Burn-in board

A technology for burn-in boards and substrates, applied in instruments, measuring devices, measuring electronics, etc., can solve problems such as loss of accessories, long time-consuming plugging and unplugging processes, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

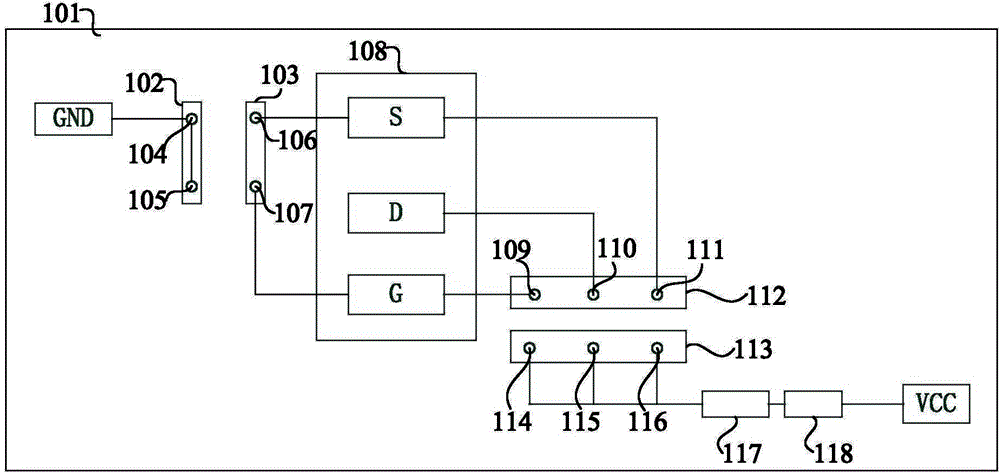

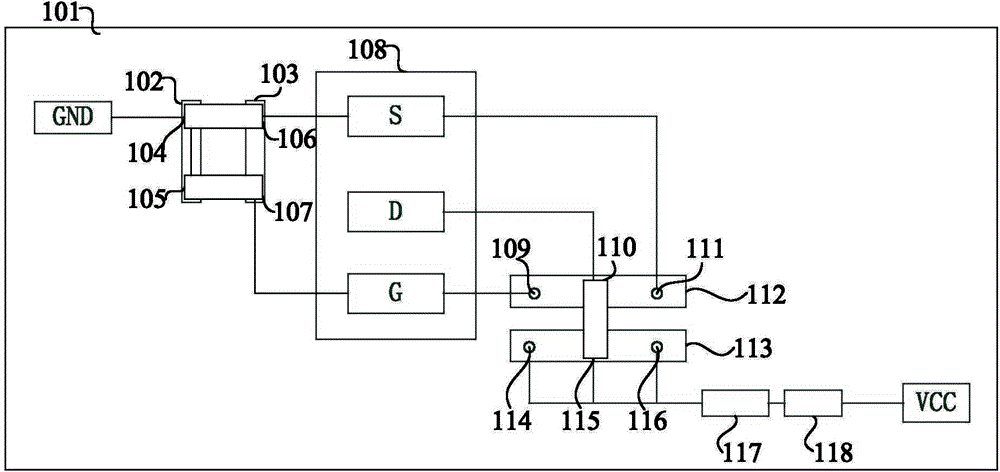

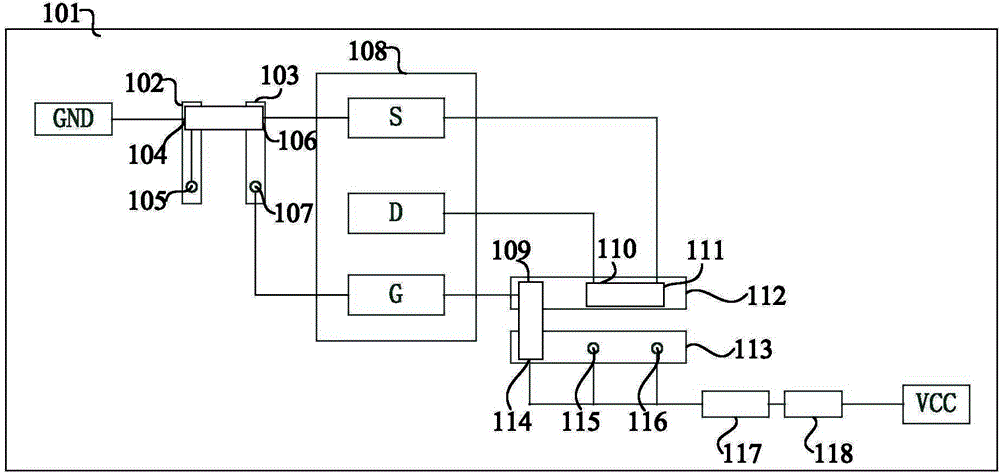

[0025] The burn-in board provided by the embodiment of the present invention includes: a substrate, on which a socket for plugging in a device under test and a first to fourth row of pins are provided. The socket includes a source S port, a drain D port, and a gate. G port; the first pin and the second pin on the first row of pins are connected, and the first pin or the second pin is grounded; the first pin on the second row of pins is connected to the S port, and the second pin is connected to the G port; third The first pin to the third pin on the pin header are respectively connected to the G port, the D port and the S port; the first pin to the third pin on the fourth pin are all connected to VCC; the first pin and the second pin of the first pin The stitches are respectively opposite to the first stitch and the second stitch of the second row of needles, and the first to third pins of the third row of needles are respectively opposite to the first to third stitches of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com