A Method for Determining the Cavitation Threshold of Liquid Metals

A technology of liquid metal and cavitation threshold, which is applied in design optimization/simulation, color TV parts, TV system parts, etc., can solve problems such as the inability to determine the liquid metal cavitation threshold, and achieve low cost and simulation process Simple, Adaptable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Embodiment 1: In this embodiment, a method for determining the cavitation threshold of liquid metal is carried out according to the following steps:

[0034] 1. Place the liquid metal droplets to be tested that are liquid at room temperature on the transparent glass of the device for determining the cavitation threshold of liquid metal;

[0035] Or place the non-liquid metal at room temperature on the transparent glass of the liquid metal cavitation threshold device, and then heat the metal to a liquid state, which is the liquid metal to be tested;

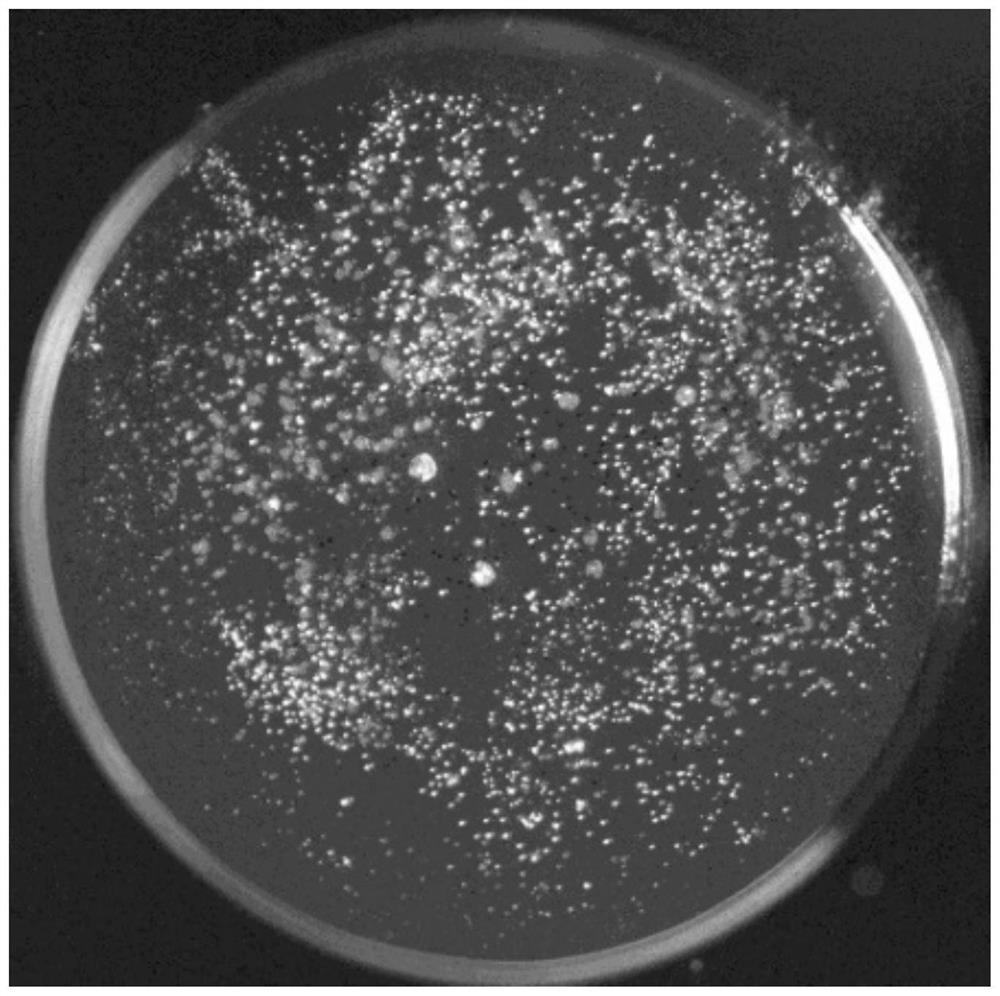

[0036] 2. Turn on the ultrasound, and use a high-speed camera to shoot the spreading process of the liquid metal droplets to be measured;

[0037] 3. Select the photo taken in step 2, and record the width of the droplet front without acoustic cavitation in the photo and the shooting time;

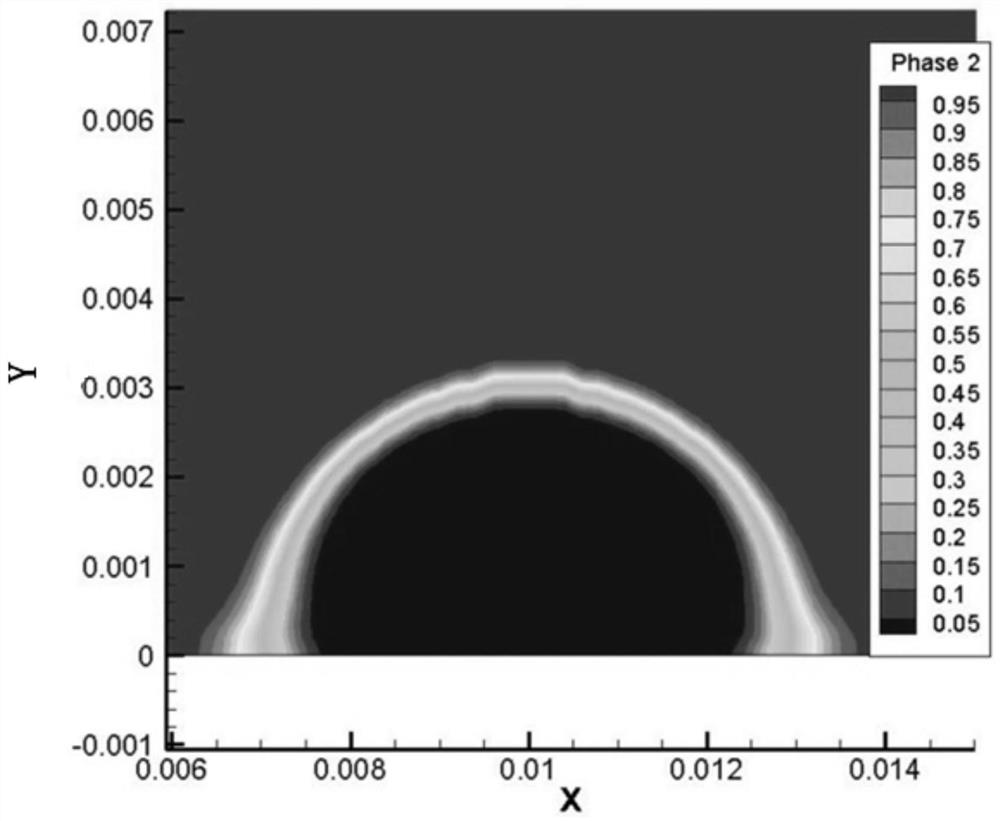

[0038] 4. Use finite element software to simulate the spreading process of the liquid metal to be tested;

[0039] 5. Corresponding t...

specific Embodiment approach 2

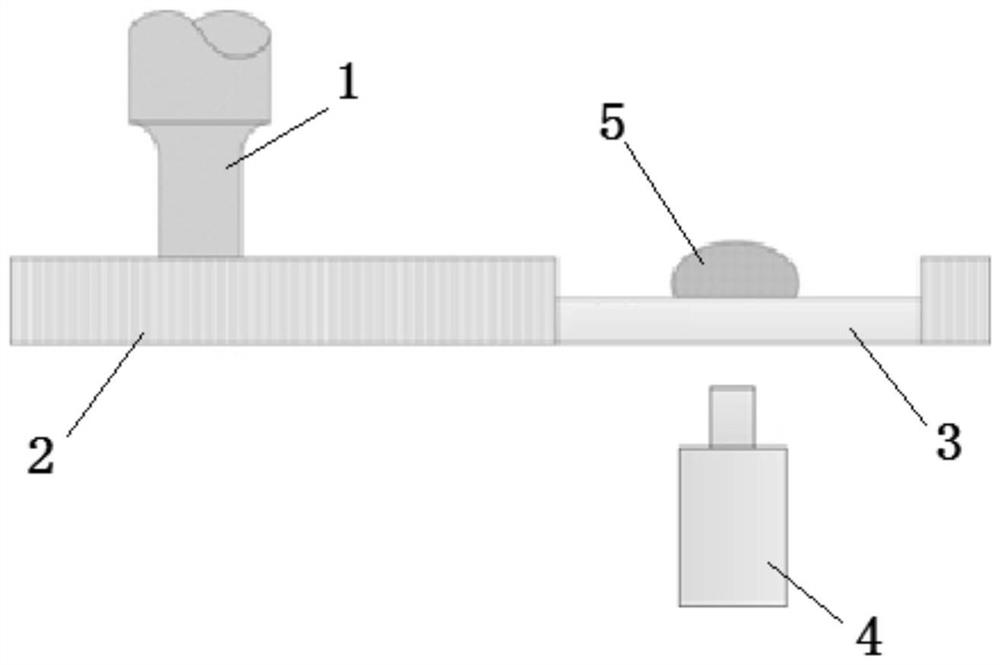

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the device for determining the liquid metal cavitation threshold includes an ultrasonic tool head 1, a base material 2, a transparent glass 3 and a high-speed camera 4, wherein the transparent glass 3 is replaced Part of the base material 2, and the transparent glass 3 is closely attached to the base material 2, the ultrasonic tool head 1 is closely attached to the upper surface of the base material 2, the liquid metal 5 to be tested is placed on the transparent glass 3, and the high-speed camera 4 is located on the transparent glass. Below 3, the lens of the high-speed camera 4 is set directly below the liquid metal 5 to be tested, and faces the liquid metal 5 to be tested. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the base material is pure aluminum. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com