Matching paste-free on-site optical fiber quick connector and connection method

A fast connection and connector technology, applied in the directions of light guides, optics, instruments, etc., can solve the problems of easy failure and unstable performance, and achieve the effect of reducing insertion loss and return loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the present application, the present application will be described in further detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the present application and is not intended to limit the present application. Also, in the case of an incapable, the features of the embodiments and embodiments in the present application can be combined with each other.

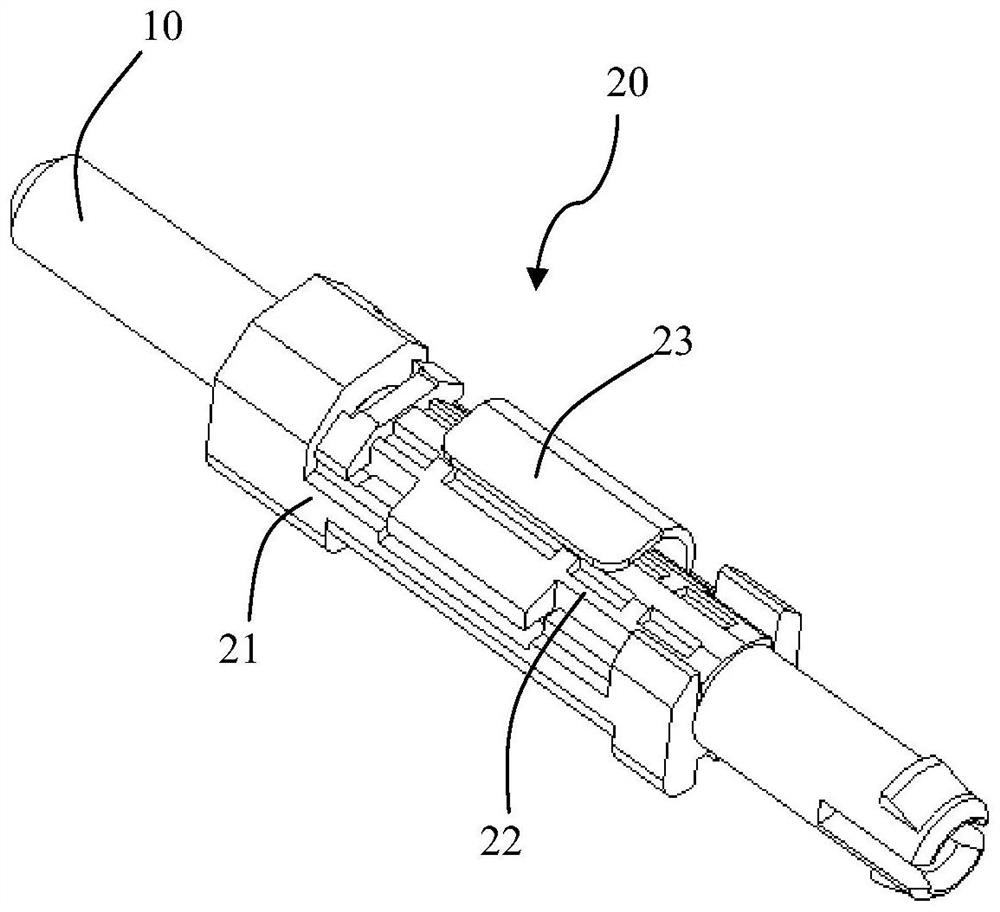

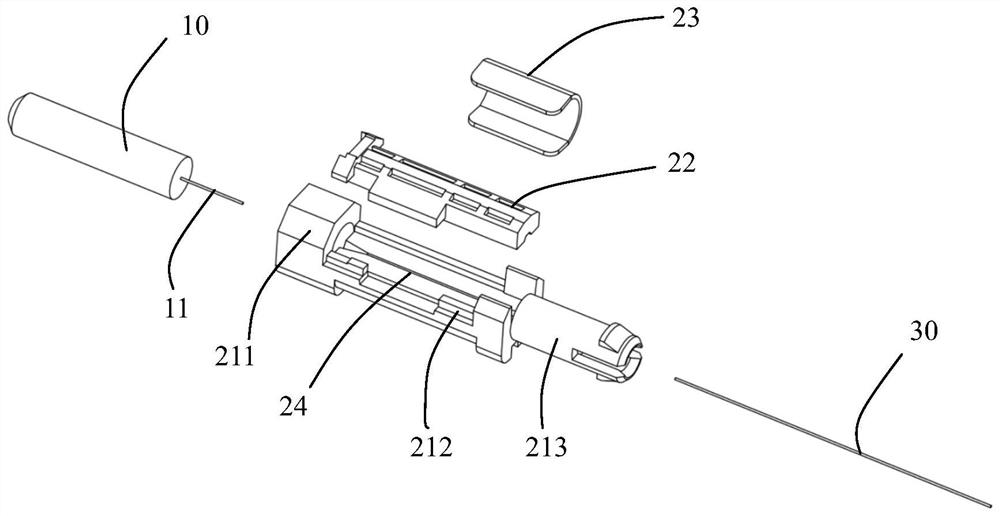

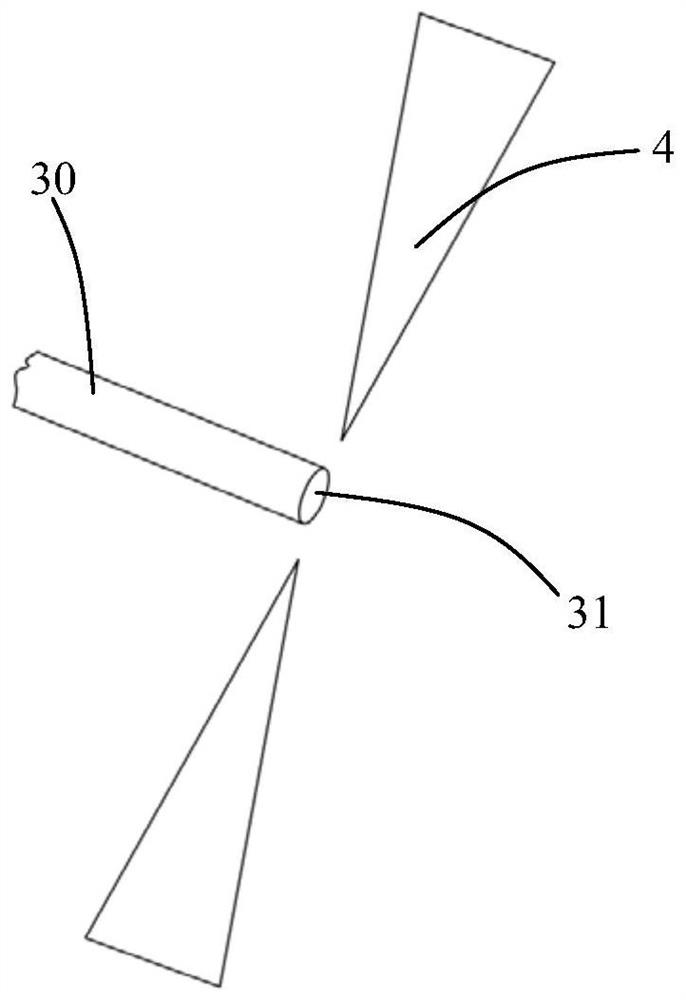

[0020] In one embodiment, a field fiber optic rapid connector that is excavatized from the cream is proposed in one embodiment. figure 1 with figure 2 As shown, including the fiber bond member 20 and the ferrule assembly 10 that is embedded therein. Among them, the fiber optic joint 20 specifically includes a joining body 21, a V groove cover 22, and a mechanical lock member 23. The joining body 21 has a first end 211, a second end 213, and a V groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com