A kind of mechanical compression device and optical fiber connector

A technology of optical fiber connector and pressing device, which is applied in the field of optical communication, can solve the problems of optical fiber glue fragmentation, etc., achieve the effect of providing smoothness, improving the yield rate, and reducing the insertion loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

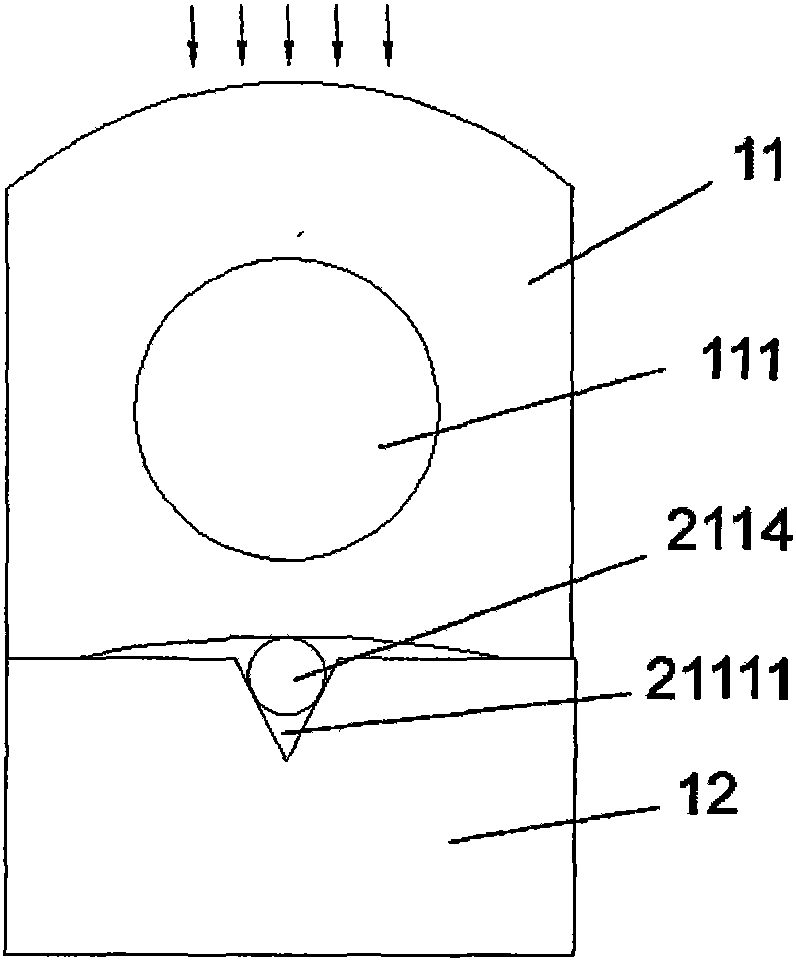

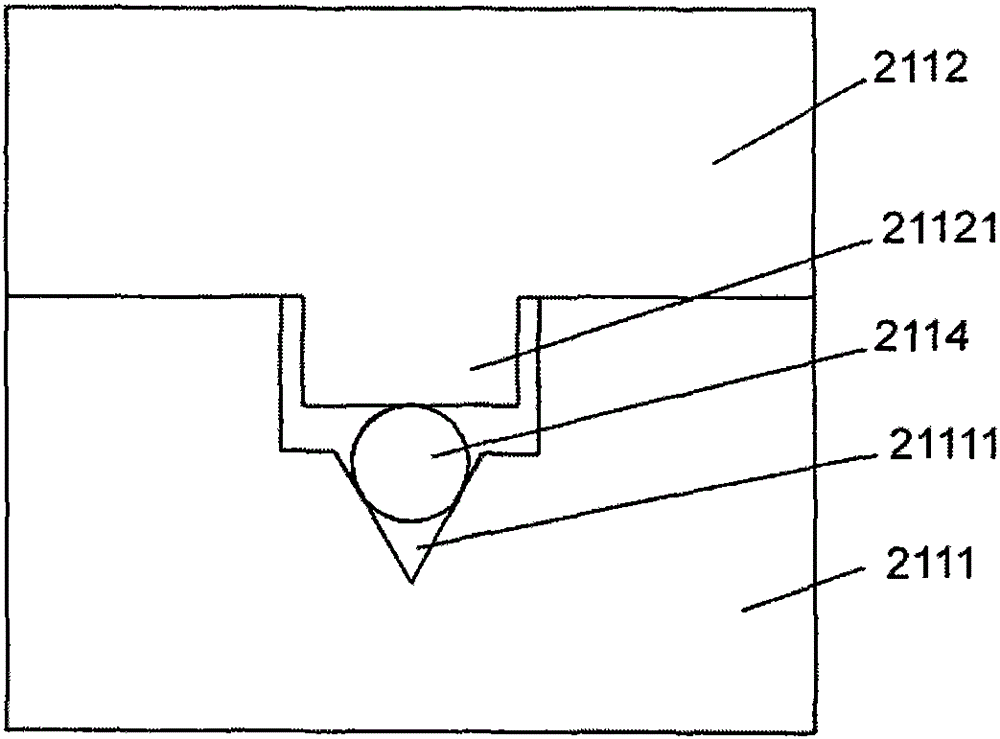

[0035] The invention provides a mechanical pressing device of an optical fiber connector and an optical fiber connector with the mechanical pressing device. like Figure 2-3 As shown, the optical fiber connector 20 includes a main body 21 of a hollow structure and a jacket 22 arranged on the periphery of the main body. The main body 21 is provided with a mechanical pressing device 211, and the mechanical pressing device 211 includes a V-groove base plate 2111, The V-groove base plate 2111 has a V-shaped groove 21111 for embedding optical fiber ferrules, a V-groove pressing block 2112, a fixing sleeve (not shown in the figure) and a sliding pressure sleeve 2113, and the V-groove base plate 2111 and the V-groove The pressing block 2112 is placed inside the cavity of the fixing sleeve, the sliding pressing sleeve 2113 is sleeved on the outside of the fixing sleeve, one side of the V-groove substrate 2111 is provided with a groove 21112, and the V-groove pressing block 2112 A bos...

Embodiment 2

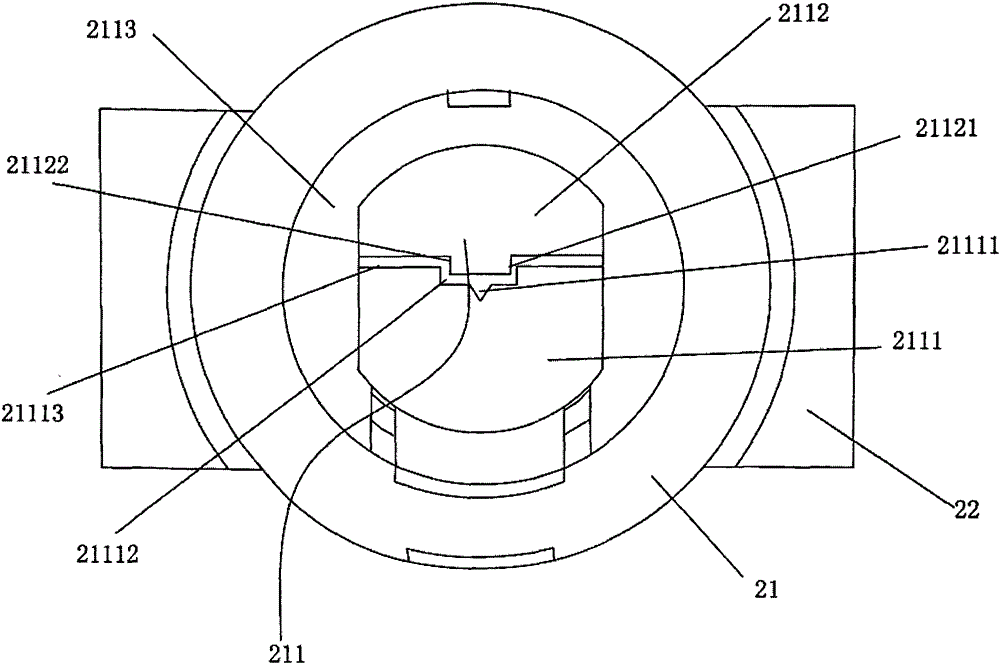

[0037] This embodiment provides another mechanical pressing device for an optical fiber connector and an optical fiber connector with the mechanical pressing device. like Figure 4-9As shown, the optical fiber connector 20 includes a main body 21 of a hollow structure and a jacket 22 arranged on the periphery of the main body. The main body 21 is provided with a mechanical pressing device 211, and the mechanical pressing device 211 includes a V-groove base plate 2111, The V-groove substrate 2111 has a V-shaped groove 21111 for embedding optical fiber ferrules, a V-groove pressing block 2112, a fixed sleeve 2115 and a sliding pressing sleeve 2113, and the V-groove base plate 2111 and the V-groove pressing block 2112 are fixed Inside the cavity of the sleeve, the sliding press sleeve 2113 is sleeved on the outside of the fixed sleeve, one side of the V-groove base plate 2111 is provided with a boss 21121, and one side of the V-groove pressing block 2112 is provided with a groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com