Curtain wall corner glass connecting structure and mounting method thereof

A technology for connecting structures and corners, applied to walls, building components, building structures, etc., can solve the problems of complex structure, high cost, inconvenient operation, etc., and achieve the effect of convenient and quick operation, high construction efficiency, and good angle adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

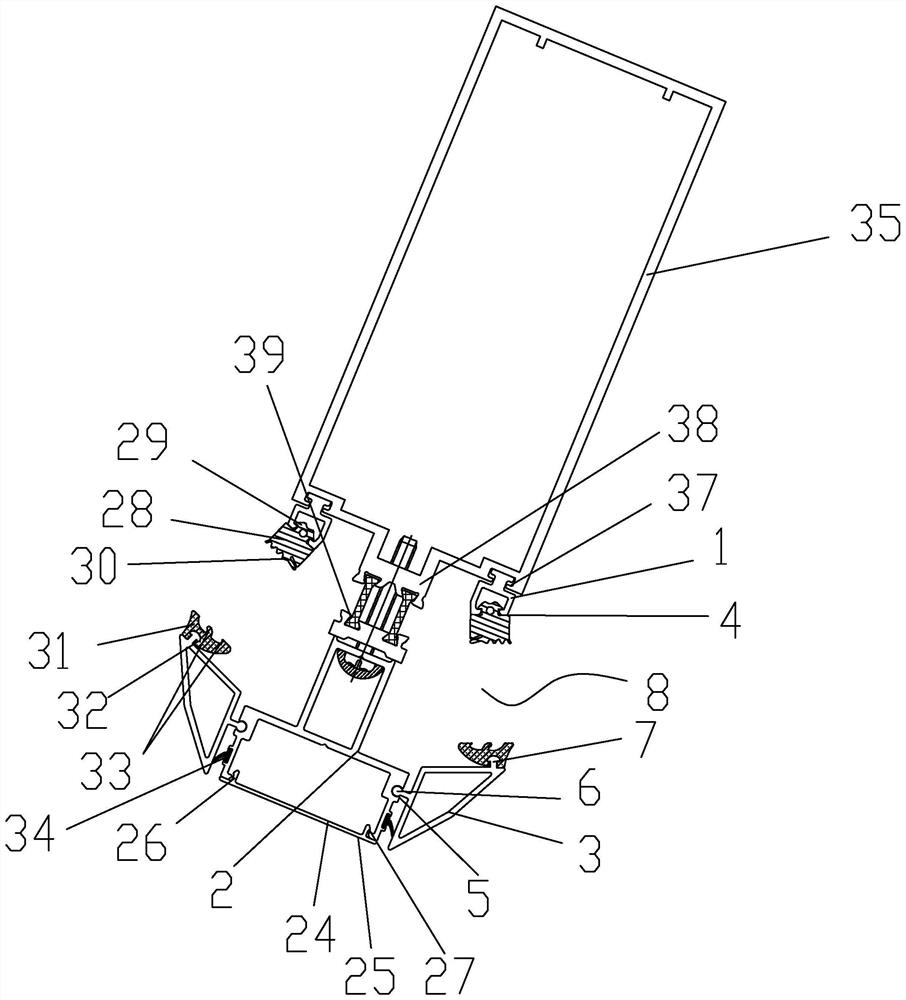

[0046] exist figure 1 , Figure 5 In the shown embodiment, a curtain wall corner glass connection structure includes:

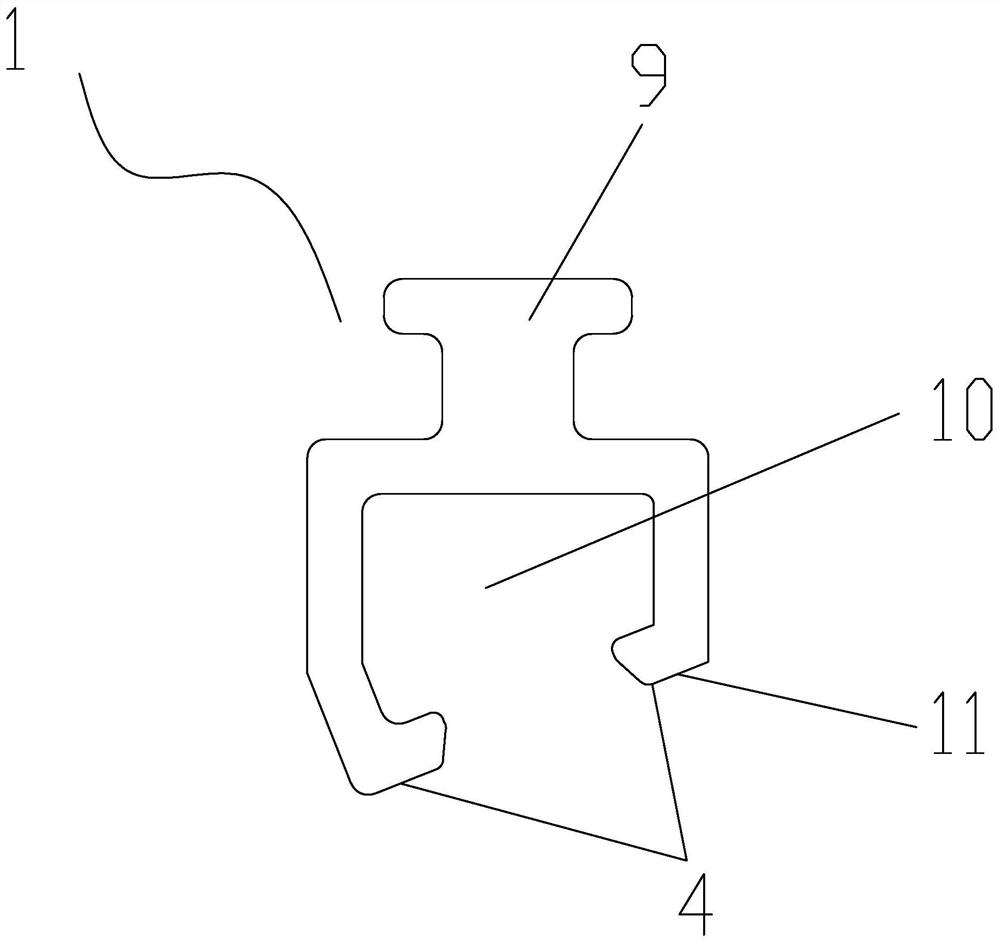

[0047] Angle adjustment press seat 1, which is connected with the column 35 and is used to determine the basic angle adjustment component of the installation angle of the glass panel; and

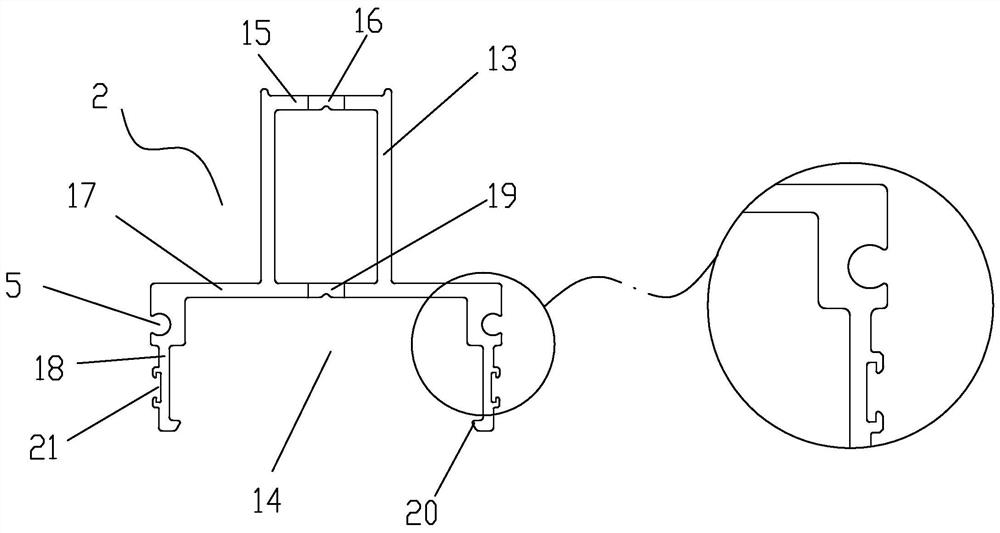

[0048] The connector 2 is connected with the column 35 to realize the fixed support; and

[0049] Angle adjustment fixing part 3, which is rotatably connected with connecting part 2 to adjust and limit the installation angle of the glass panel;

[0050] Wherein, the angle-adjusting pressure seat 1 is provided with an inclined corner surface 4 for preliminarily limiting the installation angle of the glass panel;

[0051] The connecting part 2 is provided with a rotating groove 5 for rotating connection with the angle adjustment fixing part 3;

[0052] The angle adjustment fixing part 3 is provided with an angle adjustment rotating shaft 6 and a clamping boss 7;

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com