Fabricated building glass curtain wall

A kind of architectural glass and prefabricated technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of inconvenient transportation and storage of connected components, and achieve the effect of reducing transportation accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-4 , to further describe this application in detail.

[0039] The embodiment of the present application discloses a prefabricated architectural glass curtain wall.

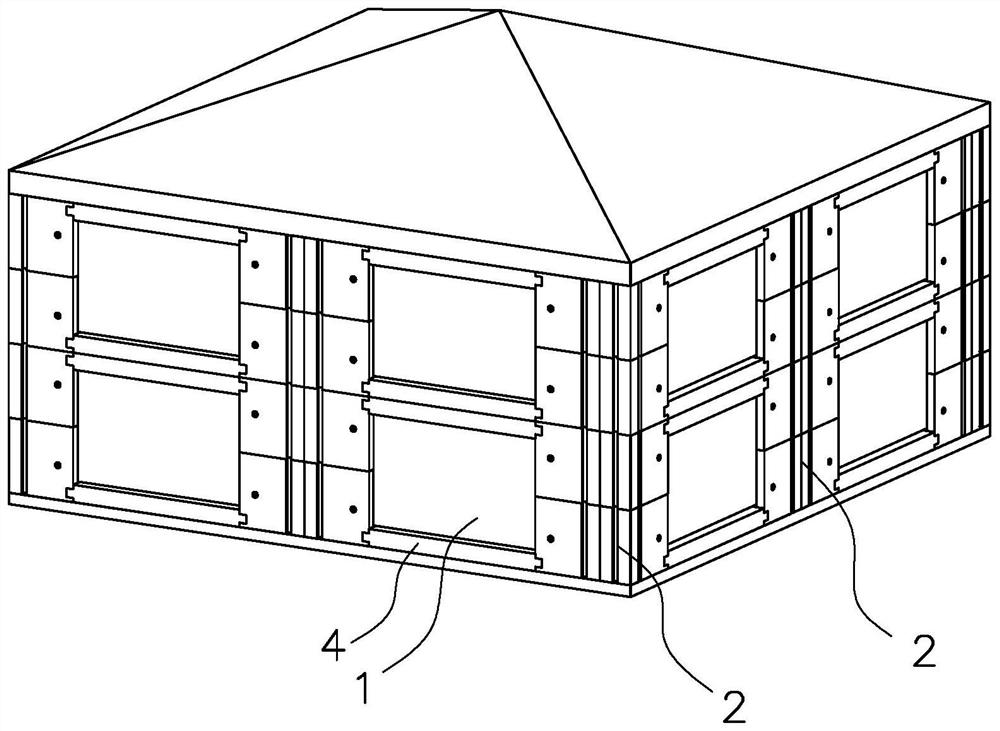

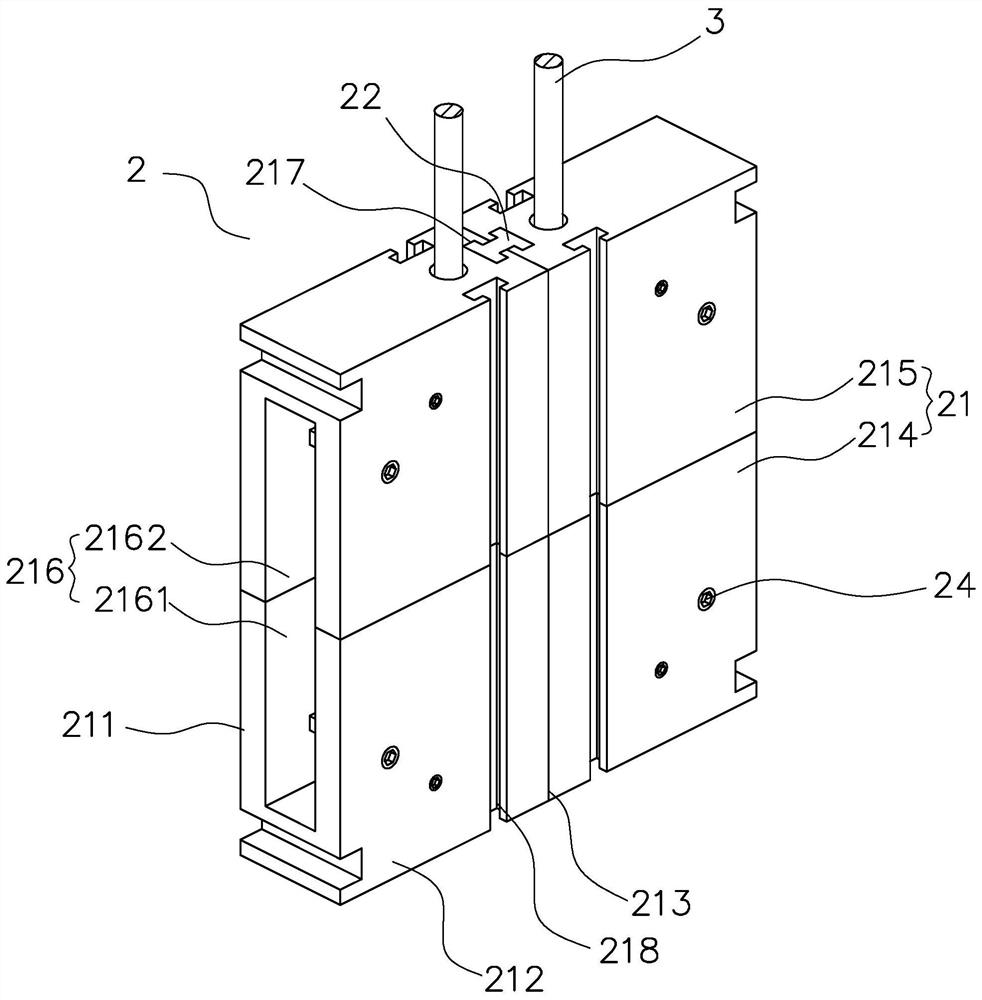

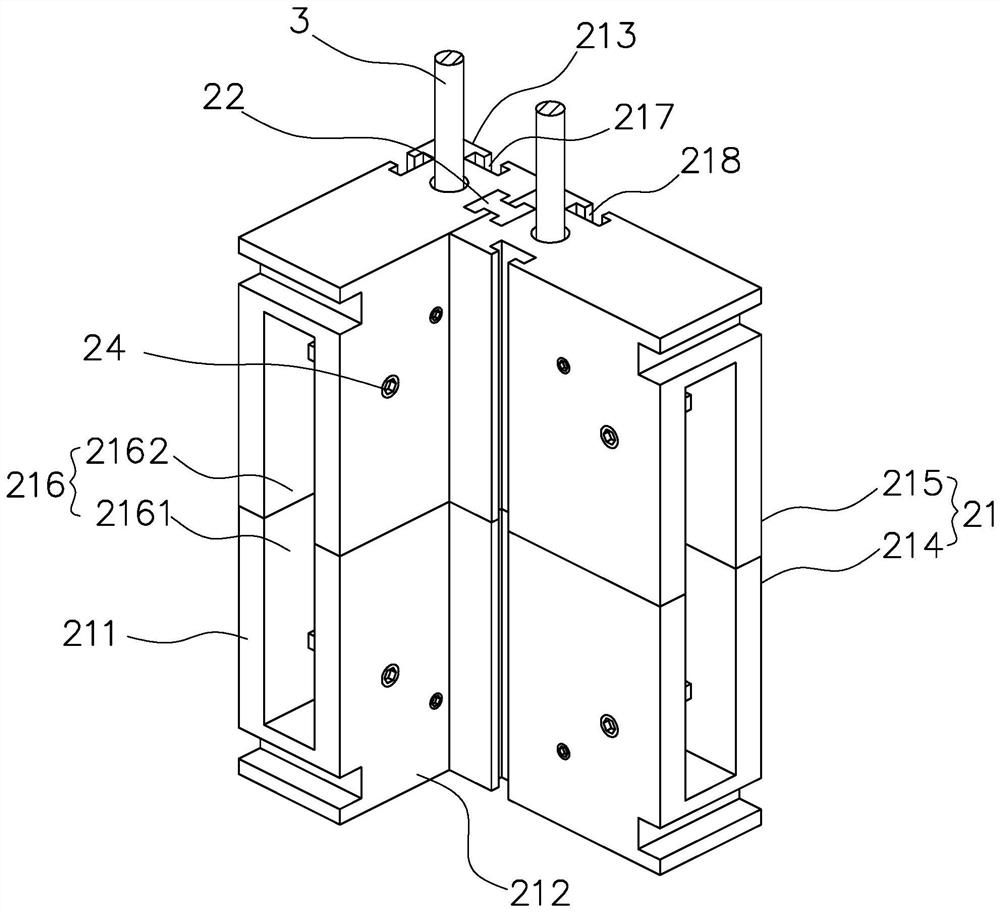

[0040] refer to figure 1 and figure 2A prefabricated building glass curtain wall includes several glass layers connected vertically and several connecting steel bars 3 arranged around the glass layers, and two layers of adjacent glass layers are connected by stacking. Each glass layer includes several glass plates 1 and several connecting assemblies 2 for installing the glass plates 1 in the same glass layer. The connecting steel bar 3 is arranged along the vertical direction, and a single connecting steel bar 3 passes through all the connecting components 2 on the same side of all the glass layers. In this embodiment, a spacer 4 is placed between the glass plates 1 of the upper and lower adjacent glass layers, and each spacer 4 corresponds to the glass plate 1 . The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap