Antenna connector structure and its manufacturing process

An antenna connector and manufacturing process technology, applied in connection, two-part connection device, assembly/disassembly of contacts, etc., can solve problems such as insufficient structural strength, high insertion loss, inability to withstand tensile and torsional damage tests, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to further understand the features and technical content of the present invention, please refer to the following detailed description of the present invention and the accompanying drawings.

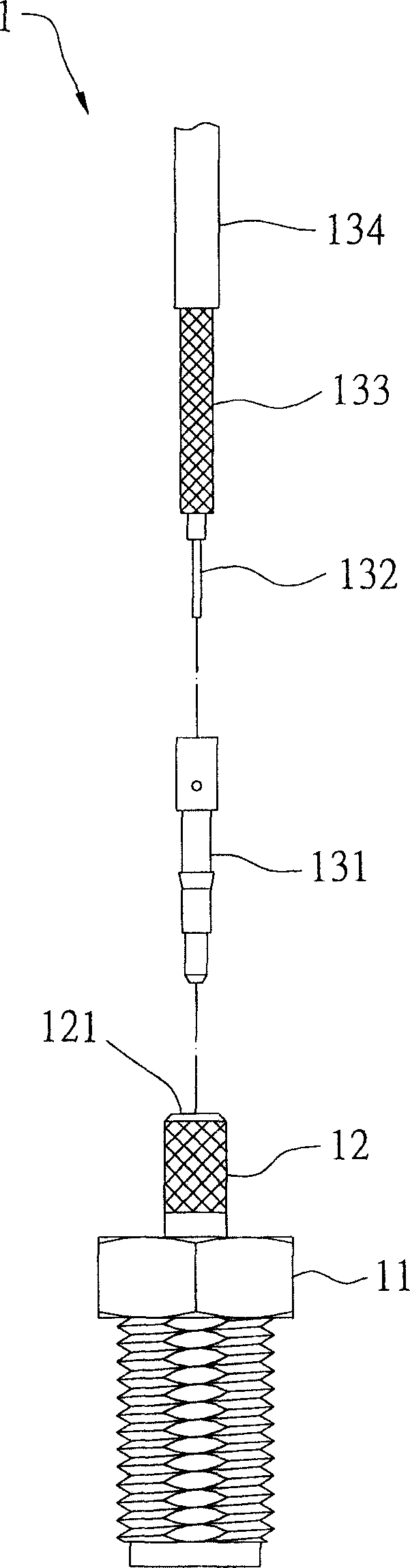

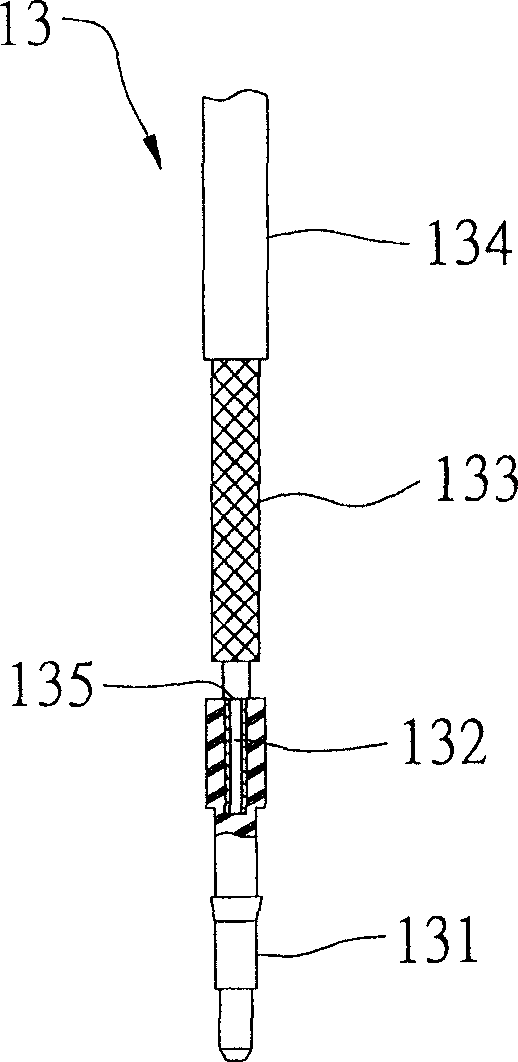

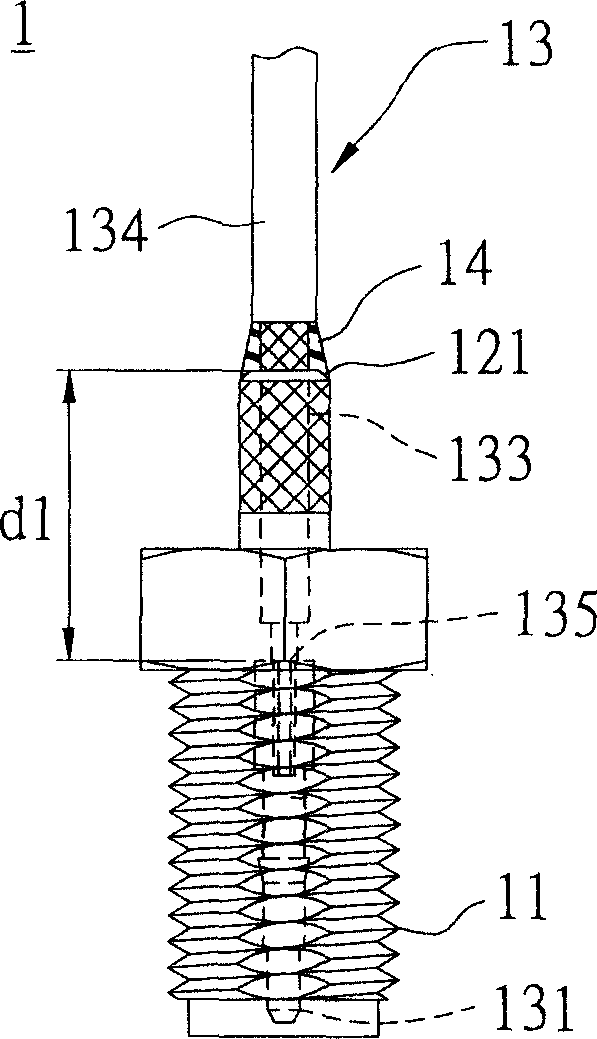

[0074] see Figure 6 , 8 , As shown in Figure 9, the present invention provides a structure and manufacturing process of an antenna connector. The structure of the antenna connector includes: a main body 3, an insulating material 4, a pin 5, a connecting shaft 6, and a cable7.

[0075] Wherein, one end shaft of the pin 5 is provided with an insertion hole 53, and the end and the roughly middle section of the pin 5 are respectively provided with first and second interference parts 51, 52, and the first interference part 51 is embossed. Handling to prevent the pin 5 from rotating, the second interference part 52 is a round barb for the car to prevent the pin 5 from retreating; the center of the insulating material 4 has a center hole opposite to the pin 5 for insertion, A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com