Corrugated paper longitudinal cutting anti-explosion line pressing processing equipment

A processing equipment and corrugated paper technology, which is applied in the field of corrugated paper slitting and explosion-proof creasing processing equipment, can solve the problems that the creasing process device is difficult to adapt to different thicknesses of cardboard in different seasons, time-consuming and laborious, and increase the cost of stocking, etc., so as to improve the quality of creasing and reduce Burst line frequency, effect of improving width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

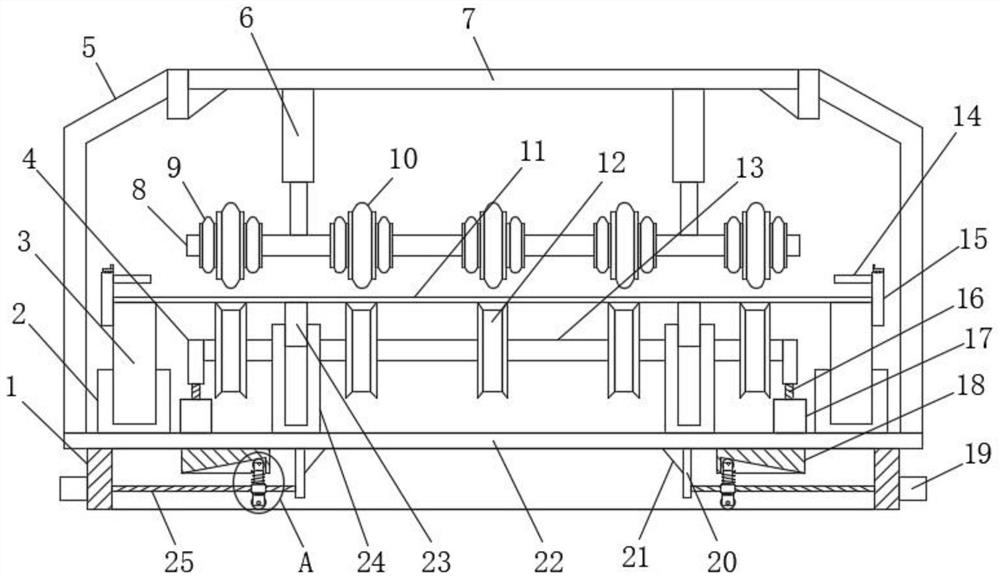

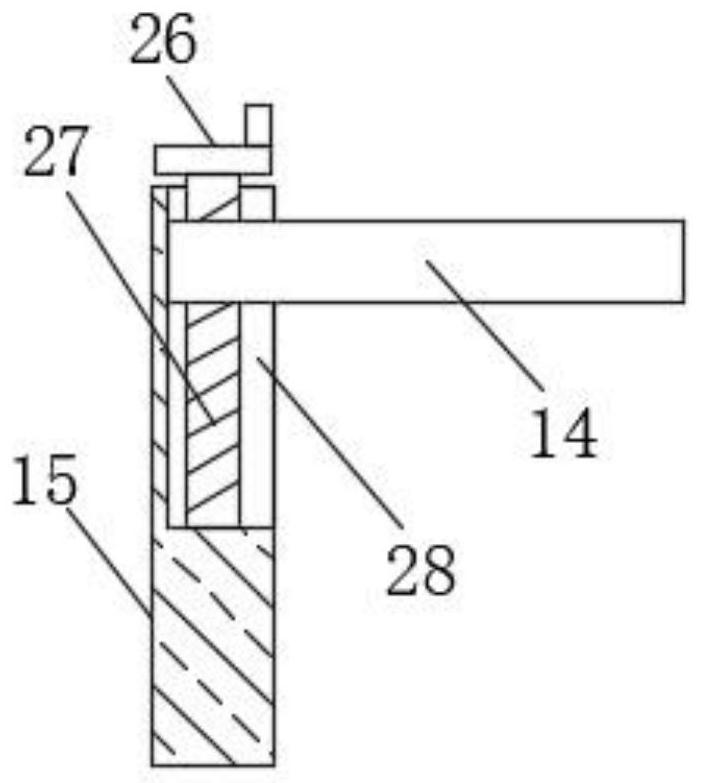

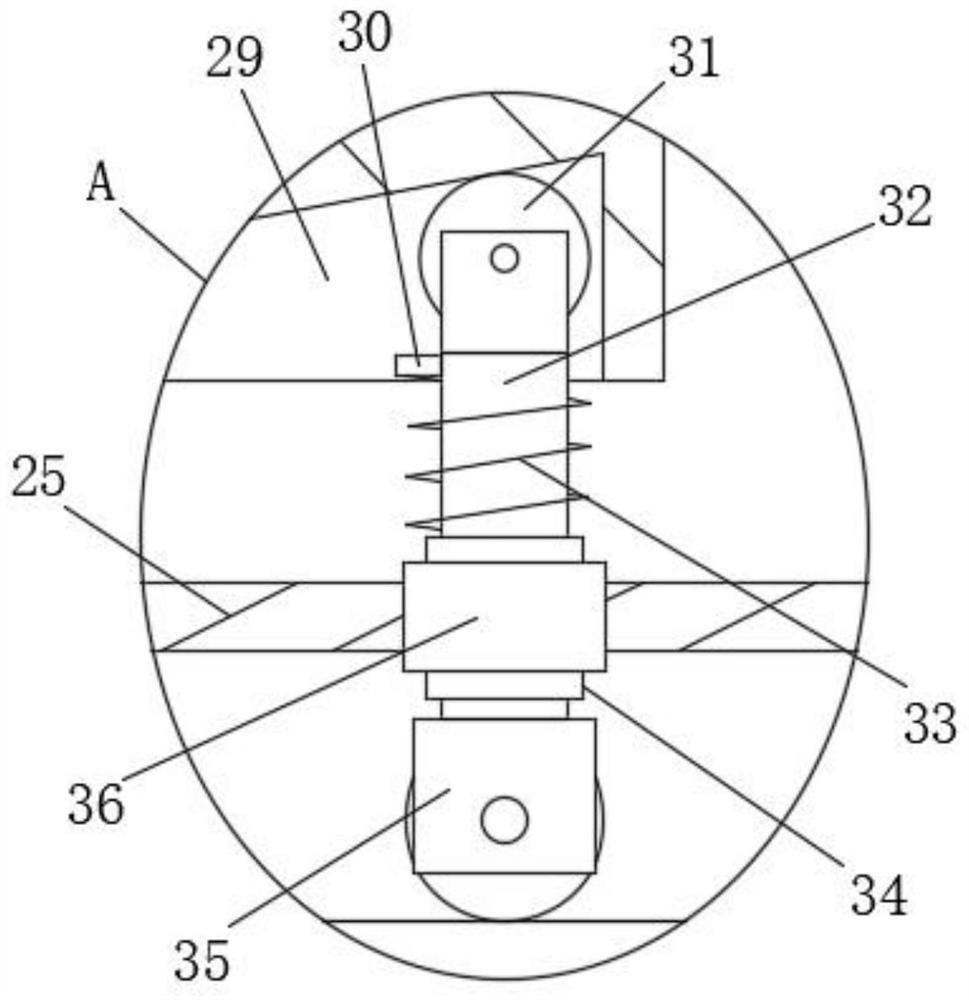

[0026] see Figure 1-3 , corrugated paper slitting explosion-proof crimping processing equipment, including an installation platform 22, the upper surface of the installation platform 22 is symmetrically fixed on the outer side of the support frame 5, the upper ends of the two support frames 5 are jointly fixedly connected with a fixed plate 7, the lower part of the fixed plate 7 The surface is symmetrically fixed with drive cylinders 6, and the lower ends of the two drive cylinders 6 are fixedly connected with the first connecting shaft 8. The outer side of the first connecting shaft 8 is evenly sleeved with a plurality of upper crimping wheels 10, and each upper crimping wheel Both sides of wheel 10 are all fixedly installed with small crimping wheel 9, and small crimping wheel 9 is positioned at the outside of first connecting shaft 8, and the middle part of the upper surface of installation platform 22 is fixedly installed with two telescopic cylinders 2, two first servo mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com