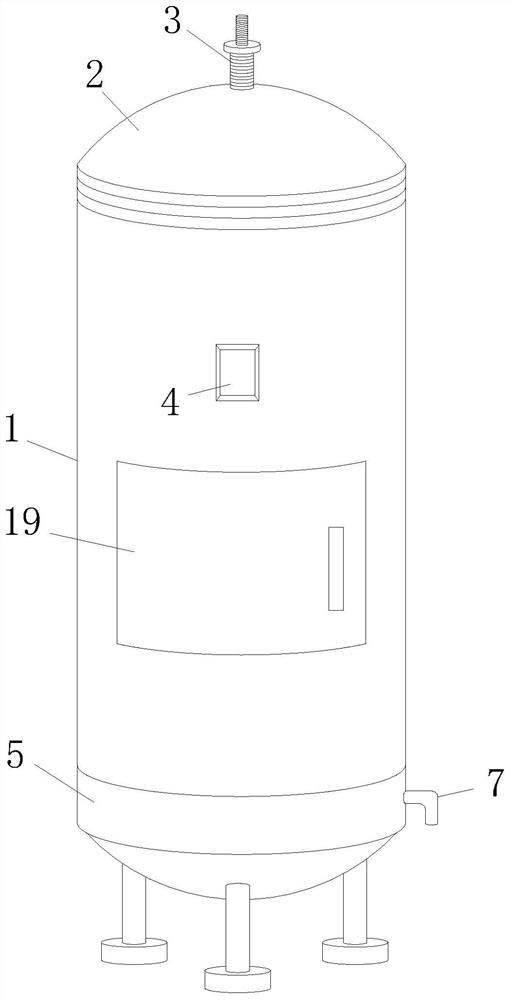

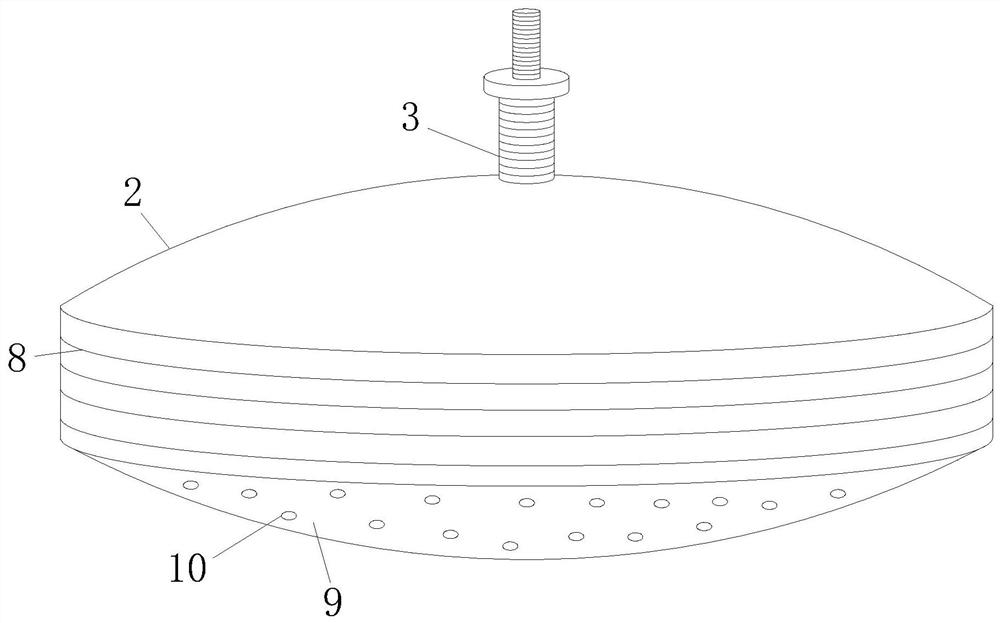

filter tank for chemical industry

A filter tank and chemical technology, applied in the field of filter tanks, can solve the problems of manpower and material resources consumption, increased filter layer replacement frequency, filter tank damage, etc., and achieve the effect of simple and convenient disassembly and installation, saving heat and material resources, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

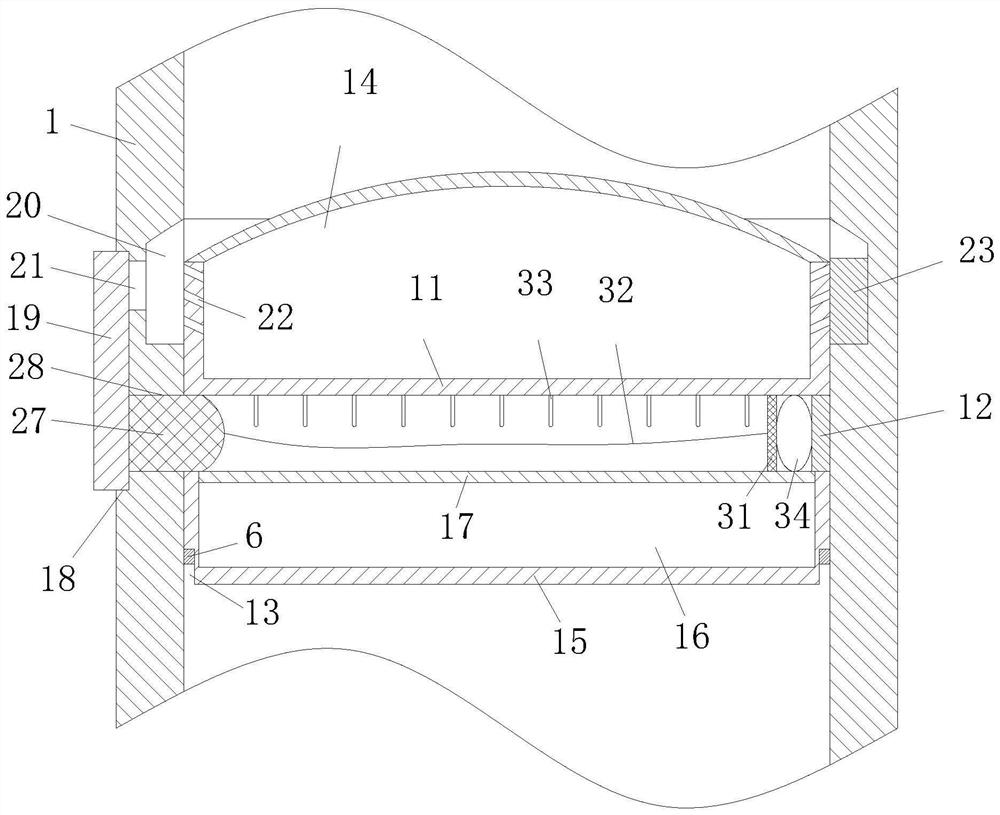

[0025] As an embodiment of the present invention, when the airtight door 19 is closed, two collection blocks 23 are slidably connected in the collection groove 20 on the side away from the airtight door 19; the opposite side of the collection block 23 is fixedly connected with a spring; The two side walls and the lower surface of the collection block 23 are all designed to be close to the collection tank 20; the opposite side surfaces of the collection block 23 are fixedly connected to the sealing door 19 through the first elastic pull cord 24 through the connection port 21; The side wall of the connecting port 21 is provided with two opposite pulleys, and the first elastic pull cord 24 is wound on the surface of the corresponding pulley; the surface of the main body of the filter tank 1 is provided with an auxiliary port 25; the auxiliary port 25 is connected to the connecting port 21 Symmetrically arranged, and the auxiliary port 25 is connected to the collection tank 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com