Stool leg generating equipment with adjustable pitch-row inclination angle for furniture production

A technology for generating equipment and adjusting holes, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor intensity for workers, and the inability to adjust the distance of stool leg punching, etc., to achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

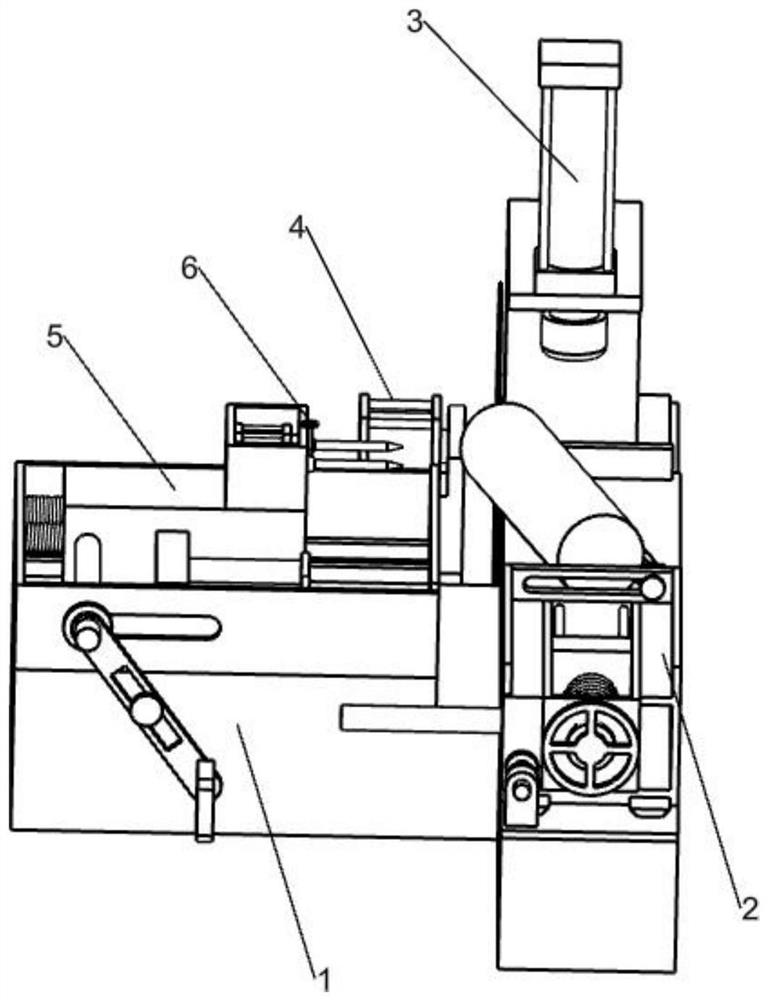

[0028] A stool leg generating device with adjustable hole distance and inclination angle for furniture production, such as figure 1 As shown, it includes a base 1, an adjustment mechanism 2, a pressing mechanism 3, a cutting mechanism 4, a punching mechanism 5 and an adjustment hole spacing mechanism 6, an adjustment mechanism 2 is installed on the right side of the top of the base 1, and an adjustment mechanism 2 is installed on the adjustment mechanism 2. Pressing mechanism 3, pressing mechanism 3 cooperates with regulating mechanism 2, the rear side left part of base 1 is fixedly connected with cutting mechanism 4, and the left side of base 1 top is equipped with punching mechanism 5, and punching mechanism 5 is provided with adjusting Hole spacing mechanism 6, punching mechanism 5 cooperates with regulating hole spacing mechanism 6.

[0029] When the stool legs need to be processed, after the user places the stool legs on the adjustment mechanism 2, the user adjusts the cu...

Embodiment 2

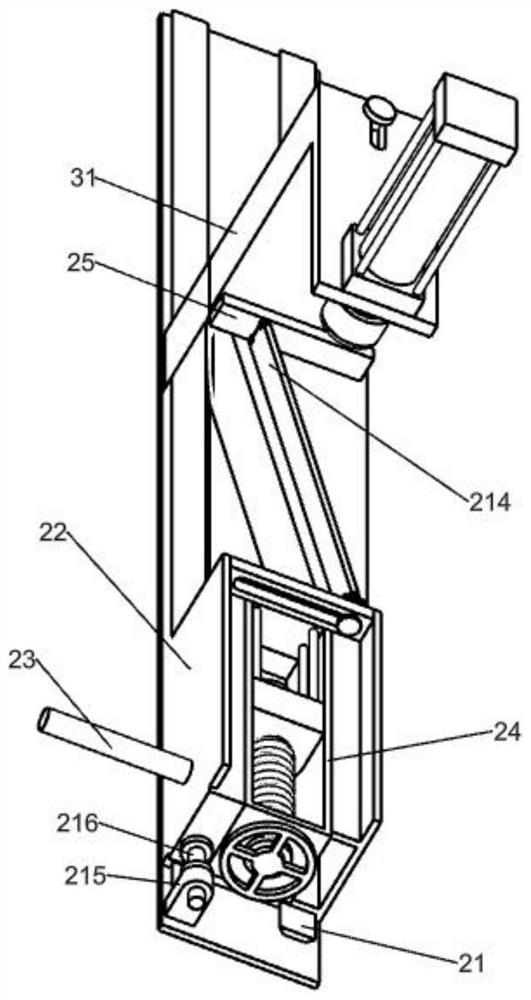

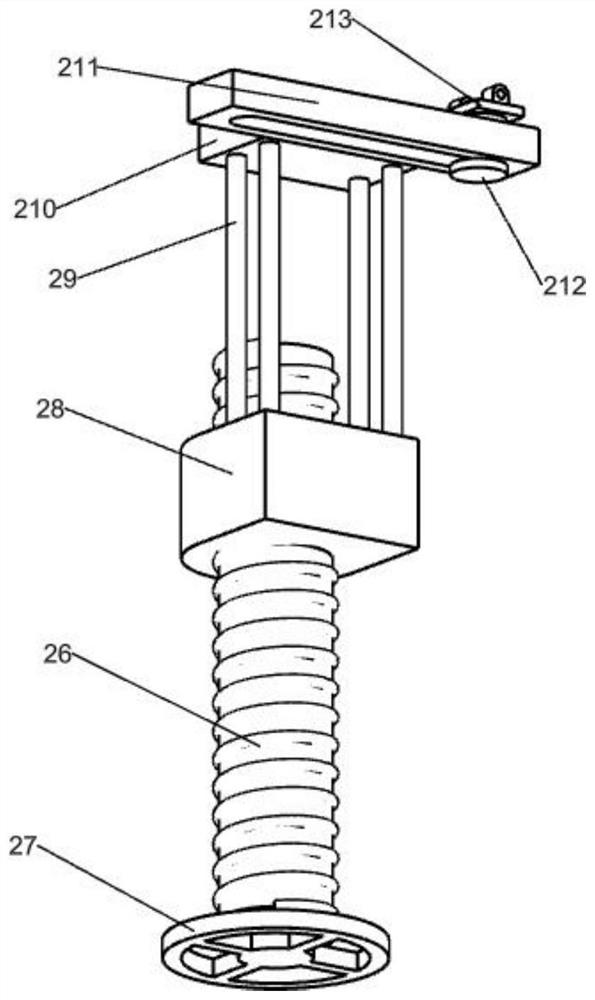

[0031] On the basis of Example 1, such as figure 1 , figure 2 and image 3 As shown, the adjustment mechanism 2 includes a slide rail 21, a sliding seat 22, a moving rod 23, a mounting frame 24, a limit plate 25, a first screw rod 26, a first turntable 27, a first nut 28, a connecting rod 29, and a fixed plate 210, slotted plate 211, slide shaft 212, connecting block 213, hinge plate 214, fixed block 215 and positioning block 216, slide rail 21 is provided with two, is all installed in the top right side of base 1, between two slide rails 21 The sliding type is provided with a sliding seat 22, the front portion of the left side wall of the sliding seat 22 is fixedly connected with a moving rod 23, the sliding seat 22 is connected with a mounting frame 24, and the mounting frame 24 is fixedly connected with a limiting plate 25, and a limiting plate 25 The mounting bracket 24 on the front side is provided with a first screw rod 26, the front end of the first screw rod 26 is e...

Embodiment 3

[0034] On the basis of Example 2, such as figure 1 , figure 2 and Figure 4 As shown, the compression mechanism 3 includes a connecting frame 31, a cylinder 32 and a pressing block 33, the mounting frame 24 on the rear side of the limit plate 25 is fixedly connected with the connecting frame 31, the connecting frame 31 is equipped with a cylinder 32, and the cylinder 32 The telescopic rod of the cylinder passes through the connecting frame 31, and the bottom end of the telescopic rod of the cylinder 32 is fixed with a compression block 33.

[0035] After the adjustment of the stool legs is completed, the user activates the cylinder 32 to move the pressing block 33 downwards, and the downward movement of the pressing block 33 can fix the stool legs, which can prevent the stool legs from moving to cause damage to the processing when the stool legs are being processed. Inconvenient, when the stool legs are processed, the user starts the cylinder 32 to move the pressing block 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap