A cable joint fire protection system and its implementation method

A technology for cable joints and fire protection systems, which is applied in the direction of cable joints, electrical components, instruments, etc., and can solve problems such as unconsidered, no anti-fire prevention measures for cable joint protective boxes, and no early warning treatment measures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the present invention more clearly, describe in detail in conjunction with accompanying drawing:

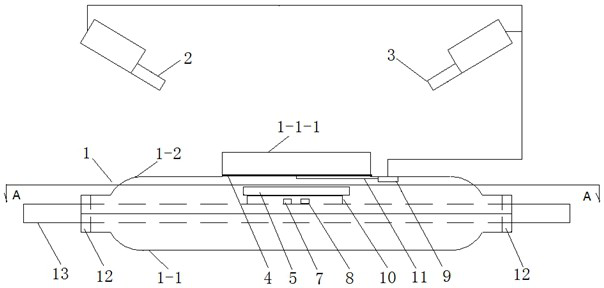

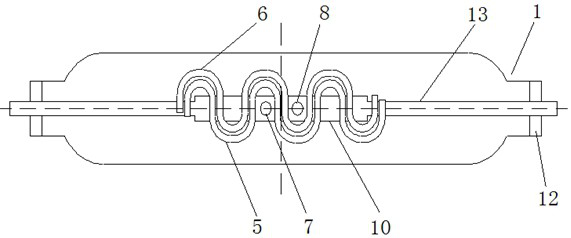

[0037] like Figure 1 to Figure 4 As shown, a cable joint fire protection system includes cable joint protective box 1, fire extinguishing device Ⅰ2, fire extinguishing device Ⅱ3, waterproof and ventilating component 4, fire extinguishing pipe Ⅰ5, fire extinguishing pipe Ⅱ6, temperature detector Ⅰ7, temperature detector Ⅱ8, magnetic generator The component 9 and the cable 13 also include a fire extinguishing pipe support 10 and a magnetic generator starting rope 11 .

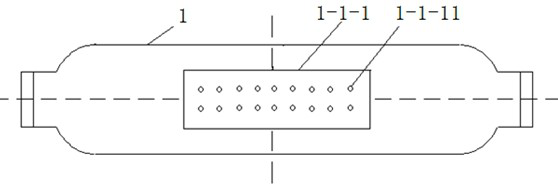

[0038] The cable joint protection box 1 is composed of an upper shell 1-1 and a lower shell 1-2. The upper shell 1-1 is provided with a rectangular explosion venting chamber 1-1-1, and a rectangular explosion venting chamber 1-1- 1. It communicates with the inside of the upper shell 1-1, and two rows of several exhaust holes 1-1-11 are symmetrically arranged on the surface of the rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com