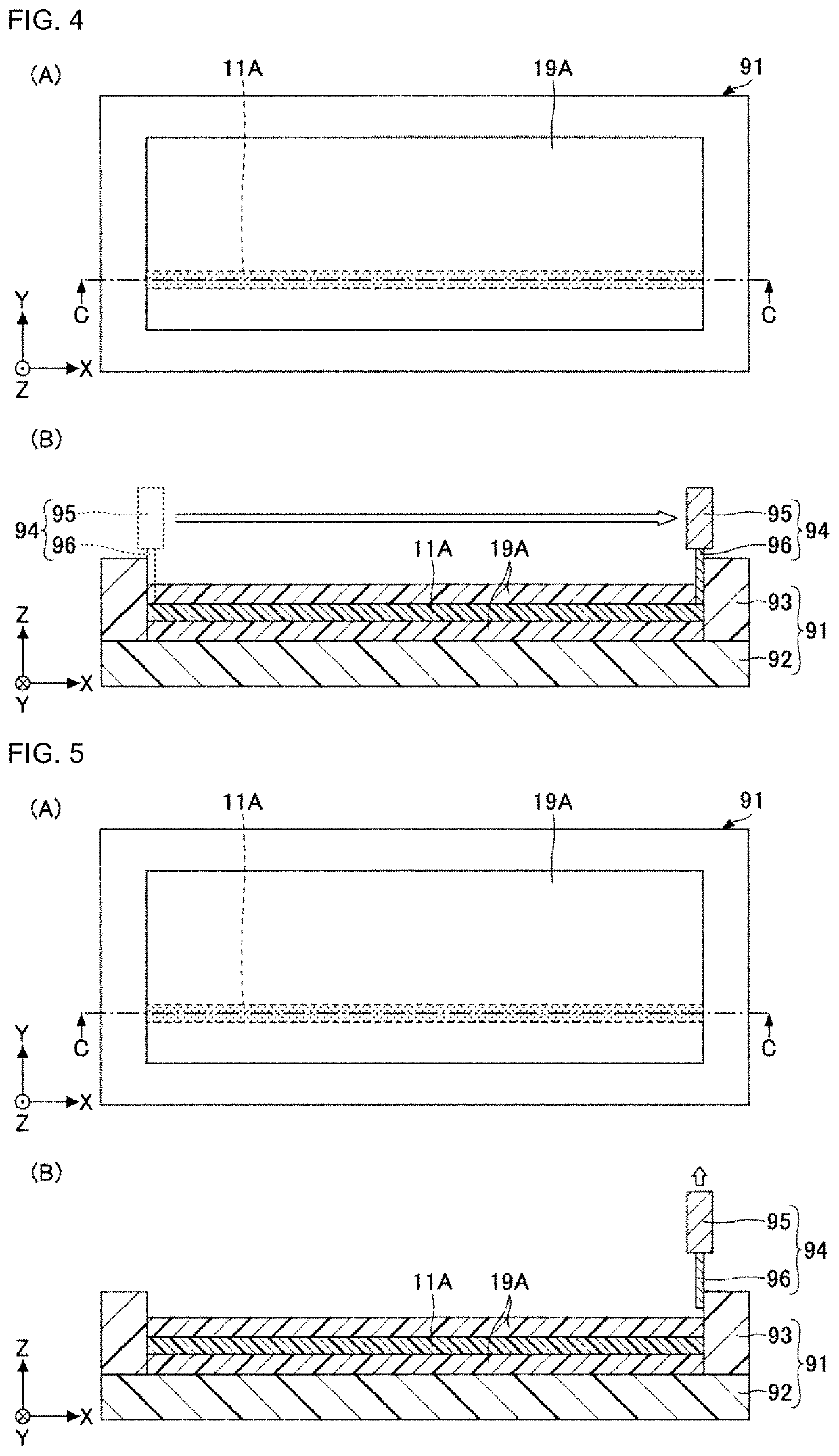

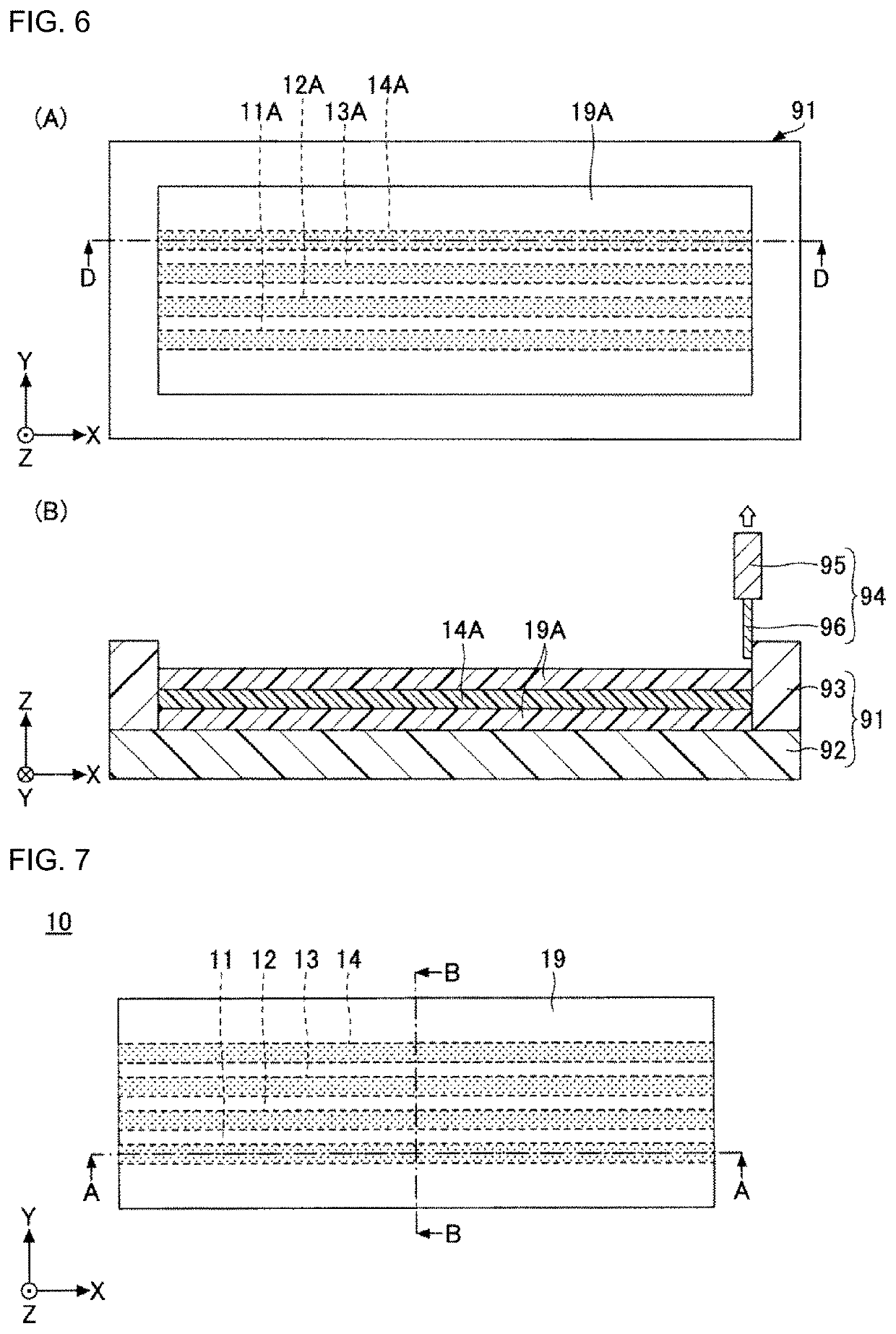

Method for manufacturing gi optical waveguide

PendingUS20200001557A1Reduce insertion lossReduced insertion lossCladded optical fibreOptical articlesComposite materialWaveguide

A GI optical waveguide includes a core having a substantially circular cross-sectional shape. A method for manufacturing an optical waveguide, includes a first step of inserting an acicular section at the tip of a discharge unit into an uncured cladding; a second step of moving the acicular section within the uncured cladding while discharging an uncured material from the acicular section, to thereby form an uncured core surrounded by the uncured cladding; a third step of removing the acicular section from the uncured cladding; and a fourth step of curing the uncured cladding and the uncured core, wherein: the ratio of the viscosity of the material for forming the uncured core to the viscosity of the uncured cladding is 1.20 to 6 at the temperature in the second step.

Owner:KEIO UNIV +1

A conductive contact piece and an electrical connector

ActiveCN105958247BAvoid damageElimination of stub radiation effectCoupling contact membersElectrical connectorPoint contact

The invention provides a conductive contact and an electric connector, wherein the conductive contact comprises a base body, the front end of the base body is connected with an upward sloping first connecting section through a first bending section, the front end of the first connecting section is connected with a contact section through a second bending section, a front contact part is arranged on the contact section, a front contact point which is used for contacting with an adaptive conductive contact is arranged on the front contact part, the lower side of the first connecting section comprises a rear contact point which is used for contacting with the adaptive conductive contact, an insertion space which is used for being inserted by the adaptive conductive contact is arranged between the front contact point and the base body in up-down direction, and an insertion guide surface which avoids abutting between the conductive contact and the adaptive conductive contact in insertion is arranged on the front side of the front contact point on the front contact part. According to the invention, the structure of the conductive contact is improved, so that the overhang structure of the front side of the conductive contact point and the short pile irradiation effect are eliminated, the conductive connection is realized through two-point contact, and the insertion loss is low.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

E-plane to H-plane waveguide probe transition structure

InactiveCN110828955AGood high-end transfer performanceReduce insertion lossCoupling devicesCoaxial probeEngineering

The invention relates to an E-plane to H-plane waveguide probe transition structure, and belongs to the field of millimeter wave band communication system design. The structure comprises an E-plane waveguide, a first transition waveguide, an H-plane waveguide, a second transition waveguide, a probe and a shifting bead. The first transition waveguide is horizontally arranged. The E-plane waveguide1 is horizontally arranged at the center of the side surface of one end of the first transition waveguide. The H-plane waveguide is vertically arranged at the center of the side surface of the other end of the first transition waveguide. The second transition waveguide is in butt joint with the output end of the H-plane waveguide. The probe is arranged on the outer side wall of the second transition waveguide, and the probe axially extends into the side wall of the second transition waveguide. The shifting bead sleeves the outer wall of the end, extending out of the second transition waveguide, of the probe. Mutual conversion between an E plane and an H plane is realized, and transition design of the turning waveguide and the waveguide to the coaxial probe is completed at the same time.

Owner:BEIJING RES INST OF TELEMETRY +1

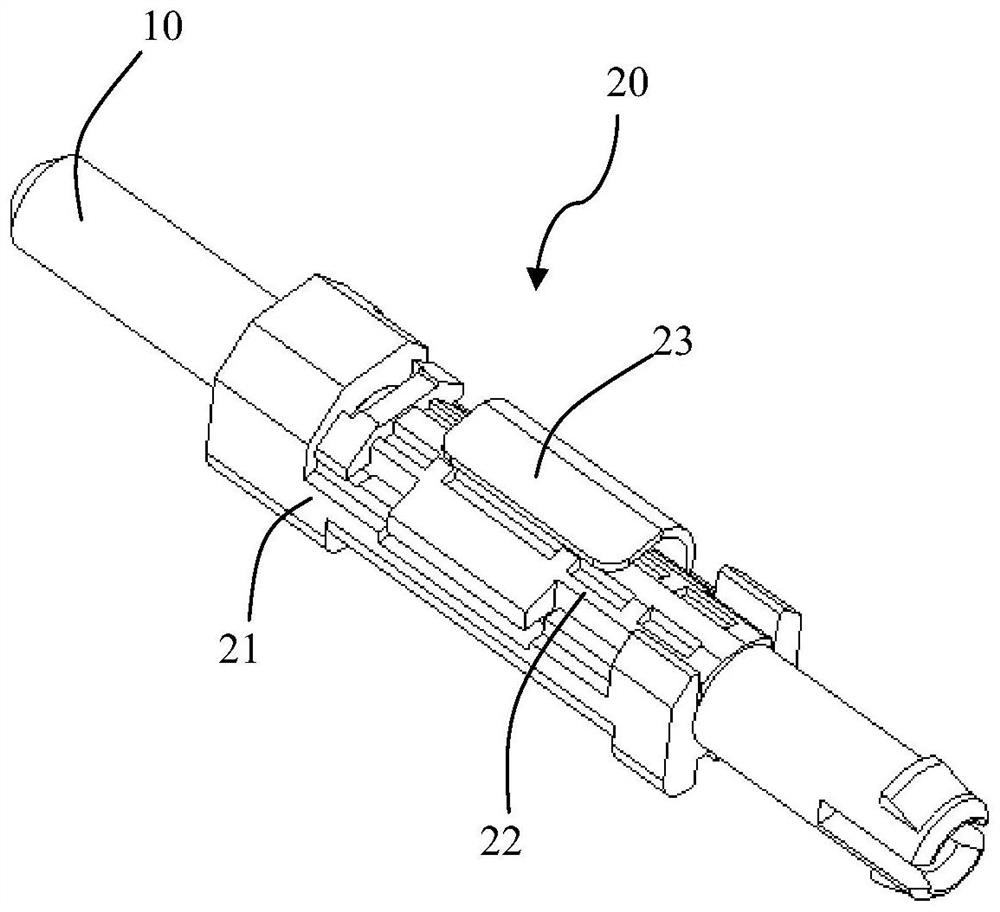

Matching paste-free on-site optical fiber quick connector and connection method

InactiveCN113126213AReduce insertion lossReduce return lossCoupling light guidesEngineeringLight signal

The invention relates to a matching paste-free on-site optical fiber quick connector and a connection method. An optical fiber joint piece and an insertion core assembly pre-embedded in the optical fiber joint piece are connected with an on-site rubber-covered wire optical cable, and a first optical fiber of the insertion core assembly has an end face subjected to surface pretreatment. The connection method comprises the following steps of: S1, carrying out surface pretreatment on the end surface of the first optical fiber of the insertion core assembly, and then pre-embedding the first optical fiber in the first end of the optical fiber connector; and / or S2, performing surface treatment on the end face of a second optical fiber of the rubber-covered wire optical cable on site, and then guiding the second end of the optical fiber joint piece to be butted with the first optical fiber of the insertion core assembly. According to the matching paste-free on-site optical fiber quick connector and the connection method, the pre-embedded optical fiber and the on-site optical fiber can be in butt joint for optical signal transmission under the condition of no matching paste, and the purpose of completing optical fiber cold connection without the optical fiber matching paste is achieved.

Owner:深圳市熠坤光电有限公司 +1

A kind of pendant methylpolyphenyl liquid crystal compound and liquid crystal composition and its application

ActiveCN110760311BLow melting pointLower eutectic pointLiquid crystal compositionsWaveguide type devicesCrystallographyPhysical chemistry

The invention discloses a pendant methyl polybiphenyl liquid crystal compound, a liquid crystal composition and applications thereof. The structure of the liquid crystal compound is shown in formula I; wherein, n is an integer of 1-7; X 1 -X 4 Each independently selected from H atom, F atom or Cl atom; k is 0 or 1; Y is NCS, F atom or R group; R is selected from straight chain alkyl containing 1-6 carbons, alkenyl-containing One of straight-chain alkyl groups with 1-6 carbons and straight-chain alkyl groups with 1-6 carbons substituted by 1-2 fluorine atoms or 1 methyl group on the H atom in the alkyl chain. The technical scheme of the present invention mixes and prepares the liquid crystal composition material with the value of Δn greater than 0.35, which improves the microwave phase modulation amount and reduces the microwave frequency insertion loss amount.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Non-reciprocal device

InactiveUS20050134397A1Reduce insertion lossBroad frequency bandWaveguide type devicesComputational physicsFrequency band

The present invention is directed to a non-reciprocal device whose use makes it possible to reduce the insertion loss, and the size and thickness of its body, and broaden the frequency band treated by it. The DC magnetic field is adjusted such that, in a Smith chart where the center O1 represents the normalized impedance, the impedance of the gyromagnetic component 2 is positioned at a value which is on a constant conductance circle smaller than the reference constant conductance circle EC0 passing the center O1 and which is on a constant reactance line above the reference constant reactance line EX0 passing the center O1. Inductor L11 or L12 has one end connected to a terminal of the center conductor such that in the Smith chart, the impedance of the gyromagnetic component 2 seen from the other end of the inductor L11 or L12 is positioned at a value which is on the reference constant conductance circle EC0 passing the center O1. First capacitor C21 or C22 is connected, in parallel with the center conductor, to the other end of the inductor L11 or L12 such that in the Smith chart, the impedance of the gyromagnetic component 2 seen through the inductor from the connection point of the first capacitor is positioned at a value which is on the center O1.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com