Electric conduction contact component and electric connector using same

A conductive contact and electrical connector technology, applied in the field of conductive contacts and electrical connectors using the conductive contacts, can solve problems such as large insertion loss, reduce space, ensure conductive contact, and avoid short pile radiation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

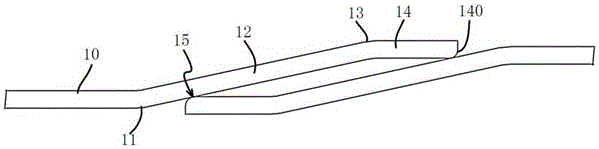

[0023] Embodiment 1 of the electrical connector of the present invention includes a connector housing and a conductive contact piece disposed in the connector housing.

[0024] The electrical connector of the present invention realizes the conductive connection through the conductive contact between the conductive contact and the matching conductive contact in the matching electrical connector, wherein the matching conductive contact has the same structure as the conductive contact, and the difference is that the matching conductive The contact piece is opposite to the installation direction of the conductive connection piece in the vertical direction, and only the structure of the conductive contact piece will be described in detail below.

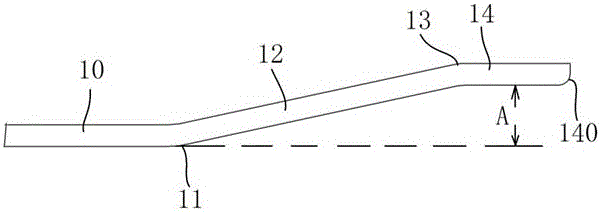

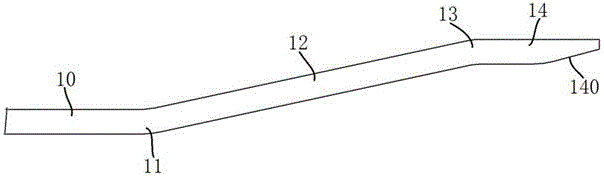

[0025] The structure of the conductive contact is as Figure 1-2 As shown, it includes a base body 10 extending straight. The front section of the base body 10 is connected to a first connecting section 12 through a first bending section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com