Self-liquid-suction type circulating ink storage environment-friendly pen based on capillary action and siphon action

A siphoning and self-priming technology, applied in the field of stationery, can solve the problems of hard pen tip, inconvenient ink change, waste of pen and ink in the pen shell, etc., and achieve the advantages of reducing the overall weight, controlling the amount of ink filling, and protecting the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

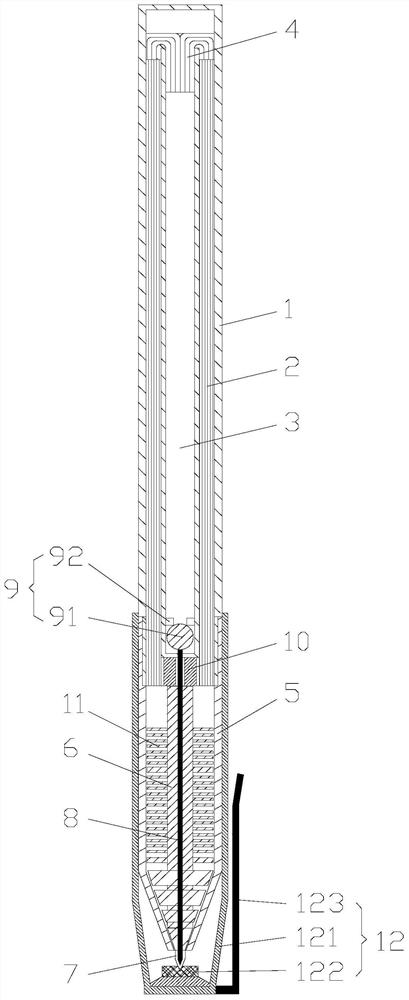

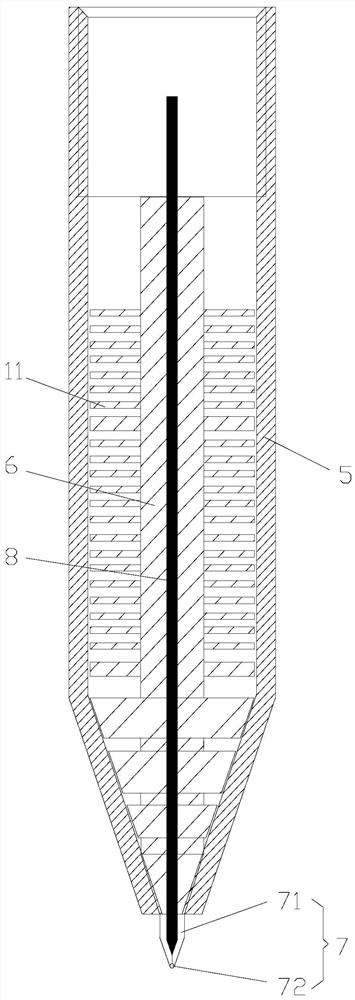

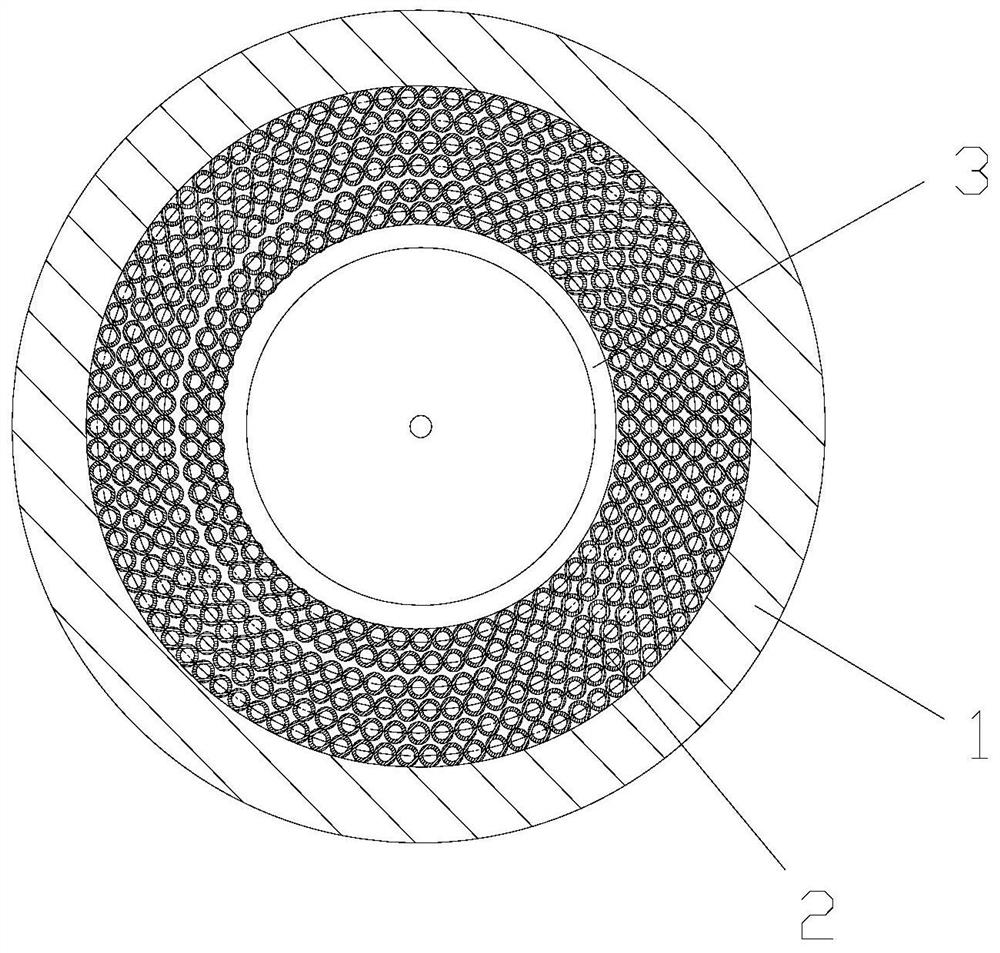

[0025] In this embodiment, the self-absorbing liquid circulation ink storage environment-friendly pen based on capillary and siphon action includes a pen holder and a nib, and the pen holder and the nib are detachably connected. The penholder comprises a penholder shell 1, a capillary liquid-absorbing core 2, an ink bag tube 3 and a siphon tube 4, the ink bag tube is located in the penholder case, and the capillary liquid-absorbing core is filled between the penholder case and the ink bag tube, so Said siphon tube is located in the rear end of the pen holder shell, the front end of the capillary liquid suction core is located at the front end of the pen holder shell, the rear end of the capillary liquid suction core is connected with the high liquid level end of the siphon tube, and the low liquid level end of the siphon tube is connected with the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com