Heat exchange plate with guide fins and battery pack box

A heat exchange plate and deflector fin technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve problems such as poor flow uniformity and unreasonable internal design of liquid cooling plates, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

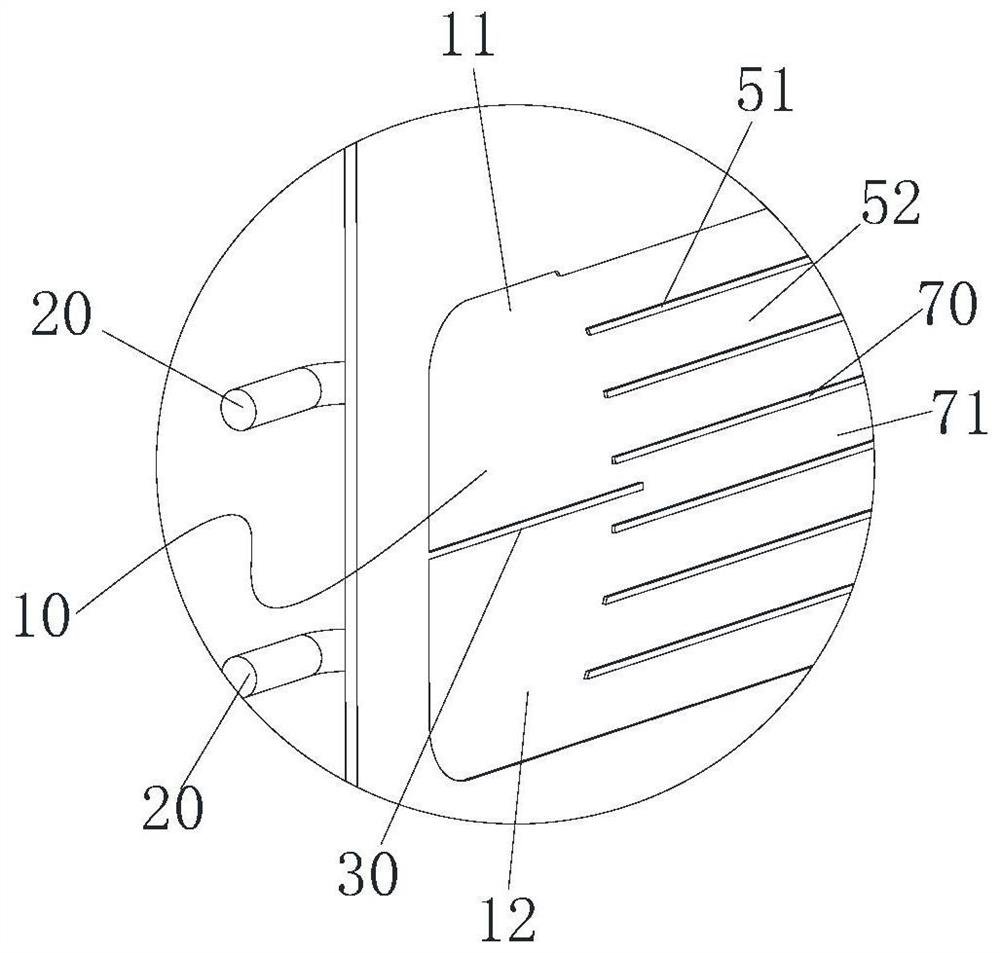

[0022] Most of the existing liquid cold plates are placed vertically when used, so the refrigerant will be affected by gravity in the vertical direction, and the current guide chamber of the cold night plate is relatively large, so the refrigerant liquid will be under the action of gravity Flow down to the bottom of the liquid cold plate, resulting in poor flow uniformity.

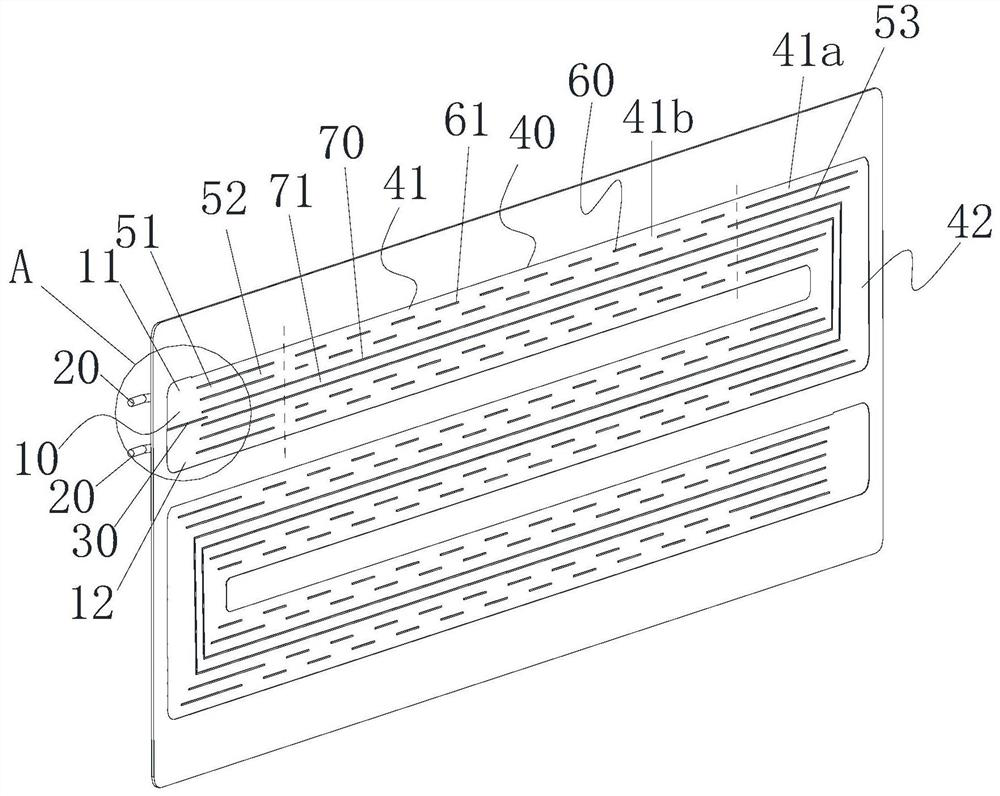

[0023] The invention discloses a heat exchange plate, comprising: a diversion cavity 10, a plurality of refrigerant inlets 20, diversion fins 30 and heat exchange channels 40, the diversion cavity 10 is arranged in the heat exchange plate; a plurality of refrigerant inlets 20 They are respectively arranged on the heat exchange plate, and a plurality of refrigerant inlets 20 are connected with the guide chamber 10; guide fins 30 are arranged in the guide chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com