Coal mine underground ventilation structure convenient to fix

A technology for underground ventilation and coal mines, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc. It can solve the problems of inconvenient folding and transportation, poor overall stability of the structure, and height adjustment of ventilation pipes, etc., to achieve mutual storage and transportation. , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

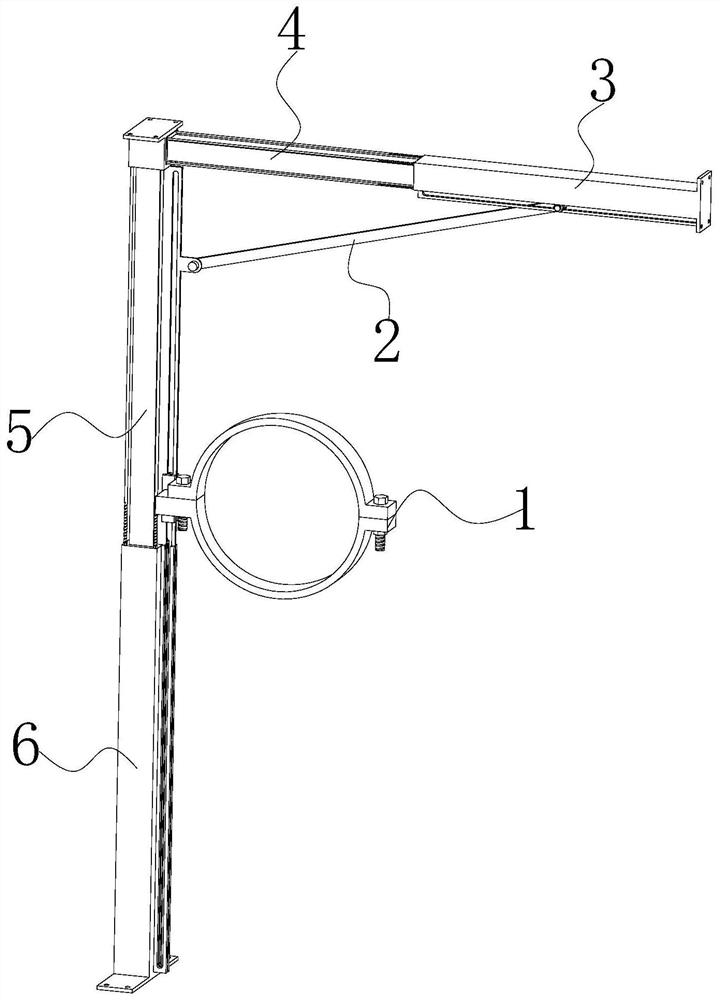

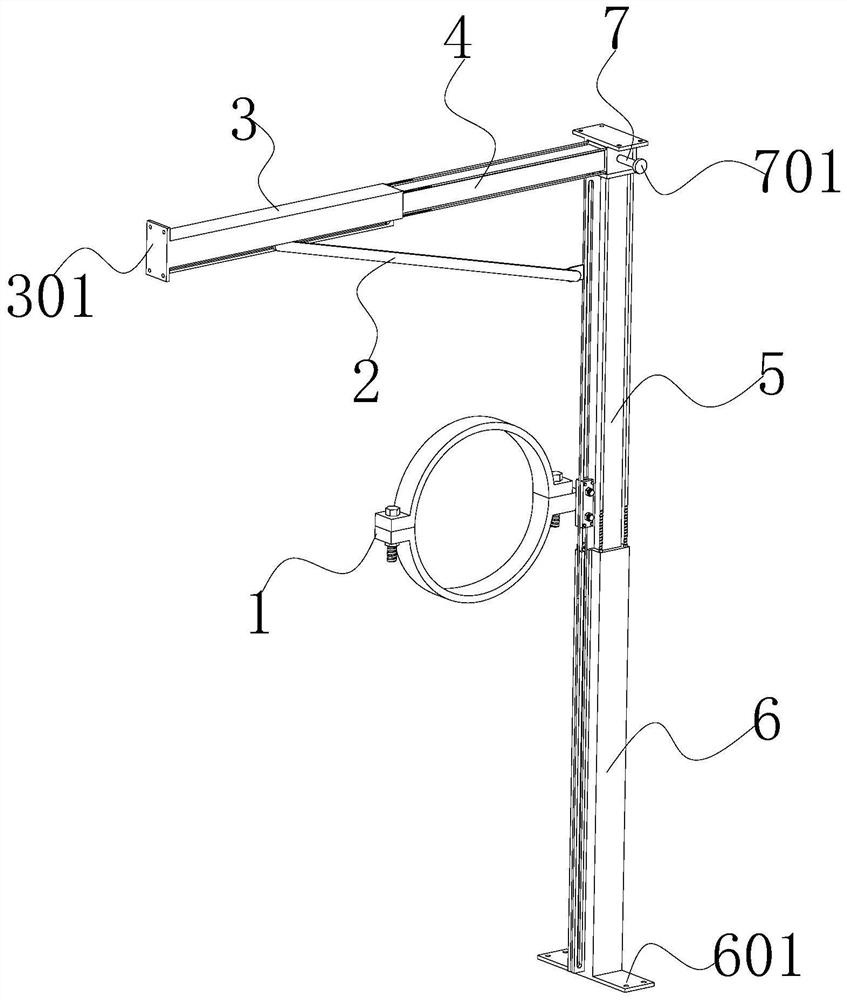

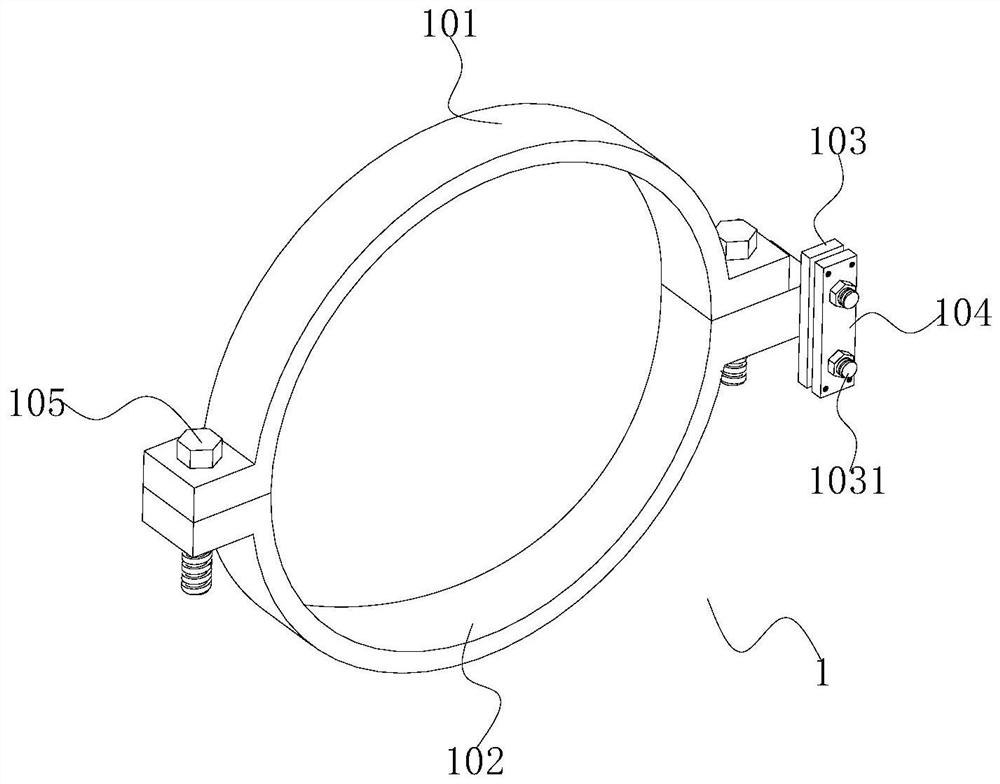

[0053] see Figure 1-2 As shown, the present invention is a coal mine underground ventilation structure that is convenient for fixing, including a first rod body 3, a second rod body 4, a third rod body 5 and a fourth rod body 6. As can be seen from the accompanying drawings, the above-mentioned components are all rectangular Set, one end of the second rod body 4 is slidingly sleeved in one end of the first rod body 3, this setting can be used to adjust the relative position adjustment between the first rod body 3 and the second rod body 4, and one end of the third rod body 5 is slidingly sleeved Connected to one end of the fourth rod body 6, the second rod body 4 is located at the upper end position of the third rod body 5 and is perpendicular to the third rod body 5; this setting can be used to adjust the relative relationship between the third rod body 5 and the fourth rod body 6. For position adjustment, the connecting body of the third rod body 5 and the fourth rod body 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com